Steel Laminae Couplings

Rokee® is Steel Laminae Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Steel Laminae Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Steel Laminae Coupling is a kind of high-performance metal flexible coupling, which compensates axial and angular displacements by the deformation of elastic diaphragm while transferring torque. It features with compact structure, large transmission torque, long service life, maintenance-free, high temperature resistance, acid and alkali resistance, and corrosion resistance, suitable for shafting transmission in high temperature, high speed and corrosive environment.

-

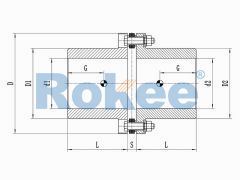

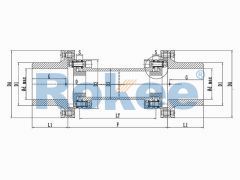

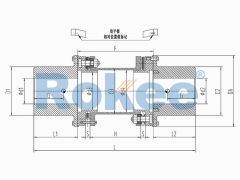

JMI Diaphragm Coupling

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end. -

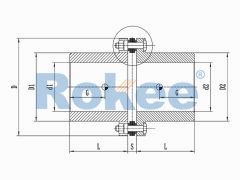

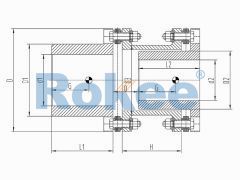

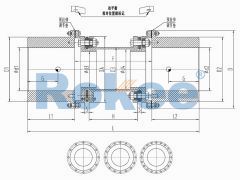

JMIJ Diaphragm Coupling

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end. -

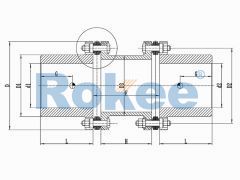

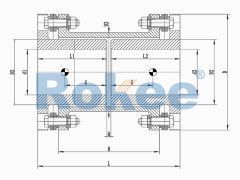

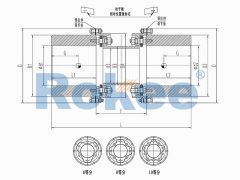

JMII Diaphragm Coupling

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure. -

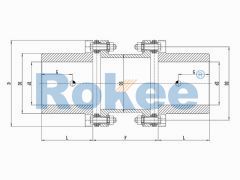

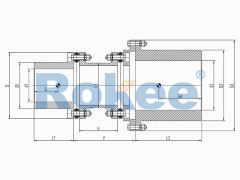

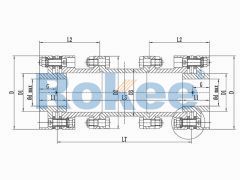

JMIIJ Diaphragm Coupling

JMIIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore. -

RLA Standard Single Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications, but cannot compensate for radial deviation. -

RLM Small Single Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors. -

RLMD Small Double Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm. -

RLAD Standard Double Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications. -

RLAT Super Long Wheelbase Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications. -

RLAR Single Shaft Sleeve Reverse-mounting Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance. -

RLARD Double Shaft Sleeve Reverse-mounting Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller. -

RLAF Large & Small Shaft Mounted Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant. -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications. -

RLQF Flange Type Quick Installation Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm. -

RLQU Improved Flange Quick Installation Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications. -

RLHD High Speed Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.

In the realm of power transmission systems, couplings play an indispensable role as mechanical components that connect two shafts to transmit torque while accommodating various forms of misalignment. Among the diverse types of couplings available, steel laminae couplings have emerged as a reliable and efficient solution for a wide range of industrial applications. Characterized by their use of thin, flexible steel plates (laminae) as the core elastic element, these couplings offer a unique combination of high torque capacity, precision, and resistance to harsh operating conditions.

