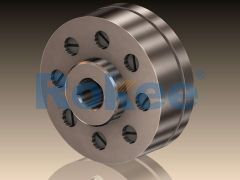

Elastic Couplings

Rokee® is Elastic Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Elastic Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Elastic Coupling is one of the major types of couplings. They find use to connect two shafts, end-to-end in the same line to transmit power that is torque from one shaft to another, thereby causing both to rotate in unison, at the same rpm.

-

LM Plum-shaped Flexible Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings. -

LMD Plum-shaped Flexible Coupling

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMS Plum-shaped Flexible Coupling

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMZ-I Plum-shaped Flexible Coupling

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required. -

LMZ-II Plum-shaped Flexible Coupling

LMZ-II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required. -

LMPK Plum-shaped Flexible Coupling

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer. -

LZ/ZL Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings. -

LZD/ZLD Pin Gear Coupling

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end. -

LZZ/ZLL Pin Gear Coupling

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. -

LX(HL) Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings. -

LXZ(HLL) Flexible Pin Coupling

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required. -

LT/TL Elastic Sleeve Pin Coupling

LT/TL Elastic Sleeve Pin Coupling is the basic form of this series of couplings. -

LTZ/TLL Elastic Sleeve Pin Coupling

LTZ/TLL Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required. -

UL Elastic Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation. -

LLA Elastic Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. -

LLB Elastic Tyre Coupling

In the realm of mechanical power transmission, the efficient and reliable transfer of torque from a driving source (such as an electric motor or an internal combustion engine) to a driven component (like a pump, fan, or conveyor) is paramount. Among the various components that facilitate this process, couplings play a critical role by connecting two rotating shafts while accommodating misalignments, absorbing shocks, and reducing vibrations. Elastic couplings, in particular, have emerged as indispensable elements in numerous industrial and automotive applications due to their unique ability to combine torque transmission with flexibility. Unlike rigid couplings, which offer no flexibility and require precise alignment, elastic couplings utilize elastic elements to compensate for axial, radial, and angular misalignments, thereby protecting machinery from excessive wear and extending service life.

To understand the functionality of elastic couplings, it is essential to first grasp the core challenges they address in power transmission systems. Rotating shafts in machinery are rarely perfectly aligned, even when installed with meticulous care. Misalignments can occur due to thermal expansion and contraction, foundation settling, component wear, or manufacturing tolerances. If left unaddressed, these misalignments generate additional forces and moments on the shafts, bearings, and other mechanical components, leading to premature failure, increased energy consumption, and excessive noise. Moreover, driving sources often produce torque fluctuations and shock loads, which can be transmitted to the driven equipment, causing damage or reducing operational efficiency. Elastic couplings mitigate these issues by incorporating elastic materials or elements that deform under load, absorbing shocks and vibrations, and allowing for relative movement between the connected shafts.

The basic working principle of an elastic coupling revolves around the interaction between the elastic element and the coupling hubs. The hubs are typically attached to the driving and driven shafts using keys, splines, or compression fittings, ensuring a secure connection that can transmit torque. The elastic element, which is positioned between the two hubs, acts as a buffer. When torque is applied, the elastic element undergoes torsional deformation, transferring the torque from one hub to the other. Simultaneously, if there is any misalignment between the shafts, the elastic element deforms axially, radially, or angularly to accommodate the misalignment without transmitting excessive forces to the shafts or bearings. Additionally, the elastic material’s damping properties help absorb shock loads and reduce vibration amplitudes, resulting in smoother operation of the entire system.

Elastic couplings are available in a wide range of types, each designed to suit specific application requirements based on factors such as torque capacity, misalignment compensation, operating speed, environmental conditions, and cost. The most common types include jaw couplings, tire couplings, disc couplings, bellows couplings, and grid couplings.

Jaw couplings are among the most widely used elastic couplings due to their simplicity, compact design, and cost-effectiveness. They consist of two metal hubs with protruding jaws and an elastic spider (or insert) made of rubber, polyurethane, or nylon that fits between the jaws. The spider’s lobes engage with the jaws of both hubs, transmitting torque while accommodating moderate levels of angular and radial misalignment. Jaw couplings are ideal for low to medium torque applications, such as small electric motors, pumps, and compressors. The elastic spider also provides some vibration damping, making them suitable for applications where noise reduction is a consideration. However, they have limited axial misalignment compensation capabilities and are not recommended for high-speed or high-torque applications.

