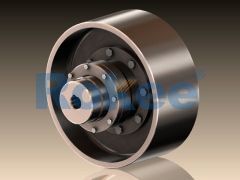

Toothed Couplings

Rokee® is Toothed Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Toothed Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Outer teeth of Toothed Coupling is made into a sphere, with the center of the sphere on the axis of the gear. The teeth clearance is slightly larger than the general products and can transfer a greater torque and allow greater angular displacement, enjoying excellent performance and longer life.

-

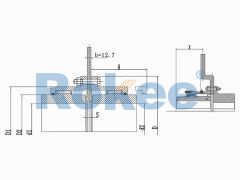

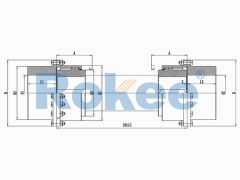

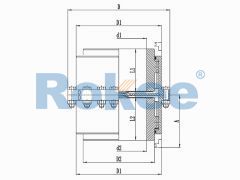

GICL Drum Gear Coupling

GICL drum gear coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement. -

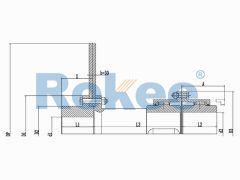

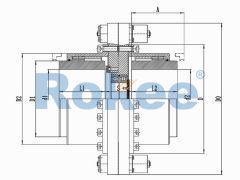

GICLZ Drum Gear Coupling

Half of the GICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. -

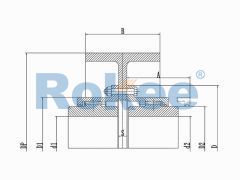

GIICL Drum Gear Coupling

GIICL drum gear coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low. -

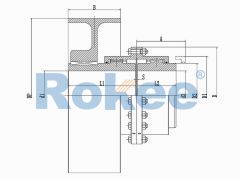

GIICLZ Drum Gear Coupling

Half of the GIICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low. -

GCLD Drum Gear Coupling

GCLD drum gear coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure. -

NGCL Drum Gear Coupling

NGCL drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. -

NGCLZ Drum Gear Coupling

NGCLZ drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking. -

WG Drum Gear Coupling

The overall characteristics of WG drum gear coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque. -

WGZ Drum Gear Coupling

WGZ drum gear coupling is designed with a brake wheel, suitable for shoe type braking. -

WGP Drum Gear Coupling

WGP drum gear coupling is designed with a brake disc, suitable for disc type braking. -

WGT Drum Gear Coupling

WGT drum gear coupling is designed with indirect tube, suitable for long distance torque transfer. -

WGC Drum Gear Coupling

WGC drum gear coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems. -

WGJ Drum Gear Coupling

WGJ drum gear coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers. -

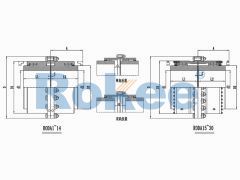

RODA Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase. -

RODP Brake Disc Drum Gear Coupling

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes. -

RODT Indirect Tube Drum Gear Coupling

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance. -

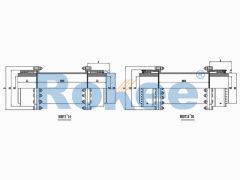

RODX Intermediate Shaft Drum Gear Coupling

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance. -

RODF Split Brake Disc Drum Gear Coupling

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes. -

RODW Brake Wheel Drum Gear Coupling

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes. -

RODU Brake Wheel Drum Gear Coupling

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance. -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque. -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.

In the realm of power transmission systems, couplings serve as critical components that connect two rotating shafts, enabling the transfer of torque while accommodating misalignments and absorbing operational stresses. Among the diverse range of couplings available, toothed couplings stand out for their exceptional torque-carrying capacity, rigidity, and ability to handle moderate to high-speed applications.