1. Understanding Steel Laminae Couplings: Definition and Core Components

A steel laminae coupling, also known as a steel disc coupling, is a type of flexible coupling that uses one or more sets of thin steel laminae (discs or plates) to transmit torque between two shafts. Unlike rigid couplings, which require precise alignment and cannot accommodate misalignment, steel laminae couplings leverage the flexibility of the steel plates to compensate for angular, parallel, and axial misalignments between the connected shafts. This flexibility is achieved without sacrificing the coupling’s ability to transmit high levels of torque, making it suitable for both light-duty and heavy-duty applications.

The core components of a typical steel laminae coupling include three main parts: the input hub, the output hub, and the laminae assembly. The input and output hubs are designed to attach to the driving and driven shafts, respectively, and are usually made of high-strength steel or alloy materials to ensure structural integrity and torque transmission efficiency. The laminae assembly, which is the heart of the coupling, consists of multiple thin steel plates arranged in a stack. These plates are often perforated around the circumference to allow for bolted connection to the hubs. The number, thickness, and material grade of the laminae plates are carefully selected based on the required torque capacity and flexibility of the coupling.

The laminae plates themselves are typically made of high-quality spring steel or stainless steel. Spring steel is preferred for most industrial applications due to its excellent fatigue resistance and flexibility, which enable it to withstand repeated bending and torsional stresses without permanent deformation. Stainless steel is used in applications where corrosion resistance is a critical requirement, such as in marine environments or chemical processing plants. The plates are often heat-treated to enhance their mechanical properties, including tensile strength and hardness, ensuring long-term reliability under demanding operating conditions.

2. Design Principles of Steel Laminae Couplings

The design of steel laminae couplings is based on two key principles: torque transmission through the laminae assembly and misalignment compensation via the flexibility of the steel plates. The torque transmission capability of the coupling is determined by the shear strength and bending strength of the laminae plates. When torque is applied to the input hub, it is transferred to the laminae assembly through the bolts connecting the hub to the plates. The laminae then transmit this torque to the output hub, which in turn drives the driven shaft. The design of the bolt pattern and the number of laminae plates are optimized to ensure uniform torque distribution across the plates, minimizing stress concentration and maximizing the coupling’s load-carrying capacity.

Misalignment compensation is achieved by the elastic deformation of the laminae plates. Angular misalignment (the angle between the two shafts) causes the laminae plates to bend slightly, while parallel misalignment (the offset between the shaft axes) results in a combination of bending and shear deformation. Axial misalignment (the axial movement of one shaft relative to the other) is accommodated by the axial flexibility of the laminae assembly. Unlike couplings that use rubber or elastomeric elements, steel laminae couplings do not rely on compression or shear of a flexible material; instead, they use the inherent flexibility of the steel plates, which allows for precise torque transmission with minimal backlash.

Another important design consideration is the balance of the coupling. For high-speed applications, such as in electric motors or turbines, the coupling must be dynamically balanced to minimize vibration and ensure smooth operation. The design of the hubs and laminae assembly is therefore optimized to achieve a balanced configuration, with uniform mass distribution around the axis of rotation. Some steel laminae couplings are also designed with replaceable laminae plates, which allows for easy maintenance and repair without replacing the entire coupling, reducing downtime and maintenance costs.

3. Working Mechanism of Steel Laminae Couplings

The working mechanism of a steel laminae coupling can be broken down into three key processes: torque transmission, misalignment compensation, and damping of torsional vibrations. When the driving shaft rotates, it imparts torque to the input hub. This torque is transferred to the laminae assembly through the bolts that fasten the hub to the laminae plates. Since the laminae plates are rigidly connected to both the input and output hubs, the torque is efficiently transmitted through the plates to the output hub, which then rotates the driven shaft. The steel laminae plates are designed to withstand the torsional stress generated during this process, ensuring that there is no slip or loss of torque.

