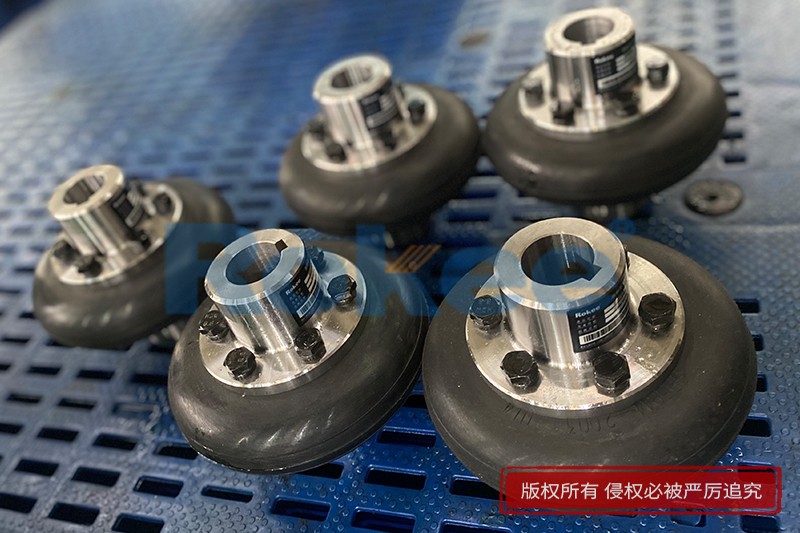

Rubber Tire Couplings

Rokee® is Rubber Tire Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Rubber Tire Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Rubber Tire Coupling adopts tyre body-shaped rubber elements, which are connected with two semi-couplings through bolts to realize torque transmission and displacement compensation. Rubber Tire Coupling has high elastic performance, small torsional rigidity, strong damping capacity, large axial compensation capacity, and good damping performance.

-

UL Elastic Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation. -

LLA Elastic Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. -

LLB Elastic Tyre Coupling

In the realm of mechanical power transmission, couplings serve as critical components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating misalignments and reducing operational stress. Among the diverse range of couplings available, rubber tire couplings have emerged as a preferred choice for numerous industrial applications due to their unique combination of flexibility, damping capabilities, and ease of maintenance.

1. Fundamental Principles of Rubber Tire Couplings

At its core, a rubber tire coupling is a flexible coupling that utilizes an elastomeric (rubber) element—commonly referred to as the "tire"—to connect two shaft hubs. The primary function of this coupling type is to transmit torque from a driving shaft (e.g., from a motor) to a driven shaft (e.g., to a pump, conveyor, or gearbox) while compensating for three types of misalignments: angular misalignment (where shafts are inclined relative to each other), parallel misalignment (where shafts are offset horizontally), and axial misalignment (where shafts move along their axial direction). Additionally, the rubber tire element acts as a vibration damper, absorbing shocks and reducing noise generated by the rotating machinery, thereby enhancing the overall stability and lifespan of the system.

Unlike rigid couplings, which require precise alignment and offer no flexibility, rubber tire couplings leverage the elastic properties of the rubber element to accommodate misalignments without imposing excessive forces on the shafts, bearings, or other adjacent components. This flexibility is particularly valuable in industrial settings where thermal expansion, installation errors, or operational wear can lead to gradual shifts in shaft alignment. The torque transmission process in a rubber tire coupling involves the transfer of rotational force from the driving hub to the rubber tire, which then imparts the force to the driven hub. The rubber element deforms slightly under torque, allowing for misalignment while maintaining a consistent torque transfer efficiency.

2. Design Characteristics of Rubber Tire Couplings

Rubber tire couplings feature a relatively simple yet robust design, consisting of three main components: two metal hubs, a rubber tire element, and fasteners (such as bolts or screws) that secure the tire to the hubs. Each component is engineered to work in harmony, ensuring optimal performance and durability.

The metal hubs are typically manufactured from high-strength materials such as carbon steel, alloy steel, or cast iron. These materials are chosen for their ability to withstand high torque loads and resist wear and deformation. The hubs are designed with a series of protrusions or slots that mesh with corresponding features on the inner surface of the rubber tire, creating a secure connection that prevents slippage during torque transmission. Some hub designs also include keyways or splines to ensure a tight fit with the shafts, further enhancing the reliability of the coupling.

