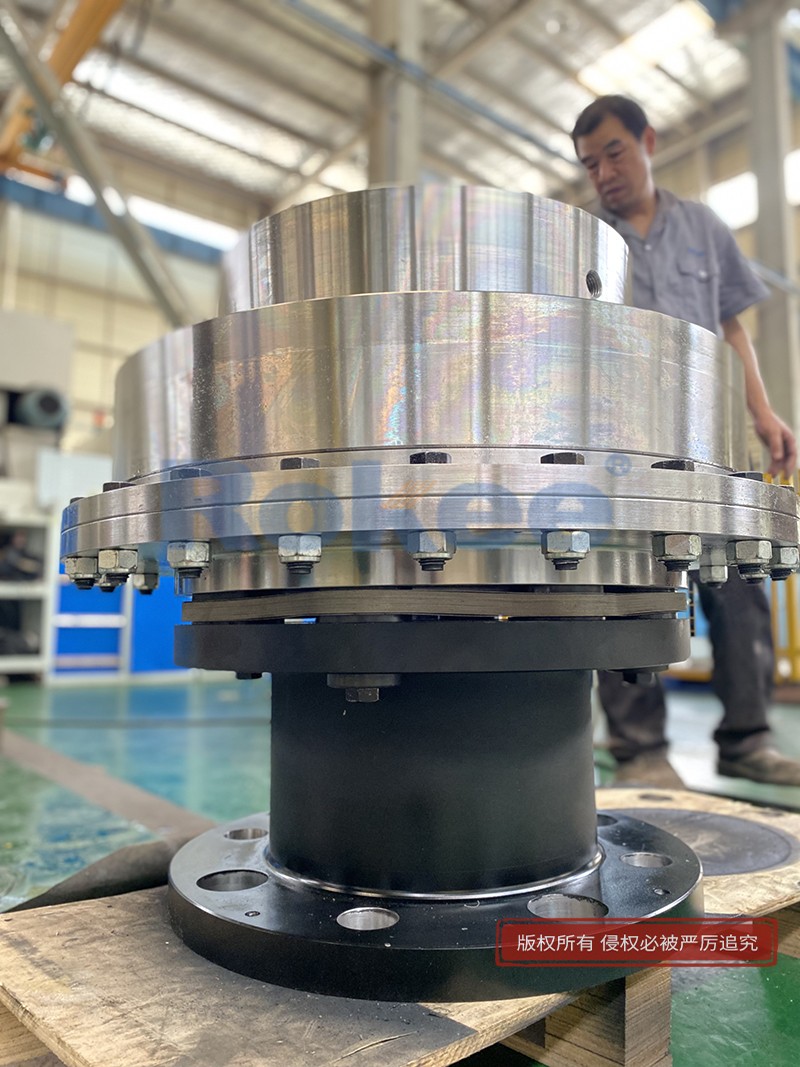

Custom-made Large Diaphragm Coupling

Rokee® provide Custom-made Large Diaphragm Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of industrial power transmission, couplings serve as the critical link between rotating shafts, ensuring the smooth and efficient transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types available, large diaphragm couplings stand out for their exceptional reliability, high torque capacity, and ability to operate in harsh industrial environments. However, standard off-the-shelf couplings often fail to meet the unique requirements of complex industrial systems, where factors such as specific shaft diameters, unusual misalignment angles, extreme operating temperatures, and specialized torque demands come into play. This is where custom-made large diaphragm couplings step in, offering tailored solutions that optimize performance, enhance durability, and ensure seamless integration with specific industrial setups.

1. Understanding Large Diaphragm Couplings: Fundamentals and Core Characteristics

Before exploring the nuances of custom-made solutions, it is essential to grasp the basic structure and functional attributes of large diaphragm couplings. A diaphragm coupling consists of two hubs that connect to the driving and driven shafts, respectively, and a flexible diaphragm pack that links these hubs. The diaphragm pack, typically composed of multiple thin metal diaphragms stacked together, is the key component that enables the coupling to accommodate misalignment—including angular, parallel, and axial misalignment—while transmitting torque. Unlike elastic couplings that rely on rubber or polymer elements, diaphragm couplings use the elastic deformation of the metal diaphragms to absorb misalignment, eliminating the need for lubrication and reducing maintenance requirements.

