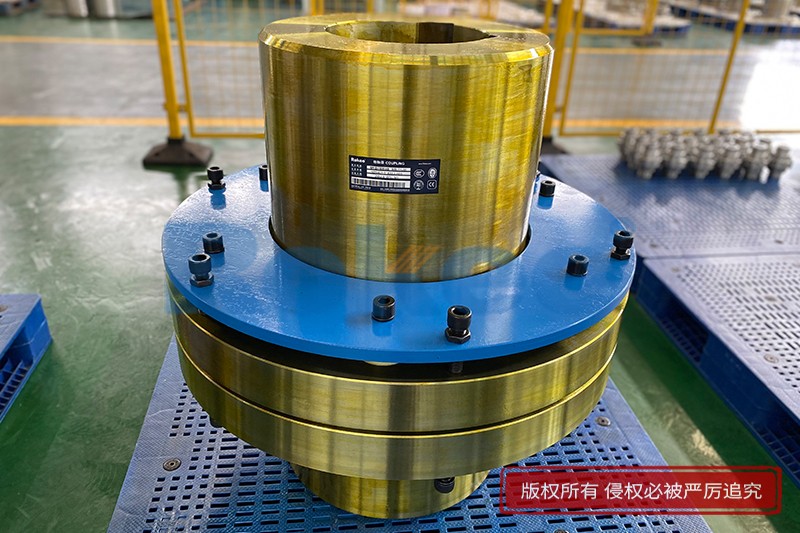

Flexible Bush Couplings

Rokee® is Flexible Bush Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Flexible Bush Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Flexible Bush Coupling is simple and clever in design and has wide applicability. It uses the pin with elastic sleeve to connect two semi-couplings with pin holes to realize torque transmission and larger angular compensation. At the same time, it has good shock absorption and buffering performance, which can be used in high-speed occasions without lubrication and requiring easy pin sleeve replacement.

-

LT/TL Elastic Sleeve Pin Coupling

LT/TL Elastic Sleeve Pin Coupling is the basic form of this series of couplings. -

LTZ/TLL Elastic Sleeve Pin Coupling

LTZ/TLL Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.

In the realm of mechanical power transmission, couplings serve as critical components that connect two rotating shafts, enabling the transfer of torque while accommodating various forms of misalignment. Among the diverse types of couplings available, the flexible bush coupling stands out for its simplicity, reliability, and cost-effectiveness. Designed to address both angular and parallel misalignment between shafts, this type of coupling has found widespread use across numerous industrial sectors, from manufacturing and agriculture to mining and transportation.

1. Understanding Flexible Bush Couplings: Definition and Core Functions

A flexible bush coupling is a type of mechanical coupling that utilizes a flexible element—typically a bush made from elastic or semi-elastic material—to connect two shaft hubs. Unlike rigid couplings, which require precise alignment between shafts to function properly, flexible bush couplings are engineered to tolerate a certain degree of misalignment, vibration, and shock loads. The core functions of a flexible bush coupling include transmitting torque from a driving shaft (e.g., from a motor) to a driven shaft (e.g., to a pump or gearbox), compensating for axial, angular, and parallel misalignment between the two shafts, absorbing vibration and shock to protect downstream components, and reducing noise generated by rotating machinery.

The flexibility inherent in these couplings arises from the deformation of the bush element, which acts as a buffer between the two hubs. This deformation allows the coupling to adjust to minor misalignments without imposing excessive stress on the shafts, bearings, or other connected parts. Additionally, the bush serves as a damping element, absorbing kinetic energy from vibrations and shocks, thereby enhancing the overall stability and lifespan of the mechanical system.

2. Structural Components of Flexible Bush Couplings

Flexible bush couplings consist of several key components, each playing a vital role in ensuring efficient power transmission and flexibility. While designs may vary slightly depending on specific applications, the basic structure typically includes the following elements:

2.1 Shaft Hubs

The hubs are the central components that attach to the driving and driven shafts. They are usually made from rigid materials such as steel, cast iron, or aluminum alloy, chosen for their high strength and ability to withstand torque. Hubs are designed with a bore that matches the diameter of the shafts, and they are secured to the shafts using keyways and set screws, or in some cases, taper locks or compression fittings. The outer surface of each hub is equipped with a series of evenly spaced projections or pins, which engage with the flexible bush.