Definition and Core Design of Toothed Couplings

A toothed coupling, also known as a gear coupling, is a type of rigid-flexible coupling that utilizes meshing teeth on two hubs to transmit torque between connected shafts. Unlike flexible couplings that rely on elastomeric elements for misalignment compensation, toothed couplings achieve flexibility through the relative movement of their toothed components, often with the assistance of a spacer or sleeve. The core design of a toothed coupling typically consists of four main parts: two toothed hubs, an outer sleeve (or two half-sleeves), and a lubrication system. Each hub is attached to one of the shafts that need to be connected, with the teeth machined on the outer circumference of the hubs. The outer sleeve features internal teeth that mesh with the external teeth of the hubs, creating a positive drive connection that ensures efficient torque transfer.

The tooth profile of toothed couplings is a critical design element that directly impacts their performance. Common tooth profiles include involute, straight, and curved (helical) teeth. Involute teeth are the most widely used due to their smooth meshing action, high load-bearing capacity, and ability to distribute stress evenly across the tooth surface. Straight teeth are simpler to manufacture but may experience higher stress concentrations and noise at high speeds. Helical teeth, on the other hand, offer improved contact area, reduced vibration, and quieter operation compared to straight teeth, making them suitable for high-speed and high-torque applications. The number of teeth, module (tooth size), and pressure angle are additional design parameters that are tailored to specific application requirements, such as torque capacity and rotational speed.

Another key design consideration is the type of toothed coupling configuration. The two primary configurations are flange-mounted toothed couplings and sleeve-type toothed couplings. Flange-mounted couplings feature flanges on the hubs that are bolted together, providing a compact design suitable for applications where space is limited. Sleeve-type couplings use a separate outer sleeve that encases the toothed hubs, offering greater flexibility in terms of misalignment compensation and ease of installation. Some toothed couplings also incorporate a spacer between the two hubs, which allows for easier maintenance and adjustment of the coupling length to accommodate different shaft distances.

Working Principle of Toothed Couplings

The working principle of a toothed coupling revolves around the meshing of teeth to transmit torque and accommodate shaft misalignments. When torque is applied to one shaft, the toothed hub attached to that shaft transfers the torque to the outer sleeve via the meshing teeth. The outer sleeve then transmits the torque to the second toothed hub, which in turn drives the second shaft. This positive meshing action ensures that there is minimal slip between the components, resulting in efficient torque transmission with high accuracy.

One of the key functionalities of toothed couplings is their ability to accommodate three types of shaft misalignments: angular misalignment, parallel misalignment, and axial misalignment. Angular misalignment occurs when the two shafts are not collinear but intersect at an angle. Toothed couplings handle this by allowing a small amount of relative rotation between the meshing teeth, as the tooth profile and clearance between teeth provide the necessary flexibility. Parallel misalignment, where the shafts are offset parallel to each other, is accommodated by the radial movement of the hubs within the outer sleeve, with the meshing teeth sliding against each other to maintain contact. Axial misalignment, which is the linear displacement of one shaft relative to the other, is handled by the axial movement of the hubs along the length of the outer sleeve's internal teeth.

Lubrication plays a vital role in the working of toothed couplings. The meshing teeth are subjected to high contact pressures and relative motion, which can lead to friction, wear, and heat generation. A proper lubrication system, typically using grease or oil, reduces friction between the teeth, minimizes wear, dissipates heat, and prevents corrosion. The lubricant also helps to flush out any debris that may enter the coupling, ensuring smooth operation and extending the service life of the components.

Material Selection for Toothed Couplings

The selection of materials for toothed couplings is crucial, as it directly affects their torque capacity, durability, resistance to wear and corrosion, and overall performance in different operating environments. The most commonly used materials for toothed coupling components are alloy steels, carbon steels, and stainless steels. Alloy steels, such as nickel-chromium-molybdenum steels, are preferred for high-torque and high-speed applications due to their excellent strength, toughness, and wear resistance. These steels are often heat-treated (quenched and tempered) to further enhance their mechanical properties, making them suitable for heavy-duty industrial applications.

Carbon steels are used in less demanding applications where torque requirements are lower. They are cost-effective and easy to machine, but they have lower strength and wear resistance compared to alloy steels. Stainless steels are employed in applications where corrosion resistance is a primary concern, such as in marine environments, food processing industries, or chemical plants. Austenitic stainless steels, in particular, offer excellent resistance to corrosion and oxidation, making them ideal for use in harsh or corrosive operating conditions.

