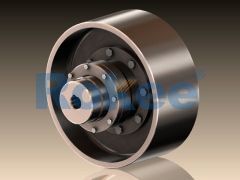

Brake Drum Gear Coupling

Rokee® is Brake Drum Gear Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Brake Drum Gear Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

The Brake Drum Gear Coupling is used to connect the motor and gearbox shaft or gearbox and machine shaft. The brake is fitted on the brake drum and thus, it serves dual purpose of being a coupling and brake drum.

-

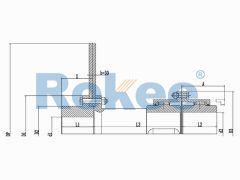

NGCL Drum Gear Coupling

NGCL drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. -

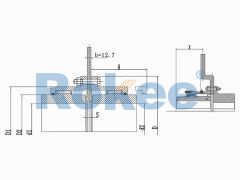

NGCLZ Drum Gear Coupling

NGCLZ drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking. -

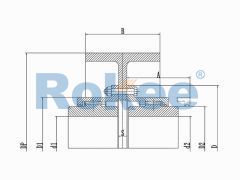

WGZ Drum Gear Coupling

WGZ drum gear coupling is designed with a brake wheel, suitable for shoe type braking. -

WGP Drum Gear Coupling

WGP drum gear coupling is designed with a brake disc, suitable for disc type braking. -

RODP Brake Disc Drum Gear Coupling

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes. -

RODF Split Brake Disc Drum Gear Coupling

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes. -

RODW Brake Wheel Drum Gear Coupling

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes. -

RODU Brake Wheel Drum Gear Coupling

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.

In the realm of mechanical power transmission, couplings play an indispensable role in connecting rotating shafts, compensating for misalignments, and ensuring the smooth transfer of torque from a driver unit (such as a motor or engine) to a driven unit (like a pump, compressor, or conveyor). Among the diverse range of couplings available, brake drum gear couplings stand out for their unique combination of torque transmission capability and integrated braking functionality. This dual-purpose design makes them a preferred choice in numerous industrial applications where space efficiency, reliability, and safety are paramount.

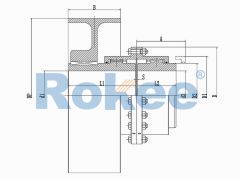

To fully understand the functionality of brake drum gear couplings, it is first necessary to examine their structural components. Unlike standard gear couplings that focus solely on torque transmission, brake drum gear couplings incorporate additional elements to facilitate braking operations. The core structure typically consists of four main parts: the gear hubs, the outer drum (which doubles as the brake drum), the gear teeth (internal or external), and the braking assembly interface. The gear hubs are designed to attach to the input and output shafts, usually via keyways, set screws, or hydraulic fitting methods to ensure a secure connection. These hubs are equipped with gear teeth that mesh with corresponding teeth on the inner surface of the outer drum. The outer drum, a cylindrical component, serves two critical roles: it encloses and protects the gear teeth from external contaminants, and it acts as the braking surface for the associated brake system (such as brake shoes or calipers). The braking assembly interface is a integral part of the outer drum, featuring a smooth or textured surface that enables effective friction when the brake is applied. Some designs may also include seals and lubrication ports to enhance durability and reduce wear, as well as spacer elements to accommodate specific shaft distances.

The working principle of brake drum gear couplings revolves around the synergy between torque transmission through gear meshing and braking through friction. During normal operation (without braking), power from the driver shaft is transmitted to the gear hub connected to it. The gear teeth on this hub mesh with the internal teeth of the outer drum, causing the drum to rotate synchronously. The outer drum then transfers this rotational force to the second gear hub (connected to the driven shaft) via the same gear meshing mechanism, thereby driving the driven unit. The gear meshing design allows for a certain degree of misalignment compensation—including angular, parallel, and axial misalignments—by accommodating small movements between the shafts without compromising torque transfer. This misalignment compensation is crucial in industrial settings where shaft alignment can be affected by thermal expansion, vibration, or installation tolerances.

