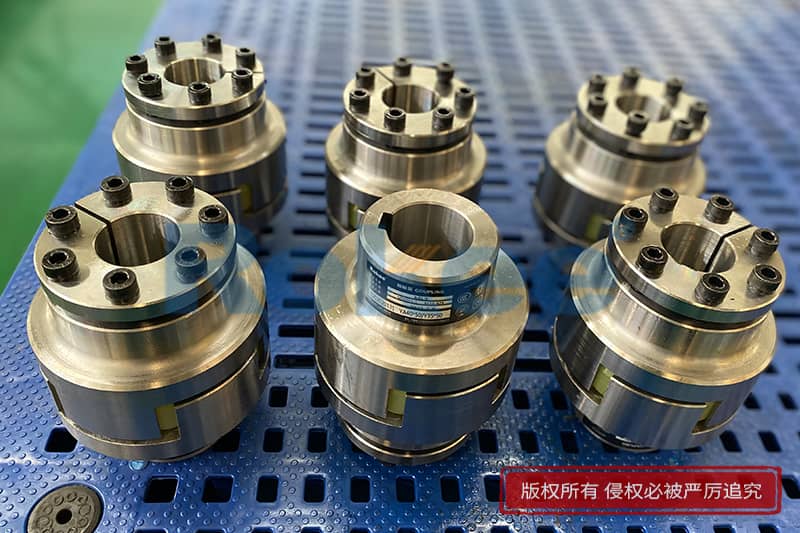

Flexible Flange Coupling

Rokee® is Flexible Flange Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Flexible Flange Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Flexible Flange Coupling is a coupling that allows for separate axial displacement of the rotor and allows for a certain deviation in the alignment of two connected rotors. Flexible Flange Coupling refers to the ability to compensate for the relative deviation of the axis of the two connected shafts.

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, enabling the seamless transfer of torque while accommodating various misalignments and operational stresses. Among the diverse range of couplings available, the flexible flange coupling stands out for its unique combination of rigidity, flexibility, and ease of installation. This type of coupling has become an indispensable component in numerous industrial systems, from small-scale machinery to large industrial complexes, due to its ability to enhance operational efficiency and reduce mechanical wear.

1. Understanding Flexible Flange Couplings: Definition and Core Functions

A flexible flange coupling is a mechanical device designed to connect two coaxial shafts for torque transmission, while incorporating flexible elements to compensate for axial, radial, and angular misalignments between the shafts. Unlike rigid flange couplings, which require precise alignment and offer no flexibility, flexible flange couplings utilize elastic components—such as rubber bushes, elastomeric sleeves, or flexible discs—to absorb vibrations, dampen shocks, and accommodate minor to moderate misalignments. The core functions of a flexible flange coupling extend beyond mere torque transfer; they also serve to protect connected equipment, such as motors, pumps, and gearboxes, from excessive stresses and premature failure caused by misalignment or operational irregularities.

At its essence, the flexible flange coupling acts as a "buffer" between rotating components, ensuring that the mechanical system operates smoothly even under dynamic conditions. This flexibility is particularly crucial in applications where shaft alignment may change over time due to thermal expansion, structural settlement, or mechanical wear. By accommodating these changes, the coupling reduces the risk of bearing damage, shaft bending, and other costly mechanical failures, thereby improving the overall reliability and lifespan of the system.

2. Design and Structural Components of Flexible Flange Couplings

The design of a flexible flange coupling is a carefully engineered balance between rigidity (to ensure efficient torque transmission) and flexibility (to accommodate misalignments and absorb vibrations). While specific designs may vary based on application requirements, most flexible flange couplings share several key structural components:

2.1 Flange Plates

The flange plates are the primary load-bearing components of the coupling, typically made from high-strength metallic materials. Each flange plate is attached to the end of a rotating shaft using keys, splines, or set screws, creating a secure connection that can withstand the torque generated during operation. The flange plates are designed with a series of bolt holes around their circumference, which allow them to be connected to each other via bolts or studs. The size and number of bolt holes are determined by the maximum torque capacity of the coupling, with larger couplings requiring more bolts to distribute the load evenly.