In addition to metallic materials, some toothed coupling components may use non-metallic materials for specific purposes. For example, some spacer elements or seals may be made from rubber, polyurethane, or plastic to provide additional flexibility, reduce vibration, or improve sealing performance. However, these non-metallic components are typically not used in the torque-transmitting parts of the coupling, as they lack the strength and durability required to handle high loads.

The selection of material also depends on the operating temperature of the application. For high-temperature environments, such as in power generation plants or industrial furnaces, materials with high-temperature strength and oxidation resistance, such as heat-resistant alloys, are used. Conversely, for low-temperature applications, materials with good toughness at low temperatures, such as cryogenic steels, are preferred to prevent brittle fracture.

Industrial Applications of Toothed Couplings

Toothed couplings are widely used in a variety of industrial applications due to their high torque capacity, rigidity, and ability to handle high speeds. One of the primary applications is in the power generation industry, where they are used to connect turbines (steam, gas, or hydro) to generators. In these applications, toothed couplings must transmit large amounts of torque efficiently while accommodating slight misalignments between the turbine and generator shafts. Their high precision and reliability make them essential for ensuring continuous power generation with minimal downtime.

Another major application area is in the mining and mineral processing industry. Mining equipment, such as crushers, conveyors, and grinding mills, operates under heavy loads and harsh conditions. Toothed couplings are used to connect the motors to these machines, transmitting the high torque required for crushing and grinding operations. Their robust design and resistance to wear make them suitable for use in dusty, abrasive environments.

The steel industry also relies heavily on toothed couplings in equipment such as rolling mills, continuous casters, and extruders. Rolling mills, for example, require precise torque transmission to shape steel into various forms, and toothed couplings provide the rigidity and accuracy needed for this process. Additionally, their ability to handle high speeds makes them suitable for use in the high-speed rolling of thin steel sheets.

Toothed couplings are also used in marine applications, such as in the propulsion systems of ships and boats. They connect the main engine to the propeller shaft, transmitting torque efficiently while accommodating misalignments caused by the movement of the ship. Stainless steel or corrosion-resistant alloys are often used in these couplings to withstand the corrosive effects of seawater.

Other applications of toothed couplings include industrial pumps, compressors, fans, and machine tools. In machine tools, such as lathes, milling machines, and grinders, toothed couplings are used to transmit torque from the motor to the spindle, ensuring precise and smooth operation. Their high rigidity helps to maintain the accuracy of the machining process, resulting in high-quality finished products.

Operational Advantages of Toothed Couplings

Toothed couplings offer several key advantages over other types of couplings, making them a preferred choice in many industrial applications. One of the most significant advantages is their high torque-carrying capacity. Due to the positive meshing of teeth, toothed couplings can transmit much higher torques than flexible couplings with elastomeric elements, making them suitable for heavy-duty applications.

Another advantage is their rigidity. Toothed couplings have a high degree of torsional rigidity, which means they experience minimal angular deflection under load. This rigidity is essential in applications where precise torque transmission and shaft alignment are critical, such as in machine tools and power generation systems. The high rigidity also helps to reduce vibration and noise, improving the overall stability and performance of the system.

Toothed couplings are also capable of handling high rotational speeds. The smooth meshing of involute or helical teeth reduces friction and heat generation, allowing them to operate at high speeds without excessive wear or damage. This makes them suitable for use in high-speed applications such as gas turbines and centrifugal compressors.

Additionally, toothed couplings have a long service life when properly maintained. The use of high-quality materials and proper lubrication ensures that the meshing teeth wear evenly, reducing the need for frequent replacement. They are also resistant to fatigue, making them suitable for continuous operation under cyclic loads.

Finally, toothed couplings are versatile and can be customized to meet specific application requirements. They are available in a wide range of sizes, configurations, and materials, allowing them to be adapted to different shaft diameters, torque requirements, and operating environments. This versatility makes them suitable for use in a diverse range of industries and applications.

