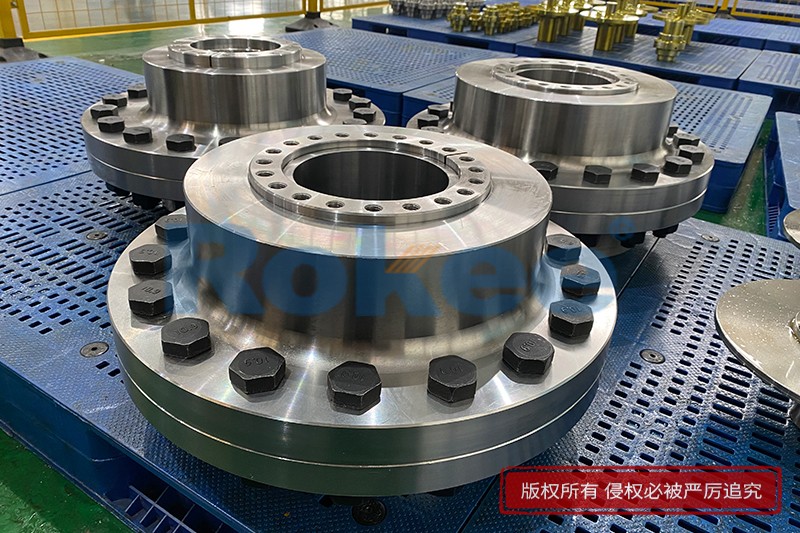

Expansion Couplings

Rokee® provide Expansion Couplings, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission systems, the efficient and reliable transfer of torque between rotating shafts is a fundamental requirement across countless industries. Among the various components designed to facilitate this critical function, expansion couplings stand out as versatile and indispensable devices. Unlike rigid couplings that demand precise alignment and offer no flexibility, expansion couplings are engineered to accommodate misalignments, absorb shocks and vibrations, and compensate for thermal expansion and contraction—factors that would otherwise lead to premature wear, reduced efficiency, or catastrophic failure of machinery.

1. Fundamental Principles of Expansion Couplings

At its essence, an expansion coupling is a mechanical assembly that connects two rotating shafts while allowing relative movement between them. The primary functions that define its design and operation include torque transmission, misalignment compensation, thermal expansion absorption, and vibration damping. To understand how these functions are achieved, it is essential to first examine the mechanical challenges that expansion couplings address.

Rotating shafts in machinery are rarely perfectly aligned, even when installed with meticulous care. Misalignments can occur in three primary forms: angular misalignment, where the shafts intersect at an angle; parallel misalignment, where the shafts are offset but remain parallel; and axial misalignment, where the shafts move toward or away from each other along their central axes. Additionally, thermal expansion and contraction—caused by temperature fluctuations during operation—can lead to axial displacement of shafts. Rigid couplings, which lock shafts into a fixed position, cannot accommodate these movements, resulting in excessive stress on bearings, seals, and the shafts themselves. Over time, this stress leads to increased friction, wear, and eventually, component failure.

Expansion couplings resolve these issues by incorporating flexible or sliding elements that allow controlled relative movement between the connected shafts. These elements transfer torque efficiently while absorbing or compensating for misalignments and axial displacements. The torque transmission capability is determined by the material strength and design of the coupling’s load-bearing components, such as bolts, hubs, and flexible inserts. Meanwhile, the flexibility required for misalignment compensation is achieved through the use of elastic materials, sliding sleeves, or articulated joints. By balancing torque transmission efficiency with flexibility, expansion couplings ensure smooth and reliable operation of rotating machinery even under less-than-ideal conditions.

2. Common Types of Expansion Couplings

Expansion couplings are available in a variety of designs, each tailored to specific application requirements, such as the magnitude of torque, the type and degree of misalignment, operating temperature, and environmental conditions. The following are the most widely used types, each with distinct structural features and performance characteristics.

