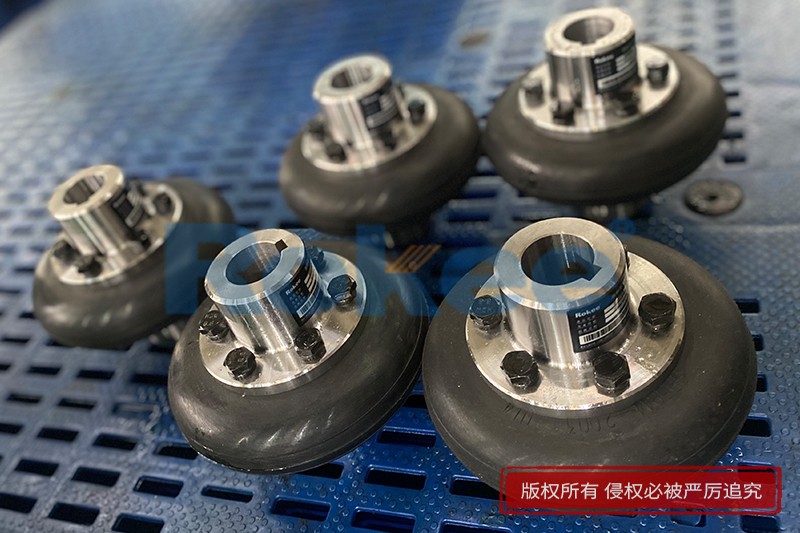

Tyre Couplings

Rokee® is Tyre Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Tyre Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Tyre Coupling adopts tyre body-shaped rubber elements, which are connected with two semi-couplings through bolts to realize torque transmission and displacement compensation. Tyre Coupling has high elastic performance, small torsional rigidity, strong damping capacity, large axial compensation capacity, and good damping performance.

-

UL Elastic Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation. -

LLA Elastic Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. -

LLB Elastic Tyre Coupling

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating various forms of misalignment. Among the diverse types of couplings available, tyre couplings have emerged as a preferred choice in numerous industrial applications due to their unique combination of flexibility, damping capacity, and ease of installation.

Overview and Structural Composition of Tyre Couplings

A tyre coupling is a flexible coupling that utilizes an elastic tyre element to connect the driving and driven shafts. Unlike rigid couplings, which require precise alignment between shafts, tyre couplings rely on the deformability of the tyre element to compensate for axial, radial, and angular misalignments. The basic structure of a tyre coupling consists of three main parts: two metal flanges (or hubs), an elastic tyre, and fastening components such as bolts and nuts.

The metal flanges are typically made of high-strength steel or cast iron, designed to attach securely to the shafts of the driving and driven machines. These flanges feature evenly distributed holes around their circumference, which are used to connect to the elastic tyre. The design of the flanges ensures that torque is efficiently transmitted from the driving shaft to the tyre element and then to the driven shaft. Some flanges may also incorporate keyways or set screws to enhance the connection with the shafts, preventing slippage during operation.

The elastic tyre is the core component of the coupling, responsible for its flexibility and damping properties. It is usually manufactured from rubber or synthetic elastomers, such as neoprene, nitrile rubber, or polyurethane. The choice of material depends on the specific application requirements, including operating temperature, chemical resistance, and load capacity. The tyre element is often designed with a cylindrical or conical shape, and its inner surface is attached to the flanges. In some designs, the tyre may have reinforcement layers, such as fabric or steel cords, to improve its tensile strength and durability, enabling it to withstand higher torque loads.

Fastening components play a vital role in securing the tyre element to the flanges. Bolts are inserted through the holes in the flanges and the tyre, and nuts are tightened to create a secure connection. The number and size of the bolts are determined based on the torque capacity of the coupling, ensuring that the connection can withstand the transmitted torque without loosening. Some tyre couplings may also use washers or locknuts to prevent vibration-induced loosening, enhancing the reliability of the coupling during long-term operation.

Working Principles of Tyre Couplings

The working principle of a tyre coupling revolves around the elastic deformation of the tyre element. When the driving shaft rotates, it transmits torque to the connected flange, which in turn exerts a rotational force on the elastic tyre. The tyre element deforms elastically under this force, transferring the torque to the other flange and ultimately to the driven shaft. This elastic deformation not only enables torque transmission but also allows the coupling to accommodate various types of shaft misalignment.

