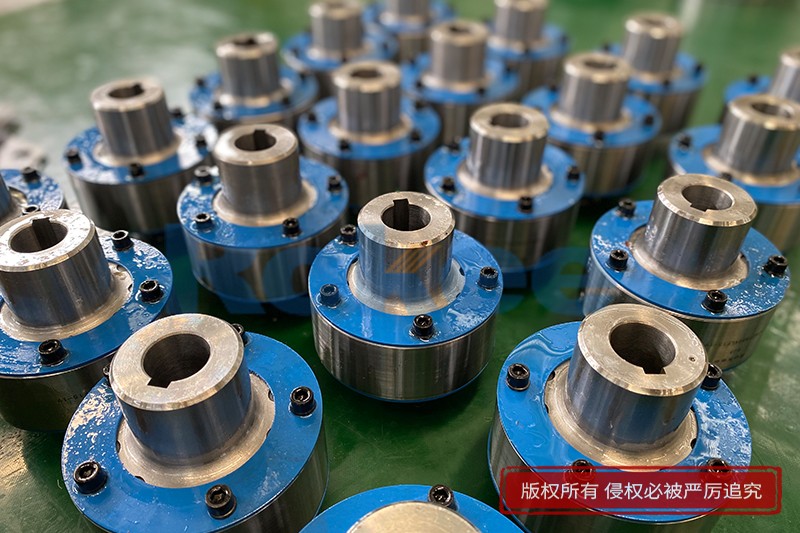

Pin Couplings

Rokee® is Pin Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Pin Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Pin Coupling is offered in the industry’s largest variety of stock bore/keyway combinations. Pin Couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

-

LZ/ZL Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings. -

LZD/ZLD Pin Gear Coupling

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end. -

LZZ/ZLL Pin Gear Coupling

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. -

LX(HL) Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings. -

LXZ(HLL) Flexible Pin Coupling

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required. -

LT/TL Elastic Sleeve Pin Coupling

LT/TL Elastic Sleeve Pin Coupling is the basic form of this series of couplings. -

LTZ/TLL Elastic Sleeve Pin Coupling

LTZ/TLL Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating misalignments, absorbing shock loads, and protecting adjacent machinery. Among the diverse range of coupling types available, pin coupling stands out for its simplicity, cost-effectiveness, and versatility.

Overview and Fundamental Principles of Pin Coupling

A pin coupling is a type of rigid-flexible coupling designed to transmit rotational power between two coaxial shafts. Unlike rigid couplings that require precise alignment and offer no flexibility, pin couplings incorporate elastic elements to accommodate moderate axial, radial, and angular misalignments. The core working principle of a pin coupling revolves around the transfer of torque from the driving shaft to the driven shaft through a series of pins and corresponding elastic sleeves (or bushes) that fit into holes drilled in the coupling flanges.

When the driving shaft rotates, the torque is transmitted to the driving flange, which in turn exerts force on the pins. The elastic sleeves surrounding the pins absorb the impact and vibration generated during operation, reducing the stress on the shafts and connected equipment. This elastic deformation of the sleeves also allows for minor misalignments between the two shafts, which is a common occurrence in practical applications due to thermal expansion, manufacturing tolerances, or mounting errors. By balancing the need for torque transmission efficiency and flexibility, pin couplings bridge the gap between rigid and fully flexible couplings, making them suitable for a wide range of industrial scenarios.

Structural Characteristics of Pin Coupling

The basic structure of a pin coupling consists of four main components: two flanges, a set of pins, elastic sleeves (or bushes), and fastening elements (such as nuts and washers). Each component plays a vital role in ensuring the overall performance and reliability of the coupling.

The two flanges are typically disk-shaped components with a central hole that fits tightly onto the ends of the driving and driven shafts. The connection between the flanges and the shafts is usually achieved through keyways and keys, which prevent relative rotation between the flange and the shaft. In some cases, interference fits or clamping sleeves may be used for higher torque applications. The flanges are equipped with a number of evenly distributed holes around their circumference, which are designed to accommodate the pins and elastic sleeves. The number and size of these holes depend on the torque capacity and size of the coupling.

The pins are cylindrical rods that pass through the holes in both flanges, forming the primary torque-transmitting interface. The elastic sleeves, often made of rubber, polyurethane, or nylon, are placed between the pins and the flange holes. These sleeves act as buffers, absorbing vibration and shock, and reducing noise during operation. Additionally, the elastic sleeves protect the metal components (pins and flanges) from direct contact, minimizing wear and extending the service life of the coupling. Fastening elements such as nuts and washers are used to secure the pins in place, ensuring that the coupling remains intact during high-speed rotation.

Variations of the basic pin coupling design exist to meet specific application requirements. For example, some pin couplings feature tapered pins for enhanced torque transmission, while others incorporate split flanges to facilitate easy installation and removal without disassembling the entire shaft system. Another variation is the pin-and-bolt coupling, which uses bolts with elastic sleeves instead of separate pins, simplifying the assembly process.

Material Considerations for Pin Coupling Components

The selection of materials for pin coupling components is critical to ensuring optimal performance, durability, and compatibility with the operating environment. Different components require materials with distinct properties to withstand torque, vibration, wear, and environmental factors such as temperature, humidity, and chemical exposure.

