Crown Gear Coupling

Rokee® is a Crown Gear Coupling Supplier from China, customized crown gear coupling according to the drawings which provided by the customer, selling chinese national standard crown gear coupling, support export, due to excellent quality, complete technical services and superior cost performance, Rokee® industrial coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

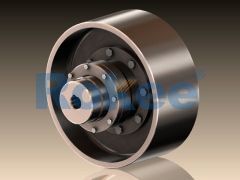

The Drum Gear Coupling is a specially designed advanced Gear Coupling. Its outer teeth are made into a sphere, with the center of the sphere on the axis of the gear. The teeth clearance is slightly larger than the general products and can transfer a greater torque and allow greater angular displacement, enjoying excellent performance and longer life.

ROD Curved-tooth Gear Coupling is one of the transmission products with core technology independently developed by Rokee and has established and reported corporate technical standards in the country. By combining with the standard coupling technology of advanced countries such as Japan and Germany, we optimized many detailed dimensions, and adopted the toothed design with a large pressure angle and short shaft design for the shaft hole, which reduces the length-diameter ratio, and has a more compact structure and excellent speed performance.

The bolts of similar types are standardized and the parts are universal. Compared with the national standard couplings, our Toothed Couplings can transfer more torque, with greatly reduced mass and small moment of inertia. It meets the European explosion-proof requirements and the comprehensive performance is greatly advanced. We highly recommend you to choose our Crown Gear Couplings for better transmission performance.

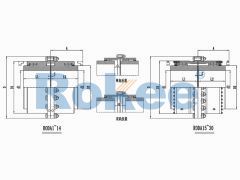

RODA Drum Gear Coupling

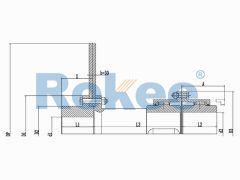

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.RODT Indirect Tube Drum Gear Coupling

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.RODX Intermediate Shaft Drum Gear Coupling

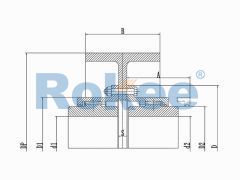

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.RODP Brake Disc Drum Gear Coupling

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.RODF Split Brake Disc Drum Gear Coupling

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.RODW Brake Wheel Drum Gear Coupling

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.RODU Brake Wheel Drum Gear Coupling

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.

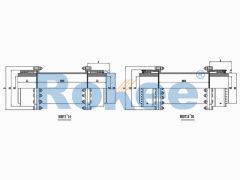

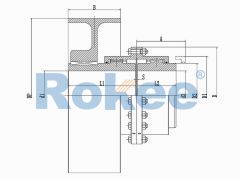

GICL Drum Gear Coupling

GICL drum gear coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.GICLZ Drum Gear Coupling

Half of the GICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.GIICL Drum Gear Coupling

GIICL drum gear coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.GIICLZ Drum Gear Coupling

Half of the GIICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.GCLD Drum Gear Coupling

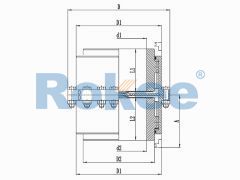

GCLD drum gear coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.NGCL Drum Gear Coupling

NGCL drum gear coupling is designed with a brake wheel, suitable for situations where braking is required.NGCLZ Drum Gear Coupling

NGCLZ drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.WG Drum Gear Coupling

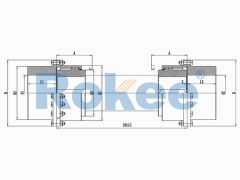

The overall characteristics of WG drum gear coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.WGZ Drum Gear Coupling

WGZ drum gear coupling is designed with a brake wheel, suitable for shoe type braking.WGP Drum Gear Coupling

WGP drum gear coupling is designed with a brake disc, suitable for disc type braking.WGT Drum Gear Coupling

WGT drum gear coupling is designed with indirect tube, suitable for long distance torque transfer.WGC Drum Gear Coupling

WGC drum gear coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.WGJ Drum Gear Coupling

WGJ drum gear coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.