2.1 Sliding Sleeve Expansion Couplings

Sliding sleeve expansion couplings, also known as slip couplings, are among the simplest and most cost-effective types of expansion couplings. Their design consists of two hubs that are keyed or splined to the respective shafts, and a central sleeve that slides over the hubs. The sleeve is typically secured to one hub with bolts or set screws, while allowing axial movement relative to the other hub. This sliding mechanism enables the coupling to compensate for axial displacement caused by thermal expansion or contraction.

While sliding sleeve couplings excel at accommodating axial misalignment, their ability to handle angular and parallel misalignments is limited. They are best suited for applications with low to moderate torque requirements and minimal angular or parallel misalignment, such as in small pumps, fans, and conveyor systems. One of the key advantages of this type is its simplicity, which makes installation and maintenance straightforward. However, they require regular lubrication of the sliding surfaces to prevent friction, wear, and seizing—especially in high-temperature or high-humidity environments.

2.2 Flexible Jaw Couplings

Flexible jaw couplings are characterized by their two jaw-shaped hubs and a flexible elastomeric insert (often referred to as a spider) that fits between the jaws. The hubs are mounted on the shafts, and the insert transmits torque through the engagement of its lobes with the jaws of the hubs. The elastomeric material—typically rubber, polyurethane, or neoprene—provides the flexibility needed to compensate for angular and parallel misalignments, as well as to absorb shocks and vibrations.

These couplings are widely used in industrial applications due to their compact design, high torque capacity, and excellent vibration damping properties. They can accommodate angular misalignments up to 1.5 degrees and parallel misalignments up to 0.5 mm, making them suitable for a range of machinery, including electric motors, gearboxes, compressors, and pumps. The elastomeric insert is the wear component of the coupling, and its material selection depends on the operating temperature and chemical environment—polyurethane inserts, for example, offer better resistance to oil and abrasion than rubber inserts. Replacement of the insert is relatively easy, allowing for quick maintenance without disassembling the entire coupling or moving the connected shafts.

2.3 Diaphragm Couplings

Diaphragm couplings are a type of rigid-flexible coupling that uses thin, metallic diaphragms to transmit torque and compensate for misalignments. The design consists of two hubs, a central spacer, and one or more diaphragms (typically made of stainless steel) that connect the hubs to the spacer. The diaphragms are designed with a series of slots or corrugations that allow them to flex under misalignment, while maintaining their structural integrity for torque transmission.

One of the key advantages of diaphragm couplings is their ability to handle high torque and high-speed applications without the need for lubrication. Unlike sliding or jaw couplings, they have no moving parts that require lubrication, making them ideal for clean environments, such as food processing, pharmaceutical manufacturing, and aerospace applications. They can accommodate angular misalignments up to 2 degrees and parallel misalignments up to 0.2 mm, as well as axial displacements. Additionally, diaphragm couplings exhibit excellent torsional stiffness, which is critical for applications where precise torque control is required, such as in servo motor systems and precision machining equipment.

2.4 Universal Joint Couplings

Universal joint (U-joint) couplings are designed to handle large angular misalignments, typically up to 30 degrees or more. They consist of two yokes (one mounted on each shaft) and a cross-shaped intermediate component (the spider) that connects the yokes. The spider is fitted with bearings at each of its four ends, allowing the yokes to rotate relative to each other at varying angles.

U-joint couplings are commonly used in applications where shafts are mounted at significant angles, such as in automotive drivetrains, agricultural machinery, and industrial conveyors. However, a single U-joint introduces a degree of speed fluctuation (torsional vibration) when operating at large angles, as the angular velocity of the driven shaft varies slightly with each rotation of the driving shaft. To mitigate this issue, double U-joint couplings (consisting of two U-joints connected by an intermediate shaft) are often used, as the speed fluctuations from the first U-joint are canceled out by the second. Like sliding sleeve couplings, U-joints require regular lubrication of their bearings to ensure smooth operation and prevent premature failure.

