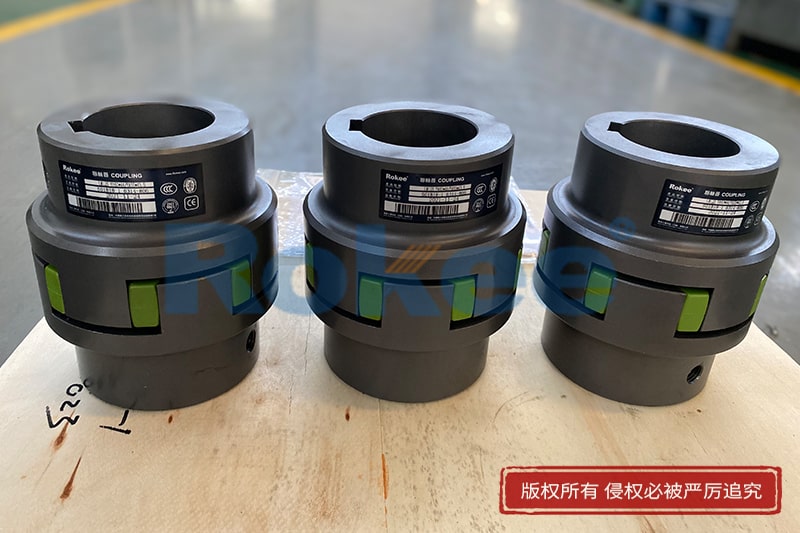

Plum Couplings

Rokee® is Plum Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Plum Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Plum Coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, Plum Coupling has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

-

LM Plum-shaped Flexible Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings. -

LMD Plum-shaped Flexible Coupling

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMS Plum-shaped Flexible Coupling

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMZ-I Plum-shaped Flexible Coupling

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required. -

LMZ-II Plum-shaped Flexible Coupling

LMZ-II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required. -

LMPK Plum-shaped Flexible Coupling

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, enabling the seamless transfer of torque while accommodating misalignments and reducing vibration. Among the diverse range of couplings available, the plum coupling—known for its simplicity, flexibility, and cost-effectiveness—has emerged as a preferred choice in numerous industrial and commercial applications.

A plum coupling, also referred to as a jaw coupling with an elastic element, consists of three main components: two metal hubs with jaw-like projections, and an elastic insert (often called a "spider" due to its shape) that fits between the jaws of the two hubs. The design of these components is meticulously engineered to balance torque transmission capability with flexibility. The metal hubs are typically machined with evenly spaced jaws—usually 3, 4, or 6 in number—that interlock with the lobes of the elastic insert. This interlocking mechanism ensures a secure connection between the driving and driven shafts while allowing for a certain degree of misalignment.

One of the key design features of plum couplings is the geometry of the jaws and the elastic insert. The jaws are often curved or tapered to distribute the load evenly across the elastic element, minimizing stress concentration and extending the service life of the coupling. The elastic insert, which is the core of the coupling’s flexibility, is designed with lobes that match the shape and number of the jaws. The thickness and hardness of the insert can be adjusted to suit different torque requirements and operating conditions. Additionally, the hubs are designed to be mounted on the shafts using various methods, such as keyways, set screws, or compression fittings, ensuring a tight and reliable connection that prevents slippage during operation.

The working principle of a plum coupling revolves around the interaction between the metal hubs and the elastic insert. When torque is applied to the driving shaft, the jaws of the driving hub exert a force on the lobes of the elastic insert. This force is then transmitted through the insert to the jaws of the driven hub, which in turn rotates the driven shaft. The elastic nature of the insert plays a crucial role in accommodating different types of misalignment, including angular misalignment (where the shafts are not colinear), parallel misalignment (where the shafts are offset), and axial misalignment (where the shafts move towards or away from each other). As the shafts rotate, the elastic insert deforms slightly to compensate for these misalignments, reducing the stress on the shafts, bearings, and other components of the mechanical system.