2.2 Flexible Bush

The bush is the critical flexible element that distinguishes this type of coupling from rigid alternatives. It is typically a cylindrical or flanged component with holes or slots that correspond to the pins on the hubs. The material of the bush is carefully selected to balance flexibility, durability, and resistance to wear and environmental factors. Common materials used for the bush include rubber, polyurethane, nylon, and composite materials. Each material offers distinct properties: rubber bushes provide excellent vibration damping but may have limited resistance to high temperatures and oil; polyurethane bushes offer higher strength and wear resistance than rubber; nylon bushes are lightweight and corrosion-resistant but may be less flexible; and composite materials can be tailored to specific requirements, such as high temperature tolerance or chemical resistance.

2.3 Pins or Studs

Pins or studs are used to connect the hubs to the flexible bush. They are typically made from high-strength steel and are inserted through the holes in the bush and into the corresponding holes or threaded openings in the hubs. In some designs, the pins are equipped with washers or collars to secure the bush in place and prevent axial movement. The number and size of the pins are determined by the torque capacity of the coupling, with larger or more numerous pins enabling the transmission of higher torques.

2.4 Cover or Guard (Optional)

Many flexible bush couplings are equipped with an optional cover or guard, typically made from sheet metal or plastic. The primary purpose of the cover is to protect the coupling components from dust, debris, and moisture, which can cause premature wear and damage. Additionally, the cover serves as a safety feature, preventing accidental contact with the rotating components of the coupling.

3. Working Mechanism of Flexible Bush Couplings

The operation of a flexible bush coupling is based on the transfer of torque through the flexible bush, which simultaneously accommodates misalignment between the driving and driven shafts. When the driving shaft rotates, it imparts torque to the corresponding hub, which in turn transfers the torque to the flexible bush via the pins. The bush then transmits the torque to the second hub, which drives the driven shaft. The flexibility of the bush allows it to deform slightly as the shafts rotate, compensating for any misalignment between the two shafts.

There are three main types of misalignment that a flexible bush coupling can accommodate:

- Angular Misalignment: This occurs when the axes of the two shafts are not colinear but intersect at a point. The flexible bush deforms to allow the hubs to rotate at an angle relative to each other, transmitting torque without excessive stress.

- Parallel Misalignment: This occurs when the axes of the two shafts are parallel but offset from each other. The bush bends slightly to bridge the gap between the misaligned hubs, ensuring smooth torque transmission.

- Axial Misalignment: This occurs when the shafts move along their axial direction relative to each other. The flexible bush can compress or extend slightly to accommodate this movement, preventing damage to the shafts or bearings.

In addition to accommodating misalignment, the flexible bush also absorbs vibration and shock. As the shafts rotate, any vibrations generated by the driving motor or the driven equipment are transmitted to the bush, which absorbs the vibrational energy through deformation. This damping effect reduces the amplitude of vibrations transmitted to other components, minimizing wear and extending the lifespan of the system.

4. Key Advantages of Flexible Bush Couplings

Flexible bush couplings offer a range of advantages that make them a popular choice for many industrial applications. These advantages include:

4.1 Simple Design and Easy Installation

One of the primary advantages of flexible bush couplings is their simple, compact design. Unlike more complex couplings such as gear couplings or disc couplings, flexible bush couplings consist of only a few components, making them easy to assemble and install. The installation process typically involves attaching the hubs to the shafts, inserting the flexible bush between the hubs, and securing the pins. This simplicity also reduces the time and labor required for installation, lowering overall costs.

4.2 Effective Misalignment Compensation

Flexible bush couplings are highly effective at accommodating angular, parallel, and axial misalignment. This eliminates the need for precise shaft alignment during installation, which can be time-consuming and costly. The ability to tolerate misalignment also reduces the stress on shafts, bearings, and seals, preventing premature failure of these components.