Flanges are typically made of metallic materials due to their need to withstand high torque and provide structural rigidity. Common materials for flanges include carbon steel, alloy steel, and cast iron. Carbon steel is widely used for general-purpose applications due to its high strength, good machinability, and cost-effectiveness. Alloy steel, which contains elements such as chromium, nickel, and molybdenum, offers higher strength, toughness, and resistance to fatigue, making it suitable for heavy-duty and high-speed applications. Cast iron is preferred for low-torque, low-speed applications due to its good damping properties and lower cost, although it is less resistant to impact compared to steel.

Pins are also usually made of high-strength metallic materials to ensure they can transmit torque without bending or breaking. Carbon steel and alloy steel are commonly used for pins, with surface treatments such as quenching and tempering to enhance their hardness and wear resistance. In some cases, stainless steel may be used for pins in corrosive environments to prevent rust and degradation.

Elastic sleeves are the most critical flexible components of a pin coupling, and their material selection directly affects the coupling's vibration absorption capacity, temperature resistance, and service life. Rubber is a common material for elastic sleeves due to its excellent elasticity, vibration damping properties, and low cost. However, rubber has limited temperature resistance, typically operating within a range of -20°C to 80°C, and may degrade when exposed to oil or chemical substances. Polyurethane is another popular material for elastic sleeves, offering higher wear resistance, better oil resistance, and a wider temperature range (-40°C to 120°C) compared to rubber. Nylon is sometimes used for elastic sleeves in light-duty applications, as it is lightweight, cost-effective, and has good wear resistance, although it has lower elasticity than rubber and polyurethane.

When selecting materials for pin coupling components, engineers must consider the operating parameters (such as torque, speed, and temperature), environmental conditions (such as humidity, corrosion, and exposure to chemicals), and performance requirements (such as vibration absorption and service life). Proper material selection ensures that the coupling can operate reliably under the specified conditions, minimizing downtime and maintenance costs.

Applications of Pin Coupling

Due to their simplicity, cost-effectiveness, and ability to accommodate moderate misalignments and absorb vibration, pin couplings find applications in a wide range of industries and mechanical systems. Their versatility makes them suitable for both light-duty and heavy-duty applications, as well as low-speed and high-speed operations.

One of the most common applications of pin couplings is in the automotive industry, where they are used to connect the engine to the transmission system. In this application, the pin coupling absorbs the vibration generated by the engine, reduces the impact on the transmission, and accommodates minor misalignments between the engine and transmission shafts. Pin couplings are also used in automotive auxiliary systems, such as power steering pumps and air conditioning compressors.

In the industrial machinery sector, pin couplings are widely used in pumps and compressors. Pumps, whether centrifugal, reciprocating, or rotary, require a reliable coupling to connect the motor to the pump shaft. Pin couplings are ideal for this application because they can absorb the vibration generated by the pump's operation, accommodate misalignments caused by thermal expansion of the shafts, and protect the motor and pump from damage. Similarly, compressors, which operate at high speeds and generate significant vibration, benefit from the vibration absorption and misalignment compensation capabilities of pin couplings.

Pin couplings are also commonly used in conveyor systems, which are widely used in manufacturing, mining, and logistics industries to transport materials. Conveyor systems typically consist of multiple shafts connected by couplings, and pin couplings are used to transmit torque between these shafts while accommodating misalignments caused by the long length of the conveyor and the uneven distribution of materials. The vibration absorption capacity of pin couplings also helps to reduce noise and wear in the conveyor system, extending its service life.

Other applications of pin couplings include agricultural machinery (such as tractors and harvesters), construction machinery (such as excavators and loaders), electric motors and generators, and marine propulsion systems. In each of these applications, pin couplings play a critical role in ensuring efficient and reliable power transmission, protecting equipment from damage, and reducing maintenance costs.

Installation and Maintenance of Pin Coupling

Proper installation and regular maintenance are essential to ensure the optimal performance and long service life of pin couplings. Improper installation can lead to excessive wear, vibration, and premature failure, while neglecting maintenance can result in unexpected downtime and costly repairs.

Installation Procedures

The installation of a pin coupling involves several key steps, starting with the preparation of the shafts and flanges. Before installation, the ends of the driving and driven shafts should be cleaned to remove any dirt, rust, or debris. The keyways on the shafts and flanges should also be inspected to ensure they are free of burrs and damage. If necessary, the keyways can be polished to ensure a tight fit between the keys and the shafts/flanges.

Next, the two flanges are mounted onto the respective shafts. The flanges should be pushed onto the shafts until they are seated firmly against the shaft shoulders (if present). The keys are then inserted into the keyways, and the flanges are secured using set screws or nuts (depending on the design). It is important to ensure that the flanges are mounted concentrically with the shafts to minimize initial misalignment.

Once the flanges are mounted, the elastic sleeves are placed into the holes in one of the flanges. The pins are then inserted through the holes in both flanges, passing through the elastic sleeves. The pins are secured in place using nuts and washers, which should be tightened to the specified torque value. Over-tightening the nuts can compress the elastic sleeves excessively, reducing their vibration absorption capacity, while under-tightening can result in loose pins that cause noise and wear.