Another important function of the elastic insert is vibration damping. In many mechanical systems, rotating shafts generate vibrations due to imbalances, uneven load distribution, or other factors. These vibrations can cause noise, reduce the efficiency of the system, and lead to premature wear of components. The elastic material of the insert absorbs and dissipates these vibrations, resulting in a smoother and quieter operation. Furthermore, the plum coupling can act as a torque limiter in some applications. If the torque exceeds a certain threshold, the elastic insert may deform excessively or shear, preventing damage to the driving and driven equipment. This protective feature makes plum couplings particularly valuable in systems where sudden torque spikes are a concern.

The selection of materials for plum couplings is a critical factor that directly impacts their performance, durability, and suitability for specific applications. The metal hubs are typically made from high-strength materials such as carbon steel, alloy steel, or aluminum alloy. Carbon steel is a common choice due to its excellent torque transmission capability, high strength, and cost-effectiveness. Alloy steel, which contains additional elements such as chromium, nickel, or molybdenum, offers enhanced durability, corrosion resistance, and resistance to wear, making it suitable for heavy-duty applications. Aluminum alloy, on the other hand, is lighter in weight, which reduces inertia and is beneficial in high-speed applications where weight reduction is a priority. The choice of hub material depends on factors such as the required torque capacity, operating speed, environmental conditions, and weight constraints.

The elastic insert is typically made from elastomeric materials such as natural rubber, nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), silicone rubber, or polyurethane. Each of these materials has unique properties that make them suitable for different operating conditions. Natural rubber offers good elasticity and flexibility but has limited resistance to oil, heat, and ozone. Nitrile rubber is highly resistant to oil, fuel, and grease, making it ideal for applications in the automotive, hydraulic, and petroleum industries. EPDM rubber exhibits excellent resistance to heat, ozone, and weathering, making it suitable for outdoor and high-temperature applications. Silicone rubber can withstand extremely high and low temperatures, as well as harsh chemical environments, making it a preferred choice for aerospace and industrial applications with extreme operating conditions. Polyurethane is a durable and rigid material that offers high torque capacity and resistance to abrasion, making it suitable for heavy-duty industrial applications.

Plum couplings find applications in a wide range of industries and mechanical systems due to their versatility, simplicity, and cost-effectiveness. One of the most common applications is in the automotive industry, where they are used in drive shafts, transmissions, and auxiliary systems such as water pumps and alternators. In these applications, the plum coupling’s ability to accommodate misalignment and dampen vibrations is crucial for ensuring the smooth operation of the vehicle and reducing wear on critical components.

In the industrial machinery sector, plum couplings are widely used in pumps, compressors, fans, conveyors, and electric motors. Pumps, for example, often experience misalignment between the motor shaft and the pump shaft due to installation errors or thermal expansion. Plum couplings can compensate for this misalignment, ensuring efficient torque transmission and preventing damage to the pump and motor bearings. Similarly, in conveyor systems, which operate continuously and are subject to varying loads, plum couplings provide the necessary flexibility to handle misalignments and reduce vibration, extending the service life of the conveyor components.

The aerospace industry also utilizes plum couplings in various applications, such as in aircraft engines, landing gear systems, and auxiliary power units. In these high-precision and high-reliability applications, plum couplings made from lightweight and high-strength materials (such as aluminum alloy hubs and silicone rubber inserts) are preferred. They must meet strict performance requirements, including the ability to withstand extreme temperatures, high speeds, and vibrations, while maintaining a compact and lightweight design.

Other applications of plum couplings include medical equipment (such as centrifuges and diagnostic machines), agricultural machinery (such as tractors and harvesters), and household appliances (such as washing machines and air conditioners). In each of these applications, the plum coupling’s ability to provide reliable torque transmission, accommodate misalignment, and dampen vibrations contributes to the overall performance and durability of the equipment.

Proper installation and maintenance are essential for ensuring the optimal performance and long service life of plum couplings. The installation process begins with the selection of the correct coupling size and type based on the torque requirements, shaft diameters, and operating conditions of the system. Before installation, it is important to inspect the shafts for any damage, such as scratches, dents, or burrs, which could affect the fit of the coupling hubs. The shafts should also be cleaned to remove any dirt, oil, or debris that could cause slippage.

