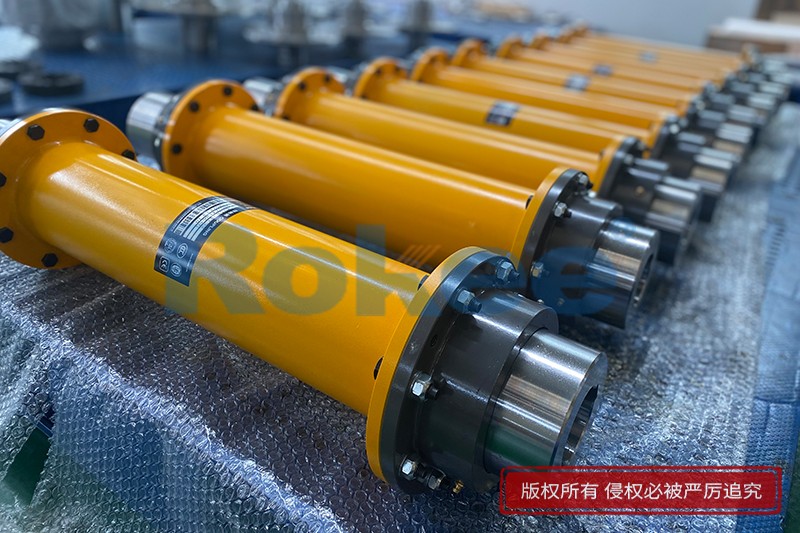

Slider Couplings

Rokee® is Slider Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Slider Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of mechanical power transmission, couplings serve as indispensable components that connect two shafts to transmit torque while accommodating various forms of misalignment. Among the diverse types of couplings available, the slider coupling stands out for its simplicity, cost-effectiveness, and ability to handle axial movement alongside angular and parallel misalignment.

A slider coupling, also referred to as a sliding coupling or slip coupling in some contexts, is a flexible coupling designed to transmit rotational power between two coaxial shafts while allowing relative axial movement (sliding) of the shafts and compensating for limited angular and parallel misalignment. Unlike rigid couplings, which require precise shaft alignment and do not permit any relative movement, slider couplings incorporate mechanisms that enable controlled displacement, thereby reducing stress on shafts, bearings, and other transmission components. The core advantage of slider couplings lies in their ability to accommodate axial expansion or contraction of shafts caused by thermal expansion, vibration, or load fluctuations, making them suitable for a wide range of industrial and automotive applications where such movements are inevitable.

To understand the functionality of slider couplings, it is essential to examine their structural components. While designs may vary slightly based on specific application requirements, the basic structure of a slider coupling typically consists of three main parts: two shaft hubs (also known as coupling halves), a sliding element (such as a slider block, slider disc, or sliding sleeve), and fasteners (bolts, set screws, or keyways) for securing the hubs to the respective shafts. The two shaft hubs are connected to the driving and driven shafts, respectively, and the sliding element acts as the interface between the hubs, facilitating torque transmission and relative movement.

The shaft hubs are usually cylindrical in shape with a bore that matches the diameter of the shafts they connect. To ensure a secure fit and prevent slippage during torque transmission, hubs may feature keyways that align with keys on the shafts, or they may use set screws that exert pressure on the shaft surface. Some designs also incorporate tapered bores for enhanced grip, particularly in high-torque applications. The sliding element, which is the defining component of the slider coupling, is typically made of a material with low friction coefficient to minimize wear during sliding movement. This element may be integrated into one of the hubs or exist as a separate component that engages with both hubs through grooves, splines, or other mating features. For example, in a common slider coupling design, one hub is equipped with a protruding slider block that fits into a corresponding groove on the other hub. As the shafts rotate, the slider block transmits torque through the groove, while allowing axial movement of the hubs relative to each other. Angular and parallel misalignment are accommodated by the slight pivoting or lateral movement of the slider element within the mating feature.

The working principle of a slider coupling revolves around the balanced transmission of torque and the accommodation of relative shaft movements. When the driving shaft rotates, it imparts rotational force to the connected hub. This force is transferred to the sliding element, which in turn transmits it to the second hub and the driven shaft. During operation, if the shafts experience axial movement (e.g., due to thermal expansion when the system heats up), the sliding element moves within its mating feature (groove, spline, etc.) without disrupting torque transmission. Similarly, if there is a small degree of angular misalignment (where the shafts are not perfectly colinear) or parallel misalignment (where the shafts are offset parallel to each other), the slider element can pivot or shift slightly to compensate for these deviations. It is important to note, however, that slider couplings have limitations in terms of the amount of misalignment they can handle. Excessive misalignment can lead to increased wear, vibration, and reduced coupling lifespan, so proper alignment during installation is still crucial.

