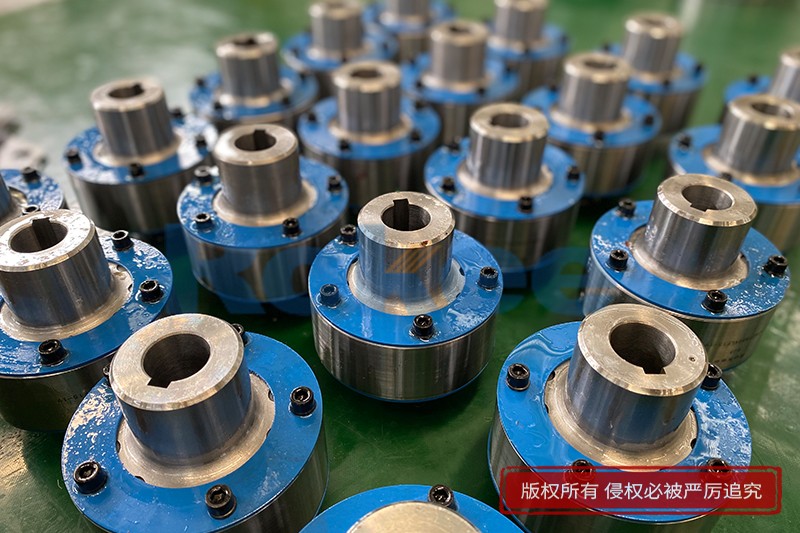

Pump Couplings

Rokee® is Pump Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Pump Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

The pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. In essence, pump couplings are the unsung heroes of fluid systems, bridging the gap between the power source and the pump.

In the realm of industrial machinery and fluid handling systems, the efficient and reliable transfer of power from a driver (such as an electric motor or internal combustion engine) to a pump is paramount. This critical task falls to a component often overlooked yet indispensable: the pump coupling. Serving as the mechanical bridge between the driver and the pump shaft, the pump coupling not only transmits torque but also accommodates misalignments, absorbs shocks, and protects both the pump and driver from potential damage. Whether in water treatment plants, oil refineries, agricultural irrigation systems, or manufacturing facilities, pump couplings play a vital role in ensuring operational continuity and minimizing downtime. This comprehensive guide delves into the core functions, various types, key considerations for selection, installation and maintenance practices, and emerging trends related to pump couplings, providing a holistic understanding of this essential component.

1. Understanding the Core Functions of Pump Couplings

At its most basic level, a pump coupling is designed to connect two rotating shafts—the output shaft of the driver and the input shaft of the pump—and transmit rotational power (torque) from one to the other. However, its role extends far beyond mere connection. Modern pump couplings are engineered to address several operational challenges that arise in real-world applications, making them a critical element in the overall performance of fluid handling systems.

First and foremost, torque transmission is the primary function. The coupling must be capable of handling the maximum torque generated by the driver while ensuring that the pump receives the necessary power to perform its intended task, whether it be pumping water, chemicals, sludge, or other fluids. This requires the coupling to have sufficient strength and rigidity to withstand the mechanical stresses associated with torque transfer without deformation or failure.

A second key function is accommodating misalignment between the driver and pump shafts. Perfect alignment between two shafts is nearly impossible to achieve and maintain in practical applications. Misalignments can be angular (where the shafts are not colinear but intersect at an angle), parallel (where the shafts are parallel but offset from each other), or a combination of both. If not addressed, such misalignments can lead to excessive vibration, increased wear on bearings and seals, and premature failure of both the pump and driver. Pump couplings are designed to absorb these misalignments, reducing the mechanical stress on the connected components.

Shock absorption is another important function of pump couplings. In many industrial settings, the driver (especially internal combustion engines) may generate torque fluctuations or shock loads during startup or operation. These sudden loads can cause damage to the pump’s impeller, shaft, and other internal components. Couplings with elastic or flexible elements are able to absorb these shocks, smoothing out the torque transfer and protecting the pump and driver from impact-related damage.