Tire couplings, also known as rubber tire couplings, feature a flexible tire-shaped element made of synthetic rubber or elastomer that connects two metal flanges. The tire element is typically bonded or bolted to the flanges, which are then attached to the driving and driven shafts. Tire couplings excel at accommodating large amounts of misalignment, especially angular and axial misalignment, and offer excellent shock absorption and vibration damping properties. Their flexible design also makes them resistant to torsional shocks and overloads, protecting the connected machinery. Tire couplings are commonly used in heavy-duty applications, such as conveyors, crushers, and marine propulsion systems. However, they have a lower torque density compared to other types of elastic couplings and may require regular inspection for tire wear, especially in harsh operating environments.

Disc couplings utilize one or more flexible discs (or diaphragms) made of thin metal sheets (usually stainless steel) to connect the hubs. The discs are bolted to the hubs, and their flexibility allows for angular and axial misalignment. Unlike jaw or tire couplings, disc couplings do not use elastomeric materials, making them suitable for high-temperature applications and environments where chemical resistance is required. They offer high torque capacity, high operating speeds, and minimal backlash, making them ideal for precision applications such as machine tools, robotics, and aerospace systems. However, disc couplings have limited radial misalignment compensation capabilities and are more expensive than jaw couplings.

Bellows couplings consist of a flexible bellows (typically made of stainless steel or Inconel) that connects two hubs. The bellows is a cylindrical, corrugated structure that can deform axially, radially, and angularly, allowing for significant misalignment compensation. Bellows couplings offer high precision, low backlash, and excellent torque transmission efficiency, making them suitable for high-speed and high-precision applications, such as servo motors, encoders, and medical equipment. They are also resistant to high temperatures and harsh environments, making them suitable for aerospace and automotive applications. However, bellows couplings are relatively fragile and can be damaged by excessive radial loads or misalignment, requiring careful installation and maintenance.

Grid couplings feature a flexible grid made of spring steel that fits between two hubs with serrated teeth. The grid transmits torque by engaging with the teeth of the hubs, and its flexibility allows for moderate misalignment compensation and shock absorption. Grid couplings are known for their high torque capacity, durability, and ability to withstand overloads, making them suitable for heavy-duty applications such as industrial gearboxes, pumps, and turbines. They are also relatively easy to maintain, as the grid can be replaced without disassembling the entire coupling. However, grid couplings have limited misalignment compensation capabilities compared to tire or bellows couplings and may produce more noise at high speeds.

When selecting an elastic coupling for a specific application, several key design considerations must be taken into account to ensure optimal performance and reliability. Torque capacity is one of the most critical factors, as the coupling must be able to transmit the maximum torque generated by the driving source without failure. It is essential to select a coupling with a torque rating that exceeds the maximum operating torque of the system to accommodate occasional overloads and torque fluctuations. Operating speed is another important consideration, as high-speed applications require couplings with minimal centrifugal force and excellent balance to avoid vibration and premature failure. The type and magnitude of misalignment present in the system also influence the selection of the coupling, as different types of couplings have varying capabilities for compensating axial, radial, and angular misalignment.

Environmental conditions, such as temperature, humidity, chemical exposure, and dust, can also affect the performance and lifespan of elastic couplings. For example, high-temperature applications require couplings made of heat-resistant materials, such as stainless steel or high-temperature elastomers, while applications exposed to chemicals require corrosion-resistant materials. The presence of dust or abrasive particles may require couplings with sealed designs to prevent contamination of the elastic elements. Backlash, which is the amount of angular movement between the driving and driven shafts when the direction of rotation is reversed, is another important consideration for precision applications, such as robotics and machine tools, where minimal backlash is essential for accurate positioning.

Maintenance requirements should also be considered when selecting an elastic coupling. Some types of couplings, such as jaw couplings, require regular replacement of the elastic spider, while others, such as disc couplings, require minimal maintenance. The ease of installation and replacement of the coupling and its components is also an important factor, especially in applications where downtime must be minimized.

Elastic couplings find applications in a wide range of industries, thanks to their versatility and ability to address the challenges of power transmission. In the automotive industry, elastic couplings are used in drivetrains to connect the engine to the transmission, absorbing torque fluctuations and vibrations, and accommodating misalignments caused by thermal expansion and contraction. They are also used in electric vehicles to connect the electric motor to the axle, ensuring smooth power transmission and reducing noise.