2.2 Flexible Elements

The flexible elements are the defining feature of the flexible flange coupling, responsible for providing the necessary flexibility and vibration damping. These elements are positioned between the two flange plates, acting as the interface that transmits torque while accommodating misalignments. Common types of flexible elements include rubber or elastomeric bushes, flexible discs (made from composite materials or metal), and grid couplings (using a flexible steel grid). The choice of flexible element depends on factors such as operating temperature, torque requirements, and the level of misalignment expected.

Rubber bushes, for example, are widely used in low to medium torque applications due to their excellent vibration damping properties and cost-effectiveness. They are typically inserted into the bolt holes of the flange plates, with the bolts passing through the bushes to connect the two flanges. The rubber material absorbs shocks and vibrations, while allowing for minor radial and angular misalignments. In contrast, flexible disc couplings use thin, flexible metal discs (often made from stainless steel) that are bolted between the flanges. These discs offer higher torque capacity and better resistance to high temperatures, making them suitable for more demanding industrial applications.

2.3 Fasteners

Fasteners, such as bolts, studs, and nuts, are used to secure the flange plates to the shafts and to each other. The fasteners must be selected to withstand the operational stresses, including torque, shear forces, and vibration. In many cases, high-tensile bolts are used to ensure a tight and secure connection, preventing slippage between the flange plates and the shafts. Lock washers or thread-locking compounds may also be used to prevent the fasteners from loosening due to vibration during operation.

3. Working Principle of Flexible Flange Couplings

The working principle of a flexible flange coupling revolves around the transfer of torque from one shaft to another through the flexible elements, while accommodating misalignments and absorbing vibrations. When the driving shaft rotates, it transmits torque to the attached flange plate. This torque is then transferred to the flexible elements, which in turn transmit it to the second flange plate and the driven shaft. The flexible elements allow for relative movement between the two flange plates, enabling the coupling to compensate for three types of misalignment:

- Axial Misalignment: This occurs when the shafts are parallel but offset along their axial (longitudinal) axis. The flexible elements can stretch or compress slightly to accommodate this offset, preventing axial forces from being transmitted to the connected equipment.

- Radial Misalignment: This is caused by the shafts being offset radially (perpendicular to their axis), resulting in a parallel misalignment. The flexible elements bend to accommodate this offset, ensuring that torque is still transmitted smoothly without putting excessive stress on the shafts or bearings.

- Angular Misalignment: This happens when the shafts are not parallel but intersect at an angle. The flexible elements twist or flex to compensate for this angular difference, allowing the coupling to operate efficiently even when the shafts are not perfectly aligned.

In addition to accommodating misalignments, the flexible elements also act as vibration dampeners. As the shafts rotate, any vibrations generated by the driving or driven equipment are absorbed by the flexible material, reducing the transmission of vibrations to other parts of the system. This not only improves the comfort of the operating environment but also reduces mechanical wear on bearings, gears, and other components, extending their lifespan.

4. Material Selection for Flexible Flange Couplings

The selection of materials for flexible flange couplings is critical to ensuring their performance, durability, and suitability for specific applications. The materials used for the flange plates, flexible elements, and fasteners must be chosen based on factors such as operating temperature, torque capacity, environmental conditions (e.g., humidity, corrosion), and the level of misalignment expected.

4.1 Flange Plate Materials

Flange plates are typically made from high-strength metallic materials that can withstand the torque and shear forces generated during operation. Common materials include:

- Carbon Steel: This is the most widely used material for flange plates due to its high strength, durability, and cost-effectiveness. Carbon steel is suitable for most industrial applications with moderate torque requirements and operating temperatures.

- Alloy Steel: For applications requiring higher torque capacity or resistance to high temperatures, alloy steel (e.g., chrome-molybdenum steel) is often used. Alloy steel offers superior strength and toughness compared to carbon steel, making it ideal for heavy-duty industrial machinery.

- Stainless Steel: In environments where corrosion resistance is critical (e.g., food processing, chemical plants, or marine applications), stainless steel flange plates are preferred. Stainless steel is resistant to rust and corrosion, ensuring the coupling's performance even in harsh conditions.

4.2 Flexible Element Materials

The materials used for the flexible elements are selected based on their elasticity, vibration damping properties, temperature resistance, and chemical compatibility. Common materials include:

- Elastomers (Rubber): Natural rubber, nitrile rubber, and neoprene are commonly used for flexible elements in low to medium torque applications. Elastomers offer excellent vibration damping and flexibility, but their performance can degrade at high temperatures (above 100°C) or in contact with certain chemicals.