3. Key Applications of Expansion Couplings

Expansion couplings are employed in a diverse range of industries and applications, where their ability to accommodate misalignments, absorb vibrations, and compensate for thermal expansion is critical. The following sections highlight some of the most prominent application areas and the specific roles that expansion couplings play in each.

3.1 Industrial Machinery and Manufacturing

In industrial manufacturing facilities, expansion couplings are integral components in a wide array of machinery, including pumps, compressors, fans, conveyors, and machine tools. For example, in centrifugal pumps, which are used to move liquids in chemical processing, water treatment, and oil and gas industries, flexible jaw couplings or diaphragm couplings are commonly used to connect the pump shaft to the electric motor shaft. These couplings compensate for the slight misalignments that can occur during installation or due to thermal expansion, reducing wear on the pump’s bearings and seals and ensuring efficient fluid transfer.

In machine tools, such as lathes, milling machines, and grinders, precision is paramount. Diaphragm couplings are often preferred in these applications due to their high torsional stiffness and ability to transmit torque with minimal backlash, ensuring accurate positioning and machining of workpieces. Additionally, their lubrication-free design prevents contamination of the machining environment, which is critical for maintaining the quality of precision components.

3.2 Automotive and Transportation

The automotive industry relies heavily on expansion couplings for power transmission in drivetrains. Universal joint couplings, for example, are used to connect the transmission to the driveshaft and the driveshaft to the differential in rear-wheel-drive and four-wheel-drive vehicles. These couplings accommodate the angular misalignments that occur as the suspension moves during vehicle operation, ensuring smooth torque transmission from the engine to the wheels.

In addition to U-joints, flexible couplings are used in automotive accessories, such as water pumps, alternators, and air conditioning compressors. These couplings absorb vibrations from the engine, reducing noise and extending the lifespan of the accessories. In electric vehicles (EVs), where torque delivery is instantaneous and high, diaphragm couplings are increasingly being used due to their high torque capacity, torsional stiffness, and reliability in high-speed applications.

3.3 Energy and Power Generation

In power generation facilities, such as thermal power plants, hydroelectric plants, and wind farms, expansion couplings play a critical role in connecting large rotating equipment, such as turbines, generators, and gearboxes. The high torque and high-speed nature of these applications demand couplings that are both robust and flexible. Diaphragm couplings and flexible disc couplings are commonly used in these settings, as they can handle the large torques generated by turbines while accommodating the slight misalignments that may occur due to thermal expansion or structural movement.

In wind turbines, for example, the rotor shaft is connected to the gearbox (or directly to the generator in direct-drive systems) using expansion couplings. These couplings must withstand the variable torque and vibrations caused by wind gusts, as well as the axial and angular misalignments that occur due to the deflection of the turbine tower. The lubrication-free design of diaphragm couplings is particularly advantageous in wind turbines, as they reduce maintenance requirements in remote and hard-to-access locations.

3.4 Marine and Offshore Applications

Marine environments present unique challenges for mechanical components, including high humidity, saltwater corrosion, and extreme temperature fluctuations. Expansion couplings used in marine applications, such as ship propulsion systems, must be corrosion-resistant and capable of handling large torques and misalignments. Stainless steel diaphragm couplings and bronze sliding sleeve couplings are commonly used in these settings, as they offer excellent corrosion resistance and durability.

In ship propulsion systems, expansion couplings connect the engine to the propeller shaft, accommodating the angular misalignments that occur as the ship rocks and rolls in the water. They also absorb the shocks and vibrations generated by the engine and propeller, reducing wear on the shaft and bearings. Additionally, in offshore oil and gas platforms, expansion couplings are used in pumps, compressors, and drilling equipment, where they must operate reliably in harsh, corrosive conditions.