In the realm of power transmission systems, couplings play an indispensable role as mechanical components that connect two rotating shafts, enabling the transfer of torque while accommodating various forms of misalignment. Among the diverse range of couplings available, crown gear couplings stand out for their exceptional ability to handle high torque loads, compensate for significant misalignments, and operate reliably in harsh industrial environments.

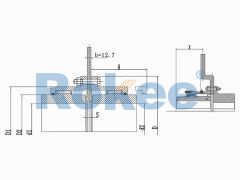

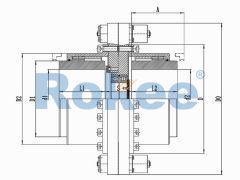

To understand the uniqueness of crown gear couplings, it is first essential to grasp their fundamental design. Unlike flexible couplings that rely on elastomeric elements or rigid couplings that demand precise alignment, crown gear couplings are a type of rigid-flexible coupling that utilizes gear teeth meshing to transmit torque. The core components of a crown gear coupling typically include two gear hubs, two outer sleeves (also known as flanges), and a set of fasteners such as bolts or studs. Each gear hub features a crown-shaped gear profile at one end, which is characterized by teeth that are cut at an angle relative to the hub’s axis. The outer sleeves, on the other hand, are equipped with internal gear teeth that mesh perfectly with the crown teeth of the hubs. When assembled, the two gear hubs are connected to the respective shafts that need to be coupled, and the outer sleeves encase the meshing gear teeth, creating a sealed and rigid connection that still allows for a certain degree of flexibility.

The design of the crown gear teeth is a critical factor that determines the coupling’s performance. The crown shape of the teeth is engineered to provide a large contact area between the hub and the outer sleeve, which not only enhances torque transmission capacity but also distributes the load evenly across the teeth, reducing wear and extending the service life of the coupling. Additionally, the angled configuration of the crown teeth enables the coupling to accommodate three types of misalignment: angular misalignment, parallel misalignment, and axial displacement. Angular misalignment occurs when the axes of the two shafts intersect at an angle, while parallel misalignment refers to a situation where the shafts are parallel but offset from each other. Axial displacement, on the other hand, is the linear movement of one shaft relative to the other along the axial direction. The crown gear design allows for a certain amount of movement in each of these directions without compromising the integrity of the torque transmission or causing excessive stress on the coupling components.

The working principle of crown gear couplings revolves around the meshing of the crown teeth on the hubs with the internal teeth on the outer sleeves. When one shaft rotates, it drives the attached gear hub, which in turn transmits the rotational force to the outer sleeve through the meshed gear teeth. The outer sleeve then transfers this torque to the second gear hub, which drives the second shaft. The key to the coupling’s functionality lies in the way the gear teeth interact during rotation. As the shafts rotate, the crown teeth slide slightly against the internal teeth of the sleeve, allowing for the accommodation of misalignment. This sliding action is facilitated by the lubrication that is applied to the gear teeth, which reduces friction and prevents excessive wear. The lubricant also helps to dissipate heat generated during operation, ensuring that the coupling operates within a safe temperature range.

One of the most significant advantages of crown gear couplings is their high torque transmission capacity. Due to the large contact area between the gear teeth and the robust construction of the components, these couplings are capable of handling much higher torque loads compared to many other types of couplings. This makes them ideal for use in heavy-duty applications where large amounts of power need to be transmitted, such as in steel mills, mining equipment, and large industrial pumps. In addition to their high torque capacity, crown gear couplings also offer excellent rigidity. While they can accommodate misalignment, they do not introduce significant torsional deflection, which is crucial in applications where precise shaft rotation is required, such as in machine tools and precision manufacturing equipment.

Another key benefit of crown gear couplings is their ability to operate in harsh environments. The sealed design of the outer sleeve protects the gear teeth from contamination by dust, dirt, moisture, and other harmful substances that are commonly present in industrial settings. This sealing also helps to retain the lubricant, ensuring that the coupling remains properly lubricated even in dirty or wet conditions. Furthermore, crown gear couplings are typically made from high-strength materials such as alloy steel or carbon steel, which are resistant to wear, corrosion, and impact. This combination of robust materials and sealed design makes crown gear couplings highly durable and reliable, even in extreme operating conditions such as high temperatures, high humidity, and heavy vibration.

