Claw Couplings

Rokee® is Claw Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Claw Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

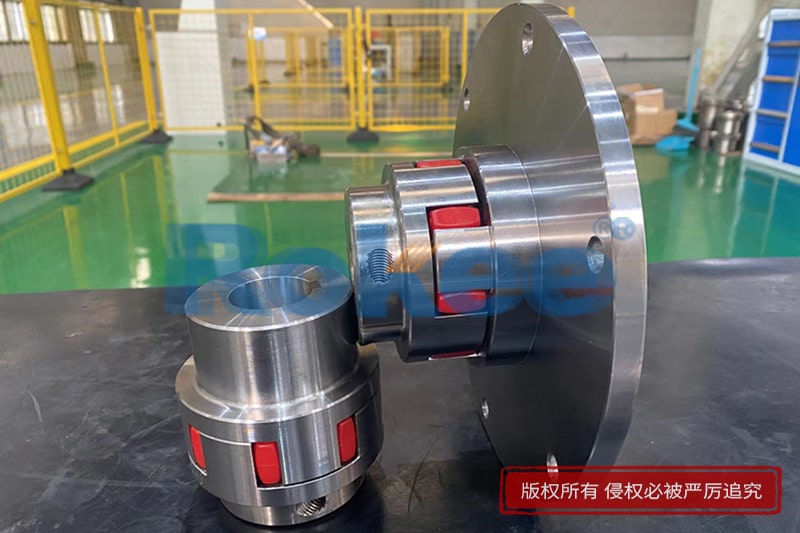

The Claw Coupling is composed of two semi-couplings with convex claws and a plum-shaped flexible non-metallic element whose hardness can be adjusted. By embedding the plum-shaped flexible element into the two semi-couplings to realize the connection, Claw Coupling has the characteristics of compensating the relative displacement of the two axes, reducing vibration and buffering, simple structure and easy maintenance without lubrication.

-

LM Plum-shaped Flexible Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings. -

LMD Plum-shaped Flexible Coupling

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMS Plum-shaped Flexible Coupling

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMZ-I Plum-shaped Flexible Coupling

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required. -

LMZ-II Plum-shaped Flexible Coupling

LMZ-II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required. -

LMPK Plum-shaped Flexible Coupling

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.

In the realm of mechanical power transmission, couplings serve as critical components that bridge rotating shafts, enabling the transfer of torque while accommodating misalignments, absorbing shocks, and reducing vibrations. Among the diverse range of couplings available, the claw coupling stands out for its simplicity, cost-effectiveness, and versatility in various industrial and commercial applications.

A claw coupling, also known as a jaw coupling, is a type of flexible coupling composed of three main parts: two metal hubs with claw-shaped projections (or jaws) and an elastomeric element (often referred to as a spider or insert) that fits between the claws of the two hubs. The design of the claws—typically evenly spaced around the circumference of the hubs—ensures that the elastomeric element is securely held in place, creating a non-slip connection between the driving and driven shafts. Unlike rigid couplings, which require precise alignment and offer no flexibility, claw couplings leverage the elasticity of the insert to compensate for minor shaft misalignments, including angular, parallel, and axial misalignments. This flexibility not only protects the shafts and other connected components from excessive stress but also contributes to smoother operation and reduced wear.

The working principle of a claw coupling is straightforward yet effective. When torque is applied to the driving shaft, the claws of the driving hub exert pressure on the elastomeric insert. The insert, in turn, transfers this torque to the claws of the driven hub, causing the driven shaft to rotate. The elastomeric material plays a pivotal role here: it acts as a buffer, absorbing shock loads and dampening vibrations generated during operation. This shock absorption capability is particularly valuable in applications where sudden starts, stops, or load fluctuations are common, as it minimizes the impact on the entire power transmission system. Additionally, the flexibility of the insert allows for small amounts of misalignment between the two shafts. Angular misalignment occurs when the shafts are not collinear but intersect at a small angle, while parallel misalignment refers to shafts that are parallel but offset from each other. Axial misalignment, on the other hand, involves axial movement of one shaft relative to the other. Claw couplings can typically accommodate angular misalignments up to 1.5 to 2 degrees, parallel misalignments up to 0.2 to 0.5 millimeters, and small axial displacements, depending on the size and design of the coupling.