In cases where the two shafts are misaligned, the laminae plates deform elastically to accommodate the misalignment. For example, if the shafts are angularly misaligned, the laminae plates on one side of the coupling will bend outward, while those on the opposite side will bend inward. This elastic deformation allows the coupling to maintain a continuous connection between the shafts while transmitting torque, preventing excessive stress on the shafts, bearings, and other components of the power transmission system. The flexibility of the laminae plates also helps to absorb and dampen torsional vibrations that may be generated by the driving shaft, such as those caused by unbalanced loads or intermittent torque pulses. This vibration damping capability helps to reduce noise, extend the lifespan of the coupling and other components, and improve the overall stability of the system.

It is important to note that the elastic deformation of the laminae plates is purely elastic, meaning that the plates return to their original shape once the load is removed. This ensures that the coupling maintains its precision and performance over time, even after repeated cycles of misalignment and torque transmission. Unlike elastomeric couplings, which can degrade over time due to wear, heat, or chemical exposure, steel laminae couplings do not suffer from material fatigue in the same way, making them more durable in long-term applications.

4. Key Advantages of Steel Laminae Couplings

Steel laminae couplings offer a range of advantages over other types of couplings, making them a preferred choice in many industrial applications. One of the most significant advantages is their high torque capacity relative to their size. Due to the high strength of steel, the laminae plates can transmit large amounts of torque without requiring a large physical footprint, making the coupling suitable for applications where space is limited. Additionally, the rigid connection between the laminae plates and the hubs ensures that there is minimal backlash, which is critical for precision applications such as machine tools, robotics, and automation systems.

Another major advantage is their excellent misalignment compensation capability. Steel laminae couplings can accommodate angular misalignment up to several degrees, parallel misalignment up to several millimeters, and axial misalignment up to a few millimeters, depending on the design. This flexibility reduces the need for precise shaft alignment during installation, which saves time and labor costs. It also helps to protect the shafts, bearings, and seals from excessive stress, reducing the risk of premature failure.

Steel laminae couplings are also known for their durability and resistance to harsh operating conditions. Unlike rubber couplings, which can degrade when exposed to high temperatures, oil, chemicals, or UV radiation, steel laminae couplings are unaffected by these factors. They can operate in a wide temperature range, from extreme cold to high heat, making them suitable for applications in automotive engines, industrial furnaces, and outdoor equipment. Additionally, steel is resistant to wear and tear, ensuring that the coupling has a long service life with minimal maintenance.

Vibration damping is another key advantage of steel laminae couplings. The elastic deformation of the laminae plates helps to absorb torsional vibrations, which reduces noise and improves the stability of the power transmission system. This is particularly beneficial in applications where vibration can affect the quality of the product or the performance of other components, such as in precision machining or electronic manufacturing.

Finally, steel laminae couplings are easy to maintain and repair. Many designs feature replaceable laminae plates, which can be replaced without removing the entire coupling from the shafts. This reduces downtime and maintenance costs, as there is no need to disassemble the entire power transmission system to repair the coupling. Additionally, steel is easy to inspect for signs of wear or damage, making it simple to identify potential issues before they lead to failure.

5. Industrial Applications of Steel Laminae Couplings

Due to their unique combination of advantages, steel laminae couplings are used in a wide range of industrial applications across various sectors. One of the most common applications is in electric motors and generators. In these systems, the coupling connects the motor shaft to the generator shaft, transmitting torque while accommodating any misalignment that may occur during operation. The high torque capacity and precision of steel laminae couplings make them ideal for this application, as they ensure efficient power transmission and minimize vibration.

Another major application area is in machine tools, such as lathes, milling machines, and grinders. These machines require precise torque transmission and minimal backlash to ensure the accuracy of the machined parts. Steel laminae couplings are well-suited for this purpose, as they offer high precision and excellent misalignment compensation, which helps to maintain the accuracy of the tool while protecting the machine’s bearings and shafts. Additionally, the vibration damping capability of the coupling helps to reduce noise and improve the surface finish of the machined parts.

