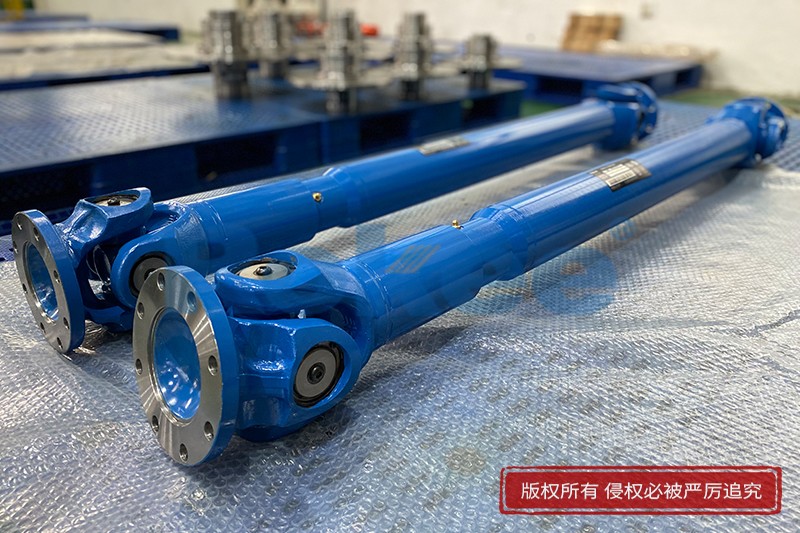

Long Shaft Coupling

Rokee® is Long Shaft Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Long Shaft Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of mechanical transmission systems, couplings serve as critical components that bridge rotating shafts, enabling the transfer of torque and motion while accommodating misalignments, absorbing shocks, and compensating for axial or radial displacements. Among the diverse range of couplings available, long shaft couplings stand out for their ability to connect shafts that are separated by substantial distances. Unlike standard couplings designed for short-distance shaft connections, long shaft couplings are engineered to address the unique challenges posed by extended span applications, such as increased deflection, vibration, and thermal expansion effects.

1. Fundamental Principles of Long Shaft Couplings

At their core, long shaft couplings operate on the same basic principle as other coupling types: to transmit rotational power from a driving shaft (e.g., from a motor or engine) to a driven shaft (e.g., to a pump, fan, or gearbox) while maintaining operational efficiency and protecting connected equipment. However, the extended length of the shaft in long shaft couplings introduces additional mechanical complexities that demand specialized design features. One of the primary challenges is shaft deflection, which occurs when the long shaft bends under the influence of torque, radial loads, or its own weight. This deflection can lead to increased wear on bearings, misalignment between shafts, and reduced transmission efficiency if not properly addressed.

Another key principle governing long shaft couplings is the accommodation of misalignments. Shaft misalignment in long span applications can arise from various factors, including installation errors, foundation settlement, thermal expansion of components, and structural vibrations. Long shaft couplings must be capable of handling three main types of misalignment: angular misalignment (where the shafts are inclined relative to each other), parallel misalignment (where the shafts are offset but parallel), and axial misalignment (where the shafts move along their axial direction). Failure to accommodate these misalignments can result in excessive stress on the coupling and connected shafts, leading to premature failure.

Torque transmission efficiency is also a critical principle for long shaft couplings. As the length of the shaft increases, the potential for power loss due to friction, bending, and vibration also rises. Therefore, long shaft couplings are designed to minimize these power losses through optimized material selection, precise manufacturing tolerances, and efficient bearing systems. Additionally, many long shaft couplings incorporate damping elements to absorb shocks and vibrations, which not only improves comfort and reduces noise but also protects sensitive components from damage.

