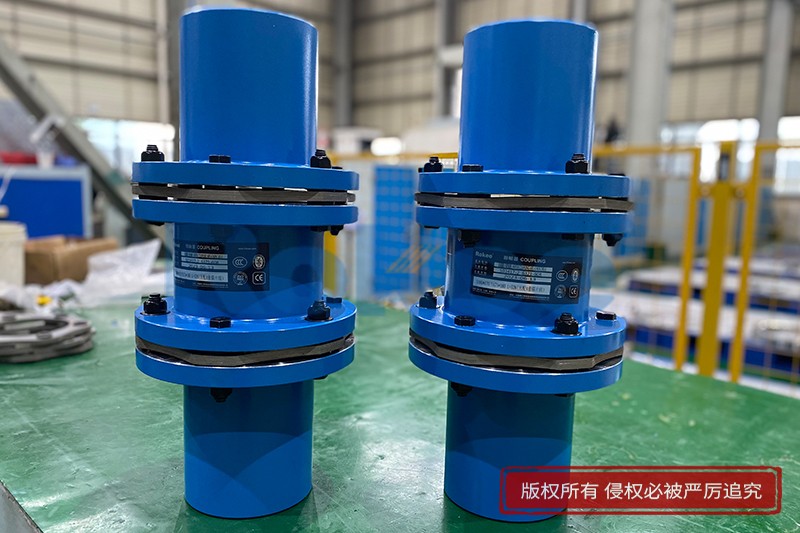

Double Diaphragm Couplings

Rokee® is Double Diaphragm Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Double Diaphragm Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Double Diaphragm Coupling uses metal diaphragm as elastic element, which has good strength and large load transmission capacity, and there are no non-metallic parts in the whole product, no aging problem, good service life, and suitable for harsh use environments. This is for non-metal elastic element couplings.

-

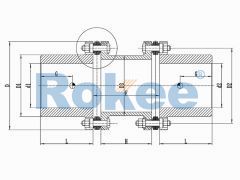

JMIJ Diaphragm Coupling

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end. -

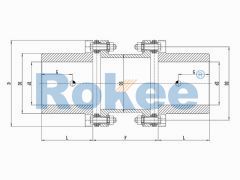

JMIIJ Diaphragm Coupling

JMIIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore. -

RLMD Small Double Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm. -

RLAD Standard Double Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications. -

RLARD Double Shaft Sleeve Reverse-mounting Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.

In the realm of mechanical transmission systems, couplings serve as critical components that connect two shafts to transmit torque while accommodating various forms of misalignment. Among the diverse types of couplings available, double diaphragm couplings have emerged as a preferred choice in numerous industrial applications due to their unique combination of high torque capacity, precision, and reliability. Unlike rigid couplings that demand near-perfect alignment, or flexible couplings that rely on elastomeric elements prone to wear, double diaphragm couplings leverage the elastic deformation of thin metallic diaphragms to achieve torque transmission and misalignment compensation.

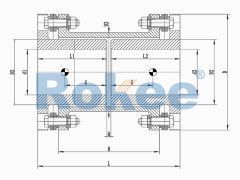

To understand the functionality of double diaphragm couplings, it is essential to first grasp their basic operating principle. At its core, a double diaphragm coupling consists of two sets of diaphragms (usually circular or annular) attached to the input and output hubs, respectively, with a central spacer connecting the two diaphragm assemblies. When torque is applied to the input shaft, the torque is transferred through the input hub to the first set of diaphragms. The diaphragms, which are designed to be thin and flexible yet rigid in the axial direction, undergo elastic deformation to accommodate any misalignment between the input and output shafts. This deformed state allows the torque to be transmitted through the central spacer to the second set of diaphragms, and ultimately to the output shaft. The key distinction between double diaphragm couplings and their single-diaphragm counterparts lies in the presence of two diaphragm assemblies, which enables them to compensate for a wider range of misalignments, including angular, parallel, and axial misalignment, without imposing excessive stress on the connected shafts or bearings.