Additionally, some pump couplings serve as a protective device by acting as a torque limiter. In the event of a pump jam (e.g., due to debris in the fluid or a mechanical failure), the coupling can shear or slip, preventing the transmission of excessive torque to the driver. This protects the driver from overloading and potential burnout, minimizing the extent of damage and reducing repair costs.

2. Common Types of Pump Couplings and Their Characteristics

Pump couplings are available in a wide range of designs, each tailored to specific application requirements such as torque capacity, misalignment tolerance, operating speed, environmental conditions, and cost. The most common types can be categorized into two main groups: rigid couplings and flexible couplings. Each group has distinct characteristics and is suited for different operational scenarios.

2.1 Rigid Couplings

Rigid couplings are designed for applications where precise alignment between the driver and pump shafts can be maintained. As the name suggests, these couplings have no flexibility and do not accommodate any misalignment. Instead, they create a rigid connection between the two shafts, ensuring that they rotate in perfect synchronization. Rigid couplings are typically used in low-speed, high-torque applications where alignment can be carefully controlled, such as in some industrial gear pumps and small centrifugal pumps.

The two primary types of rigid couplings are sleeve couplings and flange couplings. Sleeve couplings (also known as muff couplings) consist of a cylindrical sleeve that fits over the ends of the two shafts. The sleeve is secured to each shaft using set screws or keys, creating a solid connection. This design is simple, compact, and cost-effective, making it suitable for light-duty applications with small shaft diameters.

Flange couplings are more robust and are commonly used in heavy-duty applications. They consist of two flanges, each attached to the end of a shaft, which are then bolted together. The flanges are typically machined to ensure precise alignment, and the bolts provide a secure connection that can transmit high levels of torque. Flange couplings are available in both solid and split designs; split flange couplings are easier to install and remove without disassembling the entire shaft assembly, making them ideal for large pumps and industrial machinery.

While rigid couplings offer high torque capacity and simplicity, their major limitation is their inability to accommodate misalignment. Even minor misalignments can lead to excessive vibration, premature bearing failure, and increased energy consumption. As a result, rigid couplings are only suitable for applications where alignment can be maintained with precision, such as in fixed-mount pump systems with minimal thermal expansion or contraction.

2.2 Flexible Couplings

Flexible couplings are the most widely used type of pump coupling due to their ability to accommodate misalignments, absorb shocks, and reduce vibration. These couplings incorporate elastic or flexible elements that allow for relative movement between the driver and pump shafts while still transmitting torque efficiently. Flexible couplings are suitable for a wide range of applications, from small residential water pumps to large industrial pumps operating at high speeds and handling corrosive or abrasive fluids.

There are several sub-types of flexible couplings, each with unique designs and characteristics:

1. Jaw Couplings: Jaw couplings (also known as spider couplings) are one of the most popular types of flexible couplings. They consist of two metal hubs with jaw-like projections that fit around a flexible elastomeric spider (usually made of rubber or polyurethane). The spider acts as the flexible element, absorbing misalignments and shock loads. Jaw couplings are easy to install, require minimal maintenance, and are cost-effective. They are suitable for moderate torque applications and can accommodate both angular and parallel misalignments. However, they have limited misalignment capacity and are not suitable for high-temperature or high-speed applications where the elastomeric spider may degrade or fail.

2. Disc Couplings: Disc couplings use one or more thin, flexible metal discs (typically made of stainless steel) to transmit torque and accommodate misalignments. The discs are bolted to the hubs of the driver and pump shafts, and their flexibility allows for angular, parallel, and axial misalignments. Disc couplings have no elastomeric components, making them suitable for high-temperature, high-speed, and harsh environmental conditions (such as in oil refineries or chemical plants). They offer high torque capacity, low maintenance requirements, and excellent torsional stiffness. However, they are more expensive than jaw couplings and require precise alignment during installation to avoid excessive stress on the discs.