After installation, the alignment of the two shafts should be checked. This can be done using a straightedge, feeler gauge, or laser alignment tool. The maximum allowable misalignment values vary depending on the size and type of the pin coupling, and these values should be strictly followed to ensure optimal performance. If the misalignment exceeds the allowable limit, adjustments should be made to the mounting of the motor or driven equipment.

Maintenance Practices

Regular maintenance of pin couplings includes periodic inspection, lubrication (if required), and replacement of worn components. The frequency of maintenance depends on the operating conditions, with couplings operating in harsh environments (such as high temperature, high humidity, or corrosive conditions) requiring more frequent inspections.

Periodic inspection involves checking the condition of the elastic sleeves, pins, flanges, and fastening elements. The elastic sleeves should be inspected for signs of wear, cracking, or deformation. If the sleeves are worn or damaged, they should be replaced immediately, as damaged sleeves can lead to increased vibration, noise, and wear on the pins and flanges. The pins should be checked for bending, wear, or corrosion, and any damaged pins should be replaced. The flanges should be inspected for cracks, wear on the pin holes, and loosening of the set screws or nuts. Fastening elements should be checked for tightness and replaced if they are worn or damaged.

Lubrication is not required for all pin couplings, but some designs with metallic pins and flanges may benefit from periodic lubrication to reduce wear. If lubrication is required, a high-quality lubricant compatible with the coupling materials and operating conditions should be used. The lubricant should be applied to the pins and pin holes, and excess lubricant should be removed to prevent the accumulation of dirt and debris.

In addition to periodic inspections and lubrication, it is important to monitor the performance of the pin coupling during operation. Unusual noise, vibration, or temperature rise may indicate a problem with the coupling, such as worn elastic sleeves, misalignment, or loose pins. If any of these signs are observed, the equipment should be shut down immediately for inspection and repair to prevent further damage.

Emerging Trends and Future Developments

As the industrial sector continues to evolve, driven by advancements in technology and the growing demand for energy efficiency, reliability, and sustainability, pin couplings are also undergoing continuous improvements and innovations. Several emerging trends are shaping the future development of pin couplings.

One of the key trends is the development of high-performance elastic materials for pin coupling sleeves. Researchers and manufacturers are exploring new materials, such as composite materials and advanced elastomers, that offer improved temperature resistance, wear resistance, and vibration absorption capacity. These materials can extend the service life of pin couplings and make them suitable for more extreme operating conditions, such as high-temperature applications in the aerospace and energy sectors.

Another trend is the integration of smart technologies into pin couplings. Smart couplings equipped with sensors can monitor key performance parameters such as torque, vibration, temperature, and misalignment in real time. This data can be transmitted to a central monitoring system, allowing engineers to detect potential problems before they lead to failure. Predictive maintenance based on real-time data can significantly reduce downtime, improve equipment reliability, and lower maintenance costs. Smart pin couplings are particularly useful in critical applications such as power generation, where unplanned downtime can have severe economic consequences.

Lightweight design is also becoming increasingly important in the development of pin couplings, especially in the automotive and aerospace industries, where reducing weight is crucial for improving energy efficiency and reducing emissions. Manufacturers are using lightweight materials such as aluminum alloys and composite materials for flanges and pins, without compromising on strength and durability. Advanced manufacturing processes such as 3D printing are also being used to produce complex, lightweight coupling designs that are difficult to achieve with traditional manufacturing methods.

Sustainability is another emerging trend in the manufacturing of pin couplings. Manufacturers are adopting eco-friendly materials and processes to reduce the environmental impact of their products. For example, the use of recycled materials for flanges and pins, and the development of biodegradable elastic sleeves, are becoming more common. Additionally, manufacturers are focusing on improving the energy efficiency of pin couplings by reducing friction and optimizing the design to minimize power loss during torque transmission.

Conclusion

Pin coupling is a versatile and cost-effective component in mechanical power transmission systems, offering a balance between torque transmission efficiency, flexibility, and simplicity. Its basic structure, consisting of flanges, pins, elastic sleeves, and fastening elements, makes it easy to manufacture, install, and maintain. The selection of appropriate materials for each component is critical to ensuring the coupling's performance and durability in different operating conditions.

Pin couplings find applications in a wide range of industries, including automotive, industrial machinery, conveyor systems, agriculture, and construction. Proper installation and regular maintenance are essential to maximize the service life of pin couplings and prevent unexpected downtime. With the emergence of new materials, smart technologies, lightweight designs, and sustainable manufacturing practices, pin couplings are poised to become even more efficient, reliable, and environmentally friendly in the future.

As the industrial sector continues to advance, pin couplings will remain a key component in power transmission systems, adapting to the changing needs of various industries. By understanding the fundamental principles, structural characteristics, and best practices of pin couplings, engineers and industry professionals can make informed decisions when selecting, installing, and maintaining these critical components, ensuring the efficient and reliable operation of mechanical systems.

