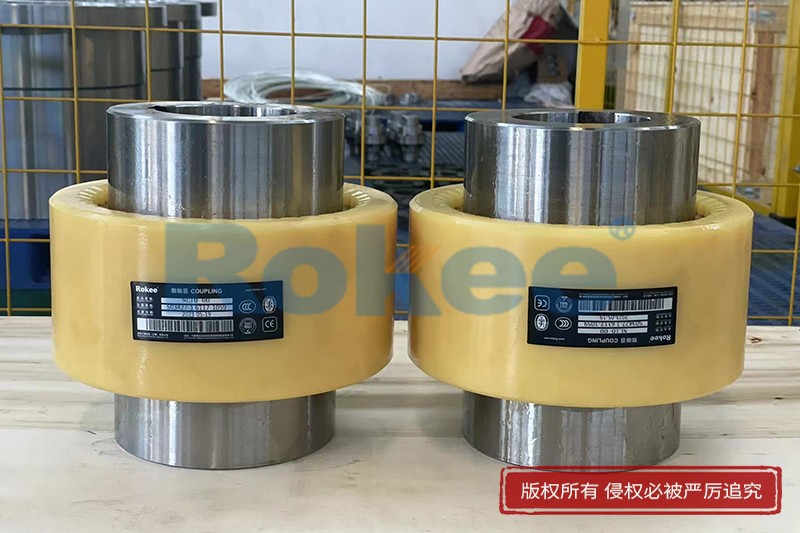

Nylon Sleeve Couplings

Rokee® is Nylon Sleeve Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Nylon Sleeve Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Nylon Sleeve Coupling half coupling adopts casting or forging technology, with cast iron HT20-40, cast steel ZG35 II, and 45 # steel. The shaft hole and keyway can be drawn into shape, and the Nylon Sleeve Coupling elastic body outer sleeve can be selected from various hardness synthetic nylon, cast nylon elastic body, and other materials according to user requirements.

In the realm of mechanical power transmission, couplings serve as indispensable components that bridge rotating shafts, enabling the transfer of torque while accommodating misalignments and mitigating shock loads. Among the diverse array of coupling types available, the nylon sleeve coupling has emerged as a preferred choice for numerous industrial and commercial applications, owing to its unique combination of cost-effectiveness, versatility, and reliable performance.

1. Understanding Nylon Sleeve Couplings: Definition and Structural Design

A nylon sleeve coupling is a type of flexible coupling designed to connect two coaxial shafts in power transmission systems. Its core design revolves around three primary components: two metal hubs, a nylon sleeve, and often sets of bolts or pins for secure assembly. The metal hubs, typically fabricated from materials such as steel, aluminum, or cast iron, are precision-machined to fit onto the ends of the shafts that require connection. These hubs feature external teeth or grooves that are specifically engineered to mesh with corresponding internal teeth or slots on the nylon sleeve.

The nylon sleeve, which serves as the central and defining element of this coupling type, acts as the interface between the two metal hubs. Its internal tooth profile is meticulously designed to ensure a tight, backlash-minimizing fit with the external teeth of the hubs, facilitating efficient torque transfer. Unlike rigid couplings that demand near-perfect shaft alignment, the nylon sleeve’s inherent flexibility allows for a certain degree of misalignment between the connected shafts, including angular, parallel, and axial misalignments. This flexibility is a critical design feature that distinguishes nylon sleeve couplings from rigid alternatives and contributes significantly to their widespread use in applications where precise alignment is challenging to maintain.

The assembly process of a nylon sleeve coupling is relatively straightforward. Each metal hub is first mounted onto its respective shaft, typically using keyways and set screws or press-fitting for a secure connection. The nylon sleeve is then slid over the teeth of one hub, and the second hub is aligned and brought into position such that its teeth engage with the other end of the nylon sleeve. Finally, bolts or pins are inserted through holes in the hubs (and sometimes the sleeve) to lock the assembly in place, preventing relative movement between the components during operation.

2. Material Properties of Nylon: The Foundation of Coupling Performance

The performance characteristics of nylon sleeve couplings are largely dictated by the properties of the nylon material used in the sleeve. Nylon, a synthetic thermoplastic polymer, possesses a unique set of mechanical and chemical properties that make it ideal for this application. One of the most notable properties of nylon is its high tensile strength and impact resistance, which enable the sleeve to withstand the torque loads and occasional shock impacts encountered in power transmission systems. This strength is complemented by nylon’s excellent wear resistance, a critical attribute that ensures long service life even in high-speed rotating applications where friction between the sleeve and hubs could otherwise lead to premature failure.

