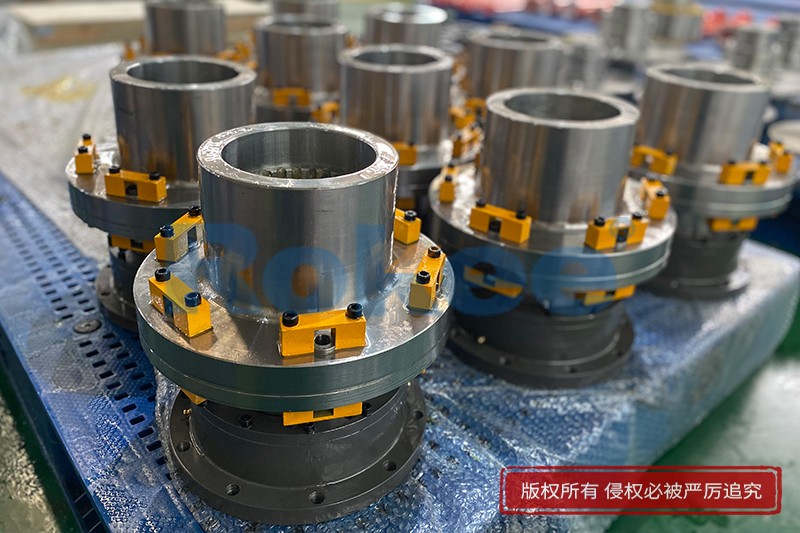

Low Speed Coupling

Rokee® is Low Speed Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Low Speed Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the complex ecosystem of industrial transmission systems, couplings serve as the critical link between power sources and driven machinery, enabling the seamless transfer of torque while accommodating various misalignments and operational stresses. Among the diverse range of couplings available, low speed couplings occupy a unique and indispensable position, designed to operate efficiently under conditions where rotational speeds are relatively low but torque requirements are often high.

To begin with, it is essential to define what constitutes a low speed coupling and distinguish it from its high-speed counterparts. While there is no universal threshold for classifying "low speed" in industrial contexts, couplings operating at rotational speeds below 1000 revolutions per minute (RPM) are generally considered low speed. However, the defining characteristic of these couplings is not merely their speed range but their ability to handle the high torque loads that typically accompany low-speed operation. In many industrial applications, such as heavy machinery, conveyor systems, and marine propulsion, the power source (e.g., an electric motor or internal combustion engine) operates at a higher speed, requiring a gearbox to reduce the speed and increase the torque before transmitting it to the driven equipment. The low speed coupling is then installed between the gearbox output shaft and the driven machinery input shaft, tasked with transferring the amplified torque while mitigating the effects of misalignment, vibration, and shock loads.

The core function of any coupling—low speed or otherwise—is to transmit torque from one shaft to another. However, low speed couplings must fulfill additional requirements due to the unique operational conditions they face. One of the primary challenges in low-speed, high-torque applications is the presence of significant misalignments between the connected shafts. These misalignments can be angular (where the shafts are not colinear but intersect at a point), parallel (where the shafts are colinear but offset), or a combination of both. If not accommodated, misalignment can lead to excessive wear on bearings, seals, and shafts, resulting in premature equipment failure and unplanned downtime. Low speed couplings are therefore designed with a high degree of flexibility to absorb these misalignments without compromising torque transmission efficiency.

Another critical function of low speed couplings is vibration damping. Low-speed operation often generates higher levels of vibration compared to high-speed operation, particularly in machinery with large rotating masses. These vibrations can propagate through the transmission system, causing noise, reducing component lifespan, and affecting the precision of the driven machinery. Many low speed couplings incorporate elastic or flexible elements that act as vibration dampers, absorbing and dissipating vibrational energy to protect the connected equipment. Additionally, these couplings must be capable of withstanding shock loads, which are common in applications such as mining, construction, and material handling, where sudden starts, stops, or overloads can place extreme stress on the transmission system.

