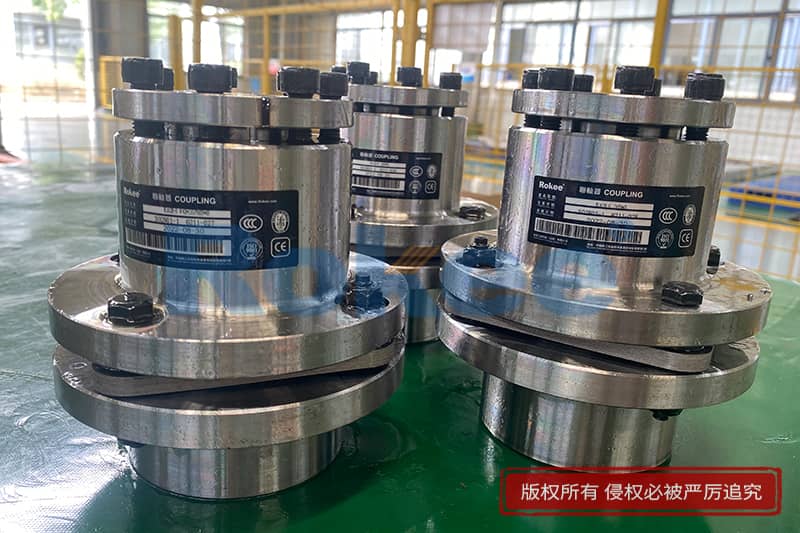

Flange Flexible Coupling

Rokee® is Flange Flexible Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Flange Flexible Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Flange Flexible Coupling is a coupling that allows for separate axial displacement of the rotor and allows for a certain deviation in the alignment of two connected rotors. Flange Flexible Coupling refers to the ability to compensate for the relative deviation of the axis of the two connected shafts.

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, enabling the seamless transfer of torque while accommodating various forms of misalignment. Among the diverse types of couplings available, the flange flexible coupling stands out for its robust construction, versatility, and ability to mitigate the adverse effects of shaft misalignment, vibration, and shock loads.

To begin with, it is essential to define what a flange flexible coupling is and how it differs from other coupling variants. A flange flexible coupling is a mechanical device designed to connect two separate shafts—typically the output shaft of a prime mover (such as an electric motor or internal combustion engine) and the input shaft of a driven machine (like a pump, compressor, or conveyor)—at their flanged ends. The defining feature of this coupling is its flexibility, which allows for limited angular, parallel, and axial misalignment between the connected shafts without compromising torque transmission. Unlike rigid flange couplings, which offer no flexibility and require near-perfect shaft alignment, flexible flange couplings incorporate elastic or semi-elastic elements that absorb misalignment and dampen vibrations. This flexibility not only protects the shafts and bearings from excessive stress but also enhances the overall reliability and lifespan of the mechanical system.

The design of a flange flexible coupling is a sophisticated integration of structural components that work in tandem to achieve both torque transmission and flexibility. While specific designs may vary based on application requirements, most flange flexible couplings share several core components: flanges, flexible elements, fasteners, and hubs. The flanges are circular discs with bolt holes that facilitate the connection between the coupling and the shafts. Each flange is attached to the end of a respective shaft, either via a keyway and key, a compression fit, or a tapered bushing—methods that ensure a secure, slip-free connection capable of transmitting high torque. The flexible elements, which are the heart of the coupling’s flexibility, are positioned between the two flanges. These elements can take various forms, including rubber or elastomeric pads, polyurethane inserts, metallic diaphragms, or grid springs. The choice of flexible element material and design directly impacts the coupling’s misalignment capacity, vibration damping ability, temperature resistance, and torque rating. Fasteners such as bolts, nuts, and washers are used to clamp the flanges and flexible elements together, ensuring that the assembly remains intact during operation. Hubs, in some designs, act as intermediaries between the shafts and flanges, providing additional support and facilitating easier installation.