4.3 Vibration and Shock Absorption

The flexible bush acts as a damping element, absorbing vibrations and shocks generated by rotating machinery. This not only improves the stability of the system but also reduces noise levels, creating a more comfortable working environment. Additionally, the absorption of shocks helps to protect sensitive components such as motors, pumps, and gearboxes from damage caused by sudden load changes.

4.4 Cost-Effectiveness

Compared to other types of flexible couplings, flexible bush couplings are generally more affordable. Their simple design requires fewer materials and less complex manufacturing processes, resulting in lower production costs. Additionally, their easy installation and low maintenance requirements further contribute to their cost-effectiveness over the lifespan of the coupling.

4.5 High Torque Capacity

Despite their simple design, flexible bush couplings are capable of transmitting high torques. The torque capacity is determined by the size and number of pins, the material of the bush, and the strength of the hubs. By selecting the appropriate size and configuration, flexible bush couplings can be used in a wide range of applications, from small electric motors to large industrial machinery.

4.6 Corrosion Resistance (with Appropriate Materials)

When constructed with corrosion-resistant materials such as stainless steel hubs and polyurethane or composite bushes, flexible bush couplings can be used in harsh environments, including those exposed to moisture, chemicals, or saltwater. This makes them suitable for applications in marine, food processing, and chemical industries.

5. Applications of Flexible Bush Couplings

The versatility, reliability, and cost-effectiveness of flexible bush couplings make them suitable for a wide range of industrial and commercial applications. Some of the most common applications include:

5.1 Manufacturing Industry

In manufacturing plants, flexible bush couplings are widely used in conveyor systems, pumps, compressors, and machine tools. For example, in assembly lines, conveyor belts are driven by motors connected to the conveyor shafts via flexible bush couplings, which accommodate minor misalignments and absorb vibrations from the motor. In machine tools such as lathes and milling machines, these couplings ensure smooth power transmission to the cutting tools, improving the precision of the machining process.

5.2 Agricultural Machinery

Agricultural equipment such as tractors, harvesters, and irrigation pumps often operate in harsh, uneven terrain, leading to frequent misalignment between shafts. Flexible bush couplings are ideal for these applications, as they can tolerate the misalignment caused by the movement of the machinery and absorb the shocks generated by operating on rough ground. They are used to connect the engine to the transmission, as well as to drive various attachments such as plows and harvesters.

5.3 Mining and Quarrying

Mining and quarrying operations involve heavy machinery such as crushers, conveyors, and pumps, which operate under high loads and harsh conditions. Flexible bush couplings are used in these applications to transmit high torques while accommodating misalignment caused by the heavy loads and vibrations. The shock absorption capability of these couplings helps to protect the machinery from damage, reducing downtime and maintenance costs.

5.4 Water and Wastewater Treatment

Water and wastewater treatment plants rely on pumps and blowers to move water and air through the treatment process. Flexible bush couplings are used to connect the motors to these pumps and blowers, accommodating misalignment and absorbing vibrations. The corrosion-resistant properties of some flexible bush couplings make them suitable for use in wet environments, where they are exposed to water and chemicals.

5.5 Transportation Industry

In the transportation industry, flexible bush couplings are used in a variety of applications, including in the drivetrains of buses, trucks, and trains. They are also used in auxiliary systems such as air compressors, power steering pumps, and cooling fans. The ability of these couplings to absorb vibrations and accommodate misalignment helps to improve the reliability and performance of the vehicles, reducing maintenance requirements and extending the lifespan of the components.

5.6 Renewable Energy Systems

Renewable energy systems such as wind turbines and solar water pumps also utilize flexible bush couplings. In wind turbines, these couplings connect the rotor to the gearbox or generator, accommodating misalignment caused by the movement of the rotor and absorbing vibrations. In solar water pumps, they connect the solar motor to the pump shaft, ensuring efficient power transmission even in remote, off-grid locations.