When mounting the coupling hubs on the shafts, it is crucial to ensure that the hubs are properly aligned. Misalignment during installation can lead to excessive stress on the elastic insert, increased vibration, and premature wear. The use of alignment tools, such as dial indicators or laser alignment systems, is recommended to achieve the correct alignment. The allowable misalignment values vary depending on the coupling size and type, and these values should be strictly followed to avoid compromising the coupling’s performance.

After installation, the coupling should be inspected regularly to ensure that it is functioning properly. Routine maintenance checks should include inspecting the elastic insert for signs of wear, such as cracks, tears, or hardening. The insert should be replaced if any of these signs are present, as a damaged insert can lead to increased vibration, reduced torque transmission, and potential failure of the coupling. The metal hubs should also be inspected for signs of wear, corrosion, or damage, and any loose fasteners (such as set screws or bolts) should be tightened.

Lubrication is another important aspect of maintenance for some types of plum couplings. While many plum couplings with elastomeric inserts do not require lubrication, those used in high-speed or high-temperature applications may benefit from the application of a small amount of lubricant to reduce friction between the jaws and the insert. It is important to use the correct type of lubricant, as some lubricants can degrade the elastomeric material of the insert. The manufacturer’s recommendations should be followed regarding lubrication frequency and type.

In addition to routine inspections and maintenance, it is important to monitor the operating conditions of the coupling. Factors such as temperature, vibration, and noise can indicate potential problems with the coupling or the surrounding system. For example, an increase in vibration or noise may indicate misalignment, a damaged elastic insert, or excessive wear on the hubs. Prompt action to address these issues can prevent further damage and ensure the continued reliability of the mechanical system.

As technology advances and industrial requirements become more stringent, the design and performance of plum couplings are continuously evolving. One of the key trends in the development of plum couplings is the use of advanced materials and manufacturing processes to improve their performance and durability. For example, the use of composite materials for the hubs, such as carbon fiber-reinforced polymers, offers the benefits of lightweight, high strength, and corrosion resistance. These materials are particularly suitable for applications where weight reduction and high performance are critical, such as in the aerospace and automotive industries.

Another trend is the development of elastic inserts with enhanced properties. Manufacturers are investing in research and development to create elastomeric materials that offer better resistance to heat, oil, chemicals, and wear, while maintaining excellent elasticity and vibration damping capabilities. For example, the development of hybrid elastomers, which combine the properties of different materials, can provide a balance of performance characteristics that meet the specific requirements of complex applications.

The integration of smart technology into plum couplings is also an emerging trend. Smart couplings equipped with sensors can monitor various parameters such as temperature, vibration, torque, and misalignment in real time. This data can be transmitted to a central monitoring system, allowing for predictive maintenance and early detection of potential problems. Predictive maintenance can significantly reduce downtime, lower maintenance costs, and improve the overall efficiency of the mechanical system. For example, if a sensor detects an increase in temperature or vibration in the coupling, maintenance personnel can be alerted to inspect the coupling and address any issues before they lead to failure.

In addition, there is a growing focus on the customization of plum couplings to meet the specific needs of different applications. Manufacturers are offering custom-designed couplings with tailored hub sizes, jaw configurations, and elastic insert materials to accommodate unique torque requirements, shaft diameters, and operating conditions. Customization allows for optimal performance and efficiency, as the coupling is designed specifically for the application rather than being a one-size-fits-all solution.

Despite the many advantages of plum couplings, they also have certain limitations that should be considered when selecting a coupling for a specific application. One of the main limitations is their limited misalignment capacity compared to other types of couplings, such as universal joints or flexible couplings with rubber sleeves. Plum couplings are best suited for applications with small to moderate misalignments; excessive misalignment can lead to premature wear of the elastic insert and reduced service life. Another limitation is their temperature range. Most elastomeric inserts have a maximum operating temperature of around 120°C to 150°C, which may not be suitable for high-temperature applications such as in industrial furnaces or gas turbines. In such cases, couplings with metal or ceramic components may be more appropriate.

Furthermore, plum couplings are not suitable for applications where high precision is required, such as in machine tools or robotics. These applications require couplings with minimal backlash and high torsional stiffness, which plum couplings may not provide. In such cases, rigid couplings or precision flexible couplings are preferred.