When braking is required, the brake system (external to the coupling but integrated with it) is activated. This typically involves brake shoes or calipers pressing against the outer surface of the brake drum. The friction generated between the brake components and the drum surface creates a braking torque that opposes the rotational motion of the drum. As the drum slows down and eventually stops, the gear hubs and connected shafts also come to a halt. The design of the brake drum is optimized to dissipate the heat generated during braking, preventing overheating and ensuring consistent braking performance. It is important to note that the gear meshing and braking functions are independent yet complementary; the coupling can transmit torque efficiently while maintaining the ability to stop the system quickly and safely when needed.

One of the primary advantages of brake drum gear couplings is their space-saving dual-function design. By integrating the brake drum directly into the coupling, they eliminate the need for a separate braking device and the additional space required to install it. This is particularly beneficial in compact industrial equipment or applications where layout constraints are a major consideration, such as in small-scale pumps, electric motors, or conveyor systems. Another key advantage is their high torque transmission capacity. The gear meshing design provides a large contact area between the teeth, allowing the coupling to handle high torque loads compared to other types of couplings with similar sizes. This makes them suitable for heavy-duty applications that require the transfer of large amounts of power.

Brake drum gear couplings also offer excellent misalignment compensation capabilities. As mentioned earlier, the gear teeth can accommodate angular misalignments (up to a certain degree, typically between 1 and 3 degrees depending on the design), parallel misalignments, and axial movements. This flexibility reduces stress on the shafts, bearings, and other components of the power transmission system, extending their service life and minimizing maintenance costs. Additionally, the enclosed design of the outer drum protects the gear teeth from dust, dirt, moisture, and other environmental contaminants, which can cause premature wear and failure. The inclusion of seals and lubrication further enhances the durability of the coupling by reducing friction between moving parts.

Safety is another significant benefit of brake drum gear couplings. The integrated braking functionality ensures that the driven unit can be stopped quickly and reliably, which is critical in applications where emergency stops are necessary to prevent accidents or equipment damage. The braking surface of the drum is designed to provide consistent friction, ensuring stable braking performance even under varying load conditions. Furthermore, the secure connection between the gear hubs and the shafts minimizes the risk of shaft slippage, which can lead to unexpected movements and potential hazards.

Brake drum gear couplings find applications in a wide range of industrial sectors, thanks to their versatile design and robust performance. One of the most common applications is in the material handling industry, particularly in conveyor systems. Conveyors are used extensively in factories, mines, ports, and warehouses to transport materials, and they require reliable torque transmission and efficient braking to ensure safe and smooth operation. Brake drum gear couplings are ideal for this purpose, as they can handle the high torque loads of conveyor motors and provide quick braking to stop the conveyor belt when needed, preventing material spillage or equipment collisions.

Another typical application area is in the pumping and compressor industry. Pumps and compressors are essential for fluid and gas transfer in various industrial processes, and they often operate under high pressure and torque conditions. Brake drum gear couplings enable efficient power transmission from the motor to the pump or compressor, while the integrated braking system allows for safe shutdowns, particularly in applications where the pump or compressor needs to be stopped quickly to prevent pressure buildup or system damage. They are also used in centrifugal pumps, reciprocating compressors, and rotary compressors, among other equipment.

The manufacturing industry also relies heavily on brake drum gear couplings, especially in machinery such as mixers, agitators, and extruders. Mixers and agitators are used in food processing, chemical manufacturing, and pharmaceutical production to blend materials, and they require consistent torque transmission and precise braking to ensure product quality and safety. Extruders, which are used in plastic and rubber manufacturing, operate at high speeds and require high torque transmission; brake drum gear couplings can handle these demands while providing the necessary braking functionality to stop the extrusion process when required.

Other applications include industrial fans and blowers, which are used for ventilation, cooling, and air circulation in factories and commercial buildings. These devices often operate continuously and require reliable power transmission and braking to ensure safe operation. Brake drum gear couplings are also used in small to medium-sized industrial vehicles, such as forklifts and warehouse trucks, where they connect the engine or motor to the drive train and provide braking functionality for safe maneuvering.

Proper installation is crucial to ensure the optimal performance and longevity of brake drum gear couplings. Before installation, it is essential to inspect the coupling components for any damage, such as cracks, worn gear teeth, or deformations. The shafts should also be checked for straightness, cleanliness, and proper sizing to ensure a secure fit with the gear hubs. The keyways on the shafts and hubs should be aligned correctly to prevent excessive stress on the keys and shafts during operation.