2. Common Types of Long Shaft Couplings

Long shaft couplings are available in several types, each tailored to specific application requirements, load conditions, and misalignment capabilities. The following are the most widely used types:

2.1 Sleeve-Type Long Shaft Couplings

Sleeve-type long shaft couplings, also known as rigid sleeve couplings, are among the simplest and most cost-effective designs. They consist of a cylindrical sleeve that is attached to both the driving and driven shafts using keys, set screws, or taper pins. The sleeve itself acts as the long shaft, connecting the two shafts over an extended distance. This type of coupling is typically used in applications where misalignment is minimal, and the shafts are collinear. However, due to their rigid construction, sleeve-type long shaft couplings have limited ability to accommodate misalignments, making them suitable only for low-vibration, low-load applications such as small pumps, fans, and light-duty conveyors.

One of the key advantages of sleeve-type long shaft couplings is their simplicity, which results in easy installation and maintenance. They are also lightweight and compact, making them ideal for applications with space constraints. However, their rigid design means that any misalignment or shock load is directly transmitted to the connected shafts and bearings, increasing the risk of premature wear. As a result, they are not recommended for high-torque, high-speed, or heavy-duty applications.

2.2 Flexible Long Shaft Couplings

Flexible long shaft couplings are designed to address the limitations of rigid sleeve couplings by incorporating flexible elements that allow for greater misalignment accommodation. These flexible elements can be made from materials such as rubber, polyurethane, or metal springs, which absorb shocks and vibrations while transmitting torque. The long shaft in flexible couplings is often supported by intermediate bearings to reduce deflection and ensure stability over extended spans.

There are several subtypes of flexible long shaft couplings, including jaw couplings, tire couplings, and disc couplings. Jaw couplings feature two jaw-shaped hubs that are connected by an elastomeric spider, which provides flexibility and damping. Tire couplings use a rubber or polyurethane tire element that connects the two shafts, offering high misalignment capacity and excellent shock absorption. Disc couplings utilize thin metal discs to transmit torque, providing high torsional stiffness while accommodating angular and parallel misalignments. Flexible long shaft couplings are widely used in applications such as industrial pumps, compressors, and marine propulsion systems, where misalignment and vibration are common concerns.

2.3 Universal Joint Long Shaft Couplings

Universal joint (U-joint) long shaft couplings are designed to transmit torque between shafts that are at an angle to each other. They consist of two U-joints connected by a long intermediate shaft, which allows for the transfer of motion even when the driving and driven shafts are not collinear. U-joint couplings are particularly useful in applications where the angle between shafts changes during operation, such as in automotive drivetrains, agricultural machinery, and construction equipment.

The key advantage of U-joint long shaft couplings is their ability to handle large angular misalignments, typically up to 30 degrees or more depending on the design. However, they have a drawback known as "velocity fluctuation," which occurs when the angular velocity of the driven shaft varies slightly as the U-joint rotates. This fluctuation can cause vibration and noise, especially at high speeds. To mitigate this issue, double U-joints (with two U-joints phased correctly) are often used, which cancel out the velocity fluctuation and provide smoother operation.

2.4 Splined Long Shaft Couplings

Splined long shaft couplings utilize splines (grooves cut into the shaft and coupling) to transmit torque while allowing for axial movement of the shafts. The long shaft is typically splined at both ends, fitting into corresponding splined hubs on the driving and driven shafts. This design enables the coupling to accommodate axial misalignment caused by thermal expansion or contraction, making it suitable for applications where temperature variations are significant, such as in steam turbines, industrial furnaces, and power generation equipment.

Splined long shaft couplings offer high torque transmission capacity and excellent axial flexibility. They are also durable and can withstand high speeds and heavy loads. However, the splined connection requires precise manufacturing to ensure proper fit and minimize wear, which can increase the cost of the coupling. Additionally, regular lubrication is necessary to reduce friction between the splines and prevent corrosion.

3. Key Design Considerations for Long Shaft Couplings

Designing a long shaft coupling requires careful consideration of several factors to ensure optimal performance, reliability, and longevity. The following are the key design considerations:

3.1 Shaft Span and Deflection

The length of the long shaft (shaft span) is one of the most critical design parameters. As the span increases, the risk of shaft deflection also increases, which can lead to misalignment, increased bearing loads, and reduced coupling efficiency. To address this, designers must calculate the maximum allowable deflection based on the application's load conditions and select an appropriate shaft diameter and material. In some cases, intermediate bearings may be required to support the long shaft and reduce deflection. The placement of intermediate bearings is also important, as it affects the distribution of loads and the overall stability of the coupling.