In the industrial sector, elastic couplings are used in a variety of machinery, including pumps, fans, compressors, conveyors, and crushers. For example, in pump systems, elastic couplings compensate for misalignments between the motor and the pump shaft, reducing wear on the pump’s bearings and seals and extending the pump’s service life. In conveyor systems, they absorb shocks caused by the loading and unloading of materials, protecting the conveyor’s gearbox and motor.

The aerospace industry utilizes elastic couplings in aircraft engines and auxiliary systems, where high precision, high temperature resistance, and reliability are critical. Bellows couplings, in particular, are used in aircraft engines to connect rotating components, as they can withstand high temperatures and provide precise torque transmission. In the robotics and automation industry, elastic couplings are used in servo motors and actuators to ensure accurate positioning and smooth operation, with minimal backlash and high torque capacity.

The medical equipment industry also relies on elastic couplings for precision applications, such as MRI machines, centrifuges, and surgical robots. These applications require couplings that can operate at high speeds with minimal vibration and backlash, ensuring the accuracy and reliability of the equipment.

In recent years, advancements in materials and design have led to significant improvements in the performance and capabilities of elastic couplings. One of the key areas of advancement is the development of new elastomeric materials with enhanced properties, such as higher temperature resistance, better chemical resistance, and improved durability. For example, the use of polyurethane elastomers in jaw couplings has increased their torque capacity and wear resistance compared to traditional rubber spiders. Additionally, the development of composite materials, such as carbon fiber-reinforced polymers, has led to the creation of lightweight, high-strength couplings suitable for aerospace and automotive applications.

Another area of advancement is the use of finite element analysis (FEA) and computational fluid dynamics (CFD) in the design of elastic couplings. These simulation tools allow engineers to optimize the design of the coupling’s elastic elements, hubs, and other components, ensuring that they can withstand the required torque, misalignment, and environmental conditions while minimizing weight and maximizing efficiency. FEA also helps in predicting the fatigue life of the coupling, allowing for the design of more reliable and durable couplings.

The integration of smart technologies into elastic couplings is another emerging trend. Smart couplings are equipped with sensors that monitor parameters such as torque, temperature, vibration, and misalignment in real-time. This data is transmitted to a control system, allowing for predictive maintenance and early detection of potential issues, such as excessive wear or misalignment. This helps to minimize downtime, reduce maintenance costs, and extend the service life of the coupling and the connected machinery.

Furthermore, advancements in manufacturing processes, such as additive manufacturing (3D printing), have enabled the production of complex coupling designs that were previously not feasible with traditional manufacturing methods. 3D printing allows for the creation of custom elastic elements with optimized geometries, improving their flexibility, torque capacity, and vibration damping properties. It also enables the production of small batches of couplings at a lower cost, making it suitable for custom and niche applications.

Despite these advancements, there are still challenges facing the development of elastic couplings. One of the main challenges is the need to balance flexibility with torque capacity. Increasing the flexibility of the coupling to accommodate greater misalignment often results in a decrease in torque capacity, and vice versa. Engineers are continuously working to develop new designs and materials that can overcome this trade-off. Another challenge is the development of couplings suitable for extreme operating conditions, such as very high temperatures, high pressures, and harsh chemical environments. These conditions require materials and designs that can withstand severe stress and degradation.

In conclusion, elastic couplings are essential components in mechanical power transmission systems, providing flexibility, shock absorption, and misalignment compensation. Their diverse types and designs make them suitable for a wide range of applications across various industries, from automotive and industrial machinery to aerospace and medical equipment. The selection of the appropriate elastic coupling depends on several key factors, including torque capacity, operating speed, misalignment type and magnitude, environmental conditions, and maintenance requirements. Recent advancements in materials, design, and manufacturing processes have significantly improved the performance and capabilities of elastic couplings, and the integration of smart technologies is expected to further enhance their reliability and efficiency in the future. As machinery becomes more complex and demanding, elastic couplings will continue to play a critical role in ensuring the efficient and reliable operation of power transmission systems.