When installing the coupling, it is important to achieve the correct shaft alignment. Misalignment beyond the coupling's rated capacity can lead to increased wear on the gear teeth, bearings, and shafts, as well as increased vibration and noise. Angular and parallel misalignments should be measured and adjusted using appropriate tools, such as dial indicators or laser alignment devices. The coupling should also be mounted with the correct axial clearance to accommodate thermal expansion and axial movements of the shafts. Additionally, the braking assembly should be properly aligned with the brake drum to ensure even contact and consistent braking performance. The brake shoes or calipers should be adjusted to provide the correct amount of clearance when not in use, preventing unnecessary friction and wear.

Lubrication is another critical aspect of installation and ongoing maintenance. The gear teeth and other moving parts of the coupling require adequate lubrication to reduce friction, minimize wear, and dissipate heat. The type of lubricant used should be compatible with the coupling materials and the operating conditions (such as temperature and load). Lubrication ports should be used to apply the lubricant evenly, and the coupling should be checked regularly to ensure that the lubricant level is sufficient and that there are no leaks.

Regular maintenance is essential to keep brake drum gear couplings operating efficiently and to prevent unexpected failures. A comprehensive maintenance program should include regular inspections, lubrication checks, and component replacements when necessary. Inspections should be conducted periodically to check for signs of wear, such as worn gear teeth, damaged seals, or cracks in the brake drum. Vibration and noise levels should also be monitored, as increased vibration or unusual noise can indicate misalignment, wear, or other issues.

Lubrication should be performed at regular intervals, as specified by the operating conditions and the coupling design. The lubricant should be replaced periodically to ensure that it remains effective, and any leaks should be repaired promptly to prevent lubricant loss and contamination. The braking assembly should also be inspected regularly to check for wear on the brake shoes or calipers, and the brake surface of the drum should be cleaned to remove any dirt, dust, or debris that could affect braking performance. If the brake surface is worn or damaged, it may need to be resurfaced or replaced.

In addition to regular maintenance, it is important to follow proper operating procedures to extend the life of the coupling. The coupling should not be operated beyond its rated torque, speed, or misalignment limits, as this can lead to premature wear and failure. Overloading the coupling can cause damage to the gear teeth, brake drum, and other components, and may also pose a safety risk. If the coupling is used in applications with varying load conditions, it should be sized appropriately to handle the maximum load.

When troubleshooting issues with brake drum gear couplings, several common problems may arise. Excessive vibration is often caused by misalignment, worn gear teeth, or unbalanced shafts. To resolve this issue, the coupling should be realigned, and any worn components should be replaced. Unusual noise, such as grinding or squealing, may indicate a lack of lubrication, worn gear teeth, or issues with the braking assembly. Adding lubricant, replacing worn components, or adjusting the brake assembly can help resolve these issues. Poor braking performance may be due to worn brake shoes or calipers, a contaminated brake surface, or misalignment of the braking assembly. Cleaning the brake surface, replacing worn brake components, and realigning the braking assembly can improve braking performance.

Looking ahead, the development of brake drum gear couplings is likely to focus on improving efficiency, durability, and safety, as well as adapting to the changing needs of industrial applications. Advances in materials technology, such as the use of high-strength, wear-resistant alloys, are expected to enhance the torque capacity and service life of couplings. The integration of smart monitoring technologies, such as sensors to monitor temperature, vibration, and lubricant condition, may also become more common, allowing for predictive maintenance and reducing the risk of unexpected failures. Additionally, as industries move towards more compact and energy-efficient equipment, the demand for space-saving, high-efficiency brake drum gear couplings is expected to grow.

In conclusion, brake drum gear couplings are a versatile and reliable solution for mechanical power transmission with integrated braking functionality. Their unique design combines the torque transmission capabilities of gear couplings with the safety and control of a braking system, making them ideal for a wide range of industrial applications. By understanding their structural composition, working principles, key advantages, and proper installation and maintenance practices, industry professionals can ensure that brake drum gear couplings operate efficiently and safely, contributing to the overall reliability and productivity of industrial systems. As technology continues to advance, these couplings are likely to evolve further, offering even greater performance and functionality to meet the ever-changing demands of the industrial sector.