3.2 Torque Capacity

The coupling must be designed to transmit the maximum torque required by the application without failure. Torque capacity depends on several factors, including the material of the coupling components, the cross-sectional area of the shaft, and the type of connection (e.g., keyed, splined, or bolted). Designers must also consider peak torque loads, which can occur during startup, shutdown, or sudden changes in operating conditions. Oversizing the coupling to handle peak torque loads can improve reliability, but it may also increase cost and weight. Therefore, a balance must be struck between torque capacity and cost-effectiveness.

3.3 Misalignment Capability

As discussed earlier, misalignment is a common issue in long shaft coupling applications. The coupling design must be tailored to the type and magnitude of misalignment expected in the application. For example, applications with large angular misalignment may require U-joint or tire couplings, while applications with axial misalignment may be better suited for splined couplings. Designers must also consider the effect of misalignment on coupling life, as excessive misalignment can lead to increased wear and premature failure.

3.4 Material Selection

The choice of material for long shaft couplings is critical to their performance and durability. Common materials include steel, stainless steel, aluminum, and various polymers. Steel is the most widely used material due to its high strength, rigidity, and torque capacity, making it suitable for heavy-duty applications. Stainless steel is preferred for applications in corrosive environments, such as marine or chemical processing. Aluminum is lightweight and offers good thermal conductivity, making it ideal for applications where weight is a concern. Polymers, such as rubber and polyurethane, are used for flexible elements due to their excellent damping and misalignment capabilities.

Material selection must also consider factors such as operating temperature, corrosion resistance, and wear resistance. For example, couplings used in high-temperature applications must be made from materials that can withstand thermal expansion and maintain their strength at elevated temperatures. Similarly, couplings used in abrasive environments must be made from wear-resistant materials to ensure long service life.

3.5 Bearing Systems

Long shaft couplings often require bearing systems to support the intermediate shaft and reduce friction. The type and placement of bearings depend on the application's load conditions, speed, and misalignment requirements. Common types of bearings used in long shaft couplings include ball bearings, roller bearings, and sleeve bearings. Ball bearings are suitable for high-speed applications with light to moderate loads, while roller bearings are better for heavy-duty applications with high radial loads. Sleeve bearings are often used in low-speed, high-load applications due to their simplicity and durability.

Bearing lubrication is also a critical consideration, as proper lubrication reduces friction, wear, and heat generation. The type of lubricant (e.g., oil, grease) must be selected based on the operating temperature, speed, and environmental conditions. Regular lubrication maintenance is necessary to ensure the bearings operate efficiently and have a long service life.

4. Practical Applications of Long Shaft Couplings

Long shaft couplings find applications in a wide range of industries, where they play a vital role in ensuring the reliable transmission of power between shafts separated by extended distances. The following are some of the key application areas:

4.1 Industrial Machinery

In industrial settings, long shaft couplings are commonly used in equipment such as pumps, compressors, fans, and conveyors. For example, in large industrial pumps, the motor and pump shafts may be separated by a significant distance due to the size of the pump or the layout of the plant. Long shaft couplings enable the transmission of torque from the motor to the pump shaft, while accommodating any misalignment caused by installation or thermal expansion. Similarly, in conveyor systems, long shaft couplings are used to connect the drive motor to the conveyor roller shafts, which may be spaced apart along the length of the conveyor.

4.2 Marine Propulsion Systems

Marine vessels, such as ships and boats, rely on long shaft couplings to transmit power from the engine to the propeller. The engine is typically located in the hull of the vessel, while the propeller is at the stern, requiring a long shaft to connect them. Marine long shaft couplings must be designed to withstand harsh marine environments, including saltwater corrosion, high humidity, and significant vibration. They must also be capable of handling large torque loads and accommodating misalignments caused by the movement of the vessel in the water. Flexible couplings, such as tire couplings or disc couplings, are often used in marine applications due to their excellent misalignment and shock absorption capabilities.