4. Selection Criteria for Expansion Couplings

Selecting the right expansion coupling for a specific application requires careful consideration of several key factors, as the performance and lifespan of the coupling (and the entire machinery) depend on matching the coupling’s characteristics to the application’s requirements. The following are the most critical selection criteria:

4.1 Torque Capacity

The primary function of an expansion coupling is to transmit torque, so the first step in selection is to determine the maximum torque that the coupling will need to handle. This includes both the nominal operating torque and any peak torques that may occur during startup, shutdown, or transient conditions (such as shock loads). The coupling’s rated torque must be equal to or greater than the maximum torque required by the application to prevent premature failure. It is important to note that some couplings, such as jaw couplings with elastomeric inserts, have a lower torque capacity at high temperatures, as the elastomeric material loses strength when heated.

4.2 Misalignment Requirements

The type and degree of misalignment present in the application will dictate the type of expansion coupling required. For applications with large angular misalignments (greater than 2 degrees), universal joint couplings are the most suitable choice. For moderate angular and parallel misalignments (up to 1.5 degrees and 0.5 mm, respectively), flexible jaw couplings are an excellent option. For applications with minimal misalignments but high precision requirements, diaphragm couplings are preferred due to their high torsional stiffness and low backlash.

4.3 Operating Speed

The operating speed of the rotating shafts is another critical factor, as high-speed applications (such as those in turbines, generators, and EV motors) require couplings with good balance and low centrifugal force. Diaphragm couplings and flexible disc couplings are well-suited for high-speed applications, as their symmetric design ensures smooth operation at high rotational speeds. Sliding sleeve couplings and U-joints, on the other hand, may introduce vibrations at high speeds due to their moving parts, making them less suitable for these applications.

4.4 Operating Temperature and Environment

The operating temperature range of the application will influence the material selection of the coupling. Elastomeric inserts in jaw couplings, for example, have a limited temperature range (typically -30°C to 120°C for rubber and -50°C to 150°C for polyurethane), so they are not suitable for high-temperature applications. In contrast, metallic couplings (such as diaphragm couplings) can operate at temperatures up to 300°C or higher. Additionally, environmental factors such as humidity, corrosion, and exposure to chemicals must be considered. For corrosive environments (such as marine or chemical processing), couplings made of stainless steel, bronze, or other corrosion-resistant materials are essential.

4.5 Maintenance Requirements

The maintenance needs of the coupling should align with the maintenance capabilities of the application. Couplings that require regular lubrication (such as sliding sleeve couplings and U-joints) are not ideal for remote or hard-to-access locations (such as wind turbines or offshore platforms). In contrast, lubrication-free couplings (such as diaphragm couplings) require minimal maintenance, making them suitable for these applications. Additionally, the ease of replacing wear components (such as elastomeric inserts in jaw couplings) should be considered, as this can reduce downtime and maintenance costs.

5. Maintenance Practices for Expansion Couplings

Proper maintenance is essential to ensure the long-term reliability and performance of expansion couplings. Neglecting maintenance can lead to premature wear, reduced torque capacity, and eventual coupling failure, which can cause costly downtime and damage to other machinery components. The following are key maintenance practices for expansion couplings:

5.1 Regular Inspection

Expansion couplings should be inspected regularly to check for signs of wear, damage, or misalignment. Visual inspections should include checking for cracks in the hubs, diaphragms, or yokes; wear or degradation of elastomeric inserts; loose bolts or set screws; and signs of lubricant leakage (for lubricated couplings). Additionally, alignment should be checked periodically using tools such as dial indicators or laser alignment systems. Misalignment can increase stress on the coupling and connected components, so any misalignment beyond the coupling’s rated capacity should be corrected immediately.

5.2 Lubrication

Lubricated couplings, such as sliding sleeve couplings and U-joints, require regular lubrication to reduce friction and prevent wear. The type of lubricant used should be compatible with the coupling’s materials and the operating environment. For example, in high-temperature applications, high-temperature grease or oil should be used, while in corrosive environments, anti-corrosive lubricants are recommended. The lubrication interval depends on the operating conditions—high-speed or high-load applications may require more frequent lubrication than low-speed, light-load applications. It is important to follow the manufacturer’s recommendations for lubrication type and interval.