Another key property of nylon is its inherent flexibility and elasticity. Unlike brittle materials that would crack or shatter under misalignment or shock, nylon can deform slightly under stress and then return to its original shape, allowing the coupling to accommodate misalignments without transmitting excessive forces to the shafts or other components in the system. This elasticity also contributes to the coupling’s ability to dampen vibration and reduce noise during operation, a significant advantage in applications where noise reduction is a priority, such as in residential HVAC systems or office equipment.

Nylon is also resistant to a wide range of chemicals, including oils, greases, and many solvents, which makes nylon sleeve couplings suitable for use in harsh environments where exposure to such substances is common, such as in industrial machinery, automotive applications, and chemical processing plants. Additionally, nylon is lightweight compared to metal, which helps reduce the overall weight of the coupling assembly, minimizing inertia and energy consumption in the power transmission system.

It is important to note that while nylon offers numerous advantages, it does have some limitations. For instance, nylon has a relatively low melting point and can lose some of its mechanical properties at elevated temperatures. As such, nylon sleeve couplings are not suitable for applications where operating temperatures exceed the material’s thermal limits (typically around 80 to 120 degrees Celsius, depending on the specific type of nylon). Additionally, nylon can absorb moisture over time, which may cause slight dimensional changes, though this is generally a minor concern in most industrial applications and can be mitigated through proper material selection and maintenance.

3. Key Advantages of Nylon Sleeve Couplings

Nylon sleeve couplings offer a multitude of advantages that make them a compelling choice for a wide range of power transmission applications. These advantages stem from their unique design and the properties of the nylon material, and they include the following:

3.1 Cost-Effectiveness

One of the primary advantages of nylon sleeve couplings is their low cost compared to other types of flexible couplings, such as elastomeric couplings, gear couplings, or universal joints. The materials used in their construction—nylon and relatively inexpensive metals—are readily available and cost-effective to manufacture. Additionally, their simple design and ease of assembly reduce production and installation costs, making them an economical option for both small-scale and large-scale applications. This cost-effectiveness does not come at the expense of performance, as nylon sleeve couplings are capable of delivering reliable torque transmission in most standard operating conditions.

3.2 Flexibility and Misalignment Compensation

As mentioned earlier, the flexible nature of the nylon sleeve allows nylon sleeve couplings to accommodate various types of shaft misalignments. Angular misalignment (where the shafts are not colinear but intersect at a point), parallel misalignment (where the shafts are parallel but offset), and axial misalignment (where the shafts move along their axial direction) can all be compensated for by the nylon sleeve. This flexibility eliminates the need for precise and costly shaft alignment during installation, reducing setup time and labor costs. Moreover, it helps protect other components in the system, such as bearings and seals, from the excessive forces that would otherwise result from misalignment, extending the overall service life of the machinery.

3.3 Vibration Damping and Noise Reduction

The elastic properties of nylon enable nylon sleeve couplings to act as effective vibration dampeners. During operation, rotating shafts often generate vibrations due to imbalances or uneven load distribution. The nylon sleeve absorbs these vibrations, preventing them from being transmitted to the connected equipment or the surrounding structure. This vibration damping not only improves the stability and performance of the machinery but also reduces the noise generated during operation. This makes nylon sleeve couplings particularly suitable for applications where noise levels need to be kept low, such as in residential areas, hospitals, or office buildings where HVAC systems, pumps, or small motors are in use.

3.4 Simple Installation and Maintenance

Nylon sleeve couplings feature a straightforward design that simplifies both installation and maintenance. Installation typically involves only a few steps: mounting the hubs on the shafts, engaging the nylon sleeve with the hubs, and securing the assembly with bolts or pins. No specialized tools or complex procedures are required, making the installation process quick and easy. Maintenance requirements are also minimal. Unlike some other coupling types that require regular lubrication (such as gear couplings), nylon sleeve couplings are self-lubricating due to the low friction coefficient of nylon. This eliminates the need for frequent lubrication checks and refills, reducing maintenance costs and downtime. In the event of wear or damage, the nylon sleeve can be easily replaced without disassembling the entire coupling or removing the shafts, further simplifying maintenance and minimizing production disruptions.

3.5 Lightweight and Compact Design

The use of lightweight nylon in the sleeve, combined with the compact design of the metal hubs, results in a coupling that is both lightweight and space-efficient. This is particularly advantageous in applications where space is limited, such as in small motors, pumps, or compact industrial machinery. The lightweight nature of the coupling also reduces inertia, which improves the responsiveness of the power transmission system and reduces energy consumption, making it more efficient.

