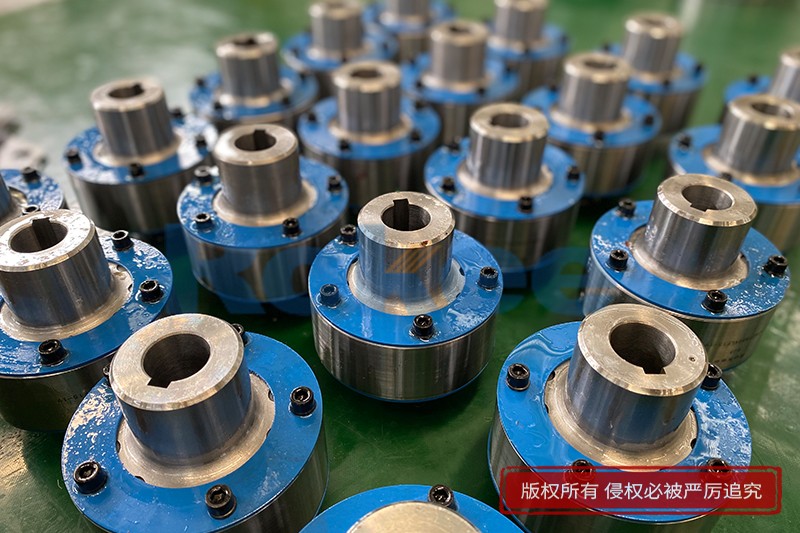

ZL Pin Gear Flexible Couplings

Rokee® provide ZL Pin Gear Flexible Couplings, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical transmission systems, couplings serve as critical components that connect two shafts to transmit power while accommodating various forms of misalignment. Among the diverse types of couplings available, the ZL Pin Gear Flexible Coupling stands out for its unique combination of flexibility, durability, and efficient power transmission capabilities. This type of coupling has been widely adopted in numerous industrial sectors, ranging from manufacturing and mining to agriculture and aerospace, due to its ability to adapt to harsh operating conditions and maintain stable performance over extended periods.

Structural Characteristics of ZL Pin Gear Flexible Coupling

The ZL Pin Gear Flexible Coupling features a sophisticated yet robust structure that is specifically designed to balance flexibility and load-bearing capacity. Unlike rigid couplings that require precise alignment between shafts, this flexible coupling incorporates components that allow for controlled relative movement between the connected shafts. The core structure of the ZL Pin Gear Flexible Coupling typically consists of four main parts: the active half-coupling, the driven half-coupling, the pin gear mechanism, and the elastic elements.

The active and driven half-couplings are the primary components that connect to the input and output shafts, respectively. These half-couplings are usually made of high-strength alloy steel or cast iron, materials chosen for their excellent mechanical properties, including high tensile strength, wear resistance, and impact toughness. The design of the half-couplings often includes keyways or splines to ensure a secure fit with the shafts, preventing slippage during power transmission. In some cases, the half-couplings may also be equipped with flanges to facilitate easy installation and disassembly.

The pin gear mechanism is the defining feature of the ZL Pin Gear Flexible Coupling, distinguishing it from other types of flexible couplings such as jaw couplings or diaphragm couplings. This mechanism consists of a series of pins mounted on one half-coupling and a corresponding set of gear teeth (pin gear) on the other half-coupling. The pins are typically cylindrical in shape and are evenly spaced along the circumference of the half-coupling. The pin gear, on the other hand, has teeth that are specially profiled to mesh with the pins smoothly. The meshing of the pins and the pin gear allows for the transmission of torque while accommodating angular, radial, and axial misalignment between the shafts.

Elastic elements are another crucial component of the ZL Pin Gear Flexible Coupling, responsible for absorbing shock, reducing vibration, and compensating for misalignment. These elements are usually made of elastic materials such as rubber, polyurethane, or nylon, which have excellent elasticity and damping properties. The elastic elements are typically installed between the pins and the pin gear, acting as a buffer between the meshing components. This not only helps to reduce noise and vibration but also protects the coupling and the connected equipment from damage caused by sudden load changes or impact loads.

Working Principles of ZL Pin Gear Flexible Coupling

The working principle of the ZL Pin Gear Flexible Coupling is based on the meshing of the pin and pin gear mechanism, combined with the elastic deformation of the elastic elements. When power is transmitted from the active shaft to the active half-coupling, the pins mounted on the active half-coupling rotate along with the shaft. As the pins rotate, they mesh with the teeth of the pin gear on the driven half-coupling, transferring torque from the active half-coupling to the driven half-coupling and ultimately to the driven shaft.

One of the key aspects of the working principle is the ability of the coupling to accommodate misalignment. Angular misalignment, which occurs when the axes of the two shafts are not collinear but intersect at a point, is compensated for by the rotational movement of the pins within the meshing teeth of the pin gear. The elastic elements also play a role in absorbing the angular deviation, as they can deform slightly to allow the pins to mesh with the pin gear at different angles. Radial misalignment, where the axes of the shafts are parallel but offset from each other, is accommodated by the radial movement of the pins relative to the pin gear. The elastic elements again facilitate this movement by deforming radially, ensuring that the pins remain in contact with the pin gear teeth even when there is a radial offset.