Steel laminae couplings are also widely used in the automotive industry, particularly in engine and transmission systems. In automotive engines, the coupling connects the crankshaft to the transmission input shaft, transmitting torque while accommodating misalignment caused by engine vibration and thermal expansion. The high temperature resistance and durability of steel laminae couplings make them suitable for this application, as they can withstand the harsh operating conditions inside the engine compartment. They are also used in electric vehicles, where they connect the electric motor to the drivetrain, ensuring efficient power transmission and smooth operation.

Other application areas include robotics and automation systems, where precision and reliability are critical. In robotic arms, for example, the coupling connects the motor to the joint, transmitting torque while accommodating the small misalignments that occur during movement. The minimal backlash and high precision of steel laminae couplings ensure that the robotic arm moves accurately and smoothly, which is essential for tasks such as assembly and pick-and-place operations.

Steel laminae couplings are also used in the marine industry, where they connect the ship’s engine to the propeller shaft. The corrosion resistance of stainless steel laminae plates makes them suitable for marine environments, where exposure to saltwater can cause other materials to degrade. Additionally, their ability to accommodate misalignment caused by the movement of the ship ensures reliable power transmission even in rough seas.

Other industrial sectors that use steel laminae couplings include chemical processing, oil and gas, and renewable energy. In chemical processing plants, the couplings are used in pumps, compressors, and mixers, where they must withstand exposure to chemicals and high temperatures. In the oil and gas industry, they are used in drilling equipment and pipeline pumps, where high torque capacity and durability are essential. In renewable energy systems, such as wind turbines and solar tracking systems, steel laminae couplings connect the turbine or tracker to the generator, transmitting torque while accommodating misalignment caused by wind or structural movement.

6. Selection Considerations for Steel Laminae Couplings

When selecting a steel laminae coupling for a specific application, several key factors must be considered to ensure optimal performance and reliability. The first and most important factor is the torque capacity of the coupling. The coupling must be able to transmit the maximum torque generated by the driving shaft without exceeding its rated load. It is important to select a coupling with a torque rating that is slightly higher than the maximum operating torque to provide a safety margin and prevent premature failure.

Another important consideration is the type and amount of misalignment that the coupling will need to accommodate. The coupling’s design must be able to handle the angular, parallel, and axial misalignment present in the application. It is important to consult the manufacturer’s specifications to ensure that the coupling’s misalignment capacity matches the requirements of the system.

The operating speed of the system is also a critical factor. For high-speed applications, such as in electric motors or turbines, the coupling must be dynamically balanced to minimize vibration. It is important to select a coupling that is rated for the operating speed of the system to ensure smooth operation and prevent damage to the coupling and other components.

The operating environment is another key consideration. If the coupling will be exposed to high temperatures, chemicals, or corrosive substances, it is important to select a coupling made from materials that can withstand these conditions. For example, stainless steel laminae plates should be used in corrosive environments, while heat-treated spring steel is suitable for high-temperature applications.

The size and installation space of the coupling must also be considered. The coupling must fit within the available space in the system, and the hubs must be compatible with the size and type of shafts being connected. It is important to ensure that the coupling’s dimensions match the requirements of the application to avoid installation issues.

Finally, maintenance requirements should be considered when selecting a steel laminae coupling. Couplings with replaceable laminae plates are easier to maintain and repair, reducing downtime and maintenance costs. It is also important to select a coupling that is easy to inspect, as this allows for early detection of potential issues and ensures long-term reliability.

7. Conclusion

Steel laminae couplings are a versatile and reliable solution for power transmission systems in a wide range of industrial applications. Their unique design, which uses flexible steel plates to transmit torque and accommodate misalignment, offers a combination of high torque capacity, precision, durability, and vibration damping that is unmatched by many other types of couplings. From electric motors and machine tools to automotive systems and marine applications, steel laminae couplings play a critical role in ensuring efficient and reliable power transmission, protecting components from damage, and improving the overall performance of industrial systems.