Crown gear couplings are also known for their ease of installation and maintenance. Unlike some other types of couplings that require precise alignment during installation, crown gear couplings can tolerate a certain degree of misalignment, which simplifies the installation process and reduces the time and labor required. Additionally, the modular design of many crown gear couplings makes it easy to disassemble and replace components if necessary. Routine maintenance typically involves checking the lubrication level, inspecting the gear teeth for wear or damage, and ensuring that the fasteners are properly tightened. With proper maintenance, crown gear couplings can have a long service life, which reduces the overall cost of ownership for industrial equipment.

The versatility of crown gear couplings makes them suitable for a wide range of industrial applications. One of the most common applications is in the steel industry, where they are used to connect the shafts of rolling mills, continuous casters, and other heavy-duty equipment. In rolling mills, for example, crown gear couplings transmit the high torque required to roll steel into various shapes and sizes, while accommodating the misalignment that may occur due to the heavy loads and vibrations generated during the rolling process. Another major application area is the mining industry, where crown gear couplings are used in crushers, conveyors, and mining pumps. In crushers, the coupling must transmit large amounts of torque to break down rock and ore, while withstanding the harsh conditions of the mining environment, such as dust, moisture, and heavy vibration.

Crown gear couplings are also widely used in the power generation industry, particularly in thermal power plants and hydropower plants. In thermal power plants, they are used to connect the shafts of turbines and generators, transmitting the rotational power generated by the turbine to the generator to produce electricity. In hydropower plants, they are used in water turbines, where they must handle the high torque generated by the flow of water while accommodating any misalignment between the turbine and generator shafts. Additionally, crown gear couplings are used in marine applications, such as in the propulsion systems of ships and boats, where they connect the engine to the propeller shaft, transmitting torque while accommodating the misalignment that may occur due to the movement of the ship.

Other applications of crown gear couplings include industrial pumps and compressors, machine tools, and material handling equipment. In industrial pumps, the coupling connects the motor to the pump shaft, transmitting the torque required to move fluids, while accommodating the misalignment that may occur due to the installation or operation of the pump. In machine tools, such as lathes, milling machines, and grinders, crown gear couplings are used to transmit precise rotational motion, ensuring that the tool operates with high accuracy. In material handling equipment, such as conveyors and elevators, the coupling transmits the torque required to move the equipment, while withstanding the vibrations and misalignment that may occur during operation.

While crown gear couplings offer numerous advantages, proper maintenance is essential to ensure their optimal performance and longevity. One of the most critical maintenance tasks is lubrication. The gear teeth of the coupling rely on lubrication to reduce friction and wear, and to dissipate heat. The type of lubricant used depends on the operating conditions, such as temperature, load, and speed. It is important to use the correct type of lubricant and to maintain the proper lubrication level. Regular inspection of the lubricant for contamination, such as water or dirt, is also necessary, as contaminated lubricant can cause premature wear of the gear teeth.

Another important maintenance task is inspecting the gear teeth for wear, pitting, or damage. Over time, the gear teeth may become worn due to normal operation, or they may be damaged due to excessive load, misalignment, or lack of lubrication. Regular inspection allows for early detection of any issues, which can prevent further damage to the coupling and the connected equipment. If wear or damage is detected, the affected components should be replaced promptly to avoid failure of the coupling. Additionally, the fasteners used to connect the components of the coupling should be inspected regularly to ensure that they are properly tightened. Loose fasteners can cause excessive vibration, which can lead to wear and damage to the coupling and other components.

In addition to routine maintenance, it is also important to consider the operating conditions when selecting a crown gear coupling. Factors such as torque load, shaft speed, misalignment requirements, and environmental conditions should all be taken into account to ensure that the coupling is properly sized and configured for the application. Selecting a coupling that is not suitable for the operating conditions can lead to premature failure, increased maintenance costs, and downtime of the equipment. It is also important to follow the manufacturer’s recommendations for installation, operation, and maintenance to ensure the optimal performance of the coupling.