In conclusion, plum couplings are a versatile and cost-effective solution for power transmission in a wide range of industrial and commercial applications. Their simple design, flexibility, and vibration damping capabilities make them an ideal choice for applications with small to moderate misalignments and varying load conditions. The selection of the correct materials for the hubs and elastic insert is crucial for ensuring optimal performance and durability, and proper installation and maintenance practices are essential for extending their service life.

As technology continues to advance, the future of plum couplings looks promising, with advancements in materials, manufacturing processes, and smart technology leading to improved performance, durability, and efficiency. By staying abreast of these developments, industry professionals can make informed decisions when selecting and using plum couplings, ensuring the reliability and efficiency of their mechanical systems. Whether in automotive, industrial, aerospace, or other applications, plum couplings will continue to play a vital role in power transmission, contributing to the smooth and efficient operation of mechanical systems around the world.

« Plum Couplings » Post Date: 2023/9/1

URL: https://www.rokeecoupling.com/en/tags/plum-couplings.html

- 2023-12-14Transmission Plum Couplings

- 2023-12-14Three Claw Plum Couplings

- 2023-12-14Star Plum Couplings

- 2023-12-14Stainless Steel Plum Couplings

- 2023-12-14MLS Plum Coupling

- 2023-12-14MLL Plum Coupling

- 2023-12-14LMS Plum Coupling

- 2023-12-14LMPK Plum Coupling

- 2023-12-14Split Type Plum Couplings

- 2023-12-14Single Flange Plum Couplings

- 2023-12-14Round Steel Plum Couplings

- 2023-12-14Plum Coupling With Keyway

- 2023-12-14Plum Coupling With Flange Plate

- 2023-12-14Plum Coupling With Brake Wheel

- 2023-12-14ML Plum Coupling

- 2023-12-14LMD Plum Coupling

- 2023-12-14LMZ Plum Coupling

- 2023-12-14MLPK Plum Coupling

- 2023-12-14MLZ Plum Coupling

- 2023-12-14Plum Coupling With Brake Disc

- 2023-12-14Plum Coupling For Water Pumps

- 2023-12-14Plum Coupling For Plunger Pumps

- 2023-12-14Plum Coupling For Oil Pumps

- 2023-12-14Plum Coupling For Injection Molding Machine

- 2023-12-14Plum Coupling For Guide Rail

- 2023-12-14Plum Coupling For Gear Pumps

- 2023-12-14Octopus Claw Plum Couplings

- 2023-12-14Octapetal Plum Couplings

- 2023-12-14Octagon Plum Couplings

- 2023-12-14LM Plum Coupling

- 2023-12-14Integrated Plum Couplings

- 2023-12-14Hexapetal Plum Couplings

- 2023-12-14Hexagonal Plum Couplings

- 2023-12-14Half Open Type Plum Couplings

- 2023-12-14Expansion Sleeve Type Plum Couplings

- 2023-12-14Four Claws Plum Couplings

- 2023-12-14Flexibility Plum Couplings

- 2023-12-14Flange Type Plum Couplings

- 2023-12-14Expansion Sleeve Plum Couplings

- 2023-12-14Electrical Machinery Plum Couplings

- 2023-12-14Elastic Plum Couplings

- 2023-12-14Double Flange Plum Couplings

- 2023-12-14Conical Sleeve Type Plum Couplings

- 2023-12-14Cast Steel Plum Couplings

- 2023-12-14Brake Wheel Plum Couplings

- 2023-12-14Automation Plum Couplings

- 2023-10-19High Torque Plum Coupling Specifications

- 2023-10-19Curved Plum Coupling

- 2023-10-19Split Type Plum Coupling

- 2023-10-19High Torque Plum Coupling Model

- 2023-10-19High Speed Plum Coupling Supply

- 2023-10-19High Precision Plum Coupling Manufacturer

- 2023-10-18High Precision Plum Coupling Enterprise

