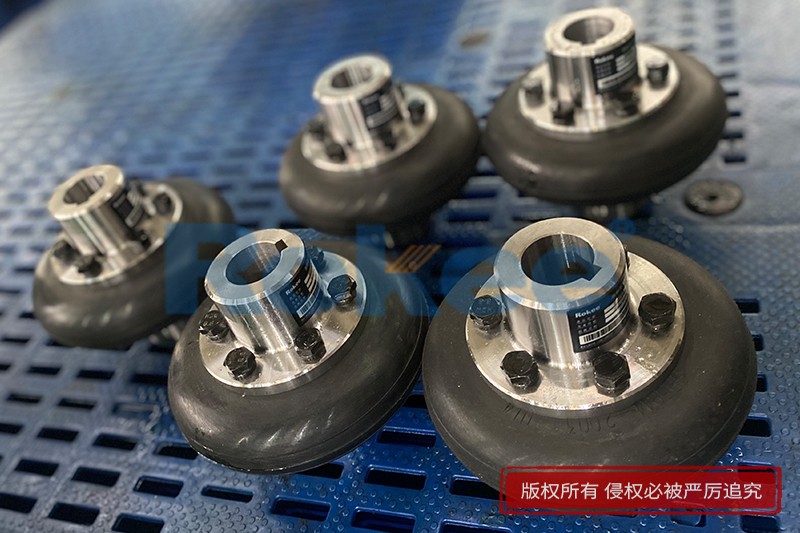

Tire Couplings

Rokee® is Tire Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Tire Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

The tire coupling adopts tyre body-shaped rubber elements, which are connected with two semi-couplings through bolts to realize torque transmission and displacement compensation. Tire coupling has high elastic performance, small torsional rigidity, strong damping capacity, large axial compensation capacity, and good damping performance.

-

UL Elastic Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation. -

LLA Elastic Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. -

LLB Elastic Tyre Coupling

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, enabling the seamless transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types available, tire couplings have emerged as a reliable and versatile solution for numerous industrial applications. Characterized by their elastic tire-shaped element that connects two shaft hubs, these couplings offer a unique combination of flexibility, damping capabilities, and ease of installation.

To appreciate the functionality of tire couplings, it is essential to first grasp their basic operating principle. At its core, a tire coupling transmits torque from a driving shaft to a driven shaft through a flexible tire element. Unlike rigid couplings that require precise alignment and offer no flexibility, the elastic tire serves as a buffer, absorbing shocks and vibrations generated during operation. This elasticity also allows the coupling to accommodate three primary types of shaft misalignment: angular misalignment (where the shafts are inclined relative to each other), parallel misalignment (where the shafts are offset horizontally), and axial misalignment (where the shafts move along their axial direction). The tire element deforms elastically to compensate for these misalignments, reducing stress on the shafts, bearings, and other connected components. Additionally, the rubber or elastomeric material of the tire provides inherent damping properties, which help minimize noise and vibration, thereby enhancing the overall stability and lifespan of the mechanical system.

The structural composition of a tire coupling is relatively straightforward, consisting of three main components: two metal hubs, a flexible tire element, and fastening hardware. The hubs are typically manufactured from high-strength metals such as steel or cast iron, designed to attach securely to the driving and driven shafts. These hubs feature a series of holes or studs around their circumference, which are used to connect to the tire element. The design of the hubs may vary depending on the specific application requirements, with options such as keyway connections, taper-lock bushings, or compression fittings to ensure a tight and reliable fit on the shafts. The flexible tire element, the defining component of the coupling, is usually made from synthetic rubber or elastomeric compounds reinforced with fabric or cord for added strength and durability. The tire is shaped to fit snugly between the two hubs, with holes corresponding to the studs or bolts on the hubs to facilitate assembly. Fastening hardware, such as bolts, nuts, and washers, secures the tire element to the hubs, ensuring that torque is efficiently transmitted while maintaining the flexibility of the coupling.