3. Gear Couplings: Gear couplings are designed for heavy-duty, high-torque applications. They consist of two gear hubs with external teeth that mesh with internal teeth on a sleeve or coupling half. The meshing gears allow for a small amount of misalignment, while a lubricated housing protects the gears from wear and contamination. Gear couplings are capable of transmitting very high levels of torque and are suitable for high-speed applications, such as in large centrifugal pumps and compressors. However, they require regular lubrication to prevent gear wear and corrosion, and their misalignment capacity is limited compared to other flexible couplings.

4. Elastomeric Couplings: Elastomeric couplings (also known as rubber couplings) use a solid or split elastomeric element to connect the two shafts. The elastomeric material (which can be natural rubber, neoprene, or polyurethane) provides flexibility, shock absorption, and vibration damping. These couplings are available in a variety of designs, including tire couplings, donut couplings, and shear pin couplings. Tire couplings, for example, use a rubber tire-like element that allows for large amounts of misalignment and is highly resistant to shock loads. Elastomeric couplings are ideal for applications where vibration reduction is critical, such as in pumps used in residential areas or sensitive manufacturing processes. However, they have limited torque capacity and are not suitable for high-temperature applications, as the elastomeric material can harden or crack over time.

5. Universal Joint Couplings: Universal joint (U-joint) couplings consist of two yokes connected by a cross-shaped spider. They are designed to accommodate large angular misalignments (up to 30 degrees or more) and are commonly used in applications where the driver and pump shafts are not in the same plane, such as in some mobile pump systems or agricultural machinery. U-joint couplings can transmit torque efficiently even at high angles of misalignment, but they can generate vibration at high speeds if not properly balanced. They also require regular lubrication to ensure smooth operation.

3. Key Considerations for Selecting the Right Pump Coupling

Selecting the appropriate pump coupling is critical to ensuring the reliability, efficiency, and longevity of the fluid handling system. The selection process involves evaluating several key factors, including torque requirements, misalignment type and magnitude, operating speed, environmental conditions, maintenance needs, and cost. By carefully considering these factors, engineers and maintenance professionals can choose a coupling that is tailored to the specific needs of the application.

3.1 Torque Capacity

The primary consideration when selecting a pump coupling is its torque capacity. The coupling must be able to handle the maximum torque generated by the driver, which is typically specified by the manufacturer. It is important to select a coupling with a torque rating that exceeds the maximum operating torque of the system to provide a safety margin. Failure to do so can result in coupling failure, which can lead to costly downtime and damage to the pump and driver. Factors that affect torque requirements include the pump’s flow rate, head pressure, fluid density, and operating speed. In addition, startup torque (which is often higher than operating torque) should be taken into account, especially for pumps that handle viscous fluids or have high inertia.

3.2 Misalignment Tolerance

The type and magnitude of misalignment between the driver and pump shafts are critical factors in selecting a flexible coupling. As discussed earlier, misalignments can be angular, parallel, or axial. Different types of couplings have different misalignment capacities, so it is important to choose a coupling that can accommodate the expected misalignment in the system. For example, jaw couplings are suitable for moderate misalignments, while tire couplings or U-joint couplings can handle larger amounts of misalignment. It is also important to note that excessive misalignment beyond the coupling’s capacity can lead to premature wear, increased vibration, and reduced coupling life. Regular alignment checks and adjustments are therefore essential to ensure optimal performance.

3.3 Operating Speed

The operating speed of the pump and driver (measured in revolutions per minute, RPM) is another important consideration. High-speed applications (such as centrifugal pumps operating at 3600 RPM or higher) require couplings that are balanced, have low torsional stiffness, and are resistant to fatigue. Disc couplings and gear couplings are often preferred for high-speed applications due to their rigid construction and ability to maintain balance. In contrast, elastomeric couplings may not be suitable for high-speed applications, as the elastomeric material can degrade at high speeds or generate excessive heat. It is also important to consider the coupling’s critical speed—the speed at which resonance occurs—which should be well above the operating speed to avoid vibration and potential failure.

