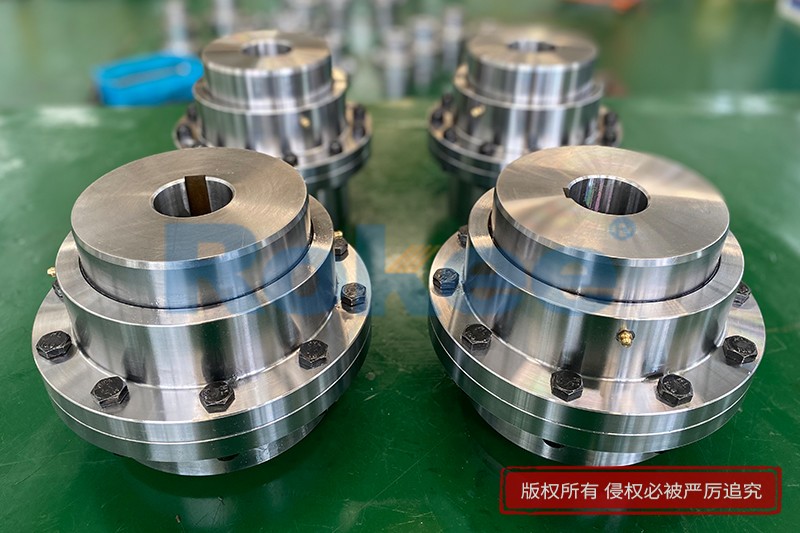

RODA Curved Tooth Coupling

Rokee® provide RODA Curved Tooth Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as critical components that connect two rotating shafts, enabling the seamless transfer of torque while accommodating misalignments and absorbing operational stresses. Among the diverse range of couplings available, curved tooth couplings stand out for their exceptional performance in high-torque, high-speed industrial environments. Characterized by their uniquely shaped tooth profiles, these couplings offer a combination of flexibility, durability, and efficiency that makes them indispensable in numerous heavy-duty applications.

1. Design Principles of Curved Tooth Couplings

The fundamental distinction between curved tooth couplings and other types of gear couplings lies in the geometry of their tooth profiles. Unlike straight tooth couplings, which feature teeth aligned parallel to the shaft axis, curved tooth couplings have teeth that are machined with a circular arc or curved profile. This curved design is not arbitrary; it is engineered to optimize the distribution of contact stress, enhance misalignment capacity, and reduce wear during operation.

A typical curved tooth coupling consists of four main components: two hubs (each attached to one of the shafts being connected), an outer sleeve (or gear ring) that meshes with the teeth of the hubs, and a lubrication system. The hubs are usually forged from high-strength alloy steels, which provide the necessary rigidity and resistance to fatigue. The teeth on the hubs and the inner teeth of the outer sleeve are precision-machined to ensure a tight, uniform mesh. The curvature of the teeth is carefully calculated based on the intended application parameters, such as torque capacity, shaft speed, and maximum allowable misalignment.

Another key design feature of curved tooth couplings is the presence of a slight backlash between the meshing teeth. Backlash is the small gap between the tooth surfaces when they are in a non-loaded state, and it plays a crucial role in accommodating thermal expansion and contraction of the shafts during operation. Additionally, the curved tooth profile allows for a larger contact area between the meshing teeth compared to straight tooth designs. This increased contact area distributes the transmitted torque more evenly, reducing the stress on individual teeth and extending the service life of the coupling.

The lubrication system is an integral part of the curved tooth coupling design. Since the meshing teeth are subjected to high pressure and sliding friction during operation, proper lubrication is essential to minimize wear, prevent corrosion, and dissipate heat. Most curved tooth couplings are equipped with grease fittings or oil channels that allow for regular lubrication, ensuring smooth operation even in harsh industrial conditions.

2. Operational Mechanics: How Curved Tooth Couplings Work

The primary function of a curved tooth coupling is to transmit torque from one rotating shaft to another while compensating for three types of misalignment: angular misalignment (where the shafts are not collinear but intersect at a point), parallel misalignment (where the shafts are parallel but offset from each other), and axial misalignment (where the shafts move along their axial direction). The curved tooth profile is specifically designed to handle these misalignments more effectively than straight tooth couplings.