There are several distinct types of low speed couplings, each engineered to meet specific application requirements based on factors such as torque capacity, misalignment tolerance, vibration damping needs, and environmental conditions. The most common types include mechanical flexible couplings, elastic couplings, and hydraulic couplings. Each type exhibits unique design features and performance characteristics that make it suitable for particular industrial scenarios.

Mechanical flexible couplings are among the most widely used low speed couplings, characterized by their robust construction and ability to handle high torque loads. This category includes couplings such as jaw couplings, Oldham couplings, and universal joints. Jaw couplings consist of two hubs with protruding jaws that engage with a flexible elastomeric spider. The spider acts as the flexible element, accommodating angular and parallel misalignments while transmitting torque. Jaw couplings are popular in low speed applications due to their simplicity, ease of installation, and cost-effectiveness. However, their misalignment capacity is relatively limited compared to other types, making them more suitable for applications with moderate misalignment requirements.

Oldham couplings, by contrast, are designed to accommodate significant parallel misalignments. They consist of two hubs with flat surfaces and a central disk that has slots perpendicular to each other. The disk slides within the slots of the hubs, allowing the shafts to move parallel to each other while maintaining torque transmission. Oldham couplings are particularly useful in low speed applications where parallel misalignment is a primary concern, such as in conveyor systems and packaging machinery. However, they have limited angular misalignment capacity and are not ideal for applications with high vibration levels.

Universal joints, also known as Cardan joints, are mechanical flexible couplings designed to accommodate large angular misalignments. They consist of two yokes connected by a cross-shaped intermediate member (the cross). Universal joints are commonly used in applications where the shafts are at an angle to each other, such as in automotive drivetrains and agricultural machinery. While they excel at handling angular misalignment, universal joints can introduce rotational speed fluctuations (known as the Cardan effect) when the angle between the shafts is large. To mitigate this, double universal joints (two universal joints connected by an intermediate shaft) are often used in low speed applications that require constant speed transmission.

Elastic couplings represent another major category of low speed couplings, distinguished by their use of elastic materials (such as rubber, polyurethane, or composite materials) to transmit torque and accommodate misalignments. Unlike mechanical flexible couplings, which rely on sliding or pivoting mechanical elements, elastic couplings use the deformation of the elastic material to absorb misalignments, dampen vibrations, and reduce noise. This makes them particularly suitable for low speed applications where vibration damping is critical, such as in pumps, compressors, and electric motor-driven equipment.

One common type of elastic coupling is the tire coupling, which uses a flexible tire-like element (typically made of rubber or polyurethane) to connect the two hubs. Tire couplings offer excellent vibration damping capabilities and can accommodate large angular and parallel misalignments. They are also resistant to shock loads and can operate in harsh environmental conditions (such as high humidity or dust). However, they have a lower torque capacity compared to mechanical flexible couplings and may require more frequent replacement of the tire element due to wear and aging.

Another type of elastic coupling is the disc coupling, which uses one or more flexible discs (made of metal or composite materials) to transmit torque. Disc couplings offer high torque capacity and precision, making them suitable for low speed applications that require accurate torque transmission and minimal backlash, such as in industrial robots and machine tools. While they have limited misalignment capacity compared to tire couplings, disc couplings are highly durable and require minimal maintenance, making them a cost-effective option for long-term industrial use.

Hydraulic couplings, also known as fluid couplings, represent a different approach to low speed torque transmission. Unlike mechanical and elastic couplings, which transmit torque through direct contact between components, hydraulic couplings use a fluid (typically oil) to transfer torque from the input shaft to the output shaft. The input shaft drives an impeller, which rotates and creates a flow of fluid. This fluid flow drives a turbine connected to the output shaft, thereby transmitting torque. Hydraulic couplings offer several advantages for low speed applications, including smooth torque transmission, overload protection, and the ability to adjust the speed of the output shaft independently of the input shaft.

Hydraulic couplings are particularly useful in low speed applications that require soft starting (to avoid shock loads on the driven machinery) and variable speed control, such as in conveyor systems, crushers, and marine propulsion systems. They also provide overload protection by allowing the input shaft to continue rotating even if the output shaft is stalled (a condition known as "slip"), which prevents damage to the motor and other components. However, hydraulic couplings are more complex and expensive than mechanical and elastic couplings, and they require regular maintenance of the fluid and seals to ensure optimal performance.