The rubber tire element is the defining component of this coupling type, and its design and material properties have a significant impact on the coupling’s performance. The tire is typically cylindrical or conical in shape, with a flexible structure that allows for deformation. The inner surface of the tire is often textured or shaped to match the hubs’ protrusions, ensuring a secure mechanical connection. In some designs, the tire may include reinforcement layers (such as fabric or fiber) to enhance its tensile strength and resistance to tearing, especially in high-torque applications.

Fasteners used in rubber tire couplings are designed to secure the rubber tire to the hubs without damaging the elastomeric material. Bolts with washers are commonly used, and the tightening torque is carefully specified to ensure a secure fit while avoiding over-compression of the rubber, which could reduce its flexibility and lifespan. Some coupling designs also incorporate quick-release mechanisms, allowing for easy removal and replacement of the rubber tire element without disassembling the entire coupling or moving the connected shafts.

Another key design consideration is the coupling’s torque capacity, which is determined by the size and material of the rubber tire, as well as the strength of the hubs and fasteners. Manufacturers typically provide torque ratings for their couplings, specifying the maximum torque that the coupling can transmit without permanent damage. Additionally, the design must account for the maximum allowable misalignment angles, which vary depending on the size and type of the coupling. For example, small rubber tire couplings may accommodate angular misalignments of up to 3 degrees, while larger couplings designed for heavy-duty applications may have lower allowable misalignment angles to ensure structural integrity.

3. Material Considerations for Rubber Tire Couplings

The performance and lifespan of a rubber tire coupling are heavily dependent on the materials used for its components, particularly the rubber tire element. The selection of rubber material is influenced by a variety of factors, including the operating temperature range, exposure to chemicals or environmental contaminants, torque requirements, and desired damping properties.

Natural rubber is a common choice for rubber tire elements due to its excellent elasticity, high tensile strength, and good damping characteristics. It performs well in moderate temperature environments (typically between -20°C and 60°C) and is suitable for applications with low to moderate torque requirements. However, natural rubber has limited resistance to oil, ozone, and UV radiation, making it less suitable for harsh industrial environments or outdoor applications.

Synthetic rubbers, such as nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), and silicone rubber, are often preferred for applications that require enhanced resistance to specific environmental conditions. Nitrile rubber, for example, offers excellent resistance to oil, fuel, and grease, making it ideal for use in automotive, hydraulic, and industrial applications where exposure to these substances is common. It operates effectively in temperatures ranging from -30°C to 100°C and has good tensile strength and abrasion resistance.

EPDM rubber is known for its exceptional resistance to ozone, UV radiation, and weathering, making it suitable for outdoor applications and environments with high levels of atmospheric contaminants. It also has good resistance to water and steam and can operate in temperatures ranging from -40°C to 120°C. EPDM is often used in couplings for outdoor machinery, such as agricultural equipment, wind turbines, and construction machinery.

Silicone rubber offers the widest temperature range of any rubber material, operating effectively from -60°C to 200°C. It has excellent resistance to ozone, UV radiation, and chemicals, and maintains its flexibility even at extreme temperatures. However, silicone rubber has lower tensile strength and abrasion resistance compared to other rubber materials, making it more suitable for low-torque applications that require high-temperature resistance, such as in industrial ovens, boilers, and aerospace equipment.

In addition to the rubber material, the metal components of the coupling (hubs and fasteners) must also be selected based on the application requirements. Carbon steel is a cost-effective option for most industrial applications, offering good strength and durability. Alloy steel is used for high-torque applications or environments where corrosion resistance is required, while stainless steel is preferred for applications in food processing, pharmaceutical, or marine environments, where hygiene and corrosion resistance are critical.

4. Applications of Rubber Tire Couplings

Due to their flexibility, damping capabilities, and ease of maintenance, rubber tire couplings find applications across a wide range of industries and machinery types. Their ability to accommodate misalignments and reduce vibration makes them particularly suitable for use in equipment where shaft alignment is difficult to maintain or where vibration reduction is essential.

One of the most common applications of rubber tire couplings is in the industrial pump industry. Pumps are often driven by electric motors, and misalignments between the motor shaft and pump shaft can occur due to thermal expansion, installation errors, or pipe stress. Rubber tire couplings compensate for these misalignments, reducing wear on the pump’s bearings and seals and improving the overall efficiency and lifespan of the pump. They are used in centrifugal pumps, reciprocating pumps, and diaphragm pumps for applications such as water treatment, chemical processing, and oil and gas production.