The structural design of double diaphragm couplings is a critical factor that determines their performance and versatility. The primary components of a typical double diaphragm coupling include hubs, diaphragms, a central spacer, and fasteners. Hubs are typically machined from high-strength materials such as alloy steel or stainless steel to ensure they can withstand the transmitted torque and maintain a secure connection with the shafts. The design of the hubs may vary depending on the application, with options such as keyway connections, taper-lock bushings, or interference fits to accommodate different shaft mounting requirements. Diaphragms, the most distinctive component of these couplings, are usually made from thin sheets of high-performance metallic materials, such as stainless steel (304, 316) or titanium alloys. The choice of material for diaphragms is governed by factors such as the required torque capacity, operating temperature, and environmental conditions. Stainless steel is the most common choice due to its excellent corrosion resistance and fatigue strength, while titanium alloys are used in high-temperature or high-performance applications where weight reduction is also a priority.

The geometry of the diaphragms is another crucial design aspect. Diaphragms are often designed with a series of radial slots or a wavy profile to enhance their flexibility while maintaining sufficient torsional rigidity. The slot design allows the diaphragms to deform more easily under misalignment, reducing the stress concentration and extending the service life of the coupling. The central spacer, which connects the two diaphragm assemblies, can be either rigid or flexible, depending on the application requirements. Rigid spacers are used in applications where precise alignment is maintained, while flexible spacers (often made from composite materials) are employed to further enhance the coupling's ability to absorb vibration and compensate for misalignment. Fasteners, such as bolts or rivets, are used to attach the diaphragms to the hubs and spacer. These fasteners must be made from high-strength materials to ensure a secure connection, and they are often torqued to specific values to prevent loosening during operation.

One of the most significant advantages of double diaphragm couplings is their ability to compensate for multiple types of misalignment without introducing excessive reaction forces. Angular misalignment, which occurs when the axes of the two shafts intersect at an angle, is compensated by the bending deformation of the diaphragms. Parallel misalignment, where the shafts are offset parallel to each other, is accommodated by the combination of bending and shear deformation of the diaphragms and the lateral movement of the central spacer. Axial misalignment, caused by thermal expansion or contraction of the shafts, is absorbed by the axial flexibility of the diaphragms. Compared to other flexible couplings, such as jaw couplings or sleeve couplings, double diaphragm couplings can handle larger misalignment angles (typically up to 3 degrees for angular misalignment) with minimal stress, reducing wear and tear on the connected bearings and extending the overall service life of the transmission system.

Another key advantage of double diaphragm couplings is their high torque transmission capacity relative to their size. Due to the use of high-strength metallic diaphragms and hubs, these couplings can transmit significant amounts of torque without the need for large, bulky designs. This compactness makes them ideal for applications where space is limited, such as in automotive transmissions, aerospace systems, and industrial gearboxes. Additionally, double diaphragm couplings operate with minimal backlash, which is critical in precision applications where accurate positioning and torque control are essential. Backlash, the clearance between mating components, can lead to inaccuracies in motion control and increased wear; the rigid design of double diaphragm couplings eliminates this issue by maintaining a tight connection between the shafts.

Double diaphragm couplings also offer excellent resistance to harsh operating conditions, including high temperatures, corrosive environments, and high-speed operation. Unlike elastomeric couplings, which can degrade at high temperatures or in the presence of chemicals, metallic diaphragms are resistant to thermal aging and chemical corrosion, making them suitable for use in applications such as internal combustion engines, gas turbines, and chemical processing equipment. In high-speed applications, such as centrifugal pumps or turbomachinery, double diaphragm couplings maintain their balance and stability, reducing vibration and noise. The absence of moving parts (other than the elastic deformation of the diaphragms) also means that these couplings require minimal maintenance, reducing downtime and operational costs for industrial users.

The versatility of double diaphragm couplings is reflected in their wide range of applications across various industries. In the automotive industry, they are used in transmissions, drive shafts, and powertrain systems, where they transmit torque between the engine and the wheels while accommodating misalignment caused by vehicle movement or thermal expansion. In the aerospace sector, double diaphragm couplings are employed in aircraft engines, auxiliary power units (APUs), and flight control systems, where their high reliability, compact size, and resistance to extreme temperatures are critical. The precision and low backlash of these couplings also make them suitable for use in aerospace testing equipment, such as dynamometers and torque sensors.