4.3 Automotive and Transportation

In the automotive industry, long shaft couplings are used in drivetrains to connect the engine to the transmission or differential. For example, in rear-wheel-drive vehicles, a long driveshaft (equipped with U-joint couplings) transmits power from the transmission to the rear differential. This design allows the engine and transmission to be mounted at the front of the vehicle, while the rear wheels are driven by the differential at the rear. Long shaft couplings in automotive applications must be lightweight, compact, and capable of handling high speeds and torque loads. They must also be durable enough to withstand the vibrations and shocks encountered during normal driving.

4.4 Agricultural Machinery

Agricultural machinery, such as tractors, combines, and harvesters, often require long shaft couplings to transmit power between various components. For example, in a tractor, the engine may be connected to a PTO (Power Take-Off) shaft, which is used to power implements such as plows, mowers, and balers. The PTO shaft is typically a long shaft equipped with U-joint couplings, which allow for misalignment between the tractor and the implement. Long shaft couplings in agricultural applications must be robust and capable of handling heavy loads and harsh operating conditions, such as dirt, dust, and moisture.

4.5 Power Generation

In power generation plants, long shaft couplings are used in equipment such as steam turbines, gas turbines, and generators. For example, in a steam turbine power plant, the turbine and generator shafts are often connected by a long shaft coupling. The coupling must be capable of transmitting large amounts of torque while accommodating any misalignment caused by thermal expansion or contraction of the shafts. Splined couplings are often used in power generation applications due to their ability to handle axial misalignment and high torque loads. Additionally, the coupling must be designed to minimize vibration and ensure smooth operation, as any disruption in power transmission can lead to significant downtime and financial losses.

5. Maintenance Practices for Long Shaft Couplings

Proper maintenance is essential to ensure the reliable operation and long service life of long shaft couplings. Neglecting maintenance can lead to premature failure, increased downtime, and costly repairs. The following are key maintenance practices for long shaft couplings:

5.1 Regular Inspection

Regular visual inspections are crucial to identify potential issues early. Inspections should include checking for signs of wear, corrosion, or damage to the coupling components, such as the shaft, sleeves, flexible elements, and bearings. Additionally, the alignment of the shafts should be checked regularly using tools such as dial indicators or laser alignment tools. Misalignment can lead to increased wear and stress on the coupling and connected equipment, so any misalignment should be corrected promptly. Inspections should also include checking for loose fasteners, such as set screws, bolts, and keys, and tightening them as necessary.

5.2 Lubrication

Proper lubrication is essential to reduce friction and wear between moving parts of the coupling, such as bearings, splines, and U-joints. The type of lubricant used should be compatible with the coupling material and operating conditions. Lubrication intervals should be followed as recommended by the manufacturer, and the lubricant should be checked regularly for contamination (e.g., dirt, water) or degradation. If the lubricant is contaminated or degraded, it should be replaced immediately to prevent damage to the coupling components.

5.3 Replacement of Worn Components

Flexible elements, such as rubber spiders, tires, and discs, are prone to wear over time and should be replaced when signs of deterioration (e.g., cracks, hardening, or tearing) are observed. Similarly, bearings should be replaced if they show signs of wear, such as excessive noise, vibration, or play. Splined connections should be inspected for wear and replaced if the splines are worn or damaged. Replacing worn components promptly can prevent further damage to the coupling and connected equipment.

5.4 Cleaning

Keeping the coupling clean is important to prevent the buildup of dirt, dust, and debris, which can cause corrosion and wear. The coupling should be cleaned regularly using a suitable cleaning agent, and any debris should be removed from the coupling components. In corrosive environments, such as marine or chemical processing plants, additional cleaning and corrosion protection measures may be necessary, such as applying a protective coating or using corrosion-resistant materials.