3.4 Environmental Conditions

The environmental conditions in which the pump operates can have a significant impact on the performance and lifespan of the coupling. Factors such as temperature, humidity, corrosive substances, abrasive particles, and exposure to sunlight or weather can all affect the coupling’s materials and components. For example, in high-temperature applications (such as in boiler feed pumps or oil refineries), couplings with metal components (like disc couplings or gear couplings) are preferred over elastomeric couplings, which can degrade at high temperatures. In corrosive environments (such as in chemical processing plants or saltwater applications), couplings made of corrosion-resistant materials (such as stainless steel or Hastelloy) are essential to prevent rust and degradation. In dusty or abrasive environments, couplings with sealed housings (like gear couplings) can protect internal components from contamination.

3.5 Maintenance Requirements

Maintenance considerations are also important when selecting a pump coupling. Some couplings (such as jaw couplings and elastomeric couplings) require minimal maintenance, with only periodic inspection of the flexible elements for wear or degradation. Other couplings (such as gear couplings and U-joint couplings) require regular lubrication to ensure smooth operation and prevent wear. In applications where downtime is costly, low-maintenance couplings are preferred to minimize the need for frequent repairs or replacements. It is also important to consider the ease of installation and replacement of the coupling, as this can reduce maintenance time and costs. Split couplings, for example, are easier to install and remove than solid couplings, making them ideal for large or hard-to-reach pump systems.

3.6 Cost

Cost is always a consideration in any equipment selection process, and pump couplings are no exception. The cost of a coupling varies depending on its type, size, material, and torque capacity. Rigid couplings and jaw couplings are generally more cost-effective than disc couplings or gear couplings. However, it is important to balance cost with performance and reliability. Choosing a cheaper coupling that is not suited to the application can lead to frequent failures, increased downtime, and higher overall costs in the long run. It is therefore recommended to select a coupling that meets all the technical requirements of the application while staying within the budget.

4. Installation and Maintenance Best Practices for Pump Couplings

Even the best-selected pump coupling will fail prematurely if not installed and maintained properly. Proper installation and regular maintenance are essential to ensuring the optimal performance and longevity of the coupling and the entire fluid handling system. The following best practices should be followed to maximize the reliability of pump couplings:

4.1 Proper Installation

The first step in ensuring the proper performance of a pump coupling is correct installation. This begins with ensuring that the driver and pump shafts are properly aligned. As mentioned earlier, misalignment is one of the leading causes of coupling failure. Alignment can be checked using traditional methods such as straightedges and feeler gauges, or more precise methods such as laser alignment tools. Laser alignment tools are preferred for high-speed or critical applications, as they provide accurate measurements and help to minimize misalignment.

When installing the coupling, it is important to ensure that the hubs are properly seated on the shafts. The hubs should be pressed or shrunk onto the shafts (depending on the design) to create a secure fit. Set screws or keys should be tightened to the manufacturer’s specifications to prevent slippage between the hub and the shaft. For split couplings, the split halves should be aligned properly before bolting together to ensure a uniform connection.

It is also important to ensure that the coupling is installed with the correct gap (axial clearance) between the hubs. The axial clearance allows for thermal expansion and contraction of the shafts during operation, preventing binding or excessive stress on the coupling components. The correct gap size is specified by the coupling manufacturer and should be checked during installation.

4.2 Regular Inspection and Maintenance

Regular inspection and maintenance are essential to detecting potential issues before they lead to coupling failure. The frequency of inspection depends on the application, operating conditions, and coupling type. In general, couplings should be inspected at least once every three months, or more frequently in harsh or high-demand applications.

During inspection, the following items should be checked:

- Flexible elements (such as spiders, discs, or elastomeric components) for signs of wear, cracking, or degradation. If any damage is detected, the flexible element should be replaced immediately.

- Hubs, bolts, and other metal components for signs of corrosion, wear, or loosening. Bolts should be tightened to the manufacturer’s specifications if they are loose.

- Lubrication levels (for couplings that require lubrication, such as gear couplings and U-joint couplings). The lubricant should be checked for contamination (such as dirt, water, or metal particles) and replaced if necessary. The manufacturer’s recommendations for lubricant type and replacement frequency should be followed.