In industrial manufacturing, double diaphragm couplings are used in a variety of equipment, including industrial robots, machine tools, and conveyor systems. Industrial robots require precise motion control and torque transmission, and the low backlash and high rigidity of double diaphragm couplings ensure accurate positioning and smooth operation. Machine tools, such as lathes, milling machines, and grinders, rely on couplings to transmit torque from the motor to the spindle; double diaphragm couplings provide the precision and stability needed to maintain tight tolerances in machined parts. Conveyor systems, which operate in harsh industrial environments, benefit from the corrosion resistance and low maintenance requirements of these couplings, ensuring reliable operation even in dusty or humid conditions.

The energy sector is another major user of double diaphragm couplings, with applications in power generation equipment such as steam turbines, gas turbines, and wind turbines. In steam and gas turbines, couplings transmit torque from the turbine to the generator, operating at high temperatures and speeds; double diaphragm couplings can withstand these harsh conditions while accommodating misalignment caused by thermal expansion. Wind turbines, which are exposed to variable wind loads and environmental conditions, rely on couplings to transmit torque from the rotor to the gearbox or generator; the flexibility and reliability of double diaphragm couplings ensure consistent performance even in turbulent wind conditions. Additionally, in the oil and gas industry, these couplings are used in drilling equipment, pumps, and compressors, where their resistance to corrosion and high pressure makes them ideal for offshore and onshore applications.

When selecting a double diaphragm coupling for a specific application, several key factors must be considered to ensure optimal performance and reliability. First, the torque capacity of the coupling must match or exceed the maximum torque generated by the system. Undersized couplings can lead to premature failure, while oversized couplings may be unnecessarily expensive and bulky. It is also important to consider the maximum speed of the application, as high-speed operation can lead to centrifugal forces that affect the balance and stability of the coupling. Couplings designed for high-speed applications must be dynamically balanced to reduce vibration and ensure smooth operation.

Misalignment requirements are another critical consideration. The coupling must be capable of accommodating the maximum angular, parallel, and axial misalignment expected in the application. This requires a thorough understanding of the system's operating conditions, including thermal expansion coefficients of the shafts and the mounting configuration. The operating temperature range of the application must also be taken into account when selecting the diaphragm material. For high-temperature applications, titanium alloys or high-temperature stainless steels are preferred, while standard stainless steel is suitable for moderate temperature ranges. Environmental conditions, such as the presence of corrosive chemicals, moisture, or dust, should also be considered to ensure the coupling materials are resistant to degradation.

Shaft size and mounting configuration are additional factors that influence coupling selection. The coupling hubs must be compatible with the diameter of the input and output shafts, and the mounting method (keyway, taper-lock, interference fit) must be suitable for the shaft design. The overall length and diameter of the coupling must also fit within the available space in the system. Finally, maintenance requirements and operational costs should be considered. While double diaphragm couplings require minimal maintenance, it is important to select a coupling that is easy to install and inspect, reducing downtime in the event of maintenance or replacement.

Despite their numerous advantages, double diaphragm couplings are not suitable for all applications. They are generally more expensive than elastomeric couplings, making them less ideal for low-cost, low-torque applications where precision is not a priority. Additionally, while they can accommodate significant misalignment, they are not designed for excessive misalignment beyond their specified limits, which can lead to diaphragm fatigue and failure. In applications where significant shock loads are present, such as in heavy-duty mining equipment, double diaphragm couplings may not be the best choice, as the metallic diaphragms are less effective at absorbing shock than elastomeric elements.