Conveyor systems are another major application area for rubber tire couplings. Conveyors are used in manufacturing, mining, agriculture, and logistics to transport materials, and they often consist of multiple rotating components (such as motors, gearboxes, and rollers) that require torque transmission. Rubber tire couplings absorb the shocks and vibrations generated by the conveyor’s operation, reducing stress on the gearboxes and motors and ensuring smooth material transport. They are also easy to maintain, which is critical in conveyor systems that operate continuously and require minimal downtime.

The automotive industry also utilizes rubber tire couplings in various applications, such as in the transmission systems of commercial vehicles, agricultural tractors, and construction equipment. These couplings help to dampen the vibrations generated by the engine and transmission, improving the comfort of the vehicle operator and reducing wear on the transmission components. They also accommodate misalignments between the engine and transmission shafts, ensuring reliable torque transmission.

Other applications of rubber tire couplings include fans and blowers, compressors, generators, and industrial mixers. In each of these applications, the coupling’s flexibility and damping capabilities contribute to improved equipment performance, reduced maintenance costs, and extended lifespan.

5. Installation and Alignment Practices for Rubber Tire Couplings

Proper installation and alignment are critical to ensuring the optimal performance and lifespan of rubber tire couplings. Incorrect installation or misalignment beyond the coupling’s allowable limits can lead to excessive stress on the rubber element, premature wear, and increased vibration, which can damage the connected shafts, bearings, and other components.

The first step in the installation process is to prepare the shafts. The shaft surfaces should be clean and free of dirt, rust, and burrs to ensure a tight fit with the hubs. The keyways (if used) should also be clean and properly sized to accommodate the keys, which prevent relative rotation between the shafts and hubs. It is important to ensure that the shafts are cut to the correct length to allow for proper hub installation and to avoid axial interference.

Next, the hubs are installed onto the shafts. The hubs should be pressed or heated onto the shafts (depending on the design) to ensure a secure fit. Care should be taken to avoid damaging the hub or shaft during installation. Once the hubs are installed, the rubber tire element is positioned between the hubs, and the fasteners are tightened to the specified torque. It is important not to over-tighten the fasteners, as this can compress the rubber element excessively, reducing its flexibility and damping capabilities.

After installation, the coupling must be aligned to ensure that the misalignment between the shafts is within the coupling’s allowable limits. Alignment can be performed using two common methods: straightedge alignment and laser alignment. Straightedge alignment is a simple method that uses a straightedge and feeler gauges to check for parallel and angular misalignment. This method is suitable for low-precision applications but may not be accurate enough for high-speed or high-torque applications.

Laser alignment is a more precise method that uses a laser beam to measure the misalignment between the shafts. This method provides real-time measurements and allows for accurate adjustment of the machinery to achieve optimal alignment. Laser alignment is recommended for high-speed, high-torque, or precision applications where even small misalignments can have a significant impact on performance.

It is important to note that rubber tire couplings can accommodate a certain amount of misalignment, but this does not mean that proper alignment is unnecessary. Operating the coupling with misalignment beyond its allowable limits will significantly reduce its lifespan and can lead to premature failure of the rubber element. Regular re-alignment is also recommended, as thermal expansion, operational wear, and foundation settlement can cause misalignment over time.

6. Maintenance and Troubleshooting of Rubber Tire Couplings

Regular maintenance is essential to ensure the reliable operation of rubber tire couplings. The maintenance requirements are relatively simple compared to other types of couplings, making them a cost-effective choice for many industrial applications.

One of the most important maintenance tasks is to inspect the rubber tire element regularly for signs of wear, damage, or degradation. The rubber element should be checked for cracks, tears, hardening, or softening, which can indicate aging or exposure to harsh environmental conditions. If any of these signs are present, the rubber tire element should be replaced immediately to avoid coupling failure.

The fasteners should also be inspected regularly to ensure that they are tight and free of corrosion. Loose fasteners can lead to slippage between the hubs and the rubber element, resulting in increased vibration and wear. Corroded fasteners should be replaced to prevent failure.

Lubrication is another important maintenance task for rubber tire couplings, although the lubrication requirements vary depending on the coupling design. Some couplings require lubrication of the hub bearings (if present), while others do not require lubrication due to the self-lubricating properties of the rubber element. It is important to follow the manufacturer’s recommendations for lubrication, as over-lubrication or the use of the wrong type of lubricant can damage the rubber element.

In addition to regular inspections and lubrication, it is important to monitor the coupling’s performance during operation. Excessive vibration, noise, or temperature rise can indicate a problem with the coupling, such as misalignment, worn rubber element, or loose fasteners. If any of these issues are detected, the machinery should be shut down immediately to prevent further damage, and the coupling should be inspected and repaired as necessary.