The design of low speed couplings is a complex process that must take into account a wide range of factors to ensure optimal performance and reliability. One of the primary design considerations is torque capacity: the coupling must be capable of transmitting the maximum torque required by the application without failure. This requires careful calculation of the nominal torque (the torque the coupling is designed to transmit continuously) and the peak torque (the maximum torque the coupling can withstand temporarily, such as during startup or shock loads). The material selection for the coupling components is also critical: for high torque applications, materials such as steel or cast iron are commonly used for the hubs and shafts, while elastic elements are made from materials that offer a balance of flexibility, durability, and resistance to wear and environmental factors.

Misalignment tolerance is another key design consideration. The coupling must be designed to accommodate the maximum expected misalignment between the connected shafts, which depends on the application and the installation conditions. Factors such as shaft deflection (due to torque loads), thermal expansion (due to temperature changes during operation), and installation errors can all contribute to misalignment. The design of the coupling’s flexible elements (e.g., the spider in a jaw coupling, the tire in a tire coupling) must be optimized to absorb these misalignments without generating excessive stress or reducing torque transmission efficiency.

Vibration damping is also an important design criterion for low speed couplings. The design must incorporate features that minimize the transmission of vibrational energy from the power source to the driven machinery. This can be achieved through the use of elastic materials (in elastic couplings) or fluid damping (in hydraulic couplings). The natural frequency of the coupling must also be carefully tuned to avoid resonance, which can occur when the coupling’s natural frequency matches the frequency of the vibrations generated by the machinery. Resonance can amplify vibrations, leading to excessive stress and premature failure of the coupling and other components.

Environmental conditions also play a significant role in the design of low speed couplings. Couplings used in harsh environments (such as high temperatures, high humidity, dust, or corrosive substances) must be constructed from materials that are resistant to these conditions. For example, couplings used in marine applications may be made from corrosion-resistant materials such as stainless steel, while couplings used in high-temperature applications (such as in furnaces or power plants) may require heat-resistant elastic elements or cooling systems.

Low speed couplings find applications across a wide range of industries, each with unique requirements and operational challenges. One of the most prominent applications is in the mining and mineral processing industry, where low speed, high torque machinery (such as crushers, grinders, and conveyors) is used to extract and process minerals. In these applications, couplings must be capable of handling extreme torque loads and shock loads, as well as accommodating misalignments caused by the heavy weight of the machinery and the uneven terrain of mining sites. Elastic couplings (such as tire couplings) and hydraulic couplings are commonly used in this industry due to their vibration damping and overload protection capabilities.

Another major application area is the manufacturing industry, where low speed couplings are used in machinery such as conveyors, packaging equipment, and machine tools. In conveyor systems, couplings must accommodate misalignments between the motor, gearbox, and conveyor shaft, as well as transmit torque efficiently to move heavy loads. Oldham couplings and jaw couplings are often used in these applications due to their simplicity and ability to handle parallel and angular misalignments. In machine tools (such as lathes and milling machines), precision is critical, so disc couplings are preferred for their accurate torque transmission and minimal backlash.

The marine industry also relies heavily on low speed couplings, particularly in propulsion systems. Marine propulsion systems typically use large diesel engines or electric motors that operate at low speeds (often below 500 RPM) to drive the propeller. The coupling between the engine/motor and the propeller shaft must be capable of handling the high torque generated by the engine, as well as accommodating misalignments caused by the movement of the ship (heave, pitch, and roll). Hydraulic couplings and elastic couplings are commonly used in marine applications due to their ability to absorb shock loads and dampen vibrations, which is critical for ensuring the smooth operation of the propulsion system and reducing noise levels on board the ship.