- Polyurethane: Polyurethane is a synthetic material that offers better wear resistance and higher temperature tolerance than rubber. It is often used in applications where the coupling is exposed to abrasion or moderate heat.

- Metal: Stainless steel or spring steel is used for flexible discs or grid elements in high-torque, high-temperature applications. Metal flexible elements offer superior strength and durability, but they provide less vibration damping than elastomers.

4.3 Fastener Materials

Fasteners are typically made from high-tensile steel to ensure they can withstand the operational stresses. In corrosive environments, stainless steel fasteners are used to prevent rust and corrosion. The choice of fastener material must be compatible with the flange plate material to avoid galvanic corrosion, which can weaken the connection over time.

5. Applications of Flexible Flange Couplings

Flexible flange couplings are used in a wide range of industrial and commercial applications, thanks to their versatility, reliability, and ability to accommodate misalignments. Some of the key application areas include:

5.1 Industrial Machinery

In industrial settings, flexible flange couplings are commonly used to connect motors to pumps, compressors, fans, and conveyors. These applications often involve varying levels of misalignment due to thermal expansion or mechanical wear, making the flexibility of the coupling essential. For example, in a water treatment plant, a flexible flange coupling connects the motor to the water pump, accommodating any misalignment caused by the thermal expansion of the pump shaft during operation.

5.2 Manufacturing Equipment

Manufacturing equipment, such as lathes, milling machines, and robotic arms, relies on precise torque transmission to ensure accurate operation. Flexible flange couplings are used in these applications to transmit torque while absorbing vibrations, which can affect the precision of the manufacturing process. The flexibility of the coupling also helps to protect the delicate components of the equipment from excessive stresses.

5.3 Automotive and Transportation

In the automotive industry, flexible flange couplings are used in drivetrains, connecting the engine to the transmission or the transmission to the differential. They help to accommodate misalignments between the components and absorb vibrations generated by the engine, improving the smoothness of the ride and reducing wear on the drivetrain components. Flexible flange couplings are also used in commercial vehicles, such as trucks and buses, to handle the high torque requirements of heavy-duty operation.

5.4 Renewable Energy Systems

Renewable energy systems, such as wind turbines and solar pumps, rely on flexible flange couplings to connect the generator to the rotating components. In wind turbines, for example, the coupling connects the rotor shaft to the generator shaft, accommodating misalignments caused by wind-induced vibrations and the movement of the turbine tower. The flexible elements also absorb vibrations, protecting the generator and other critical components from damage.

5.5 Marine Applications

In marine environments, flexible flange couplings are used in ship propulsion systems, connecting the engine to the propeller shaft. The corrosive nature of seawater requires the use of stainless steel or other corrosion-resistant materials for the flange plates and fasteners. The flexibility of the coupling helps to accommodate misalignments caused by the movement of the ship and absorb vibrations from the engine, ensuring reliable operation even in rough seas.

6. Advantages of Flexible Flange Couplings

Flexible flange couplings offer numerous advantages over other types of couplings, making them a preferred choice for many applications. Some of the key advantages include:

- Accommodates Misalignments: The ability to compensate for axial, radial, and angular misalignments reduces the need for precise shaft alignment during installation and maintenance, saving time and labor costs. This also reduces the risk of mechanical failures caused by misalignment.

- Vibration Damping: The flexible elements absorb vibrations and dampen shocks, reducing the transmission of vibrations to other components of the system. This improves the operational efficiency of the equipment and extends the lifespan of bearings, gears, and other mechanical parts.

- Easy Installation and Maintenance: Flexible flange couplings are relatively easy to install and remove, requiring only basic tools. The simple design also makes maintenance straightforward, with most couplings requiring only periodic inspection and replacement of the flexible elements.

- High Torque Capacity: Despite their flexibility, modern flexible flange couplings can handle high torque loads, making them suitable for a wide range of industrial applications. The use of high-strength materials for the flange plates and fasteners ensures that the coupling can withstand the stresses of heavy-duty operation.

- Protects Connected Equipment: By acting as a buffer between rotating shafts, flexible flange couplings protect connected equipment (such as motors and pumps) from excessive stresses, misalignment, and vibration. This reduces the risk of premature failure and lowers maintenance costs.