Material selection for tire couplings is a critical factor that directly impacts their performance, durability, and suitability for specific applications. The hubs, as the load-bearing components, are typically crafted from materials with high tensile strength and resistance to wear and fatigue. Carbon steel is a common choice for general-purpose applications due to its excellent strength-to-weight ratio and cost-effectiveness. For more demanding environments, such as those involving high temperatures or corrosive substances, alloy steels or stainless steel may be used to enhance resistance to oxidation and chemical degradation. The tire element, on the other hand, is primarily composed of elastomeric materials, with natural rubber and synthetic rubbers like neoprene, nitrile, and EPDM being the most widely used. Natural rubber offers good elasticity and damping properties but may not be suitable for high-temperature or oil-rich environments. Neoprene, by contrast, exhibits excellent resistance to oil, ozone, and weathering, making it ideal for industrial applications where exposure to such elements is common. Nitrile rubber is particularly well-suited for applications involving petroleum-based fluids, while EPDM offers superior resistance to heat, steam, and harsh chemicals. In many cases, the tire element is reinforced with synthetic fibers or steel cords to improve its tensile strength and prevent premature failure under high torque loads.

One of the primary advantages of tire couplings is their exceptional flexibility, which allows for significant misalignment compensation. This flexibility is particularly beneficial in applications where shaft alignment is difficult to maintain, such as in large industrial machinery, conveyors, or pumps. By accommodating misalignments, tire couplings reduce the risk of bearing failure, shaft bending, and other mechanical issues that can arise from excessive stress. Another key benefit is their excellent shock and vibration damping capabilities. The elastic tire element acts as a buffer, absorbing the impact of sudden load changes and reducing the transmission of vibrations between shafts. This not only improves the stability of the mechanical system but also reduces noise levels, creating a more comfortable and safer working environment. Additionally, tire couplings are relatively easy to install and maintain. Their simple design allows for quick assembly and disassembly, minimizing downtime during maintenance or replacement. Unlike some other coupling types, tire couplings do not require lubrication, which eliminates the need for regular lubrication checks and reduces maintenance costs.

Tire couplings also offer good torque transmission capacity relative to their size, making them suitable for a wide range of power ratings. From small fractional-horsepower applications to large industrial drives, tire couplings can be designed to handle varying torque loads by adjusting the size and material of the tire element and hubs. Furthermore, these couplings are resistant to wear and tear under normal operating conditions, with the elastic tire element providing a degree of protection against minor impacts and abrasions. In applications where there is a risk of shaft separation, some tire coupling designs incorporate a fail-safe feature, ensuring that the coupling remains connected even if the tire element fails, preventing catastrophic damage to the machinery.

The versatility of tire couplings makes them suitable for a diverse range of industrial applications across various sectors. One of the most common applications is in the pumping industry, where pumps are often subject to misalignment due to thermal expansion, foundation settlement, or installation errors. Tire couplings are used to connect pump shafts to motor shafts, accommodating misalignments and reducing vibration, which improves the efficiency and lifespan of the pump. In the conveyor industry, tire couplings are employed to drive conveyor belts, where they handle the varying torque loads associated with starting and stopping the conveyor and accommodate misalignments between the motor and conveyor shafts. The mining industry also relies heavily on tire couplings, using them in equipment such as crushers, grinders, and conveyors, where they must withstand harsh operating conditions, including high vibrations, dust, and temperature fluctuations.

Other notable applications include fans and blowers, where tire couplings help reduce noise and vibration while ensuring efficient power transmission. In the automotive industry, tire couplings are used in some auxiliary systems, such as power steering pumps and air conditioning compressors. They are also utilized in industrial gearboxes, connecting the gearbox output shaft to the driven machinery. Additionally, tire couplings find applications in renewable energy systems, such as wind turbines, where they help transmit power from the turbine rotor to the generator while accommodating misalignments and absorbing vibrations generated by wind loads.

Proper maintenance is essential to ensure the optimal performance and longevity of tire couplings. While these couplings are relatively low-maintenance compared to other types, regular inspections and proactive measures can prevent premature failure and minimize downtime. One of the key maintenance tasks is regular visual inspection of the tire element, hubs, and fastening hardware. Inspectors should look for signs of wear, such as cracks, tears, or degradation of the tire material, which can indicate fatigue or exposure to harsh environmental conditions. Additionally, checking the tightness of the bolts or nuts that secure the tire to the hubs is crucial, as loose fasteners can lead to excessive vibration, misalignment, and ultimately, coupling failure.