5.5 Proper Storage

If a long shaft coupling is not in use, it should be stored properly to prevent damage. The coupling should be stored in a clean, dry environment, away from moisture, dust, and extreme temperatures. Shaft ends should be protected with caps or covers to prevent damage to splines or keyways. Additionally, the coupling should be lubricated before storage to prevent corrosion of moving parts.

6. Future Trends in Long Shaft Coupling Technology

The field of long shaft coupling technology is constantly evolving, driven by advancements in materials science, manufacturing processes, and the increasing demand for more efficient, reliable, and sustainable mechanical systems. The following are some of the key future trends:

6.1 Advanced Material Development

Advancements in materials science are leading to the development of new materials for long shaft couplings that offer improved performance characteristics. For example, composite materials, such as carbon fiber-reinforced polymers (CFRPs), are being increasingly used due to their high strength-to-weight ratio, corrosion resistance, and excellent damping properties. These materials can reduce the weight of long shaft couplings, making them ideal for applications where weight is a critical factor, such as automotive and aerospace. Additionally, new alloy steels and stainless steels with enhanced strength and wear resistance are being developed for heavy-duty applications.

6.2 Smart Couplings with Condition Monitoring

The integration of sensors and IoT (Internet of Things) technology into long shaft couplings is a growing trend. Smart couplings are equipped with sensors that monitor key parameters such as temperature, vibration, torque, and misalignment in real-time. This data is transmitted to a central monitoring system, allowing for predictive maintenance and early detection of potential issues. Predictive maintenance can significantly reduce downtime by enabling maintenance to be performed before a failure occurs, rather than after. Additionally, smart couplings can provide valuable insights into the performance of the coupling and connected equipment, allowing for optimization of operating conditions.

6.3 Improved Manufacturing Processes

Advancements in manufacturing processes, such as additive manufacturing (3D printing), are revolutionizing the production of long shaft couplings. Additive manufacturing allows for the production of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This enables the design of more efficient and lightweight couplings with optimized performance. Additionally, additive manufacturing reduces material waste and allows for rapid prototyping, which can accelerate the development of new coupling designs. Other manufacturing advancements, such as precision machining and automated assembly, are improving the quality and consistency of long shaft couplings, reducing manufacturing costs and lead times.

6.4 Focus on Sustainability

Sustainability is becoming an increasingly important consideration in the design and manufacturing of long shaft couplings. Manufacturers are focusing on developing couplings that are more energy-efficient, use recycled or renewable materials, and have a longer service life. For example, couplings with improved damping properties can reduce energy loss due to vibration, improving overall system efficiency. Additionally, the use of corrosion-resistant materials reduces the need for frequent replacement, reducing waste. Manufacturers are also implementing more sustainable manufacturing processes, such as reducing energy consumption and minimizing emissions.

6.5 Customization for Specific Applications

As industries become more specialized, there is a growing demand for custom long shaft couplings tailored to specific application requirements. Manufacturers are offering more customization options, allowing customers to select the material, size, type, and features of the coupling to meet their unique needs. For example, couplings for offshore wind turbines require specialized designs to withstand harsh marine environments and high torque loads, while couplings for medical equipment require high precision and low vibration. Customization enables the development of couplings that offer optimal performance for specific applications, improving reliability and efficiency.

7. Conclusion

Long shaft couplings are essential components in a wide range of mechanical transmission systems, enabling the reliable transfer of torque and motion between shafts separated by extended distances. Their design must address the unique challenges posed by long spans, including shaft deflection, misalignment, and vibration. By understanding the fundamental principles, common types, key design considerations, applications, and maintenance practices of long shaft couplings, engineers and maintenance professionals can select and maintain the right coupling for their specific application, ensuring optimal performance and longevity.

Looking to the future, advancements in materials, smart technology, manufacturing processes, and sustainability will continue to drive innovation in long shaft coupling design. These advancements will lead to more efficient, reliable, and sustainable couplings that meet the evolving needs of industries such as automotive, marine, power generation, and agriculture. As long shaft coupling technology continues to evolve, it will play an increasingly important role in the development of more efficient and sustainable mechanical systems.

« Long Shaft Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/long-shaft-coupling.html