Large diaphragm couplings are specifically engineered to handle high torque loads and large shaft diameters, making them suitable for heavy-duty industrial applications. The metal diaphragms, usually made from high-strength alloys such as titanium, stainless steel, or nickel-based superalloys, are designed to withstand extreme levels of stress without permanent deformation. This material selection ensures that the coupling can operate reliably under conditions of high rotational speed, high temperature, and corrosive environments. Additionally, the rigid connection between the hubs and the diaphragm pack minimizes backlash, ensuring precise torque transmission— a critical feature in applications where positional accuracy is paramount.

2. The Rationale for Customization: Why Standard Couplings Fall Short

While standard large diaphragm couplings are available in a range of sizes and specifications, they are designed to meet generic industrial requirements. In many complex industrial systems, however, generic solutions are inadequate due to a combination of unique operational and mechanical constraints. One of the primary reasons for customization is the need to accommodate non-standard shaft dimensions. Industrial machinery such as large turbines, compressors, and extruders often have shaft diameters and keyway configurations that deviate from standard sizes, making it impossible to use off-the-shelf couplings without modifications that can compromise performance and safety.

Another key driver for customization is the presence of extreme operating conditions. For instance, in power generation plants, couplings may be exposed to high temperatures exceeding 500°C, while in offshore or marine applications, they must resist corrosion from saltwater and humid environments. Standard couplings may not be constructed from materials that can withstand these extreme conditions, leading to premature failure. Similarly, applications with high levels of vibration or shock loads—such as mining equipment or heavy-duty pumps—require couplings with specialized damping characteristics that standard models cannot provide.

Misalignment requirements also often necessitate customization. While standard couplings can accommodate a certain degree of misalignment, some industrial setups—such as those involving large rotating equipment with significant thermal expansion—require couplings that can handle larger angular or axial misalignment angles. Custom-designed diaphragm packs can be engineered with specific thicknesses, shapes, and numbers of diaphragms to meet these unique misalignment requirements. Additionally, applications that require precise torque control, such as in precision manufacturing or automated production lines, benefit from custom couplings that are calibrated to transmit torque with minimal loss or variation.

3. Design Principles of Custom-made Large Diaphragm Couplings

The design of custom-made large diaphragm couplings is a meticulous process that involves a thorough analysis of the application requirements, followed by the selection of appropriate materials, dimensions, and configurations. The following are the key design principles that guide the development of these tailored solutions:

3.1 Application Requirement Analysis

The first step in designing a custom large diaphragm coupling is to conduct a comprehensive analysis of the application's requirements. This includes gathering data on the torque capacity, rotational speed, shaft diameters and keyway specifications, misalignment angles (angular, parallel, axial), operating temperature range, environmental conditions (corrosive, dusty, humid), and any special requirements such as weight constraints or space limitations. This analysis forms the foundation of the design process, ensuring that the final product meets all the operational needs of the system.

3.2 Material Selection

Material selection is a critical aspect of custom diaphragm coupling design, as it directly impacts the coupling's performance, durability, and ability to withstand extreme conditions. The diaphragm pack is typically made from high-strength, fatigue-resistant metals. For standard temperature applications, stainless steel (such as 304 or 316) is a common choice due to its corrosion resistance and moderate strength. For high-temperature applications (above 300°C), nickel-based superalloys such as Inconel or Hastelloy are preferred, as they retain their strength and flexibility at elevated temperatures. In applications requiring high torque capacity and low weight, titanium alloys may be used, although they come with a higher cost. The hubs, which need to be rigid and strong, are often made from carbon steel or alloy steel, which can be heat-treated to enhance their strength.

3.3 Diaphragm Pack Design

The diaphragm pack is the most critical component of the coupling, and its design is tailored to meet the specific misalignment and torque requirements of the application. The number of diaphragms in the pack, their thickness, and their shape (such as circular, square, or hexagonal) are all customized based on the load conditions. For applications with high torque and small misalignment, a pack with fewer, thicker diaphragms is used. For applications requiring greater misalignment accommodation, more thin diaphragms are stacked together, as they can deform more easily without exceeding their fatigue limits. The diaphragms may also be designed with specific cutouts or slots to enhance their flexibility while maintaining their torque-carrying capacity.

3.4 Hub Design

The hubs of custom large diaphragm couplings are designed to fit the exact shaft dimensions of the driving and driven machinery. This includes customizing the bore diameter, keyway size and location, and any other features such as set screws or hydraulic fits. The hub material and geometry are also optimized to ensure a secure connection with the shaft, minimizing slip and ensuring efficient torque transmission. In some cases, the hubs may be designed with flanges or other mounting features to facilitate easy installation and removal.