- Alignment of the shafts. Misalignment can develop over time due to thermal expansion, vibration, or settling of the equipment. If misalignment is detected, it should be corrected immediately.

- Vibration levels. Excessive vibration can indicate misalignment, worn coupling components, or other issues. Vibration analysis can be used to detect potential problems early.

4.3 Replacement of Coupling Components

When coupling components show signs of wear or damage, they should be replaced promptly to prevent further damage to the pump and driver. Flexible elements (such as spiders or discs) are typically the first components to wear out and should be replaced with components that meet the manufacturer’s specifications. It is important to use genuine replacement parts to ensure compatibility and optimal performance.

When replacing the coupling, the shafts should be re-aligned to ensure that the new coupling operates correctly. The installation process should be repeated, including checking the axial clearance and tightening all fasteners to the correct torque.

5. Emerging Trends in Pump Coupling Technology

As industrial machinery becomes more efficient, reliable, and intelligent, pump coupling technology is also evolving to meet new demands. Several emerging trends are shaping the future of pump couplings, including the development of more durable materials, the integration of smart monitoring systems, and the focus on energy efficiency.

One of the key trends is the use of advanced materials to improve the performance and lifespan of pump couplings. For example, the use of composite materials (such as carbon fiber-reinforced polymers) in flexible elements is increasing, as these materials offer high strength, low weight, and excellent resistance to corrosion and fatigue. Composite materials also have good damping properties, making them ideal for reducing vibration and noise. In addition, the use of corrosion-resistant alloys (such as duplex stainless steel) in metal components is becoming more common in harsh environmental applications, as these alloys offer superior resistance to corrosion and wear compared to traditional materials.

Another emerging trend is the integration of smart monitoring systems into pump couplings. Smart couplings are equipped with sensors that monitor key parameters such as temperature, vibration, torque, and misalignment. These sensors transmit real-time data to a central monitoring system, allowing maintenance professionals to detect potential issues before they lead to failure. Smart monitoring systems can also help to optimize the performance of the fluid handling system by providing insights into the operating conditions of the coupling and connected components. For example, if the sensors detect an increase in vibration, the system can alert maintenance personnel to check the alignment of the shafts or replace worn coupling components. This proactive approach to maintenance can significantly reduce downtime and improve the overall reliability of the system.

The focus on energy efficiency is also driving innovations in pump coupling technology. As energy costs continue to rise, industries are looking for ways to reduce energy consumption. Pump couplings can contribute to energy efficiency by minimizing friction and reducing vibration, which can increase the overall efficiency of the fluid handling system. For example, disc couplings have low torsional stiffness and minimal friction, making them more energy-efficient than other types of couplings. In addition, the use of lightweight materials in coupling components can reduce the inertia of the rotating system, leading to lower energy consumption during startup and operation.

Finally, there is a growing trend toward modular and customizable coupling designs. Modular couplings allow for easy assembly and disassembly, making maintenance and replacement faster and more cost-effective. Customizable couplings are designed to meet the specific needs of unique applications, such as high-temperature, high-pressure, or high-torque environments. This flexibility allows engineers to select a coupling that is tailored to the exact requirements of the application, improving performance and reliability.

6. Conclusion

Pump couplings are a critical component in fluid handling systems, serving as the mechanical bridge between the driver and the pump. Their ability to transmit torque, accommodate misalignments, absorb shocks, and protect connected components makes them essential for ensuring operational continuity and minimizing downtime. With a wide range of types available—from rigid couplings for precise alignment applications to flexible couplings for misalignment-tolerant systems—selecting the right coupling requires careful consideration of torque requirements, misalignment tolerance, operating speed, environmental conditions, maintenance needs, and cost.

Proper installation and regular maintenance are also key to maximizing the performance and lifespan of pump couplings. By following best practices for alignment, installation, and inspection, maintenance professionals can ensure that couplings operate efficiently and reliably. Emerging trends in pump coupling technology, such as advanced materials, smart monitoring systems, and energy-efficient designs, are further improving the performance and reliability of these essential components.

