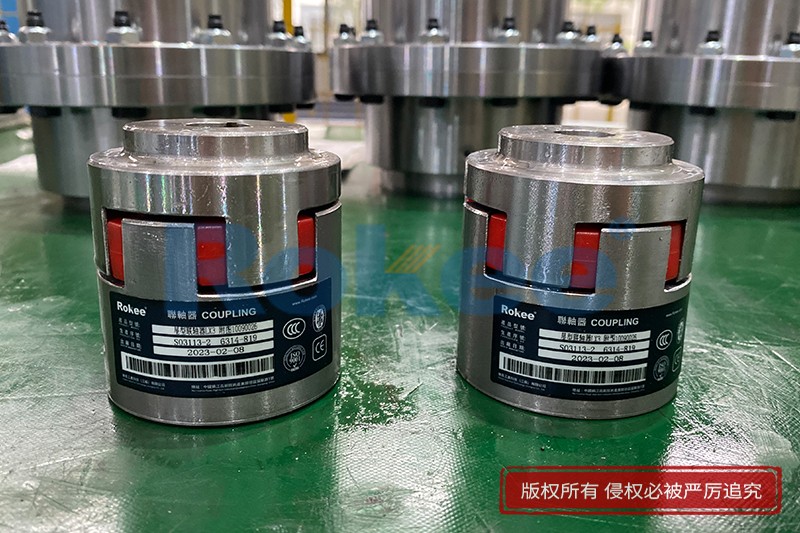

Star Couplings

Rokee® is Star Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Star Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Star coupling is an elastic component made of engineering plastic, suitable for connecting two coaxial transmission shaft systems. It has the properties of compensating for relative deviation between two shafts, buffering, shock absorption, and wear resistance. It is widely used in various situations, transmitting torque of 20-35000 N.M, and working temperature of -35-+80 degrees Celsius.

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, enabling the seamless transfer of torque while accommodating misalignments and mitigating shock loads. Among the diverse array of coupling types available, the star coupling stands out for its unique combination of simplicity, versatility, and cost-effectiveness. Designed to address the demands of both light-duty and moderate industrial applications, star couplings have become a staple in sectors ranging from manufacturing and automation to agriculture and transportation.

1. Understanding Star Couplings: Definition and Core Functions

A star coupling, also known as a jaw coupling with a star-shaped elastomer, is a type of flexible coupling that consists of three primary components: two metal hubs with jaw-like projections, and a central elastomeric element (often referred to as the "star") that fits snugly between the jaws of the two hubs. The key distinguishing feature of this coupling design is the star-shaped elastomer, which acts as the interface for torque transmission and the primary means of accommodating misalignments. Unlike rigid couplings, which require precise shaft alignment and offer no flexibility, star couplings are engineered to absorb angular, parallel, and axial misalignments between connected shafts, thereby reducing stress on bearings, shafts, and other transmission components.

The core functions of a star coupling extend beyond mere torque transfer. These couplings also play a vital role in damping vibration and minimizing noise generated by rotating machinery. The elastomeric star element acts as a buffer, absorbing shocks and vibrations that would otherwise be transmitted through the shaft system, protecting sensitive equipment and improving overall operational smoothness. Additionally, star couplings can compensate for minor shaft end float, a common issue in rotating machinery caused by thermal expansion or contraction, ensuring consistent performance even under varying operating temperatures.

2. Design Characteristics of Star Couplings

The design of star couplings is characterized by its simplicity and robustness, making it easy to manufacture, install, and maintain. Each component of the coupling is meticulously engineered to work in harmony, ensuring reliable performance under diverse operating conditions. Below is a detailed breakdown of the key design features of each component:

2.1 Metal Hubs

The two metal hubs are the primary load-bearing components of the star coupling, responsible for attaching the coupling to the driving and driven shafts and transmitting torque to the elastomeric star. These hubs are typically manufactured from high-strength metals such as steel, cast iron, or aluminum alloy, depending on the application requirements. Steel hubs are preferred for high-torque applications due to their exceptional strength and durability, while aluminum alloy hubs are chosen for lightweight applications where reducing overall system weight is a priority. Cast iron hubs offer a balance of strength and cost-effectiveness, making them suitable for general-purpose industrial use.

