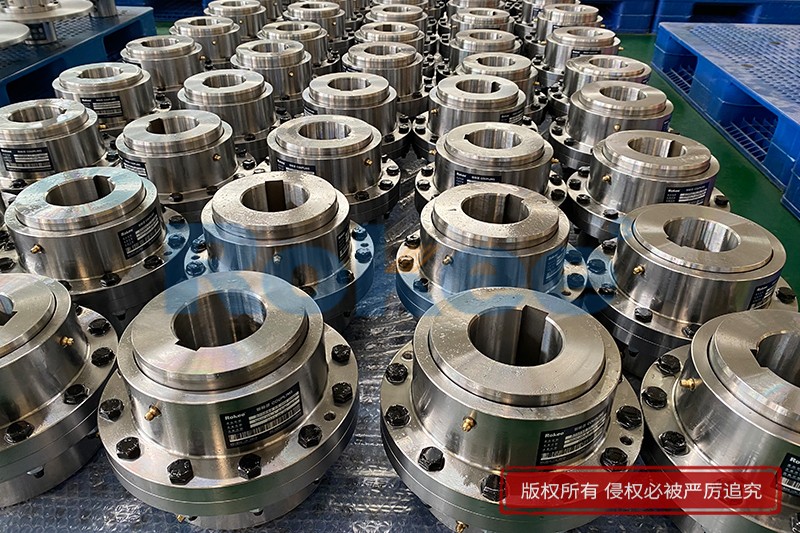

Small Shaft Coupling

Rokee® is Small Shaft Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Small Shaft Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of mechanical engineering, the efficient transfer of power between rotating shafts stands as a fundamental requirement for countless applications. From miniature electric motors in consumer electronics to compact industrial pumps and precision machining tools, the component that enables this seamless power transmission—often overlooked yet indispensable—is the small shaft coupling. Designed to connect two shafts while accommodating misalignments, absorbing shocks, and ensuring torque transfer, small shaft couplings play a critical role in maintaining the performance, reliability, and longevity of mechanical systems.

At its core, a small shaft coupling is a mechanical device that joins two rotating shafts to transmit torque from a driving source (such as a motor) to a driven component (such as a gearbox or a load). Unlike rigid connections, which demand perfect alignment between shafts, couplings are engineered to accommodate various forms of misalignment, including angular misalignment (where shafts intersect at an angle), parallel misalignment (where shafts are offset parallel to each other), and axial misalignment (where shafts move along their axial direction). Additionally, many small shaft couplings are designed to dampen vibrations, absorb shocks, and compensate for thermal expansion or contraction of shafts during operation. These capabilities are particularly crucial in small-scale applications, where even minor misalignments or vibrations can lead to excessive wear, reduced efficiency, or complete system failure.

The working principle of a small shaft coupling revolves around balancing two primary objectives: ensuring efficient torque transmission and accommodating misalignment without causing excessive stress on the shafts or other components. Torque transmission is achieved through the mechanical engagement of the coupling with the two shafts—typically via clamping, keyway connections, or set screws. The design of the coupling’s flexible or rigid elements dictates its ability to handle misalignment. Rigid couplings, for instance, rely on precise machining to maintain alignment and transmit torque directly, while flexible couplings use elastic components (such as rubber, polyurethane, or metal bellows) to allow for relative movement between shafts while still transferring torque.

One of the most important considerations when selecting a small shaft coupling is understanding the different types available and their respective advantages and limitations. The following are the most common types of small shaft couplings used in various applications:

Rigid couplings are the simplest type, consisting of two hubs that are bolted or clamped together to connect two shafts. They are designed for applications where shafts are already perfectly aligned and no misalignment is expected. Rigid couplings are typically made from metal (such as steel or aluminum) and offer high torque capacity relative to their size. However, their major limitation is their inability to accommodate any misalignment—even minor offsets can lead to increased bearing wear and premature failure of the coupling or shafts. Common subtypes of rigid couplings include sleeve couplings, clamp couplings, and flanged couplings. Sleeve couplings, the most basic type, slide over the ends of the two shafts and are secured with set screws. Clamp couplings, also known as split couplings, consist of two halves that are clamped around the shafts, eliminating the need to slide the coupling over the entire length of the shaft—a feature that simplifies installation and maintenance.

Flexible couplings are designed to accommodate misalignment and dampen vibrations, making them ideal for most small-scale applications where perfect alignment is difficult to achieve or maintain. They are categorized based on the type of flexible element used, with the most common subtypes including elastomeric couplings, beam couplings, bellows couplings, and universal joints.

Elastomeric couplings use a flexible material (such as rubber, polyurethane, or neoprene) inserted between two metal hubs. The elastomeric element absorbs shocks and vibrations and allows for moderate angular and parallel misalignment. These couplings are widely used in small electric motors, pumps, and fans due to their low cost, easy installation, and good damping properties. However, the elastomeric material can degrade over time due to heat, oil, or chemical exposure, requiring periodic replacement.