3.5 Finite Element Analysis (FEA) and Simulation

To ensure the reliability and performance of custom-designed couplings, finite element analysis (FEA) is often used during the design process. FEA allows engineers to simulate the coupling's behavior under various operating conditions, such as high torque, extreme temperatures, and maximum misalignment. This simulation helps identify potential stress concentrations, fatigue points, and areas of excessive deformation, allowing for design modifications to optimize the coupling's performance and extend its service life. Additionally, dynamic simulation may be used to assess the coupling's behavior at high rotational speeds, ensuring that it does not experience resonance or excessive vibration.

4. Key Advantages of Custom-made Large Diaphragm Couplings

Custom-made large diaphragm couplings offer a range of advantages over standard off-the-shelf solutions, making them the preferred choice for complex industrial applications. The following are the most significant benefits:

4.1 Optimized Performance

By being tailored to the specific requirements of the application, custom couplings deliver optimized performance. They are designed to transmit torque efficiently, accommodate exact misalignment angles, and operate reliably under the specific temperature and environmental conditions of the system. This optimization ensures that the coupling does not act as a bottleneck in the power transmission process, maximizing the overall efficiency of the machinery.

4.2 Enhanced Durability and Longevity

Custom couplings are constructed using materials that are specifically selected to withstand the harsh conditions of the application. This, combined with the optimized design, results in a coupling that has a longer service life and requires less maintenance. For example, a custom coupling designed for a corrosive offshore environment will use corrosion-resistant materials, preventing premature failure and reducing the need for frequent replacements.

4.3 Improved Safety

Standard couplings that are modified to fit non-standard applications can pose significant safety risks, as the modifications may compromise the coupling's structural integrity. Custom-made couplings, on the other hand, are designed from the ground up to meet the exact safety requirements of the system. They are engineered to handle the maximum torque, speed, and misalignment conditions of the application, reducing the risk of coupling failure, which can lead to costly downtime, equipment damage, or even personnel injury.

4.4 Seamless Integration

Custom couplings are designed to fit perfectly with the existing machinery, eliminating the need for modifications to the shafts or other components. This seamless integration ensures that the installation process is smooth and efficient, reducing downtime during setup. Additionally, the custom design can take into account space limitations, allowing the coupling to fit in tight or awkward spaces where standard couplings would not be feasible.

4.5 Cost-Effectiveness in the Long Run

While the initial cost of a custom-made large diaphragm coupling may be higher than that of a standard coupling, the long-term cost savings are significant. The enhanced durability and reduced maintenance requirements mean fewer replacements and less downtime, resulting in lower operational costs. Additionally, the optimized performance of the custom coupling can improve the overall efficiency of the machinery, reducing energy consumption and further lowering costs.

5. Application Scenarios of Custom-made Large Diaphragm Couplings

Custom-made large diaphragm couplings find application in a wide range of industries and systems where standard couplings are inadequate. The following are some of the key application scenarios:

5.1 Power Generation

In power generation plants—whether thermal, nuclear, or renewable energy facilities—large diaphragm couplings are used to connect turbines, generators, and pumps. These applications require couplings that can handle high torque, high rotational speeds, and extreme temperatures. For example, in a thermal power plant, the coupling connecting the steam turbine to the generator must withstand temperatures exceeding 400°C and transmit torque in excess of 10,000 Nm. Custom couplings in these applications are designed with high-temperature-resistant materials and optimized diaphragm packs to accommodate the thermal expansion of the shafts.

5.2 Oil and Gas Industry

The oil and gas industry operates in some of the harshest environments, including offshore platforms, deserts, and arctic regions. Couplings used in this industry must resist corrosion from saltwater, hydrocarbons, and chemicals, as well as handle high torque and extreme temperatures. Custom large diaphragm couplings are used in drilling rigs, compressors, pumps, and pipelines. For example, a custom coupling used in an offshore drilling rig may be designed with corrosion-resistant titanium diaphragms and reinforced hubs to withstand the high vibration and shock loads associated with drilling operations.

5.3 Heavy-Duty Manufacturing

In heavy-duty manufacturing industries such as steel production, cement manufacturing, and automotive assembly, large diaphragm couplings are used in large machinery such as rolling mills, extruders, and stamping presses. These applications require couplings that can handle very high torque and accommodate significant misalignment due to the heavy loads and thermal expansion of the machinery. Custom couplings in these industries are designed with thick, high-strength diaphragms and rigid hubs to ensure reliable torque transmission and long service life.