The hubs feature a series of evenly spaced jaws (usually 3 to 6, depending on the coupling size) that are machined to match the profile of the elastomeric star. The jaw profile is critical to ensuring a secure fit between the hub and the star element, as it determines the efficiency of torque transmission and the ability to accommodate misalignments. Common jaw profiles include straight jaws, curved jaws, and double-jaw designs, each optimized for specific load conditions and misalignment ranges. Additionally, the hubs are equipped with mounting features such as keyways, set screws, or compression sleeves to facilitate secure attachment to the shafts. Keyway connections are the most common, providing a reliable mechanical link between the hub and shaft, while set screws offer a simple and cost-effective solution for light-duty applications. Compression sleeves, on the other hand, provide a keyless connection, minimizing shaft damage and allowing for easy installation and removal.

2.2 Elastomeric Star Element

The elastomeric star is the heart of the star coupling, responsible for providing flexibility, damping vibrations, and accommodating misalignments. This component is typically molded into a star shape, with arms that correspond to the number of jaws on the metal hubs. The material used for the star element is carefully selected based on the application's operating temperature, torque requirements, chemical exposure, and environmental conditions. Common elastomeric materials include natural rubber, nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), silicone rubber, and polyurethane.

Natural rubber offers excellent elasticity and vibration damping properties but is limited by its relatively low temperature resistance (up to approximately 70°C) and susceptibility to degradation by oils and chemicals. Nitrile rubber, by contrast, exhibits superior oil and chemical resistance, making it ideal for applications involving exposure to petroleum-based fluids. EPDM is known for its exceptional resistance to weathering, ozone, and high temperatures (up to 150°C), making it suitable for outdoor and high-temperature environments. Silicone rubber provides the highest temperature resistance (up to 200°C) and excellent flexibility but is more expensive and less resistant to mechanical abrasion. Polyurethane offers a balance of high strength, wear resistance, and good elasticity, making it a popular choice for heavy-duty applications requiring high torque transmission.

The design of the star element also includes features such as tapered arms or rounded edges to reduce stress concentrations and improve durability. Some star elements are also designed with hollow centers or recessed areas to enhance flexibility and vibration damping. The hardness of the elastomeric material, measured on the Shore A scale, is another critical design parameter. Softer materials (lower Shore A values) offer better vibration damping and misalignment accommodation but have lower torque capacity, while harder materials (higher Shore A values) provide higher torque capacity but reduced flexibility.

3. Operating Principles of Star Couplings

The operating principle of a star coupling is based on the interaction between the metal hubs and the elastomeric star element. When torque is applied to the driving shaft, it is transmitted to the driving hub, which in turn exerts a compressive force on the arms of the star element. The star element then transfers this torque to the driven hub, which rotates the driven shaft. This torque transmission process is efficient because the elastomeric material maintains a secure grip on the jaws of the hubs, ensuring minimal slippage even under high load conditions.

One of the key advantages of the star coupling design is its ability to accommodate three types of shaft misalignment: angular, parallel, and axial. Angular misalignment occurs when the axes of the driving and driven shafts are not colinear but intersect at a common point. This type of misalignment is compensated for by the flexing of the star element's arms, which bend to accommodate the angle between the shafts. Parallel misalignment, by contrast, occurs when the axes of the shafts are parallel but offset from each other. This is accommodated by the lateral flexing of the star element, which stretches or compresses to bridge the gap between the misaligned jaws of the hubs. Axial misalignment, or end float, occurs when the shafts move along their axial direction relative to each other. This is accommodated by the compression or expansion of the star element along the axial direction.

The vibration damping capability of star couplings is also a result of the elastomeric star element's properties. As the shafts rotate, any vibrations generated by the machinery are absorbed by the star element, which converts the vibrational energy into heat through internal friction. This heat is then dissipated into the surrounding environment, reducing the amplitude of the vibrations transmitted to the connected components. This vibration damping effect not only improves the smoothness of operation but also extends the service life of bearings, seals, and other mechanical components by reducing fatigue and wear.