The agricultural industry is another important user of low speed couplings. Agricultural machinery such as tractors, harvesters, and irrigation pumps often operate at low speeds and require high torque to perform tasks such as plowing, harvesting, and pumping water. Universal joints are commonly used in tractor drivetrains to transmit torque between the engine and the wheels or implements, while elastic couplings are used in irrigation pumps to dampen vibrations and accommodate misalignments. The couplings used in agricultural applications must also be durable and resistant to harsh environmental conditions (such as dust, mud, and extreme temperatures).

Proper maintenance of low speed couplings is essential to ensure their long-term performance and reliability, as well as to minimize unplanned downtime and maintenance costs. The maintenance requirements vary depending on the type of coupling, but there are several general practices that apply to most low speed couplings.

Regular inspection is the foundation of effective coupling maintenance. Inspections should be conducted at regular intervals (e.g., monthly, quarterly, or annually, depending on the application and operating conditions) to check for signs of wear, damage, or misalignment. Key inspection points include the flexible elements (e.g., spider, tire, disc), hubs, shafts, and fasteners. For mechanical flexible couplings, inspectors should look for signs of wear on the sliding or pivoting surfaces, as well as loose fasteners. For elastic couplings, the elastic elements should be checked for cracks, tears, or degradation (due to age, heat, or chemical exposure). For hydraulic couplings, the fluid level and condition should be checked regularly, and the seals should be inspected for leaks.

Lubrication is another critical maintenance task for many low speed couplings. Mechanical flexible couplings (such as universal joints and some jaw couplings) require regular lubrication to reduce friction between the moving parts, prevent wear, and extend the lifespan of the coupling. The type of lubricant used depends on the coupling design and operating conditions (e.g., temperature, load). It is important to follow the manufacturer’s recommendations for lubrication intervals and lubricant type to avoid premature failure.

Alignment checks and adjustments are also essential for maintaining low speed couplings. Over time, misalignments can develop due to factors such as shaft deflection, thermal expansion, and wear on bearings or mounts. If left uncorrected, these misalignments can lead to excessive wear on the coupling and other components, as well as increased vibration and noise. Alignment should be checked using precision tools (such as laser alignment tools) at regular intervals, and adjustments should be made as needed to ensure that the shafts are properly aligned.

Replacement of worn or damaged components is another important maintenance practice. Flexible elements (such as spider inserts, tire elements, and discs) are subject to wear and degradation over time and should be replaced before they fail. Fasteners (such as bolts and nuts) should also be checked regularly and replaced if they are loose, worn, or damaged. It is important to use replacement parts that are compatible with the coupling design to ensure optimal performance and avoid further damage.

In conclusion, low speed couplings play a vital role in industrial transmission systems, enabling the efficient and reliable transfer of torque in low speed, high torque applications. Their ability to accommodate misalignments, dampen vibrations, and withstand shock loads makes them indispensable in a wide range of industries, including mining, manufacturing, marine, and agriculture. The design of low speed couplings must take into account factors such as torque capacity, misalignment tolerance, vibration damping, and environmental conditions to ensure optimal performance. Proper maintenance, including regular inspection, lubrication, alignment checks, and component replacement, is essential to maximize the lifespan of low speed couplings and minimize unplanned downtime.

As industrial machinery becomes more advanced and demands higher levels of reliability and efficiency, the role of low speed couplings will continue to evolve. Advances in materials science (such as the development of more durable and flexible elastic materials) and manufacturing technologies (such as precision machining and 3D printing) are likely to lead to the development of low speed couplings with higher torque capacities, better misalignment tolerance, and longer lifespans. Additionally, the integration of condition monitoring technologies (such as sensors and IoT devices) into low speed couplings is expected to enable predictive maintenance, allowing operators to detect potential issues before they lead to failure.

Overall, low speed couplings are a critical component of industrial infrastructure, and their proper selection, design, and maintenance are essential for ensuring the smooth and efficient operation of industrial machinery. By understanding the principles and characteristics of low speed couplings, industrial operators can make informed decisions about which type of coupling to use for their specific application, leading to improved performance, reduced maintenance costs, and increased productivity.

« Low Speed Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/low-speed-coupling.html