Barrel Couplings

Rokee® is Barrel Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Barrel Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

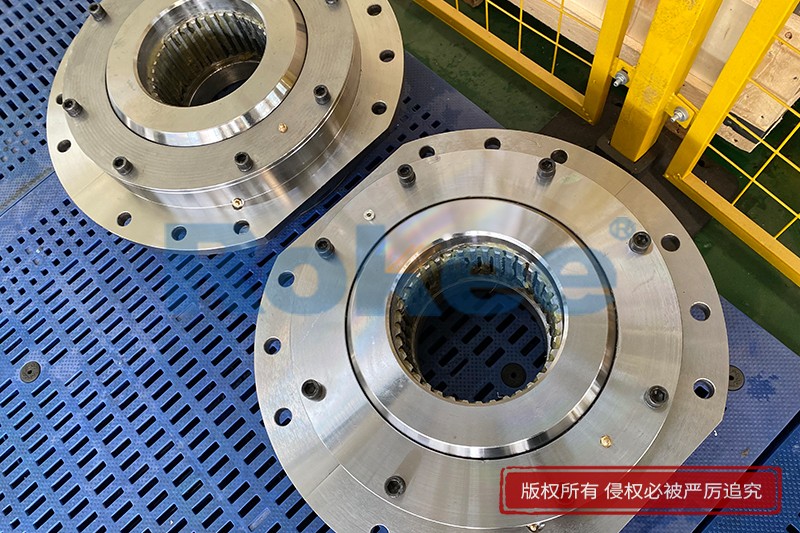

The Barrel Coupling internal sphere gear sleeve is assembled with the external drum perfectly. Relying on the specially designed key, the external sphere shaft sleeve forms the entirety with gear sleeve perfectly. Barrel coupling will promote the reliable connection of reducer shaft and drum and it is the most ideal product in the market home and abroad at present.

-

WZL Drum Coupling

WZL Drum Coupling is a spherical hinged coupling. It has a connecting flange with an inner spherical surface, a spherical semi-coupling sleeve with an outer spherical surface, a special transmission key, an inner and outer limit cover, etc. The internal control generally adopts the splined sleeve design, which transmits torque through a specially designed key bar and can withstand large torque and radial load. The maximum angular displacement compensation can reach 3°, with a life indicator and safe and reliable structure. -

DC Drum Coupling

DC Drum Coupling is designed with drum teeth, which is used for connecting the reducer of crane transmission system with the drum. It can bear radial load and transfer large torque, but cannot transfer axial load. -

WJ Drum Coupling

WJ Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. -

WJA Drum Coupling

WJA Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. The connection between the coupling and the output shaft of the reducer adopts an involute spline pair design. -

RWC Ball And Drum Gear Drum Coupling

The ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life.

In the realm of mechanical power transmission, couplings serve as critical components that bridge rotating shafts, enabling the transfer of torque while accommodating misalignments, absorbing shocks, and reducing vibration. Among the diverse array of coupling designs, barrel coupling stands out for its unique structural characteristics and versatile performance, making it a preferred choice in numerous industrial applications.

To begin with, it is essential to define what a barrel coupling is and how it differs from other coupling types. A barrel coupling is a rigid or semi-rigid coupling design characterized by a cylindrical (barrel-shaped) central hub that connects two shafts. Unlike flexible couplings that use elastomeric elements or universal joints to accommodate misalignments, barrel couplings primarily rely on their structural geometry and material properties to handle limited axial, radial, and angular misalignments. The core function of a barrel coupling is to transmit torque from a driving shaft (e.g., from a motor) to a driven shaft (e.g., to a pump, compressor, or gearbox) with minimal energy loss. What distinguishes barrel couplings is their compact design, high torque-carrying capacity, and simplicity, which make them suitable for applications where space is constrained and reliability is paramount.

The design principles of barrel coupling are rooted in the need to balance torque transmission efficiency with the ability to accommodate misalignments and withstand operational stresses. The key structural components of a typical barrel coupling include two shaft hubs (each attached to the respective shaft) and a central barrel section that connects these hubs. The shaft hubs are usually secured to the shafts using set screws, keyways, or clamping mechanisms, ensuring a tight fit that prevents slippage during operation. The central barrel section, which gives the coupling its name, is often a solid or hollow cylindrical piece that is either integrally formed with the hubs or bolted to them. The geometry of the barrel section is carefully engineered to distribute torque evenly across the coupling, reducing stress concentrations that could lead to premature failure.