In conclusion, double diaphragm couplings are a versatile and reliable type of coupling that plays a critical role in modern mechanical transmission systems. Their unique design, which leverages the elastic deformation of metallic diaphragms, enables them to transmit torque efficiently while accommodating multiple types of misalignment, with minimal backlash and high torque capacity. Their resistance to harsh operating conditions, low maintenance requirements, and compact size make them suitable for a wide range of applications across industries such as automotive, aerospace, industrial manufacturing, and energy. When selecting a double diaphragm coupling, it is essential to consider factors such as torque capacity, speed, misalignment requirements, operating temperature, and environmental conditions to ensure optimal performance. As industrial technology continues to advance, the demand for high-precision, reliable transmission components is expected to grow, and double diaphragm couplings are likely to remain a key component in meeting these evolving needs. Their ability to balance precision, reliability, and versatility makes them an indispensable part of modern mechanical systems, contributing to improved efficiency, reduced downtime, and enhanced performance across a wide range of applications.

« Double Diaphragm Couplings » Post Date: 2023/9/1

URL: https://www.rokeecoupling.com/en/tags/double-diaphragm-couplings.html

- 2024-05-05Lubrication of Double Diaphragm Coupling

- 2024-05-05Installation of Double Diaphragm Coupling

- 2024-05-05Custom Double Diaphragm Couplings

- 2024-05-05Disadvantages of Double Diaphragm Coupling

- 2024-05-05Double Diaphragm Coupling Advantages

- 2024-05-05Double Diaphragm Coupling Assembly Drawing

- 2024-05-05Double Diaphragm Coupling Calculation

- 2024-05-05Double Diaphragm Coupling Design

- 2024-05-05Double Diaphragm Coupling Drawing

- 2024-05-05Double Diaphragm Coupling Models

- 2024-05-05Double Diaphragm Coupling Picture

- 2024-05-05Double Diaphragm Coupling Price

- 2024-05-05Double Diaphragm Coupling Sales

- 2024-05-05Double Diaphragm Coupling Standard Sizes

- 2024-05-05Double Diaphragm Couplings Company

- 2024-05-05Double Diaphragm Couplings For Sale

- 2024-05-05Double Diaphragm Couplings Supplier

- 2024-05-05Double Diaphragm Couplings Wholesale

- 2024-05-05Efficiency of Double Diaphragm Coupling

- 2024-05-05Engineering Drawing of Double Diaphragm Couplings

- 2024-05-05Exploded View of Double Diaphragm Couplings

- 2024-05-05Gap Chart of Double Diaphragm Coupling

- 2024-05-05Grease of Double Diaphragm Coupling

- 2024-04-02Procurement of Double Diaphragm Coupling

- 2024-04-02Purpose of Double Diaphragm Coupling

- 2024-04-02Size Calculation of Double Diaphragm Coupling

- 2024-04-02Size Chart of Double Diaphragm Couplings

- 2024-04-02Specifications of Double Diaphragm Coupling

- 2024-04-02Structural Diagram of Double Diaphragm Couplings

- 2024-04-02Tagging of Double Diaphragm Coupling

- 2024-04-02Torque of Double Diaphragm Coupling

- 2024-03-19Coaxiality of Double Diaphragm Coupling

- 2024-03-19Classification of Double Diaphragm Couplings

- 2024-03-19Catalogue of Double Diaphragm Couplings

- 2024-03-19Application of Double Diaphragm Coupling

- 2024-03-19Angle of Double Diaphragm Coupling

- 2024-03-19Alignment of Double Diaphragm Coupling

- 2024-03-04Types of Double Diaphragm Coupling

- 2024-03-04High Performance Double Diaphragm Couplings

- 2024-03-04Parts of Double Diaphragm Coupling

- 2024-03-04Misalignment Tolerance of Double Diaphragm Coupling

- 2024-03-04Material of Double Diaphragm Coupling