In conclusion, a thorough understanding of pump couplings—their functions, types, selection criteria, and maintenance requirements—is essential for anyone involved in the design, operation, or maintenance of fluid handling systems. By choosing the right coupling and implementing proper maintenance practices, industries can ensure the efficient and reliable operation of their pump systems, reducing costs and improving overall productivity.

« Pump Couplings » Post Date: 2023/12/4

URL: https://www.rokeecoupling.com/en/tags/pump-couplings.html

- 2023-12-04Flexible Pump Couplings Wholesale

- 2023-12-04Flexible Pump Couplings Supplier

- 2023-12-04Flexible Pump Couplings Factory

- 2023-12-04Flexible Pump Coupling Uses

- 2023-12-04Flexible Pump Coupling Tagging

- 2023-12-04Flexible Pump Coupling Structural Diagram

- 2023-12-04Flexible Pump Coupling Specifications

- 2023-12-04Flexible Pump Coupling Size Calculation

- 2023-12-04Flexible Pump Coupling Purpose

- 2023-12-04Flexible Pump Coupling Procurement

- 2023-12-04Flexible Pump Coupling Parts

- 2023-12-04Flexible Pump Coupling Misalignment Tolerance

- 2023-12-04Flexible Pump Coupling Material

- 2023-12-04Flexible Pump Coupling Maintenance

- 2023-12-04Flexible Pump Coupling Lubrication

- 2023-12-04Flexible Pump Coupling Installation

- 2023-12-04Flexible Pump Coupling Grease

- 2023-12-04Flexible Pump Coupling Gap Chart

- 2023-12-04Flexible Pump Coupling Exploded View

- 2023-12-04Flexible Pump Coupling Efficiency

- 2023-12-04Flexible Pump Coupling Disadvantages

- 2023-12-04Flexible Pump Coupling Components

- 2023-12-04Flexible Pump Coupling Classification

- 2023-12-04Flexible Pump Coupling Catalogue

- 2023-12-04Flexible Pump Coupling Assembly Drawing

- 2023-12-04Flexible Pump Coupling Alignment

- 2023-12-04Flexible Pump Couplings Manufacturer

- 2023-12-04Flexible Pump Coupling Working Principle

- 2023-12-04Flexible Pump Coupling Design

- 2023-12-04Flexible Pump Coupling Applications

- 2023-12-04Flexible Pump Coupling Engineering Drawing

- 2023-12-04Flexible Pump Coupling Machine Drawing

- 2023-12-04Flexible Pump Coupling Size Chart

- 2023-12-04Flexible Pump Coupling Price

- 2023-12-04Flexible Pump Coupling Sales

- 2023-12-04Flexible Pump Coupling Torque

- 2023-12-04Types of Flexible Pump Couplings

- 2023-12-04Flexible Pump Couplings Supply

- 2023-12-04Flexible Pump Couplings For Sale

- 2023-12-04Flexible Pump Coupling Stiffness

- 2023-12-04Flexible Pump Coupling Models

- 2023-12-04Flexible Pump Coupling Manufacturing Enterprise

- 2023-12-04Flexible Pump Coupling Function

- 2023-12-04Flexible Pump Coupling Brands

- 2023-12-04Flexible Pump Coupling Calculation

- 2023-12-04Flexible Pump Coupling Drawing

- 2023-12-04Flexible Pump Coupling Company

- 2023-12-04Flexible Pump Coupling Advantages

- 2023-12-04Flexible Pump Coupling 3D Model

- 2023-12-04Custom Flexible Pump Coupling

- 2023-10-30Claw Type Water Pump Coupling

- 2023-10-24Pin Type Water Pump Coupling

- 2023-10-24Column Pin Water Pump Coupling Manufacturer

- 2023-10-10Diaphragm Pump Couplings

- 2023-10-10Claw Type Vacuum Pump Couplings

- 2023-10-10Claw Shaped Water Pump Couplings

- 2023-09-20Manufacturer Of High Elastic Toothed Water Pump Coupling

- 2023-09-18High Elastic Toothed Water Pump Coupling

- 2023-09-16Pump Coupling With Plum Blossom Gasket