One of the critical design considerations for barrel coupling is the accommodation of misalignments. Shaft misalignment in rotating machinery can occur due to installation errors, thermal expansion and contraction, or structural deflection during operation. There are three main types of misalignment: axial (along the shaft axis), radial (perpendicular to the shaft axis), and angular (tilt between the two shafts). Barrel couplings are designed to handle small to moderate levels of these misalignments. For rigid barrel couplings, the misalignment capacity is relatively limited, typically up to 0.5 degrees for angular misalignment and a few millimeters for radial and axial misalignment. Semi-rigid barrel couplings, however, may incorporate slight flexibility in the barrel section (e.g., through slits or tapered designs) to enhance their misalignment accommodation capabilities without compromising torque transmission.

Material selection is another pivotal factor that influences the performance, durability, and application range of barrel coupling. The choice of material depends on various operational parameters, including the magnitude of torque to be transmitted, operating speed, temperature, environmental conditions (e.g., presence of moisture, chemicals, or corrosive substances), and weight constraints. The most commonly used materials for barrel coupling include carbon steel, alloy steel, stainless steel, aluminum, and in some cases, high-performance polymers.

Carbon steel is a popular choice for general-purpose barrel couplings due to its high strength, durability, and cost-effectiveness. It is suitable for applications with moderate torque requirements and operating temperatures. Alloy steel, which contains additional elements such as chromium, nickel, or molybdenum, offers enhanced strength, toughness, and resistance to wear and fatigue. This makes alloy steel barrel couplings ideal for heavy-duty applications, such as in mining, construction, and industrial machinery, where high torque and harsh operating conditions are prevalent.

Stainless steel is preferred for barrel couplings used in corrosive environments, such as food processing, pharmaceutical, and marine applications. Its resistance to rust and chemical degradation ensures long-term reliability in these settings. Aluminum barrel couplings are chosen for applications where weight is a critical factor, such as in aerospace, automotive, and portable machinery. Aluminum is lightweight yet offers sufficient strength for moderate torque applications, and it also has good thermal conductivity, which helps in dissipating heat generated during operation. High-performance polymers, such as nylon or PEEK, are used in specialized applications where electrical insulation, chemical resistance, or low noise operation is required, though their torque-carrying capacity is generally lower than that of metallic couplings.

Barrel couplings can be classified into several types based on their design, flexibility, and method of shaft attachment. The primary types include rigid barrel couplings, semi-rigid barrel couplings, and split barrel couplings.

Rigid barrel couplings are the simplest type, consisting of a solid cylindrical barrel with two integral hubs. They are designed for applications where shafts are accurately aligned and minimal misalignment is expected. Rigid barrel couplings offer high torque transmission efficiency and are easy to manufacture and install. However, their inability to accommodate significant misalignments means that precise installation is crucial; otherwise, excessive stresses may be imposed on the shafts, bearings, and other components. Common applications of rigid barrel couplings include small electric motors, fans, and light-duty pumps.

Semi-rigid barrel couplings incorporate design features that provide limited flexibility, allowing them to accommodate small amounts of misalignment. This flexibility can be achieved through slits in the barrel section, tapered hubs, or a combination of both. The slits in the barrel act as flexible joints, enabling slight angular and radial movement without compromising the coupling’s structural integrity. Semi-rigid barrel couplings are a balance between rigid and flexible couplings, offering higher misalignment capacity than rigid couplings while maintaining a compact design and high torque-carrying capacity. They are widely used in applications such as medium-duty pumps, compressors, and conveyor systems.

Split barrel couplings are designed with a split barrel section, which allows them to be installed without removing the shafts or other adjacent components. This makes them particularly useful for maintenance and replacement in large machinery where disassembling the entire shaft assembly is time-consuming and costly. The split barrel is held together by bolts, ensuring a tight fit and reliable torque transmission. Split barrel couplings are available in both rigid and semi-rigid designs, catering to a wide range of applications, including large industrial pumps, turbines, and gearboxes.