Material selection is a key factor that influences the performance, durability, and application range of claw couplings. The hubs, which bear the brunt of the torque and mechanical stress, are usually made from metallic materials known for their strength, rigidity, and wear resistance. Common materials for hubs include cast iron, steel, and aluminum. Cast iron is a popular choice for general-purpose applications due to its low cost, good machinability, and excellent damping properties. Steel hubs, particularly those made from carbon steel or alloy steel, offer higher torque capacity and durability, making them suitable for heavy-duty applications. Aluminum hubs, on the other hand, are lightweight and corrosion-resistant, making them ideal for applications where weight is a concern, such as in automotive or aerospace auxiliary systems.

The elastomeric insert is equally important, and its material selection depends on the specific operating conditions of the application. Common materials for inserts include natural rubber, nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), silicone rubber, and polyurethane. Natural rubber offers good elasticity and shock absorption but has limited resistance to oil, heat, and ozone, making it suitable for dry, low-temperature environments. Nitrile rubber is highly resistant to oil and fuel, making it ideal for applications in the automotive and industrial sectors where exposure to petroleum-based products is common. EPDM excels in resistance to heat, ozone, and weathering, making it suitable for outdoor or high-temperature applications. Silicone rubber can withstand extremely high temperatures (up to 200°C or higher) and is resistant to ozone and UV radiation, making it suitable for harsh environmental conditions. Polyurethane inserts offer higher hardness, better wear resistance, and longer service life compared to rubber inserts, and they are also resistant to oil and chemicals, making them a versatile choice for many industrial applications.

Claw couplings find widespread application across a diverse range of industries and mechanical systems, thanks to their simple design, reliable performance, and cost-effectiveness. One of the most common applications is in electric motors and pumps. In these systems, the claw coupling connects the motor shaft to the pump shaft, enabling the transfer of torque while accommodating minor misalignments that may occur during installation or operation. This helps to protect the motor and pump bearings from premature failure due to misalignment-induced stress. Claw couplings are also widely used in conveyors, which are essential in manufacturing, mining, and logistics industries. Conveyor systems often experience varying loads and minor shaft misalignments due to the long length of the conveyor belt and the presence of multiple drive units. The flexibility and shock absorption capability of claw couplings make them well-suited for these applications, ensuring smooth and reliable operation of the conveyor system.

Another important application area for claw couplings is in agricultural machinery, such as tractors, harvesters, and irrigation pumps. Agricultural machinery operates in harsh and dusty environments, often with frequent starts and stops and varying loads. Claw couplings with durable metallic hubs and oil-resistant elastomeric inserts are able to withstand these harsh conditions, providing reliable power transmission between the engine and various attachments. In the automotive industry, claw couplings are used in auxiliary systems such as power steering pumps, water pumps, and air conditioning compressors. These systems require compact and lightweight couplings that can accommodate minor misalignments and absorb vibrations, making claw couplings an ideal choice. Additionally, claw couplings are used in small to medium-sized industrial gearboxes, fans, blowers, and other rotating machinery where precise torque transmission and flexibility are required.

The popularity of claw couplings can be attributed to a number of key advantages. First and foremost is their simplicity of design and ease of installation. Unlike complex couplings that require specialized tools or expertise for installation, claw couplings can be easily mounted and dismounted, reducing installation time and labor costs. The three-piece design (two hubs and one insert) also makes maintenance and replacement of worn components straightforward—if the elastomeric insert becomes worn or damaged, it can be easily replaced without removing the entire coupling from the shafts. Another major advantage is their cost-effectiveness. Claw couplings are typically less expensive to manufacture than other types of flexible couplings, such as disc couplings or gear couplings, making them an economical choice for many applications, particularly in small to medium-sized enterprises.

In addition to their simplicity and cost-effectiveness, claw couplings offer excellent shock absorption and vibration damping capabilities. The elastomeric insert acts as a buffer, absorbing sudden shock loads and reducing the transmission of vibrations from the driving shaft to the driven shaft. This not only improves the comfort and safety of the operating environment but also protects other components in the power transmission system, such as bearings, gears, and shafts, from premature wear and failure. Claw couplings also have good torque transmission capacity relative to their size, making them suitable for a wide range of torque requirements, from low to medium torque applications. Furthermore, their ability to accommodate minor misalignments reduces the need for precise shaft alignment during installation, which can be time-consuming and costly. This flexibility also helps to compensate for any misalignments that may develop over time due to thermal expansion, component wear, or foundation settlement.