Axial misalignment occurs when the two shafts are not perfectly coaxial along their length. The tyre element can stretch or compress axially to compensate for this misalignment, ensuring that torque transmission remains uninterrupted. Radial misalignment, which is a lateral offset between the shafts, is accommodated by the bending deformation of the tyre. The elastic material of the tyre bends to bridge the gap between the misaligned shafts, preventing excessive stress on the shafts and bearings.

Angular misalignment, where the shafts are inclined relative to each other, is also compensated for by the tyre's elastic deformation. The tyre element twists slightly to adapt to the angular difference between the shafts, ensuring smooth torque transmission. Additionally, the elastic tyre provides damping properties, which help to absorb shocks and vibrations generated during operation. When the machine experiences sudden load changes or starts/stops, the tyre absorbs the impact energy, reducing the transmission of vibrations to other components of the system. This damping effect not only improves the stability of the machine but also extends the service life of other mechanical parts, such as bearings and gears.

Key Advantages of Tyre Couplings

Tyre couplings offer a range of advantages that make them suitable for a wide range of industrial applications. One of the primary advantages is their excellent flexibility, which allows them to accommodate large amounts of axial, radial, and angular misalignment. This flexibility reduces the need for precise shaft alignment during installation, simplifying the installation process and saving time and labor costs. Moreover, it minimizes the stress on shafts, bearings, and other components, reducing the risk of premature failure.

Another significant advantage is their superior damping capacity. The elastic tyre element effectively absorbs shocks and vibrations generated by the machine, reducing noise and improving the smoothness of operation. This is particularly beneficial in applications where the machine is subject to frequent start-stop cycles, variable loads, or high-speed rotation. The damping effect also helps to protect sensitive components, such as electrical motors and control systems, from damage caused by vibration.

Tyre couplings are also known for their ease of installation and maintenance. Unlike some other types of flexible couplings, they do not require complex alignment procedures or specialized tools for installation. The tyre element can be easily replaced when worn or damaged, without the need to disassemble the entire coupling or move the connected machines. This reduces downtime and maintenance costs, ensuring that the machine can quickly return to operation.

In addition, tyre couplings have a compact design and lightweight construction, making them suitable for applications where space is limited. Their simple structure also results in lower manufacturing costs compared to some other types of couplings, making them a cost-effective solution for many industrial applications. Furthermore, the elastic tyre element provides electrical insulation between the driving and driven shafts, preventing the transmission of electrical currents and protecting the machine from electrical damage.

Typical Applications of Tyre Couplings

Due to their unique combination of advantages, tyre couplings are widely used in various industrial sectors. One of the most common applications is in the field of electrical motors and pumps. In pump systems, the motor and pump shafts are often subject to misalignment due to installation errors or thermal expansion. Tyre couplings can accommodate this misalignment and absorb the vibrations generated by the pump, ensuring reliable operation. They are also used in centrifugal pumps, reciprocating pumps, and water treatment pumps.

Another major application area is in the mining and construction industry. Mining equipment, such as conveyors, crushers, and mills, operates under harsh conditions with high loads, vibrations, and frequent misalignments. Tyre couplings are able to withstand these harsh conditions, providing reliable torque transmission and protecting the equipment from damage. In construction machinery, such as excavators, loaders, and bulldozers, tyre couplings are used to connect the engine to the transmission system, absorbing shocks and vibrations during operation.

Tyre couplings are also widely used in the automotive industry, particularly in the transmission systems of commercial vehicles and agricultural machinery. They are used to connect the engine to the gearbox, accommodating misalignments caused by the movement of the vehicle and absorbing vibrations generated by the engine. In agricultural machinery, such as tractors, harvesters, and irrigation systems, tyre couplings are essential for transmitting torque in harsh outdoor environments.

Other typical applications include fans and blowers, compressors, textile machinery, printing machinery, and food processing equipment. In fan and blower systems, tyre couplings help to reduce vibration and noise, improving the efficiency and reliability of the system. In compressors, they accommodate misalignments between the motor and compressor shafts and absorb the shocks generated by the compression process. In textile and printing machinery, where precision and smooth operation are critical, tyre couplings ensure stable torque transmission and minimize vibration, preventing defects in the final product.