« Pin Couplings » Post Date: 2023/9/1

URL: https://www.rokeecoupling.com/en/tags/pin-couplings.html

- 2025-08-05Shear Pin Coupling Design

- 2024-02-28Bush Pin Coupling Price

- 2024-02-28Bush Pin Coupling Picture

- 2024-02-28Bush Pin Coupling Models

- 2024-02-28Bush Pin Coupling Manufacturing

- 2024-02-28Bush Pin Coupling Drawing

- 2024-02-28Bush Pin Coupling Design

- 2024-02-28Bush Pin Coupling Calculation

- 2024-02-28Schematic Diagram of Bush Pin Couplings

- 2024-02-28Purpose of Bush Pin Couplings

- 2024-02-28Procurement of Bush Pin Coupling

- 2024-02-28Parts of Bush Pin Coupling

- 2024-02-28Misalignment Tolerance of Bush Pin Coupling

- 2024-02-28Material of Bush Pin Coupling

- 2024-02-28Maintenance of Bush Pin Coupling

- 2024-02-28Lubrication of Bush Pin Coupling

- 2024-02-28Installation of Bush Pin Coupling

- 2024-02-28Grease of Bush Pin Coupling

- 2024-02-28Gap Chart of Bush Pin Coupling

- 2024-02-28Function of Bush Pin Coupling

- 2024-02-28Exploded View of Bush Pin Couplings

- 2024-02-04Efficiency of Bush Pin Coupling

- 2024-02-04Disadvantages of Bush Pin Coupling

- 2024-02-04Custom Bush Pin Couplings

- 2024-02-04Components of Bush Pin Coupling

- 2024-02-04Coaxiality of Bush Pin Coupling

- 2024-02-04Classification of Bush Pin Couplings

- 2024-02-04Bush Pin Coupling Assembly Drawing

- 2024-02-04Bush Pin Coupling Advantages

- 2024-02-04Application of Bush Pin Coupling

- 2024-02-04Angle of Bush Pin Coupling

- 2024-02-04Alignment of Bush Pin Coupling

- 2024-02-043D Model of Bush Pin Coupling

- 2024-02-04Working Principle of Bush Pin Coupling

- 2024-02-04Uses of Bush Pin Coupling

- 2024-02-04Types of Bush Pin Coupling

- 2024-02-04Torque of Bush Pin Coupling

- 2024-02-04Supply of Bush Pin Couplings

- 2024-02-04Structural Diagram of Bush Pin Couplings

- 2024-02-04Stiffness of Bush Pin Coupling

- 2024-02-04Specifications of Bush Pin Coupling

- 2024-02-04Size Chart of Bush Pin Couplings

- 2024-02-04High Quality Bush Pin Couplings

- 2024-02-04High Performance Bush Pin Couplings

- 2024-02-04Bush Pin Couplings Wholesale

- 2024-02-04Bush Pin Couplings Supplier

- 2024-02-04Bush Pin Couplings Manufacturer

- 2024-02-04Bush Pin Couplings For Sale

- 2024-02-04Bush Pin Couplings Factory

- 2024-02-04Bush Pin Couplings Company

- 2024-02-04Bush Pin Coupling Standard Sizes

- 2024-01-29Torque of Crown Pin Coupling

- 2024-01-29Tagging of Crown Pin Coupling

- 2024-01-29Supply of Crown Pin Couplings

- 2024-01-29Structural Diagram of Crown Pin Couplings

- 2024-01-29Stiffness of Crown Pin Coupling

- 2024-01-29Size Chart of Crown Pin Couplings

- 2024-01-29Size Calculation of Crown Pin Coupling

- 2024-01-29Schematic Diagram of Crown Pin Couplings

- 2024-01-29Purpose of Crown Pin Couplings

- 2024-01-29Procurement of Crown Pin Coupling

- 2024-01-29Parts of Crown Pin Coupling

- 2024-01-29Uses of Crown Pin Couplings

- 2024-01-29Working Principle of Crown Pin Coupling

- 2024-01-29Material of Crown Pin Coupling

- 2024-01-29Maintenance of Crown Pin Coupling

- 2024-01-29Machine Drawing of Crown Pin Couplings

- 2024-01-29Lubrication of Crown Pin Coupling

- 2024-01-29Installation of Crown Pin Coupling

- 2024-01-29High Quality Crown Pin Couplings

- 2024-01-29Grease of Crown Pin Coupling

- 2024-01-29Gap Chart of Crown Pin Couplings

- 2024-01-29Function of Crown Pin Couplings

- 2024-01-29Exploded View of Crown Pin Couplings

- 2024-01-29Engineering Drawing of Crown Pin Couplings

- 2024-01-29Efficiency of Crown Pin Coupling

- 2024-01-29Disadvantages of Crown Pin Couplings

- 2024-01-22Tagging of Bush Pin Coupling

- 2024-01-22Size Calculation of Bush Pin Coupling

- 2024-01-22Engineering Drawing of Bush Pin Couplings

- 2024-01-22Catalogue of Bush Pin Couplings

- 2024-01-22Bush Pin Coupling Sales

- 2024-01-22Bush Pin Coupling Brands

- 2024-01-22Types of Crown Pin Coupling

- 2024-01-22Specifications of Crown Pin Coupling

- 2024-01-22Misalignment Tolerance of Crown Pin Coupling