Axial misalignment, which is the linear displacement of one shaft relative to the other along the axial direction, is handled by the axial flexibility of the elastic elements. The elastic materials can stretch or compress slightly to absorb the axial movement, preventing excessive stress on the coupling components and the connected shafts. Additionally, the elastic elements help to dampen vibration and absorb shock loads. When the system experiences sudden load fluctuations or impact loads, the elastic elements deform to absorb the energy, reducing the transmission of these loads to the rest of the system. This not only improves the stability of the transmission system but also extends the service life of the coupling and other equipment components.

Key Advantages of ZL Pin Gear Flexible Coupling

The ZL Pin Gear Flexible Coupling offers a range of advantages that make it a preferred choice for many industrial applications. One of the most significant advantages is its excellent misalignment compensation capability. Compared to other flexible couplings, the ZL Pin Gear type can accommodate larger amounts of angular, radial, and axial misalignment, making it suitable for applications where precise shaft alignment is difficult to achieve or maintain. This is particularly beneficial in heavy-duty applications such as mining and construction, where equipment may be subjected to uneven loads or structural movement, leading to shaft misalignment.

Another major advantage is its high torque transmission capacity. The pin gear mechanism provides a large contact area between the pins and the gear teeth, allowing for the efficient transmission of high torque. This makes the ZL Pin Gear Flexible Coupling suitable for use in high-power transmission systems, such as those found in large industrial motors, pumps, and compressors. Additionally, the use of high-strength materials for the half-couplings and pin gear mechanism ensures that the coupling can withstand heavy loads without deformation or failure.

The ZL Pin Gear Flexible Coupling also exhibits excellent shock absorption and vibration damping properties. The elastic elements effectively absorb shock loads and reduce vibration, which helps to minimize noise and prevent damage to the connected equipment. This is especially important in applications such as manufacturing machinery, where excessive vibration can affect the precision of the production process and lead to premature wear of equipment components. The vibration damping capability also improves the overall stability and reliability of the transmission system.

Durability and long service life are additional advantages of the ZL Pin Gear Flexible Coupling. The use of high-quality materials and the robust design of the coupling components ensure that it can withstand harsh operating conditions, including high temperatures, humidity, and corrosive environments. The pin gear mechanism is also designed to minimize wear, with the meshing components having a smooth surface finish to reduce friction. Additionally, the elastic elements are resistant to fatigue, ensuring that they maintain their elasticity and performance over extended periods of use. This reduces the need for frequent maintenance and replacement, resulting in lower operating costs for the user.

Easy installation and maintenance are also key benefits of the ZL Pin Gear Flexible Coupling. The coupling is designed to be easily assembled and disassembled, with simple mounting procedures that do not require specialized tools or equipment. This makes installation quick and efficient, reducing downtime during equipment setup or maintenance. Maintenance requirements are also minimal, typically involving regular inspection of the elastic elements for wear or damage and lubrication of the pin gear mechanism (if necessary). The easy maintenance ensures that the coupling remains in good working condition with minimal effort, further contributing to its cost-effectiveness.

Typical Applications of ZL Pin Gear Flexible Coupling

Due to its numerous advantages, the ZL Pin Gear Flexible Coupling is widely used in a variety of industrial sectors. One of the most common applications is in the manufacturing industry, where it is used in machinery such as conveyors, mixers, extruders, and machine tools. In these applications, the coupling's ability to accommodate misalignment and dampen vibration is crucial for maintaining the precision and efficiency of the production process. For example, in a conveyor system, the ZL Pin Gear Flexible Coupling connects the motor to the conveyor belt drive, transmitting power while accommodating any misalignment caused by the movement of the conveyor structure.

The mining industry is another major user of ZL Pin Gear Flexible Couplings. Mining equipment such as crushers, grinders, and conveyors operate under harsh conditions, with high loads, excessive vibration, and frequent shaft misalignment. The ZL Pin Gear Flexible Coupling's high torque capacity, shock absorption, and misalignment compensation capabilities make it ideal for these applications. For instance, in a crusher, the coupling connects the motor to the crusher's rotating shaft, transmitting the high torque required for crushing rocks while absorbing the shock loads generated during the crushing process.

In the agricultural sector, the ZL Pin Gear Flexible Coupling is used in equipment such as tractors, harvesters, and irrigation pumps. Agricultural equipment often operates in uneven terrain, leading to shaft misalignment, and is subjected to varying loads. The coupling's flexibility and durability make it suitable for these conditions, ensuring reliable power transmission. For example, in an irrigation pump, the coupling connects the pump to the motor, transmitting power while accommodating any misalignment caused by the installation of the pump in outdoor environments.