It is important to note that star couplings are designed for use in applications where the misalignment is within specified limits. Exceeding these limits can lead to premature failure of the star element, increased wear on the hubs, and reduced torque transmission efficiency. Manufacturers typically provide detailed specifications regarding the maximum allowable misalignment for each coupling size and type, which should be strictly adhered to during installation and operation.

4. Material Selection for Star Couplings

The selection of materials for star couplings is a critical step in ensuring optimal performance and longevity, as it directly impacts the coupling's torque capacity, temperature resistance, chemical compatibility, and durability. The choice of materials for the metal hubs and elastomeric star element must be tailored to the specific requirements of the application, including operating conditions, environmental factors, and load characteristics.

4.1 Material Selection for Metal Hubs

As mentioned earlier, the most common materials for star coupling hubs are steel, cast iron, and aluminum alloy. The selection of the appropriate hub material depends on the following factors:

- Torque Capacity: High-torque applications, such as those found in heavy machinery, require hubs made from high-strength materials like carbon steel or alloy steel. These materials offer excellent tensile strength and fatigue resistance, ensuring that the hubs can withstand the stresses associated with high torque transmission.

- Weight Considerations: In applications where weight is a critical factor, such as aerospace or automotive components, aluminum alloy hubs are preferred. Aluminum alloys are significantly lighter than steel or cast iron while still offering sufficient strength for moderate torque applications.

- Cost-Effectiveness: For general-purpose applications with moderate torque requirements, cast iron hubs provide a cost-effective solution. Cast iron is easy to manufacture and offers good wear resistance, making it suitable for a wide range of industrial applications.

- Corrosion Resistance: In harsh environments where the coupling is exposed to moisture, chemicals, or saltwater, corrosion-resistant materials such as stainless steel or aluminum alloy with protective coatings are recommended. Stainless steel offers excellent corrosion resistance but is more expensive than other materials, making it suitable for specialized applications.

4.2 Material Selection for Elastomeric Star Elements

The selection of the elastomeric material for the star element is even more critical, as it directly affects the coupling's flexibility, vibration damping, temperature resistance, and chemical compatibility. The following factors should be considered when selecting the star element material:

- Operating Temperature: The operating temperature range of the application is a key determinant of the elastomeric material. For low-temperature applications (below 0°C), materials such as nitrile rubber or silicone rubber are preferred, as they maintain their flexibility at low temperatures. For high-temperature applications (above 100°C), EPDM or silicone rubber is recommended due to their superior high-temperature resistance.

- Chemical Exposure: If the coupling is exposed to oils, greases, solvents, or other chemicals, the star element material must be chemically resistant. Nitrile rubber is excellent for oil and grease resistance, while EPDM is resistant to most chemicals and weathering. Silicone rubber is resistant to a wide range of chemicals but is not recommended for exposure to petroleum-based fluids.

- Torque and Load Requirements: High-torque applications require star elements made from harder, more rigid materials such as polyurethane or hard nitrile rubber. These materials offer higher torque capacity and better wear resistance. For low-torque applications where vibration damping is a priority, softer materials such as natural rubber or soft silicone rubber are preferred.

- Environmental Conditions: Outdoor applications require star elements that are resistant to weathering, ozone, and UV radiation. EPDM and silicone rubber are excellent choices for these conditions, as they do not degrade easily when exposed to sunlight or atmospheric elements. Indoor applications with controlled environments may allow for the use of less expensive materials such as natural rubber.

5. Applications of Star Couplings

Star couplings are versatile components that find applications in a wide range of industries and mechanical systems. Their combination of flexibility, vibration damping, and cost-effectiveness makes them suitable for both light-duty and moderate industrial applications. Below are some of the key application areas where star couplings are commonly used:

5.1 Manufacturing and Automation

In the manufacturing sector, star couplings are widely used in conveyor systems, packaging machinery, printing presses, and robotic arms. Conveyor systems, which are used to transport materials across factories, rely on star couplings to connect the motor to the conveyor belt drive shaft, accommodating misalignments caused by installation errors or belt tension variations. Packaging machinery, such as filling machines and labeling equipment, requires precise torque transmission and vibration damping to ensure accurate and efficient operation, making star couplings an ideal choice. Robotic arms, which involve multiple rotating joints, use star couplings to connect the motors to the joint shafts, providing the necessary flexibility to accommodate the complex movements of the arm while maintaining precise control.