Material selection plays a vital role in determining the performance, durability, and application range of slider couplings. The choice of materials for the hubs and sliding element depends on factors such as the torque capacity required, operating speed, environmental conditions (temperature, humidity, corrosive substances), and the nature of the load (steady, intermittent, or shock loads). For the shaft hubs, common materials include carbon steel, alloy steel, aluminum alloy, and cast iron. Carbon steel and alloy steel are preferred for high-torque applications due to their high strength and rigidity. Aluminum alloy is used in applications where weight reduction is a priority, such as in automotive and aerospace components, although it has lower torque capacity compared to steel. Cast iron is a cost-effective option for low to medium torque applications with moderate operating speeds.

The sliding element, on the other hand, requires materials with low friction, high wear resistance, and good mechanical strength. Common materials for sliding elements include bronze, brass, nylon, polyethylene, and Teflon (polytetrafluoroethylene). Bronze and brass are widely used in industrial applications due to their excellent wear resistance, low friction coefficient, and ability to withstand high temperatures. They are particularly suitable for applications involving heavy loads and high operating speeds. Nylon and polyethylene are lightweight, corrosion-resistant, and self-lubricating, making them ideal for applications in wet or corrosive environments, as well as in applications where noise reduction is important (since they dampen vibration more effectively than metal). Teflon offers the lowest friction coefficient among these materials but has lower mechanical strength, so it is typically used in light-load, low-speed applications.

Slider couplings find applications across a broad spectrum of industries, ranging from industrial machinery and automotive systems to agricultural equipment and household appliances. Their versatility stems from their ability to accommodate axial movement and misalignment, combined with their simple design and low cost. In industrial machinery, slider couplings are commonly used in conveyor systems, pumps, compressors, and fans. Conveyor systems, for example, often experience axial movement of shafts due to thermal expansion and contraction during long-term operation, and slider couplings effectively transmit torque while accommodating this movement, ensuring smooth and continuous operation. Pumps and compressors, which operate at varying speeds and loads, benefit from the slider coupling’s ability to compensate for misalignment caused by vibration, reducing wear on bearings and seals.

In the automotive industry, slider couplings are used in drive shafts, transmission systems, and auxiliary components such as water pumps and alternators. The drive shaft of a vehicle, which connects the transmission to the differential, is subject to axial movement as the suspension compresses and extends during driving. Slider couplings in the drive shaft assembly allow this axial movement while transmitting torque from the engine to the wheels. Additionally, in transmission systems, slider couplings help to align the input and output shafts, reducing stress on the transmission components and improving overall efficiency. In agricultural equipment, such as tractors and harvesters, slider couplings are used in power take-off (PTO) shafts, which transmit power from the engine to various attachments (e.g., plows, mowers). These shafts are often exposed to harsh environmental conditions and misalignment due to the uneven terrain, making slider couplings a reliable choice.

Household appliances also utilize slider couplings in components such as washing machine agitators, dryer drums, and electric motors. For example, the motor in a washing machine is connected to the agitator via a slider coupling, which accommodates the axial movement and misalignment that occurs during the agitation and spin cycles. The simple design and low cost of slider couplings make them ideal for mass-produced household appliances, where reliability and affordability are key considerations.

Proper installation is critical to ensuring the optimal performance and longevity of slider couplings. The following steps and considerations should be followed during installation: First, the shafts must be cleaned thoroughly to remove any dirt, grease, or debris that could affect the fit of the coupling hubs. Any burrs or imperfections on the shaft surfaces should be smoothed to prevent damage to the hubs or sliding element. Second, the coupling hubs should be mounted on the shafts with the correct fit. If keyways are used, the key should be properly seated in the keyway of both the shaft and the hub, and the hub should be pushed firmly onto the shaft to ensure full contact. Set screws, if used, should be tightened evenly to avoid uneven pressure on the shaft, which could cause deformation or slippage. Third, the alignment of the shafts must be checked and adjusted. While slider couplings can accommodate limited misalignment, proper initial alignment reduces wear and vibration. Angular misalignment should typically be kept within 0.5 to 1 degree, and parallel misalignment within 0.1 to 0.2 mm per 100 mm of shaft length, depending on the coupling design. Fourth, the sliding element should be inspected to ensure it moves freely within its mating feature. If the sliding element is too tight, it may not accommodate axial movement properly, leading to increased stress. If it is too loose, it may cause excessive vibration or noise.

Regular maintenance is essential to extend the lifespan of slider couplings and prevent unexpected failures. Maintenance practices for slider couplings include periodic inspection, lubrication (if required), and replacement of worn components. Periodic inspection should involve checking for signs of wear on the sliding element, hubs, and fasteners. Wear on the sliding element may be indicated by increased clearance between the element and its mating feature, excessive vibration, or unusual noise during operation. Fasteners should be checked for tightness, as loose bolts or set screws can lead to slippage and damage to the shafts or coupling components.