When torque is applied to the input shaft, the teeth on the input hub mesh with the teeth on the outer sleeve, transferring the rotational force to the outer sleeve. The outer sleeve then meshes with the teeth on the output hub, transmitting the torque to the output shaft. The curved shape of the teeth allows for relative movement between the hubs and the outer sleeve, enabling the coupling to accommodate misalignments without causing excessive stress or wear.

During operation, the contact between the curved teeth is dynamic. As the shafts rotate, the point of contact between each pair of meshing teeth shifts slightly, distributing the load across the entire tooth surface. This dynamic contact pattern reduces the concentration of stress at any single point, which is a major factor in the coupling’s ability to handle high torque loads. Additionally, the curved profile minimizes the sliding friction between the teeth, as the relative movement between the meshing surfaces is more of a rolling motion than a sliding motion. This reduction in friction not only reduces wear but also improves the overall efficiency of power transmission.

The backlash in the coupling also plays a role in its operational mechanics. When the direction of rotation changes, the backlash allows the teeth to engage smoothly without sudden shocks or vibrations. This is particularly important in applications where the direction of shaft rotation is frequently reversed, such as in certain types of pumps and conveyors.

3. Key Advantages of Curved Tooth Couplings

Curved tooth couplings offer several distinct advantages over other types of couplings, making them the preferred choice for many industrial applications. These advantages stem from their unique design and operational characteristics, and they include the following:

3.1 High Torque Capacity

One of the most significant advantages of curved tooth couplings is their ability to transmit high levels of torque. The curved tooth profile provides a larger contact area between the meshing teeth, which allows for more efficient torque transfer and reduces the stress on individual teeth. This makes curved tooth couplings suitable for use in heavy-duty applications such as industrial turbines, compressors, and large electric motors, where high torque loads are common.

3.2 Excellent Misalignment Compensation

Curved tooth couplings are capable of accommodating greater levels of angular, parallel, and axial misalignment than straight tooth couplings. The curved teeth allow for relative movement between the shafts without causing excessive wear or stress on the coupling components. This is particularly beneficial in applications where shaft misalignment is inevitable, such as in large rotating machinery where thermal expansion, vibration, or installation errors can cause misalignment.

3.3 Reduced Wear and Longer Service Life

The curved tooth profile and the resulting dynamic contact pattern reduce the wear on the meshing teeth. The larger contact area distributes the load evenly, minimizing the risk of tooth pitting, scuffing, or breakage. Additionally, proper lubrication further reduces friction and wear, extending the service life of the coupling. This longer service life translates to lower maintenance costs and less downtime for industrial operations.

3.4 Smooth Operation and Low Vibration

The curved tooth design ensures smooth engagement between the meshing teeth, reducing vibration and noise during operation. The backlash in the coupling also helps to absorb shocks and vibrations, resulting in a more stable and quiet operation. This is important in applications where precision and stability are critical, such as in machine tools and precision manufacturing equipment.

3.5 Versatility

Curved tooth couplings are available in a wide range of sizes and configurations, making them suitable for a variety of applications. They can be customized to meet specific torque, speed, and misalignment requirements, and they can be used with different types of shafts, including solid shafts, hollow shafts, and splined shafts. This versatility makes curved tooth couplings a flexible solution for many different industrial sectors.

4. Industrial Applications of Curved Tooth Couplings

Due to their high torque capacity, excellent misalignment compensation, and long service life, curved tooth couplings are used in a wide range of industrial applications. Some of the most common application areas include the following:

4.1 Power Generation

In the power generation industry, curved tooth couplings are used to connect turbines to generators. These applications require the transmission of very high torque at high speeds, and the couplings must be able to accommodate slight misalignments caused by thermal expansion and vibration. Curved tooth couplings are ideal for this purpose, as they provide reliable torque transfer and can withstand the harsh operating conditions in power plants.