The versatility of barrel coupling is reflected in its wide range of applications across various industries. Each industry has unique requirements, and barrel couplings are adapted to meet these specific needs through appropriate material selection, design modifications, and size customization.

In the manufacturing industry, barrel couplings are extensively used in machinery such as conveyors, mixers, extruders, and machine tools. Conveyors, which are used to transport materials across production facilities, rely on barrel couplings to transmit torque from electric motors to the conveyor rollers. The compact design of barrel couplings is particularly advantageous in conveyor systems where space is limited. Mixers and extruders, which operate under high torque conditions, use alloy steel barrel couplings to ensure reliable torque transmission and resistance to wear. Machine tools, such as lathes and milling machines, require precise torque transmission to maintain machining accuracy, making rigid barrel couplings an ideal choice due to their high precision and low backlash.

The energy sector, including power generation and oil and gas, is another major user of barrel couplings. In power plants, barrel couplings are used in turbines, generators, and pumps. Turbines operate at high speeds and transmit large amounts of torque, requiring robust and durable couplings. Alloy steel or stainless steel barrel couplings are preferred in these applications due to their high strength and resistance to high temperatures. In the oil and gas industry, barrel couplings are used in drilling equipment, pumps, and compressors. The harsh environmental conditions, including high pressure, corrosive fluids, and extreme temperatures, demand couplings made from corrosion-resistant materials such as stainless steel or specialized alloys.

The automotive and aerospace industries also utilize barrel couplings in various applications. In the automotive industry, barrel couplings are used in drive shafts, transmission systems, and auxiliary components such as water pumps and alternators. Aluminum barrel couplings are often used in these applications to reduce weight, improving fuel efficiency. In the aerospace industry, where weight and reliability are critical, lightweight and high-strength barrel couplings made from aluminum or titanium alloys are used in aircraft engines, landing gear systems, and auxiliary power units.

The food and pharmaceutical industries require couplings that meet strict hygiene standards and are resistant to corrosion. Stainless steel barrel couplings are ideal for these applications, as they can be easily cleaned and sterilized, preventing contamination of food products or pharmaceutical ingredients. They are used in processing equipment such as mixers, blenders, and pumps.

Proper installation and maintenance of barrel couplings are essential to ensure their optimal performance and longevity. Improper installation can lead to misalignment, excessive stress, and premature failure, while inadequate maintenance can result in wear, corrosion, and reduced efficiency.

During installation, the first step is to ensure that the shafts are properly aligned. This can be done using alignment tools such as dial indicators or laser alignment systems. For rigid barrel couplings, precise alignment is critical, as even small misalignments can cause excessive vibration and stress. The shafts should be cleaned to remove any dirt, grease, or debris that could prevent a tight fit. The coupling hubs are then slid onto the shafts and secured using the appropriate method (set screws, keyways, or clamping mechanisms). It is important to ensure that the fasteners are tightened to the recommended torque to prevent slippage during operation.

For split barrel couplings, the split sections are placed around the shafts and bolted together. Care should be taken to ensure that the split faces are clean and free of debris to ensure a tight seal. After installation, the coupling should be checked for smooth rotation and absence of vibration. Any unusual noise or vibration during operation indicates a problem, such as misalignment or loose fasteners, which should be addressed immediately.

Maintenance of barrel couplings involves regular inspection, lubrication (if required), and replacement of worn components. Regular inspections should check for signs of wear, corrosion, cracks, or loose fasteners. The frequency of inspections depends on the operating conditions; couplings used in harsh environments or high-speed applications may require more frequent checks. Lubrication is necessary for couplings with moving parts, such as semi-rigid couplings with flexible joints, to reduce friction and wear. The type of lubricant used should be compatible with the coupling material and operating conditions. If any damage or excessive wear is detected, the coupling should be replaced promptly to prevent further damage to the shafts, bearings, or other machinery components.

The field of mechanical engineering is constantly evolving, and barrel couplings are no exception. Emerging trends in barrel coupling design and development are driven by the need for higher efficiency, improved reliability, and adaptation to new industrial applications.