Maintenance Practices for Tyre Couplings

Proper maintenance is essential to ensure the long-term reliability and performance of tyre couplings. Regular inspection is the first step in maintenance, and it should be carried out periodically to check for signs of wear, damage, or loosening. During inspection, the following aspects should be examined: the condition of the elastic tyre, the tightness of the fastening components, the alignment of the shafts, and the presence of any abnormal noise or vibration.

The elastic tyre element is subject to wear and aging over time, especially in applications with high temperatures, high loads, or exposure to chemicals. Signs of tyre wear include cracks, tears, hardening, or softening of the material. If any of these signs are detected, the tyre should be replaced immediately to prevent failure. When replacing the tyre, it is important to select a tyre of the correct size and material to ensure compatibility with the coupling and the application requirements.

Fastening components, such as bolts and nuts, should be checked regularly for tightness. Vibration during operation can cause bolts to loosen, which can lead to excessive misalignment and damage to the coupling. If loose bolts are found, they should be tightened to the specified torque. In some cases, locknuts or thread-locking compounds may be used to prevent loosening.

Shaft alignment should also be checked periodically. Although tyre couplings can accommodate misalignment, excessive misalignment can increase the stress on the tyre element and reduce its service life. If the misalignment exceeds the maximum allowable limit, adjustments should be made to the position of the connected machines to correct the alignment.

In addition, the operating environment should be considered in maintenance. If the coupling is used in a dusty, humid, or corrosive environment, it should be protected with a cover to prevent the ingress of dust, water, or chemicals. This can help to extend the service life of the tyre element and the metal components. Lubrication is generally not required for tyre couplings, as the elastic tyre element does not require lubrication. However, if the coupling has any moving parts other than the tyre, such as bearings, these should be lubricated according to the manufacturer's recommendations.

Conclusion

Tyre couplings are essential components in mechanical power transmission systems, offering a unique combination of flexibility, damping capacity, ease of installation, and cost-effectiveness. Their ability to accommodate various types of shaft misalignment and absorb shocks and vibrations makes them suitable for a wide range of industrial applications, from pumps and motors to mining equipment and automotive systems. Proper maintenance, including regular inspection, replacement of worn tyre elements, and checking of fastening components and shaft alignment, is crucial to ensure their reliable operation and extend their service life.

As industrial technology continues to advance, the demand for more efficient and reliable power transmission components is increasing. Tyre couplings are likely to remain a key choice in many applications due to their proven performance and versatility. Future developments may focus on improving the material properties of the elastic tyre element, enhancing its load capacity, temperature resistance, and durability, to meet the evolving needs of modern industrial systems. Whether in traditional manufacturing or emerging industries, tyre couplings will continue to play a vital role in ensuring the smooth and efficient operation of mechanical equipment.