3.6 Corrosion Resistance

Nylon is inherently resistant to corrosion, and when combined with corrosion-resistant metals (such as aluminum or stainless steel) for the hubs, nylon sleeve couplings can withstand exposure to harsh environmental conditions, including moisture, humidity, and certain chemicals. This corrosion resistance extends the service life of the coupling in outdoor applications, marine environments, or industrial settings where corrosive substances are present.

4. Typical Applications of Nylon Sleeve Couplings

Due to their numerous advantages, nylon sleeve couplings find application in a wide range of industries and mechanical systems. Their versatility makes them suitable for both light-duty and medium-duty power transmission applications, where they connect shafts in various types of machinery. Some of the most common applications include:

4.1 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on motors and fans to circulate air. Nylon sleeve couplings are frequently used to connect the motor shafts to the fan shafts in these systems. Their vibration damping and noise reduction properties make them ideal for this application, as they help keep the noise levels of HVAC systems low, which is crucial in residential and commercial buildings. Additionally, their ability to accommodate minor misalignments simplifies installation and ensures reliable operation.

4.2 Pumps and Compressors

Pumps and compressors are essential components in many industrial, commercial, and residential applications, used for transferring fluids or gases. Nylon sleeve couplings are commonly used to connect the motor shafts to the impeller or rotor shafts of these devices. Their corrosion resistance makes them suitable for use in pumps that handle water or other fluids, while their simple maintenance and easy replacement of the nylon sleeve minimize downtime in critical applications.

4.3 Conveyor Systems

Conveyor systems are widely used in manufacturing plants, warehouses, and distribution centers to transport materials. These systems consist of multiple rotating shafts that drive the conveyor belts. Nylon sleeve couplings are used to connect these shafts, as well as to connect the motor to the main drive shaft. Their ability to accommodate misalignments is particularly beneficial in long conveyor systems where shaft alignment can be challenging to maintain. Additionally, their cost-effectiveness makes them a practical choice for large-scale conveyor systems that require multiple couplings.

4.4 Small to Medium-Sized Motors and Generators

Nylon sleeve couplings are commonly used in small to medium-sized electric motors and generators to connect the motor/generator shaft to the load (such as a pump, fan, or gearbox). Their lightweight design and low inertia help improve the efficiency of these systems, while their self-lubricating properties reduce maintenance requirements. They are also used in portable generators, where their compact size and ease of installation are significant advantages.

4.5 Agricultural Machinery

Agricultural machinery, such as tractors, harvesters, and irrigation pumps, often operates in harsh environmental conditions with exposure to moisture, dirt, and vibration. Nylon sleeve couplings are used in these machines to connect various rotating shafts, thanks to their corrosion resistance and vibration damping properties. Their ability to withstand minor misalignments also makes them suitable for use in agricultural equipment, where rough terrain can cause shifts in shaft alignment during operation.

4.6 Office and Household Equipment

Nylon sleeve couplings are even found in everyday office and household equipment, such as printers, copiers, washing machines, and dryers. In these applications, their compact size, low noise, and reliable performance make them ideal for connecting small motor shafts to the rotating components of the equipment. For example, in a washing machine, a nylon sleeve coupling may be used to connect the motor shaft to the drum shaft, ensuring smooth and quiet operation.

5. Selection Guidelines for Nylon Sleeve Couplings

Selecting the right nylon sleeve coupling for a specific application is crucial to ensure optimal performance, reliability, and longevity. Several key factors need to be considered during the selection process, including torque requirements, shaft size, misalignment, operating temperature, and environmental conditions. The following guidelines can help in making an informed selection:

5.1 Determine Torque Requirements

The primary function of a coupling is to transmit torque, so it is essential to select a nylon sleeve coupling that can handle the maximum torque generated by the system. The torque capacity of a coupling is determined by the material properties of the nylon sleeve and the design of the teeth (or grooves) that engage with the hubs. It is important to calculate the maximum operating torque of the application, including any peak torques that may occur during startup or under load. The selected coupling should have a torque rating that exceeds the maximum operating torque to ensure a safety margin and prevent premature failure.

5.2 Match Shaft Sizes

The metal hubs of the nylon sleeve coupling must be compatible with the diameters of the shafts that need to be connected. Couplings are available in a range of standard hub sizes to fit common shaft diameters. It is important to measure the shaft diameters accurately and select a coupling with hubs that match these dimensions. In cases where the two shafts have different diameters, it is possible to use hubs of different sizes, provided they are compatible with the same nylon sleeve.

Consider Misalignment Requirements

Different applications have different levels of misalignment between the connected shafts. It is important to select a nylon sleeve coupling that can accommodate the maximum misalignment expected in the application. Manufacturers typically specify the maximum angular, parallel, and axial misalignment that their couplings can handle. It is crucial to ensure that the selected coupling’s misalignment capacity exceeds the actual misalignment in the system to prevent excessive stress on the sleeve and other components.