In conclusion, crown gear couplings are a vital component in many industrial power transmission systems, offering a unique combination of high torque capacity, excellent misalignment compensation, durability, and ease of maintenance. Their robust design and versatility make them suitable for a wide range of applications, from heavy-duty steel and mining equipment to precision machine tools and power generation systems. By understanding the design characteristics, working principles, and maintenance requirements of crown gear couplings, industrial operators can ensure that their equipment operates reliably and efficiently, reducing downtime and minimizing maintenance costs. As industrial technology continues to advance, crown gear couplings are likely to remain an essential part of power transmission systems, adapting to the changing needs of modern industry.

« Crown Gear Coupling » Post Date: 2023/9/23

URL: https://www.rokeecoupling.com/en/blog/crown-gear-coupling.html

Tags: Crown Gear Couplings, pu sandwich panel line

- 2025-06-27Crown Gear Coupling Wholesale

- 2024-07-11Direct Sale Crown Gear Coupling

- 2024-06-07Procurement of Crown Gear Coupling

- 2024-06-07Purpose of Crown Gear Couplings

- 2024-06-07Schematic Diagram of Crown Gear Couplings

- 2024-06-07Crown Gear Coupling Assembly Drawing

- 2024-06-07Crown Gear Coupling Brands

- 2024-06-07Crown Gear Coupling Calculation

- 2024-06-07Crown Gear Coupling Manufacturing

- 2024-06-07Crown Gear Coupling Models

- 2024-06-07Crown Gear Coupling Price

- 2024-06-04Parts of Crown Gear Coupling

- 2024-06-04Crown Gear Coupling Sales

- 2024-05-29Lubrication of Crown Gear Coupling

- 2024-05-29Installation of Crown Gear Coupling

- 2024-05-29High Quality Crown Gear Couplings

- 2024-05-29High Performance Crown Gear Couplings

- 2024-05-29Grease of Crown Gear Coupling

- 2024-05-29Crown Gear Coupling Standard Sizes

- 2024-05-29Crown Gear Couplings Drawing

- 2024-05-29Crown Gear Couplings Factory

- 2024-05-29Crown Gear Couplings For Sale

- 2024-05-27Material of Crown Gear Coupling

- 2024-05-27Maintenance of Crown Gear Coupling

- 2024-05-27Function of Crown Gear Couplings

- 2024-05-27Exploded View of Crown Gear Couplings

- 2024-05-27Engineering Drawing of Crown Gear Couplings

- 2024-05-27Efficiency of Crown Gear Coupling

- 2024-05-27Disadvantages of Crown Gear Coupling

- 2024-05-27Customized Crown Gear Couplings

- 2024-05-27Components of Crown Gear Coupling

- 2024-05-27Classification of Crown Gear Couplings

- 2024-05-27Catalogue of Crown Gear Couplings

- 2024-05-27Application of Crown Gear Couplings

- 2024-05-27Angle of Crown Gear Coupling

- 2024-05-27Alignment of Crown Gear Coupling

- 2024-05-22Crown Gear Couplings Supplier

- 2024-05-22Size Calculation of Crown Gear Coupling

- 2024-05-22Size Chart of Crown Gear Couplings

- 2024-05-22Specifications of Crown Gear Coupling

- 2024-05-22Stiffness of Crown Gear Coupling

- 2024-05-22Structural Diagram of Crown Gear Couplings

- 2024-05-22Tagging of Crown Gear Coupling

- 2024-05-22Types of Crown Gear Coupling

- 2024-05-22Uses of Crown Gear Couplings

- 2024-05-22Working Principle of Crown Gear Coupling

- 2024-05-20Torque of Crown Gear Coupling

- 2024-05-20Crown Gear Couplings Manufacturer

- 2024-05-20Crown Gear Coupling Pictures

- 2024-05-20Crown Gear Coupling Advantages

- 2024-05-20Machine Drawing of Crown Gear Couplings

- 2024-05-203D Model of Crown Gear Couplings

- 2024-05-20Coaxiality of Crown Gear Coupling

- 2024-05-20Gap Chart of Crown Gear Couplings

- 2024-05-20Misalignment Tolerance of Crown Gear Coupling

- 2024-05-20Crown Gear Coupling Design

- 2024-05-20Crown Gear Couplings Company

- 2024-05-20Supply of Crown Gear Couplings

- 2024-05-20Crown Gear Couplings Wholesale

- 2023-09-22Standard For Crown Gear Couplings