Beam couplings, also known as flexible beam couplings, are made from a single piece of metal (typically aluminum or stainless steel) with a series of helical or parallel cuts. These cuts create flexible beams that allow for angular and parallel misalignment while maintaining high torque transmission accuracy. Beam couplings are particularly suitable for precision applications, such as CNC machines, encoders, and small robotic systems, because they have no backlash (the play between moving parts) and offer excellent repeatability. Their one-piece design also eliminates the need for assembly and reduces the risk of component failure due to loose parts.

Bellows couplings consist of a metal bellows (usually made from stainless steel) connected to two hubs. The bellows provides flexibility, allowing for angular, parallel, and axial misalignment, while the metal construction ensures high temperature resistance and durability. These couplings are commonly used in high-precision applications, such as aerospace components, medical devices, and semiconductor manufacturing equipment, where reliability and resistance to harsh environments are critical. Unlike elastomeric couplings, bellows couplings do not degrade over time and require minimal maintenance.

Universal joints, also known as U-joints, consist of two yokes connected by a cross shaft. They are designed to accommodate large angular misalignments (up to 45 degrees in some cases) and are commonly used in applications where shafts are not in the same plane, such as small vehicles, agricultural equipment, and portable power tools. However, universal joints introduce some degree of vibration at high speeds, especially when the misalignment angle is large, which limits their use in high-precision applications.

The selection of materials for small shaft couplings is a critical factor that influences their performance, durability, and suitability for specific applications. The most common materials used for coupling hubs include steel, aluminum, and stainless steel, while flexible elements are typically made from elastomers, stainless steel, or composite materials.

Steel is a popular choice for coupling hubs due to its high strength, rigidity, and torque capacity. Carbon steel is often used for general-purpose applications, while alloy steel is preferred for high-torque or high-temperature environments. However, steel is relatively heavy, which can be a disadvantage in applications where weight is a concern, such as portable electronics or aerospace components.

Aluminum is lighter than steel and offers good corrosion resistance, making it ideal for small-scale applications where weight reduction is important. It also has good thermal conductivity, which helps dissipate heat generated during operation. However, aluminum has a lower torque capacity than steel, so it is typically used in low to medium torque applications, such as small electric motors and fans.

Stainless steel is chosen for applications that require resistance to corrosion, high temperatures, or harsh chemicals. It is commonly used in food processing equipment, medical devices, and marine applications. Stainless steel couplings are also durable and have a long service life, but they are more expensive than steel or aluminum couplings.

Elastomeric materials, such as rubber, polyurethane, and neoprene, are used for the flexible elements of elastomeric couplings. These materials offer excellent damping properties, which help reduce vibrations and noise. Polyurethane is more durable than rubber and has better resistance to oil and chemicals, making it a popular choice for industrial applications. Neoprene is resistant to ozone and weathering, making it suitable for outdoor applications.

Composite materials, such as carbon fiber or glass fiber reinforced polymers, are increasingly being used in small shaft couplings due to their high strength-to-weight ratio, corrosion resistance, and ability to be molded into complex shapes. These materials are ideal for high-performance applications, such as aerospace and racing equipment, where weight and performance are critical.

When designing or selecting a small shaft coupling, several key factors must be considered to ensure optimal performance and reliability. These factors include torque capacity, misalignment requirements, operating speed, temperature, environment, and installation constraints.

Torque capacity is the maximum amount of torque that a coupling can transmit without failure. It is essential to select a coupling with a torque capacity that exceeds the maximum torque generated by the driving source. Failure to do so can result in coupling damage, shaft breakage, or system failure. The torque capacity of a coupling depends on its material, size, and design—rigid couplings typically have higher torque capacity than flexible couplings of the same size.

Misalignment requirements vary depending on the application. It is important to determine the type and magnitude of misalignment that the coupling will need to accommodate. For applications with significant misalignment, flexible couplings such as bellows or elastomeric couplings are preferred. For applications with minimal or no misalignment, rigid couplings are more suitable.

Operating speed is another critical factor. High-speed applications, such as small turbines or precision spindles, require couplings that can operate without generating excessive vibration or centrifugal force. Beam couplings and bellows couplings are often preferred for high-speed applications due to their balanced design and low backlash. Rigid couplings can also be used at high speeds if the shafts are perfectly aligned.

Operating temperature affects the performance of coupling materials. Elastomeric materials, for example, can degrade at high temperatures, while metal materials may lose strength or become brittle at extreme temperatures. It is important to select a coupling material that can withstand the operating temperature range of the application.

Environmental factors, such as exposure to moisture, chemicals, dust, or saltwater, can also impact coupling performance. Stainless steel or composite couplings are preferred for corrosive environments, while sealed couplings can protect against dust and moisture ingress.

Installation constraints, such as shaft diameter, space limitations, and ease of installation, must also be considered. Small shaft couplings are available in a range of sizes to fit different shaft diameters, and some types (such as clamp couplings) are easier to install than others (such as sleeve couplings, which require the shaft to be disassembled).

Small shaft couplings find applications in a wide range of industries and products, thanks to their compact size, versatility, and ability to transmit torque efficiently. The following are some of the most common application areas:

Consumer electronics: Small shaft couplings are used in a variety of consumer electronics, such as printers, scanners, cameras, and small appliances (e.g., blenders, food processors). In printers, for example, couplings connect the motor shaft to the roller shafts, ensuring precise movement of the paper. In cameras, they are used to transmit torque from the motor to the lens focusing mechanism, enabling smooth and accurate focusing.