- 2024-01-22High Performance Crown Pin Couplings

- 2024-01-22Custom Crown Pin Couplings

- 2024-01-17Machine Drawing of Bush Pin Couplings

- 2024-01-16Crown Pin Couplings Wholesale

- 2024-01-16Crown Pin Couplings Supplier

- 2024-01-16Crown Pin Couplings Manufacturer

- 2024-01-16Crown Pin Couplings For Sale

- 2024-01-16Crown Pin Couplings Factory

- 2024-01-16Crown Pin Couplings Company

- 2024-01-16Crown Pin Coupling Standard Sizes

- 2024-01-16Crown Pin Coupling Sales

- 2024-01-16Crown Pin Coupling Price

- 2024-01-16Crown Pin Coupling Picture

- 2024-01-16Crown Pin Coupling Models

- 2024-01-16Crown Pin Coupling Manufacturing

- 2024-01-16Crown Pin Coupling Drawing

- 2024-01-16Crown Pin Coupling Design

- 2024-01-16Crown Pin Coupling Calculation

- 2024-01-16Crown Pin Coupling Brands

- 2024-01-16Crown Pin Coupling Assembly Drawing

- 2024-01-16Crown Pin Coupling Advantages

- 2024-01-16Components of Crown Pin Coupling

- 2024-01-16Coaxiality of Crown Pin Coupling

- 2024-01-16Classification of Crown Pin Couplings

- 2024-01-16Catalogue of Crown Pin Couplings

- 2024-01-16Application of Crown Pin Couplings

- 2024-01-16Angle of Crown Pin Coupling

- 2024-01-16Alignment of Crown Pin Coupling

- 2024-01-163D Model of Crown Pin Couplings

- 2024-01-15Bushed Pin Couplings Wholesale

- 2024-01-15Bushed Pin Couplings Supplier

- 2024-01-15Bushed Pin Couplings Manufacturer

- 2024-01-15Bushed Pin Couplings For Sale

- 2024-01-15Bushed Pin Couplings Factory

- 2024-01-15Bushed Pin Couplings Company

- 2024-01-15Bushed Pin Coupling Working Principle

- 2024-01-15Bushed Pin Coupling Torque

- 2024-01-15Bushed Pin Coupling Tagging

- 2024-01-13Bushed Pin Coupling Supply

- 2024-01-13Bushed Pin Coupling Structural Diagram

- 2024-01-13Bushed Pin Coupling Stiffness

- 2024-01-13Classification of Bushed Pin Couplings

- 2024-01-13Components of Bushed Pin Coupling

- 2024-01-13Customized Bushed Pin Coupling

- 2024-01-13Disadvantages of Bushed Pin Coupling

- 2024-01-13Efficiency of Bushed Pin Coupling

- 2024-01-13Machine Drawing of Bushed Pin Coupling

- 2024-01-13Maintenance of Bushed Pin Couplings

- 2024-01-13Parts of Bushed Pin Coupling

- 2024-01-13Size Chart of Bushed Pin Coupling

- 2024-01-13Specifications of Bushed Pin Couplings

- 2024-01-13Types of Bushed Pin Couplings

- 2024-01-13Uses of Bushed Pin Couplings

- 2024-01-13Bushed Pin Coupling Size Calculation

- 2024-01-13Bushed Pin Coupling Sales

- 2024-01-13Bushed Pin Coupling Purpose

- 2024-01-13Bushed Pin Coupling Procurement

- 2024-01-13Bushed Pin Coupling Price

- 2024-01-13Bushed Pin Coupling Model

- 2024-01-05Bushed Pin Coupling Misalignment Tolerance

- 2024-01-05Bushed Pin Coupling Material

- 2024-01-05Bushed Pin Coupling Manufacturing

- 2024-01-05Bushed Pin Coupling Lubrication

- 2024-01-05Bushed Pin Coupling Installation

- 2024-01-05Bushed Pin Coupling Grease

- 2024-01-05Bushed Pin Coupling Gap Chart

- 2024-01-05Bushed Pin Coupling Function

- 2024-01-05Bushed Pin Coupling Exploded View

- 2024-01-05Bushed Pin Coupling Engineering Drawing

- 2024-01-05Bushed Pin Coupling Drawing

- 2024-01-05Bushed Pin Coupling Design

- 2024-01-05Bushed Pin Coupling Catalogue

- 2024-01-05Bushed Pin Coupling Calculation

- 2024-01-05Bushed Pin Coupling Brands

- 2024-01-05Bushed Pin Coupling Assembly Drawing

- 2024-01-05Bushed Pin Coupling Applications

- 2024-01-05Bushed Pin Coupling Advantages

- 2024-01-05Bushed Pin Coupling 3D Model

- 2024-01-05Alignment of Bushed Pin Coupling

- 2023-11-28Purpose of Flexible Pin Couplings

- 2023-11-28Models of Flexible Pin Couplings

- 2023-11-28Flexible Pin Couplings For Sale

- 2023-11-28Flexible Pin Coupling Working Principle

- 2023-11-28Flexible Pin Coupling Make

- 2023-11-16Flexible Pin Coupling Specifications

- 2023-11-16Flexible Pin Coupling Price

- 2023-11-10Flexible Pin Couplings Supply

- 2023-11-10Flexible Pin Coupling Parts

- 2023-11-10Flexible Pin Coupling Size Calculation