- 2023-10-18Motor Plum Couplings

- 2023-10-18Steel Plum Couplings

- 2023-10-18Split Brake Plum Coupling

- 2023-10-17Motor Plum Coupling Enterprise

- 2023-10-17Plum Coupling For Fans

- 2023-10-17Powder Metallurgy Plum Coupling

- 2023-10-13Split Plum Coupling With Brake Wheel

- 2023-10-13Flange Plum Couplings

- 2023-10-13High-precision Plum Couplings

- 2023-10-12Plum Coupling With Transition Section

- 2023-10-11Flexible Plum Couplings Structural Composition

- 2023-10-11Flexible Plum Couplings Structural Characteristics

- 2023-10-11Flexible Plum Couplings Structural Drawing

- 2023-10-11Flexible Plum Couplings Takeover

- 2023-10-11Two Claws Flexible Plum Couplings

- 2023-10-11Two Teeth Flexible Plum Couplings

- 2023-10-11Flexible Plum Couplings Type

- 2023-10-11Zero Backlash Flexible Plum Couplings

- 2023-10-11Zero Clearance Flexible Plum Couplings

- 2023-10-11Hexagonal Flexible Plum Couplings

- 2023-10-11Internal Concave Type Flexible Plum Couplings

- 2023-10-11Plum Couplings Components

- 2023-10-11Plum Couplings Distributor

- 2023-10-11Plum Couplings Fastening Bolts

- 2023-10-11Plum Couplings Gasket

- 2023-10-11Plum Couplings Plum Block

- 2023-10-11Plum Couplings Rubber Block

- 2023-10-11Plum Couplings Rubber Pier

- 2023-10-11Plum Couplings Rubber Ring

- 2023-10-11Plum Couplings Rubber Sleeve

- 2023-10-11Plum Couplings Seller

- 2023-10-11Flexible Plum Couplings Static Torque

- 2023-10-11Flexible Plum Couplings Selling Price

- 2023-10-11Flexible Plum Couplings Rubber Gasket

- 2023-10-11Flexible Plum Couplings Rectangular Spline

- 2023-10-11Flexible Plum Couplings Radial Displacement

- 2023-10-11Flexible Plum Couplings Radial Deviation

- 2023-10-11Flexible Plum Couplings Radial Compensation Capability

- 2023-10-11Flexible Plum Couplings Opening Keyway

- 2023-10-11Flexible Plum Couplings Metal Gasket

- 2023-10-11Flexible Plum Couplings Key Size

- 2023-10-11Flexible Plum Couplings Key Slot Position

- 2023-10-11Flexible Plum Couplings Keyway Specification

- 2023-10-11Flexible Plum Couplings Metal Claw Plate

- 2023-10-11Flexible Plum Couplings Internal Structure Diagram

- 2023-10-11Flexible Plum Couplings Inner Diameter

- 2023-10-11Flexible Plum Couplings Holes Number

- 2023-10-11Flexible Plum Couplings Hole Length

- 2023-10-11Flexible Plum Couplings Grooving

- 2023-10-11Flexible Plum Couplings For Mining

- 2023-10-11Flexible Plum Couplings Deflection

- 2023-10-11Flexible Plum Couplings Connection Requirements

- 2023-10-11Flexible Plum Couplings Connection Principle

- 2023-10-11Flexible Plum Couplings Connection Method

- 2023-10-11Flexible Plum Couplings Connection Clearance

- 2023-10-11Flexible Plum Couplings Connecting Shaft

- 2023-10-11Flexible Plum Couplings Connecting Screw Rod

- 2023-10-11Flexible Plum Couplings Cold Forging Processing

- 2023-10-11Flexible Plum Couplings Category

- 2023-10-11Flexible Plum Couplings Aperture Range

- 2023-10-11Flexible Plum Couplings Angular Compensation

- 2023-10-11Flexible Plum Couplings Angle

- 2023-10-11Flexible Plum Couplings Accuracy

- 2023-10-11Flexible Plum Coupling Connection Pieces

- 2023-10-11Cheapest Flexible Plum Couplings

- 2023-10-10Claw Type Plum Couplings

- 2023-10-09Steel Plum Coupling Company

- 2023-10-09Top Thread Type Plum Couplings

- 2023-10-08Plum Coupling For Scraper Machine

- 2023-10-07Elastic Plum Coupling Company

- 2023-09-16Plum Coupling For Pumps