Industrial automation: In industrial automation systems, such as CNC machines, robots, and conveyor systems, small shaft couplings play a critical role in ensuring precise power transmission. CNC machines, for instance, use beam or bellows couplings to connect the servo motor shafts to the lead screws or ball screws, which control the movement of the machine’s axes. These couplings provide high accuracy and low backlash, ensuring that the machine can achieve the tight tolerances required for precision machining.

Medical devices: Medical devices, such as diagnostic equipment (e.g., MRI machines, ultrasound scanners) and surgical tools (e.g., laparoscopic instruments), require small, precise, and reliable couplings. Bellows couplings are often used in these applications due to their high precision, corrosion resistance, and ability to operate in sterile environments. For example, in laparoscopic instruments, couplings connect the motor shaft to the cutting or grasping mechanism, enabling precise control during surgery.

Automotive industry: Small shaft couplings are used in various automotive components, such as electric power steering systems, windshield wipers, and fuel pumps. In electric power steering systems, couplings connect the electric motor shaft to the steering column, transmitting torque to assist with steering. These couplings must be durable, reliable, and able to withstand the harsh conditions of the automotive environment, such as high temperatures, vibration, and exposure to oil and chemicals.

Aerospace and defense: In aerospace and defense applications, such as small unmanned aerial vehicles (UAVs), missile guidance systems, and aircraft components, small shaft couplings must meet strict performance and reliability requirements. Composite or stainless steel couplings are often used in these applications due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures and pressures.

Renewable energy: Small shaft couplings are used in small-scale renewable energy systems, such as small wind turbines and solar tracking systems. In small wind turbines, couplings connect the rotor shaft to the generator shaft, transmitting torque to generate electricity. These couplings must be able to accommodate misalignment caused by wind turbulence and withstand outdoor environmental conditions.

Proper maintenance of small shaft couplings is essential to ensure their long-term performance and reliability. Neglecting maintenance can lead to premature coupling failure, increased downtime, and costly repairs. The following are some key maintenance practices for small shaft couplings:

Regular inspection: Couplings should be inspected regularly for signs of wear, damage, or misalignment. During inspection, check for cracks, corrosion, or deformation of the coupling hubs or flexible elements. Also, check for loose fasteners (such as set screws or bolts) and tighten them if necessary. In flexible couplings, inspect the elastomeric elements for signs of degradation, such as cracking, hardening, or swelling.

Lubrication: Some types of couplings, such as universal joints and flanged couplings, require lubrication to reduce friction and wear. Use the appropriate lubricant for the coupling material and operating conditions, and follow the manufacturer’s recommendations for lubrication intervals. Over-lubrication can attract dust and debris, which can cause additional wear, while under-lubrication can lead to excessive friction and heat generation.

Alignment check: Periodically check the alignment of the shafts connected by the coupling. Misalignment can cause excessive stress on the coupling and shafts, leading to premature failure. Use appropriate alignment tools, such as dial indicators or laser alignment systems, to ensure that the shafts are aligned correctly. If misalignment is detected, adjust the position of the motor or driven component to correct it.

Replacement of worn components: If any component of the coupling is worn or damaged beyond repair, it should be replaced immediately. For elastomeric couplings, replace the elastomeric element when signs of degradation are detected. For rigid couplings, replace the entire coupling if cracks or deformation are present. Using worn components can lead to sudden coupling failure, which can cause damage to other parts of the system.

Environmental protection: Protect couplings from harsh environmental conditions, such as moisture, dust, chemicals, and extreme temperatures. Use sealed couplings or protective covers to prevent ingress of dust and moisture. In corrosive environments, use couplings made from corrosion-resistant materials, such as stainless steel or composites.

In conclusion, small shaft couplings are essential components in modern mechanical systems, enabling efficient and reliable power transmission between rotating shafts. Their ability to accommodate misalignments, absorb shocks, and dampen vibrations makes them indispensable in a wide range of applications, from consumer electronics to aerospace and defense. Understanding the different types of small shaft couplings, their material selections, design considerations, and maintenance practices is crucial for selecting the right coupling for a specific application and ensuring optimal performance and longevity.

As technology continues to advance, the demand for smaller, more precise, and more durable shaft couplings is expected to grow. Manufacturers are increasingly focusing on developing couplings made from advanced materials, such as composites, and incorporating innovative designs to improve performance and reduce weight. Additionally, the trend towards automation and Industry 4.0 is driving the need for couplings that can integrate with smart monitoring systems, enabling real-time detection of wear and misalignment and predictive maintenance.

Whether in a small electric motor, a precision CNC machine, or a cutting-edge medical device, small shaft couplings play a vital role in keeping mechanical systems running smoothly. By selecting the right coupling and following proper maintenance practices, engineers and technicians can ensure that these small but critical components contribute to the overall efficiency, reliability, and success of their applications.

« Small Shaft Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/small-shaft-coupling.html