Maintenance Requirements for Toothed Couplings

Proper maintenance is essential to ensure the reliable operation and long service life of toothed couplings. The primary maintenance tasks include lubrication, inspection, and alignment checks.

Lubrication is the most critical maintenance task for toothed couplings. The meshing teeth must be properly lubricated to reduce friction, wear, and heat generation. The type of lubricant used depends on the operating conditions, such as temperature, speed, and load. Grease is commonly used for most applications, while oil is preferred for high-speed or high-temperature applications. The lubricant should be replaced at regular intervals, and the coupling should be checked for lubricant leakage. Any leakage should be repaired immediately to prevent the loss of lubricant and the subsequent wear of the teeth.

Regular inspection of the coupling components is also important. The teeth should be inspected for signs of wear, pitting, chipping, or corrosion. If any of these defects are found, the affected component should be replaced to prevent further damage to the coupling. The hubs, outer sleeve, and fasteners (such as bolts and nuts) should also be inspected for cracks, deformation, or loosening. Loose fasteners should be tightened, and cracked or deformed components should be replaced.

Shaft alignment is another critical aspect of maintenance. Misalignment of the connected shafts can cause excessive stress on the coupling teeth, leading to premature wear and failure. The alignment of the shafts should be checked regularly using precision tools such as dial indicators or laser alignment systems. Any misalignment should be corrected immediately to ensure the proper operation of the coupling and the entire power transmission system.

In addition to these routine maintenance tasks, the coupling should be cleaned regularly to remove any debris, dust, or dirt that may accumulate on the components. This helps to prevent the abrasion of the teeth and ensures that the lubricant can function effectively.

Emerging Trends in Toothed Coupling Development

The development of toothed couplings is driven by the evolving needs of industrial applications, such as increased efficiency, higher performance, and improved reliability. One of the emerging trends in toothed coupling development is the use of advanced materials and manufacturing processes. The use of composite materials, such as carbon fiber-reinforced polymers, is being explored to reduce the weight of the coupling while maintaining its strength and rigidity. These composite materials offer excellent wear resistance and corrosion resistance, making them suitable for use in lightweight and high-performance applications.

Another trend is the integration of smart technologies into toothed couplings. Smart couplings are equipped with sensors that monitor various parameters such as temperature, vibration, torque, and wear. These sensors transmit real-time data to a control system, allowing for predictive maintenance. By monitoring the condition of the coupling, potential failures can be detected early, reducing downtime and maintenance costs. This is particularly beneficial in critical applications such as power generation and aerospace.

Advancements in tooth profile design are also contributing to the improvement of toothed coupling performance. Computer-aided design (CAD) and finite element analysis (FEA) are being used to optimize the tooth profile, resulting in better stress distribution, reduced wear, and increased torque capacity. The use of helical and curved teeth is becoming more prevalent, as they offer improved performance compared to straight teeth.

Additionally, there is a growing focus on improving the lubrication systems of toothed couplings. Self-lubricating couplings, which use solid lubricants or lubricant-impregnated materials, are being developed to eliminate the need for regular lubrication. This reduces maintenance requirements and makes the couplings suitable for use in applications where lubrication is difficult or impractical, such as in remote or harsh environments.

Conclusion

Toothed couplings are essential components in power transmission systems, offering high torque-carrying capacity, rigidity, and the ability to handle high speeds and misalignments. Their robust design, versatile configurations, and wide range of material options make them suitable for use in numerous industrial applications, from power generation and mining to steel production and marine propulsion. Proper maintenance, including regular lubrication, inspection, and alignment checks, is crucial to ensure their reliable operation and long service life.

As industrial technologies continue to advance, toothed couplings are evolving to meet the changing needs of the industry. The integration of smart technologies, the use of advanced materials, and the optimization of tooth profile design are driving improvements in performance, efficiency, and reliability. These advancements are ensuring that toothed couplings remain a vital part of power transmission systems for years to come.