The working principle of a flange flexible coupling revolves around balancing two primary objectives: efficient torque transmission and the accommodation of shaft misalignment. When the prime mover generates torque, it is transferred through the input shaft to the attached flange. This torque is then transmitted to the flexible element, which in turn transfers it to the output flange and ultimately to the driven shaft. The flexible element plays a pivotal role here: as the shafts deviate from perfect alignment, the element deforms elastically to absorb the misalignment. For angular misalignment (where the shafts are not collinear but intersect at a point), the flexible element bends slightly to bridge the angle between the flanges. For parallel misalignment (where the shafts are parallel but offset), the element stretches or compresses asymmetrically to accommodate the offset. Axial misalignment (where the shafts move toward or away from each other) is absorbed by the element’s ability to expand or contract along the axial direction. Additionally, the flexible element acts as a vibration damper, reducing the transmission of mechanical vibrations from the prime mover to the driven machine (or vice versa). This vibration damping is particularly beneficial in systems where excessive vibration can lead to component wear, noise pollution, or reduced operational efficiency.

Material selection is a critical factor in the performance and durability of flange flexible couplings, as different materials offer varying levels of strength, flexibility, temperature resistance, and chemical compatibility. The flanges and hubs are typically constructed from metallic materials due to their high torque-bearing capacity. Common metals used include carbon steel, alloy steel, and stainless steel. Carbon steel is a cost-effective option for general-purpose applications, offering good strength and machinability. Alloy steel, which contains additional elements such as chromium, nickel, or molybdenum, provides enhanced strength, hardness, and resistance to fatigue, making it suitable for high-torque or heavy-duty applications. Stainless steel is preferred in corrosive environments, such as marine, chemical, or food processing industries, due to its excellent resistance to rust and chemical degradation. The flexible elements, on the other hand, are often made from non-metallic or metallic materials depending on the application requirements. Non-metallic elements, such as rubber, polyurethane, or neoprene, are ideal for applications requiring high vibration damping and moderate temperature resistance (typically up to 120°C). These materials are also lightweight and cost-effective. Metallic flexible elements, such as stainless steel diaphragms or grid springs, offer higher temperature resistance (up to 300°C or more), greater torque capacity, and longer service life in harsh operating conditions. However, they are generally stiffer than non-metallic elements and provide less vibration damping.

The versatility of flange flexible couplings makes them suitable for a wide range of industrial applications, spanning multiple sectors where reliable power transmission is essential. One of the most common applications is in the pump and compressor industry. Pumps and compressors are used extensively in water treatment plants, oil and gas refineries, chemical processing facilities, and HVAC systems. These machines often experience shaft misalignment due to thermal expansion, installation errors, or foundation settlement. Flange flexible couplings accommodate this misalignment, protecting the pump or compressor shafts and bearings from premature failure. In the automotive industry, flange flexible couplings are used in drive trains, connecting the engine to the transmission or differential. They help absorb the vibrations generated by the engine and accommodate the slight misalignments that occur during vehicle operation. The manufacturing sector also relies heavily on flange flexible couplings, particularly in conveyor systems, robotic arms, and machine tools. Conveyor systems, which are used to transport materials in factories, warehouses, and mining operations, require couplings that can handle variable loads and misalignments caused by conveyor belt tension. Robotic arms and machine tools, on the other hand, demand precise torque transmission and minimal vibration to ensure accuracy in manufacturing processes. Flange flexible couplings with metallic diaphragms are often used in these precision applications due to their high stiffness and accurate torque transfer.

Another important application area is the power generation industry. In power plants (both thermal and renewable), flange flexible couplings connect turbines to generators, enabling the conversion of mechanical energy into electrical energy. These couplings must handle extremely high torque and accommodate misalignments caused by thermal expansion of the shafts during operation. Metallic flange flexible couplings are preferred here due to their high temperature resistance and torque capacity. The marine industry also utilizes flange flexible couplings in ship propulsion systems, connecting the main engine to the propeller shaft. The harsh marine environment, with its high humidity, saltwater corrosion, and variable loads, requires couplings made from corrosion-resistant materials such as stainless steel, with flexible elements that can withstand the dynamic forces encountered at sea.

