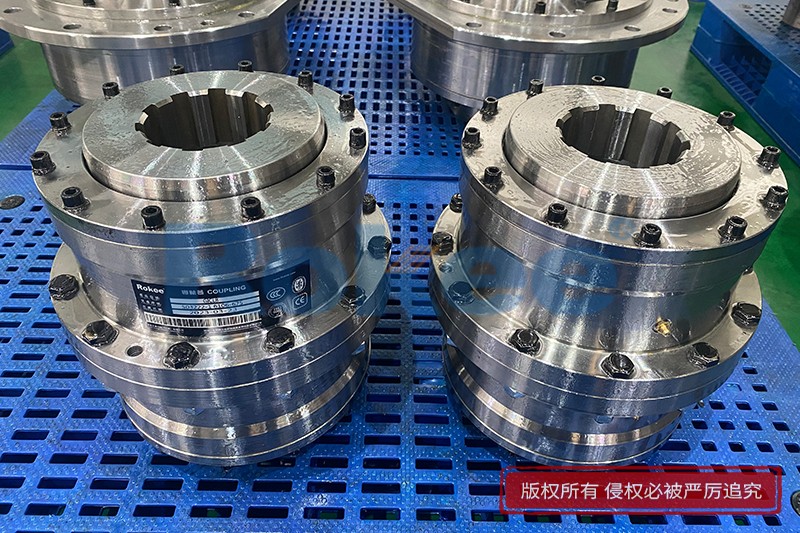

High Torque Coupling

Rokee® is High Torque Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® High Torque Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of industrial power transmission, the efficient and reliable transfer of high rotational forces is a critical requirement for countless applications. From heavy machinery in manufacturing plants to large-scale marine propulsion systems, the component responsible for bridging the gap between power sources and driven equipment—while accommodating misalignments and absorbing operational shocks—plays an indispensable role. This component is the high torque coupling. Unlike standard couplings designed for moderate load conditions, high torque couplings are engineered to withstand extreme rotational forces, making them essential in industries where power and durability are non-negotiable.

To understand high torque couplings, it is first necessary to establish a clear definition of the broader coupling concept. A coupling is a mechanical device that connects two shafts together to transmit power from a driving source (such as an electric motor, diesel engine, or turbine) to a driven machine (such as a pump, compressor, or gearbox). The primary function of any coupling is to ensure the efficient transfer of torque while addressing inherent challenges in shaft alignment. Shaft misalignment can occur due to installation errors, thermal expansion during operation, or structural vibrations, and failure to accommodate this misalignment can lead to premature wear, increased energy consumption, and even catastrophic equipment failure. High torque couplings build on this basic functionality by being specifically designed to handle torque loads that far exceed those of standard couplings. While there is no universal threshold for defining “high torque,” these couplings typically operate in applications where torque requirements range from several thousand to millions of Newton-meters, demanding robust construction and advanced material science to ensure reliability.

The design of high torque couplings is a sophisticated balance of strength, flexibility, and durability. At the core of their design is the need to transmit extreme torque without compromising on the ability to accommodate misalignment and dampen vibrations. Key design elements include the choice of materials, the configuration of torque-transmitting components, and the integration of flexible elements (where applicable). Materials used in high torque couplings must possess exceptional tensile strength, fatigue resistance, and wear resistance. Common materials include high-grade alloy steels, which offer an excellent combination of strength and ductility, and in some cases, composite materials or specialized alloys for applications requiring corrosion resistance or reduced weight. The torque-transmitting components—such as gears, bolts, or friction surfaces—are precision-engineered to distribute loads evenly, minimizing stress concentrations that could lead to failure under high torque conditions. Additionally, many high torque couplings incorporate flexible elements, such as elastomers or metallic diaphragms, which allow for angular, parallel, or axial misalignment while isolating vibrations between the driving and driven shafts.

There are several common types of high torque couplings, each tailored to specific application requirements based on factors such as misalignment tolerance, vibration damping needs, and operational environment. One of the most widely used types is the gear coupling. Gear couplings consist of two gear hubs with external teeth that mesh with internal teeth on a sleeve or flange. This design provides high torque capacity due to the large contact area between the gear teeth, which allows for the even distribution of load. Gear couplings are capable of accommodating moderate angular and parallel misalignments and are commonly used in heavy-duty applications such as steel mills, mining equipment, and large industrial compressors. However, they require regular lubrication to reduce friction and wear between the gear teeth, making them less suitable for applications where maintenance access is limited.