Despite their many advantages, claw couplings also have certain limitations that must be considered when selecting a coupling for a specific application. One of the main limitations is their limited misalignment capacity. While they can accommodate minor misalignments, they are not suitable for applications with large angular or parallel misalignments. In such cases, other types of couplings, such as universal joints or flexible disc couplings, may be more appropriate. Another limitation is the temperature range of the elastomeric insert. Most elastomeric materials have a limited temperature range, and exposure to temperatures outside this range can cause the insert to degrade, harden, or soften, reducing its performance and service life. Therefore, it is important to select an insert material that is compatible with the operating temperature of the application. Additionally, claw couplings are not suitable for high-speed applications, as the centrifugal forces generated at high speeds can cause the elastomeric insert to distort or fail. For high-speed applications, couplings with higher rotational speed capabilities, such as disc couplings, are preferred.

Proper selection of a claw coupling is crucial to ensure optimal performance and reliability. When selecting a claw coupling, several factors must be considered, including the torque requirement, shaft diameter, operating speed, misalignment type and magnitude, operating temperature, and environmental conditions. The first step in selection is to determine the maximum torque that the coupling will need to transmit. This includes not only the nominal operating torque but also any peak torque that may occur during startup or load fluctuations. It is important to select a coupling with a torque rating that exceeds the maximum expected torque to ensure a safety margin. The next factor is the shaft diameter— the coupling hubs must be compatible with the diameters of the driving and driven shafts. Most manufacturers offer claw couplings in a range of sizes to accommodate different shaft diameters.

Operating speed is another critical factor. As mentioned earlier, claw couplings have a maximum rotational speed limit, and exceeding this limit can lead to premature failure. The operating speed of the application must be compared to the maximum speed rating of the coupling to ensure compatibility. The type and magnitude of misalignment must also be considered. If the application involves significant angular or parallel misalignment, a claw coupling may not be suitable, and alternative coupling types should be considered. However, if the misalignment is minor, a claw coupling with the appropriate elastomeric insert can provide adequate compensation. Operating temperature and environmental conditions are also important for selecting the right elastomeric insert material. For example, applications involving exposure to oil or fuel require a nitrile rubber or polyurethane insert, while applications in high-temperature environments require a silicone rubber or EPDM insert. Additionally, if the application is in a dusty or corrosive environment, the hub material should be selected for its corrosion resistance, such as aluminum or stainless steel.

Proper maintenance is essential to extend the service life of claw couplings and ensure reliable performance. Regular inspection is the cornerstone of effective maintenance. Couplings should be inspected periodically for signs of wear, damage, or misalignment. The elastomeric insert should be checked for cracks, hardening, softening, or excessive wear, as these are indicators that the insert needs to be replaced. The hubs should be inspected for signs of corrosion, deformation, or wear on the claw surfaces. If any damage to the hubs is detected, they should be replaced to prevent further damage to the shafts or other components. In addition to visual inspection, the coupling should be checked for proper alignment. Misalignment can increase stress on the coupling and connected components, leading to premature failure. If misalignment is detected, it should be corrected immediately by adjusting the position of the driving or driven shaft.

Lubrication is not typically required for claw couplings, as the elastomeric insert acts as a self-lubricating element. However, in some cases, if the coupling is used in a dusty or dirty environment, it may be necessary to clean the coupling periodically to remove debris that could cause wear on the insert or hubs. When replacing the elastomeric insert, it is important to select the correct material and size for the application. Using an insert that is not compatible with the operating conditions can lead to premature failure. Additionally, the insert should be installed correctly, ensuring that it is properly seated in the claws of both hubs to prevent slippage or misalignment during operation.

In conclusion, claw couplings are versatile and cost-effective components that play a vital role in mechanical power transmission systems. Their simple design, ease of installation, and ability to accommodate minor misalignments, absorb shocks, and dampen vibrations make them suitable for a wide range of applications across various industries, including manufacturing, agriculture, automotive, and logistics. Proper material selection, based on operating conditions such as temperature, exposure to chemicals, and torque requirements, is crucial to ensure optimal performance. Additionally, proper selection and regular maintenance, including inspection for wear and misalignment and timely replacement of worn components, are essential to extend the service life of claw couplings and ensure the reliability of the entire power transmission system. While claw couplings have certain limitations, such as limited misalignment capacity and temperature range, their advantages make them a popular choice for many small to medium-sized torque applications. As technology advances, improvements in elastomeric materials and hub designs are likely to further enhance the performance and application range of claw couplings, ensuring their continued relevance in modern mechanical systems.