6. Selection Criteria for Flexible Bush Couplings

Selecting the appropriate flexible bush coupling for a specific application requires careful consideration of several factors, including torque requirements, misalignment type and magnitude, operating speed, environmental conditions, and shaft dimensions. The following are the key selection criteria:

6.1 Torque Capacity

The primary consideration when selecting a flexible bush coupling is its torque capacity. The coupling must be able to transmit the maximum torque generated by the driving shaft without failure. The torque capacity of a coupling is typically specified by the manufacturer and depends on the size of the hubs, the number and diameter of the pins, and the material of the bush. It is important to select a coupling with a torque capacity that exceeds the maximum operating torque of the system to provide a safety margin.

6.2 Misalignment Requirements

The type and magnitude of misalignment between the shafts must be considered when selecting a flexible bush coupling. Different couplings have different misalignment capabilities, and it is important to select a coupling that can accommodate the expected misalignment in the system. For example, if the system has a high degree of angular misalignment, a coupling with a more flexible bush material may be required.

6.3 Operating Speed

The operating speed of the shafts is another important factor. At high speeds, the centrifugal forces generated by the rotating components of the coupling can cause excessive stress and vibration. It is important to select a coupling that is designed for the operating speed of the system, with balanced components to minimize vibration.

6.4 Environmental Conditions

The environmental conditions in which the coupling will operate must also be considered. Factors such as temperature, humidity, exposure to chemicals, and presence of dust or debris can affect the performance and lifespan of the coupling. For example, in high-temperature environments, a bush material with high temperature resistance (such as composite materials) should be selected. In corrosive environments, stainless steel hubs and corrosion-resistant bush materials are recommended.

6.5 Shaft Dimensions

The diameter and length of the shafts must be compatible with the bore size and length of the coupling hubs. It is important to select a coupling with hubs that have a bore size matching the shaft diameter, and that can be secured to the shafts using the appropriate method (e.g., keyway, set screws).

6.6 Cost and Maintenance Requirements

Finally, the cost of the coupling and its maintenance requirements should be considered. While flexible bush couplings are generally cost-effective, the cost can vary depending on the material and design. Additionally, some bush materials may require more frequent replacement than others, increasing maintenance costs over time. It is important to balance the initial cost of the coupling with its long-term maintenance requirements.

7. Maintenance Practices for Flexible Bush Couplings

Proper maintenance is essential to ensure the reliable performance and long lifespan of flexible bush couplings. The following maintenance practices are recommended:

7.1 Regular Inspection

Flexible bush couplings should be inspected regularly for signs of wear, damage, or misalignment. During inspection, check for cracks or wear in the bush, loose pins or set screws, and signs of corrosion on the hubs. Additionally, check for excessive vibration or noise, which may indicate misalignment or wear in the coupling.

7.2 Lubrication (if Required)

Some flexible bush couplings may require lubrication to reduce friction between the pins and the bush. The manufacturer's recommendations should be followed regarding the type and frequency of lubrication. Over-lubrication or under-lubrication can lead to premature wear and damage to the coupling.

7.3 Bush Replacement

The flexible bush is the most wear-prone component of the coupling and will need to be replaced periodically. The frequency of replacement depends on the operating conditions and the material of the bush. Signs that the bush needs replacement include excessive vibration, noise, or visible wear (e.g., cracks, deformation). When replacing the bush, ensure that the new bush is compatible with the coupling and that it is installed correctly.

7.4 Alignment Check

While flexible bush couplings can accommodate misalignment, excessive misalignment can lead to premature wear of the bush and other components. It is recommended to check the alignment of the shafts periodically and adjust as necessary to ensure that the misalignment remains within the coupling's capabilities.

7.5 Cleaning

Keeping the coupling clean is important to prevent the buildup of dust, debris, or moisture, which can cause corrosion and wear. The coupling should be cleaned regularly using a suitable cleaning agent, and the cover (if present) should be checked to ensure that it is intact and properly secured.

8. Conclusion

Flexible bush couplings are essential components in modern mechanical power transmission systems, offering a unique combination of simplicity, reliability, and cost-effectiveness. Their ability to accommodate misalignment, absorb vibration, and transmit high torques makes them suitable for a wide range of applications across various industries, from manufacturing and agriculture to mining and renewable energy. By understanding the structural components, working mechanisms, advantages, selection criteria, and maintenance practices of flexible bush couplings, engineers and maintenance professionals can select and maintain these couplings effectively, ensuring the efficient and reliable operation of mechanical systems.