« Tyre Couplings » Post Date: 2023/11/28

URL: https://www.rokeecoupling.com/en/tags/tyre-couplings.html

- 2025-06-27Tyre Coupling Rubber

- 2023-11-23Flexible Tyre Couplings Supply

- 2023-11-23Flexible Tyre Coupling Working Principle

- 2023-11-23Flexible Tyre Coupling Purpose

- 2023-11-23Flexible Tyre Coupling Function

- 2023-11-23Flexible Tyre Coupling Structural Diagram

- 2023-11-23Types of Flexible Tyre Couplings

- 2023-11-23Models of Flexible Tyre Couplings

- 2023-11-16Flexible Tyre Coupling Specifications

- 2023-11-16Flexible Tyre Coupling Price

- 2023-11-16Flexible Tyre Coupling Disadvantages

- 2023-11-16Flexible Tyre Coupling Customized

- 2023-11-16Flexible Tyre Coupling Advantages

- 2023-11-11Flexible Tyre Coupling For Sale

- 2023-11-11Flexible Tyre Coupling Size Calculation

- 2023-11-11Flexible Tyre Couplings Manufacturer

- 2023-11-10Flexible Tyre Coupling Procurement

- 2023-11-10Flexible Tyre Coupling Size Chart

- 2023-11-09Flexible Tyre Coupling Drawing

- 2023-11-09Flexible Tyre Couplings Company

- 2023-11-09Flexible Tyre Coupling Applications

- 2023-11-09Flexible Tyre Coupling Manufacturing Enterprise

- 2023-11-09Flexible Tyre Coupling Parts

- 2023-11-09Flexible Tyre Coupling Tagging

- 2023-11-09Flexible Tyre Couplings Wholesale

- 2023-11-09Flexible Tyre Couplings Supplier

- 2023-11-09Flexible Tyre Couplings Factory

- 2023-11-09Flexible Tyre Coupling Design

- 2023-11-09Catalogue of Flexible Tyre Couplings

- 2023-10-30Rubber Tyre Couplings Parameters

- 2023-10-30Rubber Tyre Couplings Price

- 2023-10-30Water Pump Tyre Couplings Wholesale

- 2023-10-30Vibration Screen Tyre Couplings Supplier

- 2023-10-20Tyre Coupling Uses

- 2023-10-20Tyre Coupling Advantages And Disadvantages

- 2023-10-20Custom Tyre Coupling

- 2023-10-18Water Pump Tyre Coupling Price

- 2023-10-18Vibration Screen Tyre Coupling Design

- 2023-10-18Tyre Couplings With Brake Disc

- 2023-10-18Natural Rubber Tyre Couplings

- 2023-10-18Rubber Tyre Couplings

- 2023-10-17Rubber Open Tyre Coupling For Crusher

- 2023-10-17High Elastic Composite Tyre Coupling

- 2023-10-17Electric Hoist Elastic Tyre Coupling

- 2023-10-17Elastic Tyre Coupling Model

- 2023-10-17Detachable Tyre Coupling

- 2023-10-13Steel Open Tyre Couplings

- 2023-10-13Toothed Tyre Couplings

- 2023-10-13Tyre Coupling For Mining Machinery

- 2023-10-13Two Half Tyre Couplings

- 2023-10-13Tyre Coupling For Electric Locomotives

- 2023-10-13Water Pump Tyre Couplings Company

- 2023-10-13Tyre Couplings For Vibrating Screen

- 2023-10-13Underwater Tyre Couplings

- 2023-10-13Tractor Tyre Couplings

- 2023-10-12Rubber Tyre Couplings Brand

- 2023-10-12Water Pump Tyre Couplings

- 2023-10-12Tyre Couplings For Press Machines

- 2023-10-12Vibration Screen Tyre Couplings

- 2023-10-12Rubber Tyre Couplings Model

- 2023-10-12Rubber Ring Tyre Couplings

- 2023-10-12Natural Rubber High Elastic Tyre Couplings

- 2023-10-12Locking Sleeve Tyre Couplings

- 2023-10-11Extended Tyre Couplings

- 2023-10-11Expansion Sleeve Tyre Couplings

- 2023-10-11Elevator Tyre Couplings

- 2023-10-11Dual Tyre Couplings

- 2023-10-11Double Roller Slag Crusher Tyre Couplings

- 2023-10-11Convex Tyre Couplings

- 2023-10-11Cone Type Tyre Couplings Company

- 2023-10-11Cone Sleeve Tyre Couplings

- 2023-10-11Cone Sleeve Type Tyre Couplings Make

- 2023-10-11Compressor Tyre Couplings

- 2023-10-11Circular Vibrating Screen Tyre Couplings

- 2023-10-11Centrifugal Blower Tyre Couplings

- 2023-10-11Cast Iron Tyre Couplings

- 2023-10-11Brake Wheel Tyre Couplings

- 2023-10-09Polyurethane Tyre Couplings

- 2023-10-08Tyre Coupling For Fan

- 2023-10-08Spline Type Tyre Coupling

- 2023-10-08Radial Cut Tyre Coupling

- 2023-10-08High Vibration Absorbing Tyre Coupling

- 2023-10-08Steel Tyre Coupling

- 2023-10-08Open Tyre Coupling

- 2023-10-08Hexagonal Tyre Coupling

- 2023-10-08Concave Tyre Coupling

- 2023-10-08Forklift Tyre Coupling

- 2023-10-08High Elastic Tyre Coupling