It is also important to monitor the operating conditions of the coupling, including temperature, vibration levels, and noise. Abnormal increases in temperature may indicate excessive friction due to misalignment or a damaged tire element. Similarly, unusual vibration or noise can be a sign of impending failure, requiring immediate investigation. In applications where the coupling is exposed to dust, dirt, or corrosive substances, regular cleaning of the hubs and tire element can help prevent the buildup of debris, which can accelerate wear. If the tire element shows signs of significant wear or damage, it should be replaced promptly. When replacing the tire, it is important to ensure that the new tire is compatible with the existing hubs and meets the application's torque and misalignment requirements. Additionally, proper installation of the new tire is critical, including ensuring that the hubs are correctly aligned before tightening the fasteners.

While tire couplings offer numerous advantages, there are also some limitations to consider. One of the main limitations is their temperature range. Elastomeric materials have a maximum operating temperature, typically between -40°C and 120°C, depending on the material. Exceeding this temperature range can cause the tire element to degrade rapidly, leading to premature failure. Therefore, tire couplings are not suitable for high-temperature applications, such as those involving direct exposure to exhaust gases or high-temperature process fluids. Another limitation is their resistance to certain chemicals. Some elastomeric materials may be susceptible to degradation when exposed to specific chemicals, such as strong acids, bases, or solvents. In such applications, it is essential to select a tire material that is compatible with the surrounding environment.

Additionally, tire couplings have a limited axial displacement capacity compared to some other coupling types, such as universal joints or Oldham couplings. This means that they may not be suitable for applications where significant axial movement of the shafts is expected. Finally, while tire couplings can handle moderate torque loads, they may not be the best choice for extremely high-torque applications, where rigid couplings or gear couplings may be more appropriate.

In conclusion, tire couplings are a valuable and versatile component in mechanical power transmission systems, offering a unique combination of flexibility, damping capabilities, and ease of maintenance. Their simple yet effective design makes them suitable for a wide range of applications across various industries, from pumping and conveyor systems to mining and renewable energy. By understanding the principles of operation, material selection, key advantages, and maintenance requirements of tire couplings, engineers and maintenance professionals can make informed decisions about their use, ensuring optimal performance and longevity of the mechanical systems they are part of. While tire couplings have some limitations, their benefits often outweigh these drawbacks in many industrial applications, making them a popular choice for modern machinery.

As technology continues to advance, there is potential for further improvements in tire coupling design and materials. Developments in elastomeric materials may lead to tire elements with higher temperature resistance, better chemical compatibility, and increased durability. Additionally, advancements in manufacturing processes may result in more precise and cost-effective production of hubs and tire elements, further enhancing the performance and affordability of tire couplings. As industries continue to demand more efficient and reliable power transmission solutions, tire couplings are likely to remain a key component in meeting these needs, adapting to new applications and operating conditions.

« Tire Couplings » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/tire-couplings.html