One of the key trends is the use of advanced materials and manufacturing processes. Advances in material science have led to the development of high-strength, lightweight alloys and composites that offer enhanced performance compared to traditional materials. For example, titanium alloys and carbon fiber composites are being used in barrel couplings for aerospace and high-performance applications, providing higher strength-to-weight ratios and improved corrosion resistance. Additive manufacturing (3D printing) is another emerging technology that is revolutionizing the production of barrel couplings. This process allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods, enabling the design of couplings with optimized stress distribution and improved misalignment accommodation. Additive manufacturing also reduces material waste and allows for rapid prototyping, making it easier to customize couplings for specific applications.

Another trend is the integration of smart technologies into barrel couplings. Smart couplings are equipped with sensors that monitor parameters such as torque, temperature, vibration, and misalignment in real-time. This data is transmitted to a central monitoring system, allowing for predictive maintenance and early detection of potential issues. By monitoring these parameters, operators can identify problems before they lead to equipment failure, reducing downtime and maintenance costs. Smart barrel couplings are particularly useful in critical applications such as power generation, oil and gas, and aerospace, where unplanned downtime can have significant economic and safety consequences.

The demand for more compact and efficient couplings is also driving innovation in barrel coupling design. As industrial machinery becomes more compact, there is a need for couplings that occupy less space while maintaining high torque-carrying capacity. Manufacturers are developing slim-profile barrel couplings with optimized geometries that reduce size without compromising performance. Additionally, improvements in lubrication technology are enabling the development of barrel couplings that operate with minimal friction, reducing energy loss and improving overall system efficiency.

Environmental sustainability is another important trend influencing the development of barrel couplings. There is a growing focus on reducing the environmental impact of industrial components, and barrel couplings are being designed to be more energy-efficient and recyclable. The use of recycled materials in coupling manufacturing is increasing, and manufacturers are adopting processes that reduce energy consumption and waste. Additionally, the development of maintenance-free barrel couplings reduces the need for lubricants and other consumables, further minimizing environmental impact.

In conclusion, barrel coupling is a vital component in mechanical power transmission, offering a compact, reliable, and efficient solution for connecting rotating shafts. Its design principles, material selection, and type classification are tailored to meet the diverse requirements of various industries, from manufacturing and energy to automotive and aerospace. Proper installation and maintenance are crucial to ensuring its optimal performance and longevity, while emerging trends such as advanced materials, additive manufacturing, smart technologies, and sustainability are shaping the future of barrel coupling development.

As industrial machinery continues to evolve, the role of barrel coupling will remain essential, adapting to new challenges and requirements. Whether in heavy-duty industrial applications or precision aerospace systems, barrel couplings play a critical role in ensuring the smooth and reliable operation of rotating machinery. By understanding the fundamentals and advancements of barrel coupling, engineers and industry professionals can make informed decisions regarding the selection, installation, and maintenance of this essential mechanical component, ultimately improving the efficiency and reliability of their systems.

« Barrel Couplings » Post Date: 2023/9/26

URL: https://www.rokeecoupling.com/en/tags/barrel-couplings.html

- 2023-11-06Barrel Couplings Wholesale

- 2023-11-06Types of Barrel Couplings

- 2023-11-06Barrel Couplings Supply

- 2023-11-06Barrel Couplings Supplier

- 2023-11-06Barrel Coupling Structural Diagram

- 2023-11-06Barrel Coupling Specifications

- 2023-11-06Barrel Coupling Size Chart

- 2023-11-06Barrel Coupling Purpose

- 2023-11-06Barrel Coupling Price

- 2023-11-06Barrel Coupling Parts

- 2023-11-06Barrel Coupling Model

- 2023-11-06Barrel Couplings Manufacturer

- 2023-11-06Barrel Coupling Manufacturing Enterprise

- 2023-11-06Barrel Couplings For Sale

- 2023-11-06Barrel Couplings Factory

- 2023-11-06Barrel Coupling Function

- 2023-11-06Barrel Coupling Drawing

- 2023-11-06Disadvantages of Barrel Couplings

- 2023-11-06Barrel Coupling Design

- 2023-11-06Customized Barrel Coupling

- 2023-11-06Barrel Couplings Company

- 2023-11-06Barrel Couplings Catalogue

- 2023-11-06Application of Barrel Couplings

- 2023-11-06Barrel Coupling Advantages

- 2023-10-20Split Tooth Barrel Coupling