As technology continues to advance, the design and materials of flexible bush couplings are likely to evolve, further improving their performance and expanding their range of applications. However, their fundamental role as a cost-effective and reliable solution for power transmission and misalignment compensation will remain unchanged, making them a staple in the field of mechanical engineering for years to come.

« Flexible Bush Couplings » Post Date: 2023/9/1

URL: https://www.rokeecoupling.com/en/tags/flexible-bush-couplings.html

- 2024-02-28Flexible Bush Couplings For Sale

- 2024-02-28Flexible Bush Couplings Manufacturer

- 2024-02-28Flexible Bush Couplings Supplier

- 2024-02-28Flexible Bush Couplings Wholesale

- 2024-02-28Function of Flexible Bush Couplings

- 2024-02-28Gap Chart of Flexible Bush Couplings

- 2024-02-28Material of Flexible Bush Coupling

- 2024-02-28Misalignment Tolerance of Flexible Bush Coupling

- 2024-02-28Parts of Flexible Bush Coupling

- 2024-02-28Procurement of Flexible Bush Coupling

- 2024-02-28Purpose of Flexible Bush Couplings

- 2024-02-28Schematic Diagram of Flexible Bush Couplings

- 2024-02-28Machine Drawing of Flexible Bush Couplings

- 2024-02-28Lubrication of Flexible Bush Coupling

- 2024-02-28Installation of Flexible Bush Coupling

- 2024-02-28High Quality Flexible Bush Couplings

- 2024-02-28High Performance Flexible Bush Couplings

- 2024-02-21Flexible Bush Couplings Drawing

- 2024-02-21Flexible Bush Couplings Company

- 2024-02-21Flexible Bush Coupling Standard Sizes

- 2024-02-21Flexible Bush Coupling Sales

- 2024-02-21Flexible Bush Coupling Price

- 2024-02-21Size Chart of Flexible Bush Couplings

- 2024-02-21Specifications of Flexible Bush Coupling

- 2024-02-21Stiffness of Flexible Bush Coupling

- 2024-02-21Structural Diagram of Flexible Bush Couplings

- 2024-02-21Tagging of Flexible Bush Coupling

- 2024-02-21Torque of Flexible Bush Coupling

- 2024-02-21Types of Flexible Bush Coupling

- 2024-02-21Uses of Flexible Bush Couplings

- 2024-02-21Working Principle of Flexible Bush Coupling

- 2024-02-01Flexible Bush Coupling Models

- 2024-02-01Flexible Bush Coupling Manufacturing

- 2024-02-01Flexible Bush Coupling Design

- 2024-02-01Flexible Bush Coupling Calculation

- 2024-02-01Flexible Bush Coupling Brands

- 2024-02-01Flexible Bush Coupling Advantages

- 2024-02-01Exploded View of Flexible Bush Couplings

- 2024-02-01Engineering Drawing of Flexible Bush Couplings

- 2024-02-01Efficiency of Flexible Bush Coupling

- 2024-02-01Disadvantages of Flexible Bush Coupling

- 2024-02-01Components of Flexible Bush Coupling

- 2024-02-01Coaxiality of Flexible Bush Coupling

- 2024-02-01Classification of Flexible Bush Couplings

- 2024-02-01Application of Flexible Bush Couplings

- 2024-02-01Angle of Flexible Bush Coupling

- 2024-02-01Alignment of Flexible Bush Coupling

- 2024-02-013D Model of Flexible Bush Couplings

- 2024-01-22Supply of Flexible Bush Couplings

- 2024-01-22Size Calculation of Flexible Bush Coupling

- 2024-01-22Maintenance of Flexible Bush Coupling

- 2024-01-22Grease of Flexible Bush Coupling

- 2024-01-22Flexible Bush Couplings Factory

- 2024-01-22Flexible Bush Coupling Pictures

- 2024-01-22Catalogue of Flexible Bush Couplings

- 2024-01-22Flexible Bush Coupling Assembly Drawing

- 2024-01-17Customized Flexible Bush Couplings