« Claw Couplings » Post Date: 2023/9/16

URL: https://www.rokeecoupling.com/en/tags/claw-couplings.html

- 2025-12-02Octagon Claw Couplings

- 2025-12-02Octapetal Claw Couplings

- 2025-12-02Round Steel Claw Couplings

- 2025-12-02Single Flange Claw Couplings

- 2025-12-02Split Type Claw Couplings

- 2025-12-02Stainless Steel Claw Couplings

- 2024-03-11Transmission Claw Couplings

- 2024-01-15Integrated Claw Couplings

- 2024-01-15Hexagonal Claw Couplings

- 2024-01-15Half Open Type Claw Couplings

- 2024-01-15Flexibility Claw Couplings

- 2024-01-15Flange Type Claw Couplings

- 2024-01-15Expansion Sleeve Type Claw Couplings

- 2023-12-26Expansion Sleeve Claw Couplings

- 2023-12-26Elastic Claw Couplings

- 2023-12-26Double Flange Claw Couplings

- 2023-12-26Conical Sleeve Type Claw Couplings

- 2023-12-26Claw Coupling With Keyway

- 2023-12-26Claw Coupling With Flange Plate

- 2023-12-26Claw Coupling With Brake Wheel

- 2023-12-26Claw Coupling With Brake Disc

- 2023-12-26Claw Coupling For Water Pump

- 2023-12-26Claw Coupling For Pumps

- 2023-12-26Claw Coupling For Plunger Pump

- 2023-12-26Claw Coupling For Oil Pump

- 2023-12-26Claw Coupling For Injection Molding Machine

- 2023-12-26Claw Coupling For Guide Rail

- 2023-12-26Claw Coupling For Gear Pump

- 2023-12-26Claw Coupling For Electrical Machinery

- 2023-12-26Cast Steel Claw Couplings

- 2023-12-26Brake Wheel Claw Couplings

- 2023-12-26Automation Claw Couplings

- 2023-10-30Coaxiality Of Claw Coupling

- 2023-10-30Claw Couplings For Pumps

- 2023-10-30Claw Coupling Deviation

- 2023-10-30How Much Is The Claw Coupling

- 2023-10-25Claw Coupling Structural Diagram

- 2023-10-25Claw Coupling Material

- 2023-10-25Claw Coupling Specification

- 2023-10-25Working Principle Of Claw Coupling

- 2023-10-25Type Of Claw Coupling

- 2023-10-20Claw Coupling Types

- 2023-10-19Claw Coupling Drawing

- 2023-10-19Non Standard Rigid Claw Coupling

- 2023-10-193 Claw Coupling

- 2023-10-19Curved Claw Coupling Model

- 2023-10-19Curved Concave Claw Coupling

- 2023-10-19Seven Claw Coupling

- 2023-10-17Motor End Claw Coupling

- 2023-10-17Motor Plum Claw Couplings

- 2023-10-13Steel Claw Coupling Working Principle

- 2023-10-12Triple Claw Coupling Plum Blossom Gasket For Pumps

- 2023-10-12Claw Coupling Price

- 2023-10-12Claw Coupling Characteristics

- 2023-10-12Claw Coupling Advantages

- 2023-10-12Claw Coupling With Extension Section

- 2023-10-11Claw Coupling Processing

- 2023-10-11Claw Coupling Clearance

- 2023-10-11Claw Coupling Manufacturer

- 2023-10-10Claw Coupling Model

- 2023-10-10Claw Coupling Dimensions

- 2023-10-10Claw Coupling Design

- 2023-10-10Claw Coupling Company

- 2023-10-10Claw Couplings Brand

- 2023-10-09Steel Plum Blossom Claw Coupling

- 2023-10-09Triangular Claw Couplings

- 2023-10-09Curved Claw Couplings

- 2023-10-08Ball Mill Claw Coupling

- 2023-10-08High Speed Elastic Claw Coupling

- 2023-10-07Claw Coupling With Intermediate Joint

- 2023-09-25Steel Claw Coupling

- 2023-09-25Powder Metallurgy Claw Coupling

- 2023-09-25Rigid Claw Coupling

- 2023-09-25Multi Stage Pump Claw Coupling

- 2023-09-25Motor Claw Coupling

- 2023-09-25Electric Hoist Claw Coupling

- 2023-09-19Three Claw Coupling Model For Pumps

- 2023-09-19Eight Claw Coupling

- 2023-09-16Tooth And Claw Couplings

- 2023-09-16Pump Claw Coupling