Another prominent type is the diaphragm coupling. Diaphragm couplings use one or more thin, flexible metallic diaphragms to transmit torque. The diaphragms are typically made from high-strength stainless steel and are designed to flex under misalignment, eliminating the need for lubrication. This lubrication-free design makes diaphragm couplings ideal for applications where contamination from lubricants is a concern, such as food processing, pharmaceuticals, or clean energy systems. Diaphragm couplings also offer excellent vibration damping capabilities and can handle high torque loads with minimal maintenance. However, they have a lower tolerance for extreme misalignments compared to gear couplings, making them more suitable for applications with precise shaft alignment.

Friction couplings, also known as clutch couplings, are another type of high torque coupling that relies on frictional force to transmit torque. These couplings consist of two friction plates that are pressed together by springs or hydraulic pressure. The amount of torque transmitted is proportional to the frictional force between the plates, which can be adjusted by varying the pressure. Friction couplings are particularly useful in applications where torque needs to be controlled or where soft starting is required to protect driven equipment from shock loads. Common applications include conveyor systems, crushers, and heavy-duty vehicles. However, friction couplings can experience wear over time due to the frictional forces involved, requiring periodic replacement of the friction plates.

Grid couplings represent another popular option for high torque applications. These couplings use a flexible grid element made from spring steel that fits between two hubs with curved teeth. The grid element absorbs shocks and vibrations while accommodating angular and parallel misalignments. Grid couplings are known for their durability, high torque capacity, and relatively low cost compared to other high torque coupling types. They are commonly used in industrial pumps, fans, and gearboxes. Like gear couplings, grid couplings require lubrication to ensure smooth operation and prevent wear, but their simple design makes maintenance relatively straightforward.

Key performance characteristics of high torque couplings are critical factors in determining their suitability for specific applications. Torque capacity is undoubtedly the most important characteristic, as it defines the maximum amount of rotational force the coupling can transmit without failure. It is essential to select a coupling with a torque capacity that exceeds the maximum operating torque of the application to provide a safety margin. Misalignment tolerance is another key factor, as different applications require varying degrees of accommodation for angular (shafts intersecting at an angle), parallel (shafts offset parallel to each other), and axial (shafts moving toward or away from each other) misalignment. Vibration damping capability is also important, as excessive vibrations can lead to premature wear of equipment components and reduced operational efficiency. Couplings with good vibration damping properties, such as diaphragm or grid couplings, help to isolate vibrations between the driving and driven shafts, improving overall system reliability.

Other important performance characteristics include fatigue life, operating temperature range, and resistance to environmental factors. Fatigue life refers to the number of operating cycles the coupling can withstand before failing due to repeated stress, which is critical in applications with continuous or cyclic operation. Operating temperature range is important because extreme temperatures can affect the material properties of the coupling, reducing its strength and flexibility. High torque couplings used in high-temperature applications, such as industrial furnaces or gas turbines, must be constructed from materials that can withstand these conditions. Environmental resistance, including resistance to corrosion, moisture, and dust, is essential for applications in harsh environments such as marine, offshore, or mining operations.

The applications of high torque couplings span a wide range of industries, each with unique requirements that drive the selection of specific coupling types. In the manufacturing industry, high torque couplings are used in heavy-duty machinery such as steel rolling mills, where they transmit torque from large electric motors to the rolling stands. The high torque and moderate misalignment tolerance required in these applications make gear or grid couplings ideal choices. Similarly, in automotive manufacturing plants, high torque couplings are used in assembly line conveyors and robotic arms, where precise torque transmission and vibration damping are essential for maintaining production efficiency.

The mining and mineral processing industry relies heavily on high torque couplings to power equipment such as crushers, grinders, and conveyor systems. These applications involve extreme torque loads, heavy shock loads, and harsh environmental conditions, requiring couplings that are both durable and resistant to wear and corrosion. Friction couplings are often used in crushers to provide soft starting and protect the equipment from shock loads, while gear or grid couplings are used in conveyor systems to handle high torque and moderate misalignments.

The marine industry is another major user of high torque couplings, particularly in ship propulsion systems. Marine propulsion systems require couplings that can transmit high torque from diesel engines or gas turbines to the propeller shafts, while accommodating misalignments caused by hull flexing and thermal expansion. Diaphragm couplings are often preferred in marine applications due to their lubrication-free design, which eliminates the risk of lubricant contamination in the marine environment. Additionally, their excellent vibration damping capabilities help to reduce noise and improve the comfort of the ship’s crew.