5.2 Agriculture and Farming

Agricultural machinery, such as tractors, harvesters, and irrigation pumps, operates in harsh environments with significant vibrations and misalignments. Star couplings are used in these applications to connect the engine to various auxiliary components, such as pumps, generators, and gearboxes. The vibration damping properties of star couplings help protect these components from the harsh operating conditions encountered in agriculture, extending their service life. Additionally, the ability to accommodate misalignments makes star couplings suitable for use in machinery that is often subjected to rough handling and uneven terrain.

5.3 Automotive and Transportation

In the automotive industry, star couplings are used in a variety of applications, including power steering systems, air conditioning compressors, and transmission systems. Power steering systems rely on star couplings to connect the steering column to the power steering pump, providing the necessary flexibility to accommodate the movement of the steering column while transmitting torque efficiently. Air conditioning compressors use star couplings to connect the engine to the compressor, damping vibrations and accommodating misalignments between the engine and the compressor shaft. Additionally, star couplings are used in electric vehicles to connect the electric motor to the drivetrain, providing a compact and efficient torque transmission solution.

5.4 Pump and Compressor Systems

Pumps and compressors are critical components in many industrial and commercial applications, and star couplings are widely used to connect their motors to the pump or compressor shafts. Centrifugal pumps, positive displacement pumps, and air compressors all benefit from the use of star couplings, which accommodate misalignments between the motor and the pump/compressor shafts, reduce vibration, and protect the bearings and seals from premature wear. The ability of star couplings to dampen vibrations is particularly important in pump systems, as excessive vibration can lead to cavitation and reduced pump efficiency.

5.5 Renewable Energy Systems

Renewable energy systems, such as wind turbines and solar tracking systems, also utilize star couplings. In wind turbines, star couplings are used to connect the gearbox to the generator, accommodating misalignments caused by the dynamic loads exerted by the wind. The vibration damping properties of star couplings help protect the generator and gearbox from the harsh operating conditions encountered in wind energy applications. Solar tracking systems, which adjust the position of solar panels to maximize sunlight exposure, use star couplings to connect the motors to the tracking mechanism, providing the necessary flexibility to accommodate the movement of the panels while maintaining precise control.

6. Installation and Maintenance Best Practices for Star Couplings

Proper installation and maintenance are essential to ensuring the optimal performance and longevity of star couplings. Incorrect installation or inadequate maintenance can lead to premature failure of the coupling, increased wear on connected components, and reduced system efficiency. Below are some key best practices for the installation and maintenance of star couplings:

6.1 Installation Guidelines

- Shaft Alignment: While star couplings can accommodate misalignments, proper shaft alignment during installation is critical to maximizing the coupling's service life. Excessive misalignment can lead to premature failure of the star element and increased wear on the hubs. Shaft alignment should be checked using precision tools such as dial indicators or laser alignment systems. The maximum allowable misalignment values specified by the manufacturer should be strictly adhered to.

- Hub Installation: The metal hubs should be installed on the shafts with the correct interference fit. For keyway connections, the key should be properly sized and seated in the keyway to ensure a secure fit. Set screws should be tightened to the torque specified by the manufacturer to prevent slippage between the hub and the shaft. For compression sleeve connections, the sleeve should be tightened evenly to ensure a uniform grip on the shaft.

- Star Element Installation: The elastomeric star element should be installed between the two hubs with care to ensure that it is properly seated in the jaws of both hubs. The star element should not be stretched or compressed excessively during installation, as this can lead to premature failure. It is important to ensure that the star element is compatible with the operating temperature and chemical environment of the application.

- Torque Loading: The coupling should be subjected to the specified torque loading gradually during initial operation. Sudden or excessive torque loads can damage the star element and the hubs. It is recommended to run the system at a reduced speed for a short period after installation to check for any abnormal noise or vibration.