« Elastic Couplings » Post Date: 2023/8/18

URL: https://www.rokeecoupling.com/en/tags/elastic-couplings.html

- 2023-10-28Steel Diaphragm Elastic Couplings

- 2023-10-28Custom Double Diaphragm Elastic Coupling

- 2023-10-28Diaphragm Elastic Coupling Specification

- 2023-10-28Standard For Diaphragm Elastic Couplings

- 2023-10-28Diaphragm Elastic Coupling Technical Parameters

- 2023-10-28Diaphragm Elastic Coupling Working Principle

- 2023-10-28Diaphragm Elastic Coupling Principle

- 2023-10-28Diaphragm Elastic Coupling Price

- 2023-10-28Diaphragm Elastic Coupling Material

- 2023-10-28Diaphragm Elastic Coupling Installation Method

- 2023-10-28Diaphragm Elastic Coupling Installation Deviation

- 2023-10-28How To Install The Diaphragm Elastic Coupling

- 2023-10-28Diaphragm Elastic Coupling Disadvantages

- 2023-10-28Diaphragm Elastic Coupling Dimensions

- 2023-10-28Diaphragm Elastic Coupling Types

- 2023-10-28Diaphragm Elastic Coupling Supply

- 2023-10-28Diaphragm Elastic Coupling Structure

- 2023-10-28Customized Diaphragm Elastic Coupling

- 2023-10-28Custom Diaphragm Elastic Coupling

- 2023-10-28Diaphragm Elastic Coupling Advantages

- 2023-10-28Single Diaphragm Elastic Coupling Characteristics

- 2023-10-24Rubber Sleeve Pin Elastic Coupling

- 2023-10-24Pin Spring Elastic Coupling

- 2023-10-19Motor Plum Blossom Shaped Elastic Coupling

- 2023-10-18Motor End Plum Blossom Elastic Coupling

- 2023-10-18Diaphragm Elastic Coupling Sectional View

- 2023-10-18Fan Diaphragm Elastic Couplings

- 2023-10-17Split Plum Blossom Elastic Couplings

- 2023-10-17Custom Tyre Elastic Couplings

- 2023-10-13Tyre Elastic Coupling Company

- 2023-10-13Tyre Elastic Coupling Design

- 2023-10-12Half Plum Blossom Shaped Elastic Couplings

- 2023-10-12Bi-directional Diaphragm Elastic Couplings

- 2023-10-12Double Diaphragm Elastic Coupling Types

- 2023-10-12Diaphragm Elastic Couplings Production

- 2023-10-12Diaphragm Elastic Coupling Design

- 2023-10-11Claw Disc Elastic Couplings

- 2023-10-11Claw Type Elastic Coupling Factory

- 2023-10-10Diaphragm Elastic Couplings

- 2023-10-10Diaphragm Elastic Couplings Wholesale

- 2023-10-10Diaphragm Elastic Coupling Flange Plate

- 2023-10-10Diaphragm Elastic Coupling Supplier

- 2023-10-10Diaphragm Elastic Coupling Company

- 2023-10-10Diaphragm Elastic Coupling Manufacturer

- 2023-10-10Diaphragm Elastic Coupling Parameters

- 2023-10-10Claw Shaped Elastic Coupling For Sale

- 2023-10-10Claw Type Elastic Couplings

- 2023-10-10Claw Shaped Elastic Couplings

- 2023-10-09Wholesale Of Tyre Elastic Couplings

- 2023-10-09Tyre Elastic Coupling Manufacturer

- 2023-10-08Tyre Elastic Coupling Supply

- 2023-10-08Gear Pin Elastic Coupling

- 2023-09-27Advantages Of Double Diaphragm Elastic Couplings

- 2023-09-27Plum Blossom Elastic Coupling With Keyway

- 2023-09-27Plum Blossom Elastic Coupling With Brake Wheel

- 2023-09-27Plum Blossom Elastic Coupling With Brake Disc

- 2023-09-27Claw Type Elastic Coupling For Pumps

- 2023-09-26Metal Diaphragm Elastic Coupling

- 2023-09-26Metal Double Diaphragm Elastic Coupling

- 2023-09-26Precision Diaphragm Elastic Coupling

- 2023-09-26High Speed Cone Sleeve Diaphragm Elastic Coupling

- 2023-09-22Claw Shaped Elastic Coupling For Pumps

- 2023-09-22Connecting Rod Diaphragm Elastic Coupling

- 2023-09-22Toothed Elastic Coupling

- 2023-09-21Double Diaphragm Elastic Coupling

- 2023-09-21Specification And Model Of Toothed Elastic Coupling

- 2023-09-19Half Open Plum Blossom Elastic Coupling

- 2023-08-24Unidirectional Diaphragm Elastic Coupling