When selecting a steel laminae coupling, it is important to consider factors such as torque capacity, misalignment compensation, operating speed, environment, size, and maintenance requirements to ensure that the coupling is well-suited for the specific application. With proper selection and maintenance, steel laminae couplings can provide long-term reliability and performance, making them an essential component in modern industrial power transmission systems. As industrial technology continues to advance, the demand for high-performance couplings such as steel laminae couplings is expected to grow, driving further innovations in their design and applications.

« Steel Laminae Couplings » Post Date: 2023/8/17

URL: https://www.rokeecoupling.com/en/tags/steel-laminae-couplings.html

- 2023-10-27Steel Laminae Coupling Lamination Thickness

- 2023-10-27Steel Laminae Couplings Permissible Values

- 2023-10-27Steel Laminae Coupling Principle

- 2023-10-27Requirements For Steel Laminae Couplings

- 2023-10-27Schematic Diagram Of Steel Laminae Coupling

- 2023-10-27Wear Form Of Steel Laminae Coupling

- 2023-10-27Steel Laminae Coupling Preload Effect

- 2023-10-27Steel Laminae Couplings Allow Welding

- 2023-10-27Types Of Steel Laminae Couplings

- 2023-10-27Steel Laminae Coupling Transmission Efficiency

- 2023-10-27Steel Laminae Coupling Flange Plate Thickness

- 2023-10-27Structural Diagram Of Steel Laminae Coupling

- 2023-10-27Steel Laminae Coupling Stretch Amount

- 2023-10-27Steel Laminae Coupling Tightening Bolts

- 2023-10-27Steel Laminae Coupling Structure

- 2023-10-27Steel Laminae Coupling Shear Pin

- 2023-10-27Steel Laminae Coupling Rigidity

- 2023-10-27Steel Laminae Coupling Liner

- 2023-10-27Steel Laminae Coupling Laminated Rivet Washer

- 2023-10-27Steel Laminae Coupling Gas Turbine

- 2023-10-27Steel Laminae Coupling Form

- 2023-10-27Steel Laminae Coupling End Face

- 2023-10-27Steel Laminae Coupling Diaphragm Material

- 2023-10-27Steel Laminae Coupling Buffer Sleeve

- 2023-10-27Steel Laminae Coupling Bolt Direction

- 2023-10-27Steel Laminae Coupling Accessories

- 2023-10-09Steel Laminae Coupling Function

- 2023-10-09Steel Laminae Coupling Processing

- 2023-10-09Steel Laminae Coupling Model

- 2023-10-07Steel Laminae Coupling Damping

- 2023-10-07Price Of Steel Laminae Coupling

- 2023-10-07Outer Diameter Size Of Steel Laminae Coupling

- 2023-10-07Installation Specification For Steel Laminae Couplings

- 2023-10-07Function Of Steel Laminae Coupling

- 2023-10-07Compensation Value Of Steel Laminae Coupling

- 2023-10-07Dimensions Of Steel Laminae Couplings

- 2023-10-07Centering Deviation Of Steel Laminae Coupling

- 2023-10-07Advantages Of Steel Laminae Couplings

- 2023-09-25Dynamic Balance Of Steel Laminae Coupling

- 2023-09-25Characteristics Of Steel Laminae Couplings

- 2023-09-25Allowable Deviation For Alignment Of Steel Laminae Couplings

- 2023-09-25Adjustment Of Pre Tension Of Steel Laminae Coupling

- 2023-09-23Standard For Steel Laminae Couplings

- 2023-09-23Steel Laminae Coupling Efficiency

- 2023-09-22Stiffness Of Steel Laminae Coupling

- 2023-09-22Working Principle Of Steel Laminae Coupling

- 2023-09-22Steel Laminae Coupling Manufacturer

- 2023-09-22Steel Laminae Coupling Brand

- 2023-09-22Selection Of Steel Laminae Coupling

- 2023-09-22Material Standard For Steel Laminae Couplings

- 2023-09-22Causes Of Rupture Of Steel Laminae Couplings

- 2023-09-22How To Determine The Distance Of Steel Laminae Couplings

- 2023-09-22Deformation Of Steel Laminae Coupling