In summary, toothed couplings play a critical role in enabling the efficient and reliable operation of a wide range of industrial equipment. Their unique combination of strength, rigidity, and flexibility makes them indispensable in applications where high torque and precision are required. By understanding their design, working principle, material selection, applications, and maintenance requirements, industries can make informed decisions about the use of toothed couplings, ensuring optimal performance and productivity.

« Toothed Couplings » Post Date: 2023/8/18

URL: https://www.rokeecoupling.com/en/tags/toothed-couplings.html

- 2023-11-08Toothed Coupling Price

- 2023-11-08Toothed Coupling Size Chart

- 2023-11-08Toothed Couplings Supply

- 2023-11-08Disadvantages of Toothed Couplings

- 2023-11-08Toothed Coupling Size Calculation

- 2023-11-08Toothed Coupling Function

- 2023-11-08Purpose of Toothed Couplings

- 2023-11-08Toothed Coupling Manufacturing Enterprise

- 2023-11-08Toothed Coupling Parts

- 2023-11-08Toothed Coupling Structural Diagram

- 2023-11-08Toothed Coupling Working Principle

- 2023-11-08Models of Toothed Couplings

- 2023-11-08Toothed Coupling Applications

- 2023-11-08Toothed Coupling Specifications

- 2023-11-08Toothed Couplings Supplier

- 2023-11-08Toothed Couplings Factory

- 2023-11-08Toothed Couplings Company

- 2023-11-08Toothed Couplings Wholesale

- 2023-11-08Toothed Couplings Manufacturer

- 2023-11-08Toothed Coupling Types

- 2023-11-08Toothed Coupling Seller

- 2023-11-08Customized Toothed Couplings

- 2023-11-08Toothed Coupling Advantages

- 2023-11-08Toothed Coupling Design

- 2023-11-08Toothed Coupling Drawing

- 2023-11-08Toothed Couplings Catalogue

- 2023-10-24Conveyor Belt Pin Toothed Coupling

- 2023-10-24Pin Toothed Couplings With Brake Wheel Column

- 2023-10-24Pin Toothed Couplings

- 2023-10-24Cylindrical Pin Toothed Coupling Drawing

- 2023-10-24Cylindrical Pin Toothed Coupling

- 2023-10-24Column Pin Toothed Couplings Wholesale

- 2023-10-24Column Pin Toothed Couplings Sales

- 2023-10-24Column Pin Toothed Coupling Price

- 2023-10-24Column Pin Toothed Coupling

- 2023-10-24Brake Wheel Nylon Pin Toothed Couplings

- 2023-10-18Toothed Coupling Half Coupling

- 2023-10-18Toothed Couplings Specification

- 2023-10-18Toothed Couplings Marking

- 2023-10-17High Quality Elastic Pin Toothed Couplings

- 2023-10-13Toothed Coupling Nominal Torque

- 2023-10-09Toothed Coupling For Drum

- 2023-09-22Flat Head Toothed Coupling

- 2023-09-22Manufacturer Of Elastic Toothed Couplings For Diesel Engines

- 2023-09-22Characteristics Of Half Toothed Couplings

- 2023-09-22Benefits Of Half Toothed Couplings

- 2023-09-22Standard For Mechanical Toothed Couplings

- 2023-09-22Standard For Industrial Toothed Couplings

- 2023-09-22Standard For Low Speed Toothed Couplings

- 2023-09-22Working Principle Of Motor Toothed Coupling

- 2023-09-22Weight Of Elastic Pin Toothed Coupling

- 2023-09-22Steel Ball Toothed Coupling

- 2023-09-22Standard For End Face Toothed Couplings

- 2023-09-22Roller Chain Coupled Shaft Toothed Coupling

- 2023-09-22Quotation For Mechanical Toothed Couplings

- 2023-09-22Working Principle Of Industrial Toothed Couplings

- 2023-09-22Wholesale Of Elastic Pin Toothed Couplings