7. Selection Criteria for Flexible Flange Couplings

Selecting the right flexible flange coupling for a specific application requires careful consideration of several key factors. The following criteria should be taken into account to ensure optimal performance and reliability:

7.1 Torque Requirement

The first and most important factor is the maximum torque that the coupling will need to transmit. The coupling's torque capacity must be greater than the maximum torque generated by the driving shaft to ensure that it can handle the load without failure. The torque requirement can be calculated based on the power of the motor and the rotational speed of the shaft.

7.2 Shaft Misalignment

The level of misalignment (axial, radial, angular) expected between the shafts must be considered when selecting the coupling. Different types of flexible elements can accommodate different levels of misalignment, so it is important to choose a coupling that can handle the maximum misalignment expected in the application.

7.3 Operating Temperature

The operating temperature of the application will influence the choice of materials for the flexible elements and flange plates. Elastomeric elements, for example, have a lower temperature tolerance than metal elements, so they may not be suitable for high-temperature applications. It is important to select a coupling that can operate within the temperature range of the application.

7.4 Environmental Conditions

Environmental conditions, such as humidity, corrosion, and exposure to chemicals, must also be considered. In corrosive environments, stainless steel or other corrosion-resistant materials should be used for the flange plates and fasteners. If the coupling is exposed to chemicals, the flexible elements must be made from a material that is chemically compatible with the surrounding environment.

7.5 Shaft Size and Speed

The size of the shafts (diameter) and the rotational speed (RPM) must be compatible with the coupling. The coupling's bore size must match the diameter of the shafts, and the maximum rotational speed of the coupling must be greater than the operating speed of the shafts to prevent excessive wear or failure.

8. Maintenance and Inspection of Flexible Flange Couplings

Proper maintenance and inspection are essential to ensure the long-term performance and reliability of flexible flange couplings. Regular maintenance practices can help to identify potential issues early, preventing costly downtime and mechanical failures. The following maintenance steps are recommended:

8.1 Periodic Inspection

Couplings should be inspected regularly (e.g., monthly or quarterly) for signs of wear, damage, or loosening. During inspection, check the flexible elements for cracks, tears, or degradation, the flange plates for signs of corrosion or deformation, and the fasteners for tightness. Any signs of damage or wear should be addressed immediately.

8.2 Lubrication

Some types of flexible flange couplings (e.g., grid couplings) require lubrication to reduce friction and wear. The lubricant should be checked regularly and replaced as needed, following the manufacturer's recommendations. It is important to use the correct type of lubricant for the application and operating conditions.

8.3 Replacement of Flexible Elements

The flexible elements are the most wear-prone components of the coupling and will need to be replaced periodically. The frequency of replacement depends on the application, operating conditions, and the type of flexible element used. Elastomeric elements, for example, may need to be replaced more frequently than metal elements.

8.4 Shaft Alignment Check

Even though flexible flange couplings can accommodate misalignments, it is still important to check the shaft alignment periodically. Excessive misalignment can put additional stress on the coupling and the connected equipment, reducing their lifespan. If misalignment is found to be beyond the coupling's capacity, it should be corrected immediately.

9. Conclusion

Flexible flange couplings play a vital role in modern mechanical power transmission systems, offering a unique combination of torque transmission, flexibility, and vibration damping. Their ability to accommodate misalignments and protect connected equipment makes them an indispensable component in a wide range of industrial, automotive, and renewable energy applications. The design, material selection, and maintenance of flexible flange couplings are critical to ensuring their optimal performance and reliability.

As industrial technology continues to advance, the demand for more efficient, durable, and versatile couplings is expected to grow. Manufacturers are constantly innovating, developing new materials and designs to improve the performance of flexible flange couplings, making them suitable for even more demanding applications. By understanding the principles, applications, and maintenance requirements of flexible flange couplings, engineers and maintenance professionals can select and use these components effectively, ensuring the smooth and reliable operation of mechanical systems.

In summary, the flexible flange coupling is a testament to the ingenuity of mechanical engineering, providing a simple yet effective solution to the challenges of torque transmission and shaft misalignment. Its widespread use across various industries is a testament to its versatility and reliability, making it a cornerstone of modern mechanical systems.

« Flexible Flange Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/flexible-flange-coupling.html