- 2025-06-27Tire Coupling Tires and Flexible Elements

- 2023-11-14Rubber Tire Couplings Wholesale

- 2023-11-14Rubber Tire Couplings Supply

- 2023-11-14Rubber Tire Couplings Manufacturing Enterprise

- 2023-11-14Rubber Tire Couplings Manufacturer

- 2023-11-14Rubber Tire Coupling Working Principle

- 2023-11-14Rubber Tire Coupling Purpose

- 2023-11-14Rubber Tire Coupling Function

- 2023-11-14Rubber Tire Coupling Parts

- 2023-11-14Models of Rubber Tire Couplings

- 2023-11-10Rubber Tire Coupling Specifications

- 2023-11-10Rubber Tire Coupling Applications

- 2023-11-10Rubber Tire Coupling Size Calculation

- 2023-11-09Rubber Tire Couplings Supplier

- 2023-11-09Rubber Tire Coupling Structural Diagram

- 2023-11-09Disadvantages of Rubber Tire Couplings

- 2023-11-09Rubber Tire Coupling Drawing

- 2023-11-09Rubber Tire Coupling Seller

- 2023-11-08Rubber Tire Coupling Price

- 2023-11-08Catalogue of Rubber Tire Couplings

- 2023-11-08Customized Rubber Tire Couplings

- 2023-11-08Rubber Tire Coupling Design

- 2023-11-08Types of Rubber Tire Couplings

- 2023-11-08Rubber Tire Coupling Size Chart

- 2023-11-08Rubber Tire Coupling Advantages

- 2023-11-08Rubber Tire Coupling Factory

- 2023-11-08Rubber Tire Couplings Company

- 2023-10-30Tire Coupling Leveling

- 2023-10-30Tire Coupling Installation Standard

- 2023-10-30Tire Coupling Installation Deviation

- 2023-10-30Tire Coupling Installation Clearance

- 2023-10-25Tire Coupling Distance Standard

- 2023-10-25Tire Coupling Displacement Compensation

- 2023-10-25Tire Coupling Compensation Coefficient

- 2023-10-25Tire Coupling Body Thickness

- 2023-10-25Tire Coupling Body Specifications

- 2023-10-25Tire Coupling Alignment Standard

- 2023-10-25Tire Coupling Adjustment Amount

- 2023-10-25Trial Occasions For Tire Couplings

- 2023-10-25Trial Environment For Tire Coupling

- 2023-10-25Tire Couplings Radial Disturbance

- 2023-10-25Tire Couplings Principle

- 2023-10-25Tire Couplings Practical Application

- 2023-10-25Tire Couplings Materials

- 2023-10-25Tire Couplings Concentricity

- 2023-10-25Tire Couplings Applicable Occasions

- 2023-10-25Tire Coupling Usage Temperature

- 2023-10-25Tire Coupling Tire Thickness

- 2023-10-25Tire Coupling Tire Specifications & Models

- 2023-10-25Tire Coupling Tire Material

- 2023-10-25Tire Coupling Tire Body Parameters

- 2023-10-25Tire Coupling Standard

- 2023-10-25Tire Coupling Technology

- 2023-10-25Tire Coupling Structural Diagram

- 2023-10-25Tire Coupling Soft Connection

- 2023-10-25Tire Coupling Service Life

- 2023-10-25Tire Coupling Replacement Standard

- 2023-10-25Tire Coupling Production Process

- 2023-10-25Tire Coupling Processing Technology

- 2023-10-25Tire Coupling Offset Characteristics

- 2023-10-25Tire Coupling Power

- 2023-10-25Tire Coupling Physical Manufacturer

- 2023-10-25Tire Coupling Material

- 2023-10-25Tire Coupling Elastic Element

- 2023-10-25Tire Coupling Compensation Amount

- 2023-10-25Tire Coupling Compensation Range

- 2023-10-25Tire Coupling Disadvantages

- 2023-10-25Tire Coupling End Face Clearance

- 2023-10-25Tire Coupling Friction

- 2023-10-25Tire Coupling Opening

- 2023-10-25Tire Coupling Quotation

- 2023-10-25Tire Couplings Grooving

- 2023-10-25Tire Coupling Working Principle

- 2023-10-25Tire Coupling Usage Scenarios

- 2023-10-25Tire Couplings Alignment

- 2023-10-25Tire Couplings Classification

- 2023-10-25Tire Couplings Wholesale

- 2023-10-25Tire Couplings Benefits

- 2023-10-25Tire Coupling Torque

- 2023-10-25Tire Coupling Supplier

- 2023-10-25Tire Coupling Size

- 2023-10-25Tire Coupling Specifications

- 2023-10-25Tire Coupling Processing Factory

- 2023-10-25Tire Coupling Price

- 2023-10-25Tire Coupling Parameters

- 2023-10-25Tire Coupling Manufacturer

- 2023-10-25Tire Coupling Elastomer Manufacturer

- 2023-10-25Tire Coupling Enterprises

- 2023-10-25Tire Coupling Gap

- 2023-10-25Tire Coupling Factory

- 2023-10-25Tire Coupling Drawing

- 2023-10-25Tire Coupling Design

- 2023-10-25Tire Coupling Customization

- 2023-10-25Tire Coupling Cost

- 2023-10-25Tire Coupling Characteristics

- 2023-10-25Tire Coupling Company

- 2023-10-25Tire Coupling Coaxiality

- 2023-10-25Tire Coupling Clearance

- 2023-10-25Tire Coupling Brand

- 2023-10-25Tire Coupling Angle

- 2023-10-25Tire Coupling & Tire Body Manufacturer

- 2023-10-25Tire Coupling Accessories

- 2023-10-25Flexible Tire Coupling Design

- 2023-10-25Flexible Tire Coupling

- 2023-10-25Emulsion Pump Tire Coupling

- 2023-10-25Fan Tire Coupling

- 2023-10-25Compressor Tire Coupling

- 2023-10-25Agricultural Vehicle Tire Coupling

- 2023-10-253D Model Of Tire Coupling