5.4 Marine and Naval Applications

Marine vessels, including commercial ships and naval warships, rely on large diaphragm couplings to connect their engines to propellers. These couplings must withstand the corrosive effects of saltwater, handle high torque at varying speeds, and accommodate misalignment caused by the movement of the vessel. Custom couplings in marine applications are designed with corrosion-resistant materials and flexible diaphragm packs to ensure smooth operation even in rough sea conditions. Additionally, they may be designed to be lightweight to minimize the overall weight of the vessel.

5.5 Aerospace and Defense

In the aerospace and defense industries, custom large diaphragm couplings are used in aircraft engines, missile systems, and ground-based military equipment. These applications require couplings that are lightweight, high-strength, and capable of operating in extreme temperature and pressure conditions. Custom couplings in this sector are often made from advanced materials such as titanium or carbon fiber composites, ensuring optimal performance in critical applications.

6. Considerations for Selecting and Designing Custom-made Large Diaphragm Couplings

When selecting or designing a custom-made large diaphragm coupling, there are several key considerations that must be taken into account to ensure that the final product meets the application's requirements. These considerations include:

6.1 Torque and Speed Requirements

The maximum torque and rotational speed that the coupling will be required to handle are the primary design parameters. These values must be accurately determined, as they directly influence the selection of materials, the size of the diaphragm pack, and the geometry of the hubs. Overestimating or underestimating these values can lead to a coupling that is either overdesigned (resulting in unnecessary cost) or underdesigned (leading to premature failure).

6.2 Misalignment Tolerances

The type and magnitude of misalignment that the coupling will need to accommodate must be carefully assessed. This includes angular misalignment (the angle between the two shafts), parallel misalignment (the offset between the shaft axes), and axial misalignment (the relative movement of the shafts along their axes). The diaphragm pack design is tailored to these misalignment tolerances, ensuring that the coupling can operate smoothly without excessive stress.

6.3 Operating Environment

The environmental conditions in which the coupling will operate—such as temperature, humidity, corrosion, and dust—are critical factors in material selection. For example, a coupling operating in a corrosive environment will require corrosion-resistant materials, while one operating in a high-temperature environment will need materials that retain their strength and flexibility at elevated temperatures.

6.4 Shaft Specifications

The exact dimensions of the driving and driven shafts—including bore diameter, keyway size, and shaft length—must be provided to ensure that the hubs fit perfectly. Any deviations from the standard shaft dimensions will require custom hub design to avoid issues such as loose fits or excessive stress on the shafts.

6.5 Installation and Maintenance Requirements

The installation and maintenance requirements of the coupling should also be considered during the design process. For example, if the coupling will be installed in a tight space, a compact design may be necessary. Additionally, couplings that require minimal maintenance are preferred in applications where access is difficult or downtime is costly.

6.6 Cost and Lead Time

While custom-made couplings offer numerous advantages, they typically have a higher initial cost and longer lead time than standard couplings. It is important to balance the performance requirements with the budget and timeline constraints of the project. Working closely with a reputable coupling manufacturer can help optimize the design to minimize costs while meeting all the necessary requirements.

7. Conclusion

Custom-made large diaphragm couplings play a vital role in modern industrial power transmission, offering tailored solutions that meet the unique requirements of complex applications. By leveraging advanced design principles, high-quality materials, and simulation tools, these couplings deliver optimized performance, enhanced durability, and improved safety compared to standard off-the-shelf solutions. From power generation and oil and gas to heavy-duty manufacturing and aerospace, custom large diaphragm couplings are essential components in a wide range of industries, ensuring the smooth and efficient operation of critical machinery.

When designing or selecting a custom-made large diaphragm coupling, it is essential to conduct a thorough analysis of the application's requirements, including torque and speed, misalignment tolerances, operating environment, and shaft specifications. By working closely with experienced engineers and manufacturers, industrial operators can obtain a coupling that is perfectly suited to their needs, resulting in long-term cost savings, reduced downtime, and enhanced overall system performance. As industrial machinery continues to become more complex and demanding, the role of custom-made large diaphragm couplings will only grow in importance, driving innovation in design and material technology to meet the evolving needs of the industry.

« Custom-made Large Diaphragm Coupling » Post Date: 2023/11/22

URL: https://www.rokeecoupling.com/en/customer-cases/custom-made-large-diaphragm-coupling.html

- Cross Type Universal Joints

- Manufacturer Of Mining Gear Coupling

- Non Standard Rigid Claw Coupling

- Rubber Gasket For Water Pump Pin Coupling

- Curved-tooth Gear Coupling Lubrication Hole

- Cardan Shaft Coupling Function

- Flexible Tyre Coupling Purpose

- Brake Drum Gear Couplings Company

- Bush Type Flexible Couplings Supplier

- Laminated Coupling Function