When selecting a flange flexible coupling for a specific application, several key factors must be considered to ensure optimal performance and reliability. The first and foremost factor is the torque requirement. The coupling must be capable of transmitting the maximum torque generated by the prime mover without exceeding its torque rating. Oversizing or undersizing the coupling can lead to inefficiency or premature failure. Second, the type and magnitude of shaft misalignment must be evaluated. Different flexible elements have varying misalignment capacities: for example, rubber elements can accommodate larger angular and parallel misalignments than metallic diaphragms. Understanding the expected misalignment in the system helps in selecting the appropriate flexible element design. Third, the operating temperature range is a critical consideration. Non-metallic flexible elements have lower temperature limits than metallic ones, so if the application involves high temperatures (such as in power plants or industrial furnaces), a metallic coupling is necessary. Fourth, the environmental conditions, such as the presence of corrosive substances, dust, or moisture, influence material selection. In corrosive environments, stainless steel flanges and chemically resistant flexible elements are essential. Fifth, the speed of operation (in revolutions per minute, RPM) must be taken into account. High-speed applications require couplings with balanced designs to minimize centrifugal forces and vibration. Finally, ease of installation and maintenance should be considered, as some coupling designs are easier to assemble and disassemble than others, reducing downtime during maintenance.

Proper maintenance of flange flexible couplings is essential to ensure their long-term performance and prevent unexpected failures. Regular inspection is the cornerstone of effective maintenance. Inspections should include checking for signs of wear or damage to the flexible elements, such as cracks, tears, or hardening (in the case of rubber elements). Worn or damaged flexible elements should be replaced immediately, as they can compromise the coupling’s flexibility and lead to increased vibration and shaft stress. Fasteners should also be inspected regularly to ensure they are tight, as loose bolts can cause the flanges to separate or vibrate excessively. Additionally, checking the alignment of the connected shafts is crucial, as misalignment beyond the coupling’s capacity can accelerate wear on the flexible elements and other components. Shaft alignment can be performed using tools such as dial indicators or laser alignment systems. Lubrication is another important maintenance task for certain types of flange flexible couplings, such as those with grid springs. Proper lubrication reduces friction and wear between the moving parts, extending the coupling’s service life. However, it is important to use the correct type and amount of lubricant, as specified by the manufacturer.

In recent years, advancements in materials and manufacturing technologies have led to improvements in flange flexible coupling design and performance. For example, the development of high-performance elastomers and composite materials has enhanced the vibration damping capacity and temperature resistance of non-metallic flexible elements. Additive manufacturing (3D printing) has also enabled the production of complex flange and flexible element designs that were previously difficult or impossible to manufacture using traditional methods. These advancements have expanded the range of applications for flange flexible couplings, allowing them to be used in more extreme operating conditions and precision systems. Additionally, the integration of condition monitoring sensors into flange flexible couplings has become increasingly common. These sensors can detect changes in vibration, temperature, and torque, providing real-time data on the coupling’s performance. This allows for predictive maintenance, where potential issues are identified and addressed before they lead to failure, reducing downtime and maintenance costs.

Despite the availability of other coupling types, such as jaw couplings, disc couplings, and universal joints, flange flexible couplings remain a popular choice for many industrial applications due to their unique combination of strength, flexibility, and versatility. They offer a reliable and cost-effective solution for power transmission in systems where shaft misalignment, vibration, and shock loads are present. Whether in a small industrial pump or a large power plant turbine, flange flexible couplings play a vital role in ensuring the smooth and efficient operation of mechanical systems.

In conclusion, flange flexible couplings are essential components in mechanical power transmission systems, providing a balance between torque transmission efficiency and the ability to accommodate shaft misalignment. Their design, which incorporates flanges, flexible elements, and fasteners, is tailored to meet the specific requirements of different applications. Material selection, based on factors such as torque capacity, temperature resistance, and environmental conditions, is critical to ensuring optimal performance. With applications spanning industries such as pump and compressor, automotive, manufacturing, power generation, and marine, flange flexible couplings are indispensable in modern industrial operations. Proper selection and maintenance practices further enhance their reliability and lifespan, making them a cost-effective and efficient solution for power transmission. As materials and manufacturing technologies continue to advance, flange flexible couplings are likely to become even more versatile and capable, adapting to the evolving needs of the industrial sector.

« Flange Flexible Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/flange-flexible-coupling.html