« Brake Drum Gear Coupling » Post Date: 2023/8/19

URL: https://www.rokeecoupling.com/en/tags/brake-drum-gear-coupling.html

- 2024-01-23Uses of Brake Drum Gear Coupling

- 2024-01-23Torque of Brake Drum Gear Coupling

- 2024-01-23Tagging of Brake Drum Gear Coupling

- 2024-01-23Supply of Brake Drum Gear Couplings

- 2024-01-23Stiffness of Brake Drum Gear Coupling

- 2024-01-23Specifications of Brake Drum Gear Coupling

- 2024-01-23Size Chart of Brake Drum Gear Couplings

- 2024-01-23Size Calculation of Brake Drum Gear Coupling

- 2024-01-23Schematic Diagram of Brake Drum Gear Couplings

- 2024-01-23Purpose of Brake Drum Gear Coupling

- 2024-01-23Parts of Brake Drum Gear Coupling

- 2024-01-23Misalignment Tolerance of Brake Drum Gear Coupling

- 2024-01-23Material of Brake Drum Gear Coupling

- 2024-01-23Machine Drawing of Brake Drum Gear Couplings

- 2024-01-23Lubrication of Brake Drum Gear Coupling

- 2024-01-23Installation of Brake Drum Gear Coupling

- 2024-01-23High Performance Brake Drum Gear Couplings

- 2024-01-23Grease of Brake Drum Gear Coupling

- 2024-01-23Gap Chart of Brake Drum Gear Couplings

- 2024-01-23Function of Brake Drum Gear Coupling

- 2024-01-23Exploded View of Brake Drum Gear Couplings

- 2024-01-23Efficiency of Brake Drum Gear Coupling

- 2024-01-23Disadvantages of Brake Drum Gear Coupling

- 2024-01-23Components of Brake Drum Gear Coupling

- 2024-01-23Coaxiality of Brake Drum Gear Coupling

- 2024-01-23Classification of Brake Drum Gear Couplings

- 2024-01-23Catalogue of Brake Drum Gear Couplings

- 2024-01-23Brake Drum Gear Couplings Supplier

- 2024-01-23Brake Drum Gear Couplings For Sale

- 2024-01-22Brake Drum Gear Couplings Company

- 2024-01-22Brake Drum Gear Coupling Standard Sizes

- 2024-01-22Brake Drum Gear Coupling Sales

- 2024-01-22Brake Drum Gear Coupling Picture

- 2024-01-22Brake Drum Gear Coupling Models

- 2024-01-22Brake Drum Gear Coupling Manufacturing

- 2024-01-19Brake Drum Gear Coupling Design

- 2024-01-19Brake Drum Gear Coupling Calculation

- 2024-01-19Brake Drum Gear Coupling Brands

- 2024-01-19Brake Drum Gear Coupling Advantages

- 2024-01-19Application of Brake Drum Gear Coupling

- 2024-01-19Angle of Brake Drum Gear Coupling

- 2024-01-19Alignment of Brake Drum Gear Coupling

- 2024-01-17Brake Drum Gear Couplings Manufacturer

- 2024-01-17Types of Brake Drum Gear Coupling

- 2024-01-17Maintenance of Brake Drum Gear Coupling

- 2024-01-17Custom Brake Drum Gear Couplings

- 2024-01-17Brake Drum Gear Couplings Factory

- 2024-01-173D Model of Brake Drum Gear Coupling

- 2024-01-17Brake Drum Gear Coupling Drawing

- 2024-01-17Working Principle of Brake Drum Gear Coupling

- 2024-01-17Structural Diagram of Brake Drum Gear Couplings

- 2024-01-17Procurement of Brake Drum Gear Coupling

- 2024-01-17High Quality Brake Drum Gear Couplings

- 2024-01-17Engineering Drawing of Brake Drum Gear Couplings

- 2024-01-17Brake Drum Gear Coupling Price

- 2024-01-17Brake Drum Gear Coupling Assembly Drawing

- 2024-01-17Brake Drum Gear Couplings Wholesale