7. Future Trends in Rubber Tire Coupling Technology

As industrial machinery becomes more advanced, with higher speeds, greater torque requirements, and more stringent environmental regulations, the demand for high-performance rubber tire couplings is expected to grow. Manufacturers are continuously innovating to improve the design, materials, and performance of rubber tire couplings to meet these evolving needs.

One of the key trends in rubber tire coupling technology is the development of advanced elastomeric materials. Researchers are working to create rubber materials with improved tensile strength, abrasion resistance, and resistance to extreme temperatures and chemicals. These advanced materials will enable rubber tire couplings to be used in more demanding applications, such as high-temperature industrial processes, deep-sea oil and gas exploration, and aerospace applications.

Another trend is the integration of smart technology into rubber tire couplings. Smart couplings equipped with sensors can monitor parameters such as torque, temperature, vibration, and misalignment in real-time. This data can be transmitted to a central monitoring system, allowing for predictive maintenance and early detection of potential issues. Predictive maintenance can significantly reduce downtime and maintenance costs by allowing maintenance to be performed before a failure occurs.

Lightweight design is also a growing trend in rubber tire coupling technology. Manufacturers are using lightweight materials such as aluminum alloys and composite materials for the hubs and other components to reduce the overall weight of the coupling. Lightweight couplings are particularly beneficial in applications where weight is a critical factor, such as in automotive and aerospace applications, as they can improve fuel efficiency and reduce energy consumption.

Finally, there is a growing focus on sustainability in the design and manufacturing of rubber tire couplings. Manufacturers are working to reduce the environmental impact of their products by using recycled materials, improving energy efficiency during manufacturing, and designing couplings that are easier to recycle at the end of their lifespan. This focus on sustainability is driven by increasing environmental regulations and consumer demand for more eco-friendly products.

8. Conclusion

Rubber tire couplings are versatile and reliable components that play a critical role in mechanical power transmission. Their unique combination of flexibility, damping capabilities, and ease of maintenance makes them a preferred choice for a wide range of industrial applications, from pumps and conveyors to automotive and aerospace equipment. The performance and lifespan of rubber tire couplings are influenced by factors such as design, material selection, installation, and maintenance. By understanding these factors and following best practices for installation, alignment, and maintenance, engineers and technicians can ensure that rubber tire couplings operate optimally, reducing downtime and maintenance costs and extending the lifespan of the connected machinery.

Looking to the future, advances in elastomeric materials, smart technology, lightweight design, and sustainability are expected to drive the development of more advanced and efficient rubber tire couplings. These innovations will enable rubber tire couplings to meet the evolving needs of modern industrial machinery, ensuring that they remain a critical component in power transmission systems for years to come.

« Rubber Tire Couplings » Post Date: 2023/11/8

URL: https://www.rokeecoupling.com/en/tags/rubber-tire-couplings.html

- 2023-11-14Rubber Tire Couplings Wholesale

- 2023-11-14Rubber Tire Couplings Supply

- 2023-11-14Rubber Tire Couplings Manufacturing Enterprise

- 2023-11-14Rubber Tire Couplings Manufacturer

- 2023-11-14Rubber Tire Coupling Working Principle

- 2023-11-14Rubber Tire Coupling Purpose

- 2023-11-14Rubber Tire Coupling Function

- 2023-11-14Rubber Tire Coupling Parts

- 2023-11-14Models of Rubber Tire Couplings

- 2023-11-10Rubber Tire Coupling Specifications

- 2023-11-10Rubber Tire Coupling Applications

- 2023-11-10Rubber Tire Coupling Size Calculation

- 2023-11-09Rubber Tire Couplings Supplier

- 2023-11-09Rubber Tire Coupling Structural Diagram

- 2023-11-09Disadvantages of Rubber Tire Couplings

- 2023-11-09Rubber Tire Coupling Drawing

- 2023-11-09Rubber Tire Coupling Seller

- 2023-11-08Rubber Tire Coupling Price

- 2023-11-08Catalogue of Rubber Tire Couplings

- 2023-11-08Customized Rubber Tire Couplings

- 2023-11-08Rubber Tire Coupling Design

- 2023-11-08Types of Rubber Tire Couplings

- 2023-11-08Rubber Tire Coupling Size Chart

- 2023-11-08Rubber Tire Coupling Advantages

- 2023-11-08Rubber Tire Coupling Factory

- 2023-11-08Rubber Tire Couplings Company