The energy sector, including both traditional fossil fuel power plants and renewable energy systems, also relies on high torque couplings. In thermal power plants, high torque couplings are used to connect turbines to generators, transmitting the high torque generated by the turbine to the generator to produce electricity. These applications require couplings with high torque capacity, excellent alignment tolerance, and high-temperature resistance, making gear or diaphragm couplings suitable choices. In wind energy systems, high torque couplings are used in wind turbines to connect the rotor to the gearbox, transmitting the torque generated by the rotating blades to the gearbox for speed conversion. The harsh environmental conditions (high winds, temperature fluctuations, and salt spray in offshore wind farms) require couplings that are corrosion-resistant and durable, such as diaphragm couplings made from stainless steel.

Selecting the right high torque coupling for a specific application requires careful consideration of several factors. First and foremost, the torque requirements of the application must be accurately determined. This includes not only the nominal operating torque but also any peak torque loads that may occur during start-up or transient conditions. Selecting a coupling with a torque capacity that is too low will result in premature failure, while selecting one that is too large may lead to unnecessary costs and increased weight.

Shaft misalignment is another critical factor to consider. The type and magnitude of misalignment present in the application will dictate the choice of coupling. For applications with large angular or parallel misalignments, gear or grid couplings are more suitable, while diaphragm couplings are better suited for applications with minimal misalignments. The operating environment must also be taken into account, including factors such as temperature, humidity, corrosion potential, and the presence of dust or debris. For example, in corrosive environments such as offshore applications, couplings made from corrosion-resistant materials such as stainless steel or composite materials are essential.

Maintenance requirements are also an important consideration. Couplings that require regular lubrication, such as gear and grid couplings, may not be suitable for applications where maintenance access is limited or where lubricant contamination is a concern. In such cases, lubrication-free couplings such as diaphragm couplings are a better choice. Additionally, the cost of the coupling and its expected service life should be weighed against the overall cost of the system to ensure that the selected coupling provides the best value for money.

Proper maintenance of high torque couplings is essential to ensure their reliable operation and extend their service life. Regular inspection is the cornerstone of effective maintenance, and should include checking for signs of wear, corrosion, or damage to the coupling components. For lubricated couplings, regular lubrication is critical to reduce friction and wear between moving parts. The type and frequency of lubrication should be in accordance with the manufacturer’s recommendations, and the lubricant should be checked regularly for contamination or degradation.

Alignment checks should also be performed periodically, as misalignment can increase stress on the coupling and other system components. This is particularly important after any maintenance work or equipment relocation. If misalignment is detected, it should be corrected immediately to prevent premature wear. Additionally, any worn or damaged components, such as friction plates, diaphragms, or grid elements, should be replaced promptly to avoid further damage to the coupling or the connected equipment.

In recent years, advancements in material science and manufacturing technology have led to significant improvements in high torque coupling design and performance. The use of advanced composite materials has resulted in couplings that are lighter, stronger, and more corrosion-resistant than traditional metal couplings. Additionally, precision manufacturing techniques such as 3D printing have allowed for the production of complex coupling geometries that optimize torque transmission and misalignment tolerance. These advancements have expanded the range of applications for high torque couplings, making them suitable for even more demanding environments and operating conditions.

Looking to the future, the demand for high torque couplings is expected to grow as industries continue to pursue higher levels of power and efficiency. The expansion of renewable energy sources such as wind and tidal power, which require high torque couplings to transmit power from large rotating components, is likely to drive significant growth in the market. Additionally, the increasing automation of manufacturing processes and the growing demand for heavy-duty electric vehicles will further increase the need for reliable high torque transmission components.

In conclusion, high torque couplings are critical components in industrial power transmission systems, enabling the efficient and reliable transfer of extreme rotational forces while accommodating misalignments and damping vibrations. Their design, which balances strength, flexibility, and durability, is tailored to meet the specific requirements of a wide range of applications across industries such as manufacturing, mining, marine, and energy. The selection of the right high torque coupling requires careful consideration of factors such as torque capacity, misalignment tolerance, operating environment, and maintenance requirements. Proper maintenance, including regular inspection, lubrication, and alignment checks, is essential to ensure their long-term reliability and performance. As technology continues to advance, high torque couplings will continue to evolve, providing even greater levels of efficiency, durability, and versatility to meet the changing needs of modern industry.

« High Torque Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/high-torque-coupling.html