- 2023-09-22Which Is The Best Manufacturer For Elastic Pin Toothed Couplings

- 2023-09-22Specification For Industrial Toothed Couplings

- 2023-09-21Toothed Coupling Compensation Function

- 2023-09-21Semi Enclosed Toothed Coupling

- 2023-09-21Stainless Steel Toothed Coupling

- 2023-09-21Toothed Coupling Spacer Sleeve

- 2023-09-21Standard Tolerances For Toothed Couplings

- 2023-09-21Toothed Coupling With Brake Wheel

- 2023-09-21Toothed Coupling With Band Brake

- 2023-09-21Toothed Coupling Sleeve

- 2023-09-21Toothed Coupling Flange

- 2023-09-21Installation Principle Of Toothed Coupling

- 2023-09-20Production Of Elastic Pin Toothed Couplings

- 2023-09-20Principle Of Motor Toothed Coupling

- 2023-09-20Motor Toothed Coupling Function

- 2023-09-20Model Of Elastic Pin Toothed Coupling

- 2023-09-20Mine Toothed Coupling

- 2023-09-20Merchant Of Elastic Pin Toothed Coupling

- 2023-09-20Laminated Toothed Coupling

- 2023-09-19Supplier Of Elastic Toothed Couplings For Diesel Engines

- 2023-09-19Advantages Of Half Toothed Couplings

- 2023-09-18Picture Of End Face Toothed Coupling

- 2023-09-18Mixing And Kneading Pot Toothed Coupling

- 2023-09-18Metering Pump Toothed Coupling

- 2023-09-18Key Connected Toothed Coupling

- 2023-09-18Hub Type Toothed Coupling

- 2023-09-18Machined Toothed Coupling

- 2023-09-18Mechanical Toothed Coupling

- 2023-09-18Steel Sleeve Toothed Coupling

- 2023-09-18Toothed Coupling For Gearbox Output

- 2023-09-18Toothed Coupling For Cold Bending Forming Unit

- 2023-09-18Types Of Chain Toothed Couplings

- 2023-09-18Multiple Unit Toothed Coupling

- 2023-09-18Motor Drum Type Toothed Coupling

- 2023-09-18Mixer Toothed Coupling

- 2023-09-18Industrial Toothed Coupling

- 2023-09-18Hub Shaped Toothed Coupling

- 2023-09-18High Speed Toothed Coupling

- 2023-09-18High Speed Rail Toothed Coupling

- 2023-09-18Forged Steel Toothed Coupling

- 2023-09-16Flexible Toothed Coupling

- 2023-09-16Flange Toothed Coupling

- 2023-09-16Explosion Proof Toothed Coupling

- 2023-09-16Executive Standard For Mechanical Toothed Couplings

- 2023-09-16Executive Standard For Industrial Toothed Couplings

- 2023-09-16End Face Toothed Coupling

- 2023-09-16Electric Side Toothed Coupling

- 2023-09-16Electric Drill Toothed Coupling

- 2023-09-16Elastic Taper Pin Toothed Coupling

- 2023-09-16Composition Of Elastic Pin Toothed Coupling

- 2023-09-16Connected To Intermediate Shaft Pin Toothed Coupling

- 2023-09-16Elastic Pin Toothed Coupling Manufacturer

- 2023-09-16Drawing Of Elastic Pin Toothed Coupling

- 2023-09-16Application Of Elastic Pin Toothed Couplings

- 2023-09-16Alignment Of Elastic Pin Toothed Coupling

- 2023-09-16Adjustable Directional Toothed Coupling

- 2023-09-16A Reputable Manufacturer Of Toothed Couplings

- 2023-09-16Advantages Of Elastic Pin Toothed Couplings

- 2023-09-16Customized Industrial Toothed Couplings

- 2023-09-16Diameter Of Elastic Pin Toothed Coupling

- 2023-09-16Electric Toothed Coupling

- 2023-09-16Flange Inner Gear Sleeve Toothed Coupling

- 2023-09-16Machining Of End Face Toothed Couplings

- 2023-09-16Motor Toothed Coupling

- 2023-09-16Quick Release Toothed Coupling

- 2023-09-16Roller Toothed Coupling

- 2023-09-16Steel Toothed Coupling

- 2023-09-16Toothed Coupling For Water Supply Pumps

- 2023-09-16Wear Amount Of Elastic Pin Toothed Coupling