- 2023-11-09Flexible Pin Couplings Supplier

- 2023-11-09Disadvantages of Flexible Pin Couplings

- 2023-11-09Flexible Pin Coupling Size Chart

- 2023-11-08Flexible Pin Coupling Diagram

- 2023-11-08Flexible Pin Couplings Factory

- 2023-11-08Flexible Pin Couplings Wholesale

- 2023-11-08Flexible Pin Coupling Manufacturing Enterprise

- 2023-11-08Flexible Pin Coupling Function

- 2023-11-08Applications of Flexible Pin Couplings

- 2023-11-08Catalogue of Flexible Pin Couplings

- 2023-11-08Flexible Pin Coupling Advantages

- 2023-11-08Flexible Pin Coupling Drawing

- 2023-11-08Flexible Pin Couplings Company

- 2023-11-08Flexible Pin Coupling Design

- 2023-11-08Customized Flexible Pin Coupling

- 2023-11-08Types of Flexible Pin Couplings

- 2023-11-08Flexible Pin Couplings Manufacturer

- 2023-10-24Nylon Rod Pin Couplings Make

- 2023-10-24Nylon Rod Pin Coupling Usage

- 2023-10-24Nylon Elastic Pin Couplings Wholesale

- 2023-10-24Nylon Rod Pin Coupling Supplier

- 2023-10-24Nylon Rod Pin Coupling Specification

- 2023-10-24Nylon Rod Pin Coupling Processing

- 2023-10-24Nylon Rod Pin Coupling Price

- 2023-10-24Nylon Rod Pin Coupling Model

- 2023-10-24Nylon Rod Pin Coupling For Sale

- 2023-10-24Nylon Rod Pin Coupling Drawing

- 2023-10-24Nylon Rod Pin Coupling Design

- 2023-10-24Nylon Rod Pin Coupling Company

- 2023-10-24Nylon Rod Pin Coupling Characteristics

- 2023-10-24Nylon Rod Pin Coupling Advantages

- 2023-10-24Roots Blower Column Pin Coupling

- 2023-10-24Nylon Rod Gear Pin Coupling

- 2023-10-24Nylon Rod Toothed Pin Coupling

- 2023-10-24Nylon Rod Pin Coupling

- 2023-10-24Nylon Rod Flexible Pin Coupling

- 2023-10-24Nylon Rod Elastic Pin Coupling

- 2023-10-24Nylon Elastic Pin Coupling

- 2023-10-24Nylon Elastic Column Pin Coupling Manufacturer

- 2023-10-24Mill Pin Couplings

- 2023-10-24Internal Toothed Elastic Pin Coupling

- 2023-10-24Inner Hexagonal Elastic Pin Coupling

- 2023-10-24Inner & Outer Gear Ring Column Pin Coupling

- 2023-10-24Friction Elastic Pin Coupling

- 2023-10-24Flexible Sleeve Pin Coupling

- 2023-10-24Flexible Pin Coupling

- 2023-10-24Embedded Pin Coupling

- 2023-10-24Custom Nylon Rod Pin Coupling

- 2023-10-24Coal Mill Pin Coupling Design

- 2023-10-24Coal Mill Pin Coupling

- 2023-10-24Bolt Pin Coupling

- 2023-10-24Water Pump Rubber Pin Coupling

- 2023-10-24Water Pump Pin Couplings Wholesale

- 2023-10-24Water Pump Pin Coupling Price

- 2023-10-24Water Pump Pin Coupling Model

- 2023-10-24Water Pump Pin Coupling Manufacturer

- 2023-10-24Water Pump Pin Coupling Factory

- 2023-10-24Water Pump Pin Coupling Drawing

- 2023-10-24Water Pump Pin Coupling Design

- 2023-10-24Water Pump Pin Coupling Company

- 2023-10-24Water Pump Pin Coupling

- 2023-10-24Water Pump Factory Pin Coupling

- 2023-10-24Water Pump Elastic Sleeve Pin Coupling

- 2023-10-24Water Pump Elastic Pin Couplings Wholesale

- 2023-10-24Water Pump Elastic Pin Coupling Price

- 2023-10-24Water Pump Elastic Pin Coupling Model

- 2023-10-24Water Pump Elastic Pin Coupling Factory

- 2023-10-24Water Pump Elastic Pin Coupling Drawing

- 2023-10-24Water Pump Elastic Pin Coupling Design

- 2023-10-24Water Pump Elastic Pin Coupling Company

- 2023-10-24Water Pump Elastic Pin Coupling

- 2023-10-24Water Pump Column Pin Coupling Specification

- 2023-10-24Water Pump Column Pin Coupling Sales

- 2023-10-24Water Pump Column Pin Coupling Function

- 2023-10-24Water Pump Column Pin Coupling Dimensions

- 2023-10-24Tower Crane Column Pin Coupling

- 2023-10-24Snake Shaped Elastic Pin Coupling

- 2023-10-24Sleeve Type Pin Coupling

- 2023-10-24Sleeve Pin Coupling

- 2023-10-24Serpentine Pin Coupling

- 2023-10-24Rubber Gasket For Water Pump Pin Coupling

- 2023-10-24Plastic Pin Coupling

- 2023-10-24Pin Couplings For Harvesters

- 2023-10-24Nylon Column Pin Coupling For Tower Crane

- 2023-10-24Customized Water Pump Pin Coupling

- 2023-10-24Cross Pin Coupling Drawing