The aerospace and automotive industries also utilize ZL Pin Gear Flexible Couplings in certain applications. In aerospace, they may be used in auxiliary power units (APUs) or in the transmission systems of small aircraft, where their compact design and high reliability are essential. In the automotive industry, they can be found in heavy-duty vehicles such as trucks and buses, where they connect the engine to the transmission, transmitting high torque while absorbing vibration and accommodating misalignment.

Other applications include the energy sector, where the coupling is used in power generation equipment such as turbines and generators, and the marine industry, where it is used in ship propulsion systems. In all these applications, the ZL Pin Gear Flexible Coupling plays a critical role in ensuring the efficient and reliable operation of the transmission system.

Selection and Maintenance Considerations for ZL Pin Gear Flexible Coupling

When selecting a ZL Pin Gear Flexible Coupling for a specific application, several key factors need to be considered to ensure optimal performance and reliability. One of the most important factors is the torque capacity of the coupling. The selected coupling must be able to transmit the maximum torque required by the application without exceeding its rated torque. It is recommended to choose a coupling with a torque rating that is slightly higher than the maximum operating torque to provide a safety margin and prevent overload failure.

Another important consideration is the misalignment requirements of the application. The coupling must be able to accommodate the maximum amount of angular, radial, and axial misalignment that is expected to occur during operation. It is essential to consult the manufacturer's specifications to determine the maximum misalignment values that the coupling can handle, as exceeding these values can lead to premature wear, increased vibration, and reduced service life.

The operating environment is also a crucial factor in the selection process. Factors such as temperature, humidity, corrosive substances, and dust levels can affect the performance and durability of the coupling. For example, in high-temperature environments, it is important to select a coupling with elastic elements that can withstand high temperatures without losing their elasticity. In corrosive environments, the coupling components should be made of corrosion-resistant materials or coated with a protective layer to prevent rust and degradation.

The size and installation space of the coupling are also important considerations. The coupling must fit within the available installation space and be compatible with the size of the shafts it is connecting. It is essential to ensure that the coupling's bore diameter matches the diameter of the shafts, and that the length of the coupling does not interfere with other equipment components.

Proper maintenance is essential to ensure the long service life and reliable performance of the ZL Pin Gear Flexible Coupling. Regular inspection is one of the key maintenance tasks. The coupling should be inspected periodically for signs of wear, damage, or misalignment. This includes checking the elastic elements for cracks, tears, or hardening, inspecting the pins and pin gear for wear or deformation, and checking the half-couplings for signs of loosening or damage.

Lubrication is another important maintenance task, depending on the type of coupling. Some ZL Pin Gear Flexible Couplings require lubrication of the pin gear mechanism to reduce friction and wear. The type and frequency of lubrication should be in accordance with the manufacturer's recommendations. It is important to use the correct type of lubricant, as using the wrong lubricant can lead to increased friction, overheating, and premature wear of the coupling components.

When replacing the elastic elements, it is important to use components that are compatible with the coupling model and specifications. Using inferior or incorrect elastic elements can affect the coupling's performance, reduce its misalignment compensation capability, and increase the risk of failure. Additionally, when disassembling and reassembling the coupling, care should be taken to ensure that the components are installed correctly and that the shafts are aligned as accurately as possible.

Conclusion

The ZL Pin Gear Flexible Coupling is a versatile and reliable component that plays a crucial role in mechanical transmission systems. Its unique structural design, which combines a pin gear mechanism with elastic elements, provides excellent misalignment compensation, high torque transmission capacity, and effective shock absorption and vibration damping. These characteristics make it suitable for a wide range of industrial applications, from manufacturing and mining to agriculture and aerospace.

When selecting a ZL Pin Gear Flexible Coupling, it is important to consider factors such as torque capacity, misalignment requirements, operating environment, and installation space. Proper maintenance, including regular inspection and lubrication, is also essential to ensure the coupling's long service life and optimal performance. By understanding the structural characteristics, working principles, and advantages of the ZL Pin Gear Flexible Coupling, engineers and equipment operators can make informed decisions about its use, ensuring the efficient and reliable operation of their transmission systems.

As industrial technology continues to advance, the ZL Pin Gear Flexible Coupling is likely to undergo further improvements in design and material technology, enhancing its performance and expanding its range of applications. Its ability to adapt to harsh operating conditions and maintain stable performance makes it a valuable component in the ever-evolving industrial landscape.

« ZL Pin Gear Flexible Couplings » Post Date: 2023/11/6

URL: https://www.rokeecoupling.com/en/customer-cases/zl-pin-gear-flexible-couplings.html

- High Quality Merchants Of Curved-tooth Gear Couplings

- Drum Coupling Size

- Pin Bush Type Flexible Coupling Misalignment Tolerance

- Jaw Flex Coupling Size Chart

- Short Telescopic Universal Shaft Factory

- Coaxiality of Bushed Pin Type Flexible Coupling

- Metal Double Diaphragm Elastic Coupling

- Purpose of Flexible Membrane Couplings

- Hexagonal Tyre Coupling

- What Is The Price Of A Single Diaphragm Coupling