Lubrication requirements depend on the material of the sliding element. Metal sliding elements (e.g., bronze, brass) typically require periodic lubrication with grease or oil to reduce friction and wear. The type of lubricant should be selected based on the operating temperature and load conditions. For example, high-temperature greases are used in applications where operating temperatures exceed 100°C. Self-lubricating materials such as nylon or Teflon do not require additional lubrication, but they should be inspected for signs of dryness or degradation, especially in high-temperature environments. If the sliding element shows significant wear (e.g., excessive material loss, cracks, or deformation), it should be replaced promptly to prevent further damage to the coupling and shafts. Similarly, if the hubs are worn or damaged (e.g., keyway wear, bore deformation), they should be replaced to ensure a secure fit and reliable torque transmission.

To optimize the performance of slider couplings, several factors should be considered during the design and selection process. First, the torque capacity of the coupling must match or exceed the maximum torque generated by the system. Selecting a coupling with insufficient torque capacity can lead to premature failure, while selecting an oversized coupling may result in unnecessary cost and weight. The torque capacity of a slider coupling depends on the material of the hubs and sliding element, the size of the coupling, and the design of the mating features (e.g., the width of the slider block and groove). Second, the operating speed should be within the recommended range for the coupling. Excessive operating speed can cause centrifugal forces that damage the coupling components or lead to imbalance and vibration. The maximum operating speed of a slider coupling is determined by the material strength, the size of the coupling, and the type of sliding element.

Third, the environmental conditions should be taken into account when selecting the coupling materials. In corrosive environments (e.g., marine, chemical processing), corrosion-resistant materials such as aluminum alloy, stainless steel, or nylon should be used for the hubs and sliding element. In high-temperature environments (e.g., industrial furnaces, automotive exhaust systems), high-temperature materials such as bronze or alloy steel should be selected. Fourth, the amount of axial movement and misalignment expected in the system should be compatible with the coupling’s capabilities. If the system requires a large amount of axial movement, a slider coupling with a longer sliding stroke should be selected. Similarly, if the system is prone to significant misalignment, a coupling with a more flexible design (e.g., incorporating multiple sliding elements) may be necessary.

Another aspect of performance optimization is the reduction of vibration and noise. Slider couplings made with non-metallic sliding elements (e.g., nylon, polyethylene) are more effective at dampening vibration and reducing noise compared to all-metal couplings. This makes them suitable for applications where noise reduction is a priority, such as in household appliances or office equipment. Additionally, proper alignment and lubrication can help reduce vibration and noise by minimizing friction and wear between the coupling components.

Despite their many advantages, slider couplings have certain limitations that should be considered when selecting a coupling for a specific application. One of the main limitations is their limited ability to handle large angular and parallel misalignment. Compared to other flexible couplings such as jaw couplings or universal joints, slider couplings can accommodate only small to moderate amounts of misalignment. Excessive misalignment can lead to increased wear, reduced efficiency, and premature failure. Another limitation is that slider couplings are not suitable for applications requiring high precision torque transmission, as the sliding movement can introduce a small amount of backlash (play) between the coupling components. Backlash can be problematic in applications such as robotics or CNC machinery, where precise positioning is critical.

Furthermore, slider couplings may not be suitable for high-speed applications where centrifugal forces can cause the sliding element to become unstable. In such applications, couplings with a more rigid design or specialized high-speed couplings may be more appropriate. Finally, all-metal slider couplings can be prone to corrosion in harsh environments if not properly protected, which can reduce their lifespan. However, this limitation can be mitigated by selecting corrosion-resistant materials or applying protective coatings.

In recent years, advancements in materials and manufacturing processes have led to improvements in the performance and versatility of slider couplings. For example, the development of high-strength, lightweight composites has allowed for the production of slider couplings that are both strong and lightweight, making them suitable for aerospace and automotive applications where weight reduction is critical. Additionally, the use of advanced machining techniques such as CNC milling and turning has improved the precision of coupling components, reducing backlash and improving torque transmission efficiency. The integration of sensors into slider couplings is another emerging trend, allowing for real-time monitoring of coupling performance (e.g., temperature, vibration, wear) and enabling predictive maintenance, which helps to prevent unexpected failures and reduce downtime.

In conclusion, slider couplings are essential components in mechanical power transmission systems, offering a simple, cost-effective solution for transmitting torque while accommodating axial movement and limited misalignment. Their structural simplicity, diverse material options, and wide range of applications make them a popular choice across various industries. Proper material selection, installation, and maintenance are critical to ensuring their optimal performance and longevity. While slider couplings have certain limitations, advancements in materials and manufacturing processes continue to expand their capabilities and application range. By understanding the principles, characteristics, and optimization strategies of slider couplings, engineers and technicians can select and utilize these components effectively, enhancing the reliability, efficiency, and lifespan of mechanical systems.

« Slider Couplings » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/slider-couplings.html