- 2023-10-24Cross Pin Coupling

- 2023-10-24Cheap Water Pump Pin Coupling

- 2023-10-24Brake Wheel Column Pin Couplings Company

- 2023-10-24Brake Wheel Column Pin Couplings Customized

- 2023-10-24Brake Wheel Column Pin Couplings Factory

- 2023-10-24Elastic Nylon Pin Couplings Supplier

- 2023-10-24Elastic Pin Couplings With Brake Wheel

- 2023-10-24Elastic Ring Pin Couplings Company

- 2023-10-24Elastic Ring Pin Couplings Manufacturer

- 2023-10-24Elastic Ring Pin Couplings Drawing

- 2023-10-24Elastic Ring Pin Couplings Manufacturing

- 2023-10-24Elastic Ring Pin Couplings Model

- 2023-10-24Elastic Ring Pin Couplings Parameters

- 2023-10-24Elastic Ring Pin Couplings Processing

- 2023-10-24Elastic Shell Pin Couplings

- 2023-10-24Elastic Sleeve Nylon Pin Couplings

- 2023-10-24Elastic Sleeve Pin Couplings Design

- 2023-10-24Elastic Sleeve Pin Couplings With Brake Wheel

- 2023-10-24Elastic Steel Core Pin Couplings

- 2023-10-24Elastic Toothed Pin Couplings

- 2023-10-24Elastic Washer Pin Couplings

- 2023-10-24Holding Brake Wheel Column Pin Couplings

- 2023-10-24Nylon Column Pin Couplings With Brake

- 2023-10-24Outer Sleeve Pin Couplings

- 2023-10-24Rubber Sleeve Column Pin Couplings

- 2023-10-24Spring Pin Couplings

- 2023-10-24Spring Pin Couplings Price

- 2023-10-24Spring Sleeve Pin Couplings

- 2023-10-24Spring Sleeve Pin Couplings Design

- 2023-10-24Suction Fan Column Pin Coupling

- 2023-10-24Small Pin Coupling

- 2023-10-24Rubber Ring Pin Coupling

- 2023-10-24Rubber Pin Couplings Design

- 2023-10-24Rubber Pin Coupling Company

- 2023-10-24Rubber Pin Coupling

- 2023-10-24Rubber Metal Pin Coupling

- 2023-10-24Rubber Elastic Ring Pin Coupling

- 2023-10-24Rubber Elastic Pin Coupling

- 2023-10-24Rubber Elastic Column Pin Coupling Company

- 2023-10-24Rubber Column Pin Coupling Manufacturer

- 2023-10-24Retractable Taper Sleeve Pin Coupling

- 2023-10-24Outer Hexagonal Pin Coupling

- 2023-10-24Milling Machine Main Motor Pin Coupling

- 2023-10-24Leveling Machine Elastic Pin Coupling

- 2023-10-24Keyless Pin Coupling Manufacturer

- 2023-10-24Keyless Pin Coupling

- 2023-10-24Horizontal Mixed Flow Column Pin Coupling

- 2023-10-24Flange Pin Coupling

- 2023-10-24External Electric Roller Pin Coupling

- 2023-10-24Elastic Pin Couplings For Helical Gears

- 2023-10-24Tapered Pin Coupling

- 2023-10-24Tapered Hole Elastic Pin Coupling

- 2023-10-24Professional Pin Coupling

- 2023-10-24Professional Elastic Pin Couplings Wholesale

- 2023-10-24Professional Elastic Pin Couplings Price

- 2023-10-24Professional Elastic Pin Coupling Company

- 2023-10-24Professional Elastic Pin Coupling

- 2023-10-24Conical Sleeve Type Pin Coupling

- 2023-10-24Conical Elastic Pin Coupling

- 2023-10-24Cone Sleeve Pin Coupling

- 2023-10-24Cast Steel Pin Couplings Design

- 2023-10-24Cast Steel Elastic Pin Coupling

- 2023-10-24Cast Steel Column Pin Coupling

- 2023-10-24Cast Iron Elastic Pin Coupling Manufacturer

- 2023-10-24Cast Iron Elastic Pin Coupling Design

- 2023-10-24Cast Iron Elastic Pin Coupling

- 2023-10-24Standard For Gear Column Pin Couplings

- 2023-10-24Model Of Elastic Sleeve Pin Coupling For Pumps

- 2023-10-24Specification Of Elastic Sleeve Pin Coupling For Pumps

- 2023-10-24Standard Elastic Pin Coupling Aperture

- 2023-10-24Standard For Gear Pin Couplings

- 2023-10-24Gear Pin Coupling Parameters

- 2023-10-24Model Of Elastic Pin Coupling For Pumps

- 2023-10-24Gear Elastic Pin Coupling

- 2023-10-24Force Analysis Of Gear Pin Coupling

- 2023-10-24Gear Pin Coupling Drawing

- 2023-10-24Assembly Method Of Gear Column Pin Coupling

- 2023-10-24Alignment Standards For Gear Pin Couplings

- 2023-10-24Vibrating Screen Column Pin Couplings

- 2023-10-24Tooth Embedded Pin Couplings

- 2023-10-24Presser Pin Couplings

- 2023-10-24Long Shaft Elastic Sleeve Pin Couplings

- 2023-10-24Keyway Elastic Pin Couplings

- 2023-10-24Intermediate Shaft Elastic Pin Couplings

- 2023-10-24Induced Draft Fan Nylon Pin Couplings