Evaluate Operating Temperature

As mentioned earlier, nylon has a limited temperature range in which it can maintain its mechanical properties. It is important to consider the operating temperature of the application and select a nylon sleeve coupling that is suitable for that temperature range. If the application involves high temperatures (exceeding 80 to 120 degrees Celsius), a nylon sleeve coupling may not be the appropriate choice, and alternative materials or coupling types should be considered.

Assess Environmental Conditions

The environmental conditions in which the coupling will operate also play a role in selection. If the coupling will be exposed to moisture, humidity, corrosive chemicals, or abrasive particles, it is important to select a coupling with corrosion-resistant hubs (such as aluminum or stainless steel) and a nylon sleeve that is resistant to the specific chemicals present. In outdoor applications, UV-resistant nylon may be required to prevent degradation due to exposure to sunlight.

Consider Speed Requirements

The rotational speed of the shafts is another important factor to consider. Nylon sleeve couplings have a maximum rotational speed limit, which is determined by the centrifugal forces that act on the sleeve and hubs at high speeds. Exceeding this speed limit can cause the sleeve to deform or fail. It is important to calculate the rotational speed of the shafts (in revolutions per minute, RPM) and select a coupling that can handle this speed.

6. Maintenance Practices for Nylon Sleeve Couplings

While nylon sleeve couplings are relatively low-maintenance components, proper maintenance is still essential to ensure their long service life and reliable performance. The following maintenance practices are recommended:

6.1 Regular Inspection

Regular visual inspections should be conducted to check for signs of wear, damage, or misalignment. During inspection, look for cracks, chips, or excessive wear on the nylon sleeve, as well as signs of corrosion or damage on the metal hubs. Also, check the tightness of the bolts or pins that secure the assembly, as loose fasteners can lead to excessive movement and premature wear.

6.2 Lubrication

Most nylon sleeve couplings are self-lubricating, so they do not require regular lubrication. However, if the coupling is used in an application where the nylon sleeve is exposed to excessive friction or high temperatures, a light application of a compatible lubricant (such as a dry lubricant or a lubricant specifically designed for nylon) may be beneficial. It is important to avoid using lubricants that can degrade nylon, such as petroleum-based lubricants in some cases.

6.3 Replacement of Worn Components

The nylon sleeve is the component most prone to wear in a nylon sleeve coupling. When signs of excessive wear or damage are detected, the sleeve should be replaced promptly to prevent failure and avoid damage to the shafts or other components. Replacement of the nylon sleeve is a simple process that can be done without disassembling the entire coupling or removing the shafts, minimizing downtime.

6.4 Alignment Checks

While nylon sleeve couplings can accommodate misalignments, excessive or prolonged misalignment can lead to premature wear of the sleeve and hubs. Periodic alignment checks should be conducted to ensure that the shafts remain within the acceptable misalignment limits. If misalignment exceeds the coupling’s capacity, adjustments should be made to realign the shafts.

6.5 Protection from Harsh Environments

In applications where the coupling is exposed to harsh environmental conditions (such as moisture, corrosive chemicals, or abrasive particles), protective measures should be taken to extend its service life. This may include installing a protective cover around the coupling or using corrosion-resistant materials for the hubs and sleeve.

7. Conclusion

Nylon sleeve couplings have established themselves as a versatile, cost-effective, and reliable solution for power transmission in a wide range of applications. Their unique design, which leverages the favorable properties of nylon, enables them to accommodate misalignments, dampen vibrations, reduce noise, and simplify installation and maintenance. From HVAC systems and pumps to conveyor systems and household equipment, nylon sleeve couplings play a crucial role in ensuring the smooth and efficient operation of numerous mechanical systems.

When selecting a nylon sleeve coupling, it is essential to consider factors such as torque requirements, shaft sizes, misalignment, operating temperature, and environmental conditions to ensure optimal performance. Proper maintenance, including regular inspections, prompt replacement of worn components, and alignment checks, can further extend the service life of the coupling and prevent costly downtime.

As technology continues to advance, improvements in nylon material technology may further enhance the performance characteristics of nylon sleeve couplings, expanding their range of applications and making them even more competitive with other coupling types. For now, however, nylon sleeve couplings remain a popular choice for engineers and manufacturers seeking a balance of performance, cost-effectiveness, and ease of use in power transmission systems.

« Nylon Sleeve Couplings » Post Date: 2023/11/8

URL: https://www.rokeecoupling.com/en/tags/nylon-sleeve-couplings.html