6.2 Maintenance Practices

- Regular Inspection: Star couplings should be inspected regularly for signs of wear, damage, or degradation. The star element should be checked for cracks, tears, hardening, or softening, which are indicators of impending failure. The metal hubs should be inspected for wear on the jaws, corrosion, or deformation. Any signs of damage should be addressed immediately to prevent further deterioration.

- Lubrication: Some star coupling designs require lubrication of the hub jaws to reduce friction and wear. The manufacturer's recommendations regarding lubrication type and frequency should be followed strictly. Over-lubrication or the use of incompatible lubricants can damage the elastomeric star element.

- Replacement of Star Element: The elastomeric star element is a wear component and should be replaced periodically, even if no visible signs of damage are present. The replacement interval depends on the application's operating conditions, including temperature, torque, and vibration levels. It is recommended to keep a spare star element on hand to minimize downtime in the event of failure.

- Shaft Alignment Check: Shaft alignment should be rechecked periodically, as misalignments can develop over time due to thermal expansion, vibration, or mechanical wear. Any deviations from the specified alignment should be corrected immediately to prevent damage to the coupling and connected components.

7. Future Development Trends of Star Couplings

As industrial technology continues to advance, the demand for more efficient, durable, and environmentally friendly mechanical components is growing. Star couplings are no exception, and several key trends are shaping their future development:

7.1 Advanced Material Development

The development of new elastomeric materials with enhanced properties is a key area of focus. Researchers are working on developing elastomers with higher temperature resistance, improved chemical compatibility, and increased durability. For example, the use of nanocomposite elastomers, which incorporate nanoparticles into the polymer matrix, has shown promise in improving the mechanical properties and wear resistance of star elements. Additionally, the development of bio-based elastomers, derived from renewable resources, is gaining traction as the industry moves toward more sustainable practices.

7.2 Lightweight and Compact Design

The trend toward lightweight and compact machinery, particularly in the automotive and aerospace industries, is driving the development of smaller, lighter star couplings. Manufacturers are using advanced manufacturing techniques, such as additive manufacturing (3D printing), to produce complex hub designs that reduce weight while maintaining strength. Additionally, the use of lightweight materials such as titanium alloys and carbon fiber composites for the hubs is being explored, although cost considerations currently limit their widespread adoption.

7.3 Smart Couplings with Condition Monitoring

The integration of sensors and condition monitoring technology into star couplings is another emerging trend. Smart couplings equipped with sensors can monitor parameters such as temperature, vibration, and torque in real time, providing valuable data on the coupling's performance and health. This data can be used to predict potential failures before they occur, enabling predictive maintenance and minimizing downtime. The development of wireless sensor technology has made it possible to integrate these monitoring capabilities without compromising the coupling's design or performance.

7.4 Improved Efficiency and Energy Savings

Efforts are being made to improve the torque transmission efficiency of star couplings, reducing energy losses and improving overall system efficiency. This includes optimizing the design of the hub jaws and star element to minimize friction and slippage. Additionally, the development of low-friction elastomeric materials and lubricants is helping to reduce energy consumption in coupling systems.

8. Conclusion

Star couplings are essential components in mechanical power transmission systems, offering a unique combination of flexibility, vibration damping, and cost-effectiveness. Their simple yet robust design, coupled with their ability to accommodate misalignments and protect connected components, makes them suitable for a wide range of applications across various industries. The selection of appropriate materials for the hubs and star element is critical to ensuring optimal performance, and proper installation and maintenance practices are essential to maximizing their service life.

As industrial technology continues to evolve, star couplings are poised to benefit from advancements in material science, manufacturing techniques, and condition monitoring technology. The development of advanced elastomeric materials, lightweight designs, and smart coupling systems will further enhance their performance and expand their range of applications. Whether in manufacturing, agriculture, automotive, or renewable energy, star couplings will continue to play a vital role in ensuring the reliable and efficient operation of mechanical systems for years to come.

« Star Couplings » Post Date: 2023/11/28

URL: https://www.rokeecoupling.com/en/tags/star-couplings.html

- 2023-10-10Claw Type Star Couplings