- 2023-10-24Hydraulic Quick Release Nylon Pin Couplings

- 2023-10-24Brake Wheel Elastic Pin Couplings Design

- 2023-10-24Circulating Pump Column Pin Couplings

- 2023-10-24Brake Wheel Type Rigid Pin Couplings

- 2023-10-24Brake Wheel Elastic Pin Couplings Price

- 2023-10-24Brake Wheel Elastic Pin Couplings For Sale

- 2023-10-24Brake Wheel Elastic Pin Couplings Company

- 2023-10-24Brake Wheel Column Pin Couplings Specification

- 2023-10-24Brake Wheel Column Pin Couplings Price

- 2023-10-24Brake Wheel Column Pin Couplings Model

- 2023-10-24Brake Wheel Column Pin Couplings Make

- 2023-10-20Sleeve And Shear Pin Coupling

- 2023-10-20Shear Pin Coupling

- 2023-10-19Bushed Pin Couplings

- 2023-10-18Standard Pin Coupling Parameters

- 2023-10-18Standard Pin Coupling Material

- 2023-10-17Elastic Ring Pin Couplings Design

- 2023-10-17Elastic Tooth Type Column Pin Couplings Drawing

- 2023-10-17Slurry Pump Column Pin Couplings

- 2023-10-17Oil Pump Pin Couplings

- 2023-10-17Brake Wheel Elastic Sleeve Pin Couplings

- 2023-10-17Cylindrical Hole Elastic Pin Couplings

- 2023-10-17High Quality Pin Couplings

- 2023-10-17Hydraulic Elastic Pin Couplings

- 2023-10-17Cylindrical Ring Elastic Pin Couplings

- 2023-10-17Expansion Sleeve Type Elastic Pin Couplings

- 2023-10-17Expansion Sleeve Pin Couplings

- 2023-10-17Compression Block Pin Couplings

- 2023-10-17Brake Wheel Nylon Pin Couplings

- 2023-10-17Brake Wheel Elastic Pin Couplings Factory

- 2023-10-17Brake Wheel Column Pin Couplings Supply

- 2023-10-17Brake Wheel Column Pin Couplings Design

- 2023-10-13Hydraulic Column Pin Couplings

- 2023-10-13Intermediate Shaft Pin Couplings

- 2023-10-13Expansion Sleeve Type Pin Couplings

- 2023-10-13Cylindrical Pin Couplings

- 2023-10-13Circular Pin Couplings

- 2023-10-13Brake Wheel Elastic Pin Couplings

- 2023-10-13Brake Wheel Column Pin Couplings

- 2023-10-13Brake Disc Elastic Pin Couplings

- 2023-10-13Spring Coil Pin Couplings

- 2023-10-13Elastic Sleeve Pin Couplings For Sale

- 2023-10-13Elastic Spherical Pin Couplings

- 2023-10-12Elastic Rubber Ring Pin Couplings

- 2023-10-12Elastic Ring Sleeve Pin Couplings

- 2023-10-12Elastic Pad Pin Couplings

- 2023-10-12Elastic Pin Couplings With Rubber Ring

- 2023-10-12Elastic Ring Pin Couplings

- 2023-10-12Elastic Plate Pin Couplings

- 2023-10-12Elastic Pin Couplings With Brake Disc

- 2023-10-12Elastic Nylon Pin Couplings

- 2023-10-12Driving Wheel Column Pin Couplings

- 2023-10-12Brake Wheel Column Pin Couplings Manufacturer

- 2023-10-12Column Pin Couplings With Disc Brake

- 2023-10-12Column Pin Couplings With Brake Elastic Sleeve

- 2023-10-12Brake Nylon Pin Couplings

- 2023-10-12Brake Elastic Column Pin Couplings

- 2023-10-11Gear Pin Coupling Price

- 2023-10-11Sand Pump Column Pin Couplings

- 2023-10-11Large Elastic Pin Couplings

- 2023-10-11Gear Column Pin Coupling Manufacturer

- 2023-10-11Stainless Steel High Torque Column Pin Couplings

- 2023-10-11Stainless Steel Elastic Pin Couplings

- 2023-10-11Gear Pin Coupling Specification

- 2023-10-10Diaphragm Pin Couplings

- 2023-10-09Rod Type Pin Coupling

- 2023-10-09Pump Column Pin Coupling

- 2023-10-09Elastic Sleeve Pin Coupling For Pumps

- 2023-10-09Gear Type Elastic Pin Coupling

- 2023-10-09Elastic Pin Couplings For Pumps

- 2023-10-08Gear Column Pin Coupling

- 2023-10-08Gear Pin Coupling Company

- 2023-10-08Diesel Engine Elastic Pin Coupling

- 2023-10-08Gear Nylon Pin Coupling

- 2023-10-08Large Fan Column Pin Coupling

- 2023-10-08Marine Pin Couplings

- 2023-10-08Pump Pin Coupling

- 2023-10-08Safety Pin Coupling

- 2023-10-08Standard Elastic Pin Couplings

- 2023-10-08Wholesale Of Gear Pin Couplings

- 2023-10-08High Torque Elastic Pin Coupling

- 2023-10-07Elastic Gear Shaft Pin Coupling

- 2023-09-22Toothed Safety Pin Coupling

- 2023-09-22Toothed Rod Pin Coupling

- 2023-09-22Supply Of Gear Pin Couplings

- 2023-09-19Toothed Elastic Pin Coupling