- 2024-03-04Maintenance of Double Diaphragm Coupling

- 2024-03-04Uses of Double Diaphragm Coupling

- 2024-03-04Working Principle of Double Diaphragm Coupling

- 2024-03-02High Quality Double Diaphragm Couplings

- 2024-01-17Supply of Double Diaphragm Couplings

- 2024-01-17Schematic Diagram of Double Diaphragm Couplings

- 2024-01-17Machine Drawing of Double Diaphragm Couplings

- 2024-01-17Function of Double Diaphragm Couplings

- 2024-01-17Double Diaphragm Coupling Brands

- 2024-01-17Double Diaphragm Couplings Factory

- 2024-01-173D Model of Double Diaphragm Coupling

- 2024-01-17Components of Double Diaphragm Coupling

- 2024-01-17Double Diaphragm Coupling Manufacturing

- 2023-10-28Short Type Double Diaphragm Coupling Model

- 2023-10-28Short Shaft Double Diaphragm Coupling

- 2023-10-28Short Double Diaphragm Coupling Function

- 2023-10-28Short Double Diaphragm Coupling Price

- 2023-10-28Double Diaphragm Coupling Supply

- 2023-10-18Long Span Double Diaphragm Coupling

- 2023-10-18Double Diaphragm Couplings Types

- 2023-10-18Short Double Diaphragm Coupling

- 2023-10-17Double Diaphragm Coupling Angle Deviation

- 2023-10-17Double Diaphragm Coupling Accuracy

- 2023-10-17Double Diaphragm Coupling Coaxiality

- 2023-10-17Double Diaphragm Coupling Sectional View

- 2023-10-17Double Diaphragm Couplings Instructions

- 2023-10-17Expansion Double Diaphragm Coupling

- 2023-10-17Stepped Double Diaphragm Coupling

- 2023-10-17Heavy Duty Double Diaphragm Coupling

- 2023-10-12Step Double Diaphragm Couplings

- 2023-10-12Double Diaphragm Coupling Specification

- 2023-10-09Flange Type Double Diaphragm Coupling

- 2023-10-08Wholesale Of Double Diaphragm Couplings

- 2023-10-08Characteristics Of Double Diaphragm Couplings

- 2023-10-08Double Diaphragm Coupling Distributor

- 2023-10-08Double Diaphragm Coupling Enterprise

- 2023-10-08Double Diaphragm Coupling Type

- 2023-10-08Double Diaphragm Coupling Manufacturer

- 2023-10-07Stiffness Of Double Diaphragm Coupling

- 2023-10-07Durable Double Diaphragm Coupling

- 2023-09-27Double Diaphragm Coupling Supplier

- 2023-09-27Double Diaphragm Coupling For Sale

- 2023-09-27Corrosion Resistant Double Diaphragm Coupling

- 2023-09-27Ball Mill Double Diaphragm Coupling

- 2023-09-26Customized Double Diaphragm Coupling

- 2023-09-26Flexible Double Diaphragm Coupling

- 2023-09-26Extended Double Diaphragm Coupling

- 2023-09-26Metal Double Diaphragm Coupling

- 2023-09-26Double Diaphragm Couplings For Machine Tools

- 2023-09-26Circular Double Diaphragm Coupling

- 2023-09-25Fan Double Diaphragm Coupling

- 2023-09-25Flange Double Diaphragm Coupling

- 2023-09-22Chain Double Diaphragm Coupling

- 2023-09-21High Quality Double Diaphragm Coupling

- 2023-09-21Drawing Of Double Diaphragm Coupling

- 2023-09-21Double Diaphragm Coupling Intermediate Gasket

- 2023-09-21Correction Of Double Diaphragm Coupling

- 2023-09-21Conical Sleeve Type Double Diaphragm Coupling

- 2023-09-14Specification Of Elastic Double Diaphragm Coupling

- 2023-09-13Double Diaphragm Coupling With Extension Joint

- 2023-09-13Alignment Of Double Diaphragm Couplings For Large Fans

- 2023-09-06Function Of Elastic Double Diaphragm Coupling

- 2023-08-31High Torque Double Diaphragm Coupling

- 2023-08-31Characteristics Of Transmission Double Diaphragm Couplings

- 2023-08-31Transmission Double Diaphragm Coupling

- 2023-08-24Model Of Elastic Double Diaphragm Coupling

- 2023-08-24Specification And Model Of Elastic Double Diaphragm Coupling

- 2023-08-24Structural Diagram Of Elastic Double Diaphragm Coupling

- 2023-08-24Elastic Double Diaphragm Coupling