5.3 Replacement of Wear Components

Many expansion couplings have wear components that need to be replaced periodically. For jaw couplings, the elastomeric insert is the primary wear component, and it should be replaced when signs of cracking, hardening, or excessive wear are observed. For U-joints, the bearings and seals should be replaced if they show signs of wear or leakage. For sliding sleeve couplings, the sliding surfaces may need to be resurfaced or replaced if they become worn or scored. Replacing wear components in a timely manner can extend the lifespan of the coupling and prevent more severe damage.

5.4 Proper Storage and Handling

When not in use, expansion couplings should be stored in a clean, dry environment to prevent corrosion and damage. They should be kept away from direct sunlight, extreme temperatures, and chemicals that could degrade their materials. Additionally, couplings should be handled carefully during installation and removal to avoid bending or damaging the hubs, diaphragms, or other components. Proper installation is critical—hubs should be properly aligned and secured to the shafts using the correct fasteners and torque specifications.

6. Future Trends in Expansion Coupling Technology

As industries continue to evolve toward higher efficiency, greater precision, and more sustainable operations, expansion coupling technology is also advancing to meet these demands. One of the key trends is the development of lightweight, high-strength couplings using advanced materials such as carbon fiber composites. These materials offer excellent strength-to-weight ratios, making them ideal for high-speed applications in aerospace and automotive industries, where reducing weight is critical for improving fuel efficiency and performance.

Another trend is the integration of smart monitoring technologies into expansion couplings. Sensors embedded in the coupling can measure temperature, vibration, torque, and misalignment in real time, providing valuable data to operators. This predictive maintenance approach allows potential issues to be detected before they lead to coupling failure, reducing downtime and maintenance costs. Smart couplings are particularly useful in large-scale industrial applications, such as power generation and wind energy, where unplanned downtime can be extremely costly.

Additionally, there is a growing focus on developing lubrication-free and low-maintenance couplings to meet the needs of remote and hard-to-access applications. Advances in material science have led to the development of self-lubricating materials and improved elastomers that offer longer lifespans and better resistance to harsh environments. These innovations are helping to reduce the environmental impact of couplings by eliminating the need for lubricants, which can be a source of pollution if not properly managed.

7. Conclusion

Expansion couplings are essential components in mechanical power transmission systems, providing the flexibility and reliability needed to accommodate misalignments, absorb vibrations, and compensate for thermal expansion. Their diverse range of types—from simple sliding sleeve couplings to high-precision diaphragm couplings—makes them suitable for a wide array of applications across industries such as manufacturing, automotive, energy, and marine.

Selecting the right expansion coupling requires careful consideration of torque capacity, misalignment requirements, operating speed, temperature, and maintenance needs. Proper maintenance, including regular inspection, lubrication, and replacement of wear components, is critical to ensuring the long-term performance and reliability of the coupling.

As technology advances, expansion couplings are becoming lighter, stronger, and more intelligent, enabling them to meet the evolving demands of modern industries. By embracing these innovations, industries can improve the efficiency, reliability, and sustainability of their mechanical systems, ensuring that expansion couplings remain a vital part of power transmission for years to come.

« Expansion Couplings » Post Date: 2023/11/22

URL: https://www.rokeecoupling.com/en/customer-cases/expansion-couplings.html

- Torque Gear Coupling Function

- Claw Coupling Structural Diagram

- Flexible Pump Coupling Brands

- Jaw Coupling Supplier

- Classification of Bush Type Couplings

- Membrane Disc Coupling Size Calculation

- Engineering Drawing of Bush Pin Type Flexible Couplings

- Flexible Diaphragm Coupling Procurement

- Jaw Coupling With Keyway

- Automatic Diaphragm Coupling