4.2 Oil and Gas Industry

The oil and gas industry relies heavily on curved tooth couplings for use in pumps, compressors, and drilling equipment. These applications involve high torque loads, harsh environmental conditions (such as high temperatures, pressure, and corrosive substances), and frequent misalignment. Curved tooth couplings are able to withstand these conditions, providing reliable performance in upstream, midstream, and downstream operations.

4.3 Heavy Machinery and Construction

In the heavy machinery and construction industry, curved tooth couplings are used in equipment such as excavators, bulldozers, and cranes. These machines require the transmission of high torque to move heavy loads, and the couplings must be able to accommodate misalignments caused by the dynamic nature of the equipment. Curved tooth couplings provide the necessary durability and flexibility for these applications.

4.4 Manufacturing and Processing

In manufacturing and processing facilities, curved tooth couplings are used in a variety of equipment, including conveyors, mixers, and machine tools. These applications require smooth, reliable power transmission to ensure the quality and efficiency of the manufacturing process. Curved tooth couplings provide the necessary stability and precision, reducing vibration and minimizing downtime.

4.5 Marine Industry

In the marine industry, curved tooth couplings are used to connect ship engines to propellers. These applications involve high torque loads, high speeds, and significant misalignments caused by the movement of the ship. Curved tooth couplings are able to withstand the harsh marine environment (including saltwater corrosion) and provide reliable torque transfer, ensuring the safe and efficient operation of the ship.

5. Maintenance Considerations for Curved Tooth Couplings

To ensure the optimal performance and long service life of curved tooth couplings, proper maintenance is essential. The following are key maintenance considerations for these couplings:

5.1 Regular Lubrication

As mentioned earlier, lubrication is critical for the smooth operation of curved tooth couplings. The meshing teeth must be properly lubricated to reduce friction, prevent wear, and dissipate heat. The type of lubricant used should be appropriate for the operating conditions (such as temperature, speed, and load), and the coupling should be lubricated at regular intervals as recommended by the manufacturer. It is also important to check for lubricant leaks and replace the lubricant if it becomes contaminated.

5.2 Inspection for Wear and Damage

Regular inspection of the coupling components is essential to detect wear and damage early. This includes checking the teeth for pitting, scuffing, or breakage, inspecting the hubs and outer sleeve for cracks or deformation, and checking the fasteners (such as bolts and nuts) for tightness. If any wear or damage is detected, the affected components should be repaired or replaced immediately to prevent further damage to the coupling or the connected machinery.

5.3 Alignment Checks

Even though curved tooth couplings can accommodate misalignments, excessive or prolonged misalignment can lead to premature wear and failure. Therefore, it is important to regularly check the alignment of the connected shafts and adjust them if necessary. Alignment checks should be performed using precision tools such as laser alignment systems to ensure accurate results.

5.4 Cleaning

Keeping the coupling clean is also important for its performance. Dirt, dust, and other contaminants can accumulate on the coupling components, causing wear and reducing the effectiveness of the lubricant. The coupling should be cleaned regularly using a suitable cleaning agent to remove any contaminants.

5.5 Proper Storage

If a curved tooth coupling is not in use, it should be stored properly to prevent damage. The coupling should be stored in a clean, dry environment, and the teeth should be coated with a protective lubricant to prevent corrosion. The coupling should also be stored in a way that prevents deformation of the components.

6. Conclusion

Curved tooth couplings are essential components in modern mechanical power transmission systems, offering a unique combination of high torque capacity, excellent misalignment compensation, reduced wear, and smooth operation. Their versatile design makes them suitable for a wide range of industrial applications, from power generation and oil and gas to heavy machinery and marine operations. By understanding the design principles, operational mechanics, and maintenance requirements of curved tooth couplings, industrial operators can ensure that these components perform optimally, reducing downtime and maintenance costs and improving the overall efficiency of their mechanical systems.

As industrial technology continues to advance, the demand for high-performance power transmission components such as curved tooth couplings is expected to grow. Manufacturers are constantly working to improve the design and materials of curved tooth couplings, further enhancing their performance and durability. With their proven track record of reliability and efficiency, curved tooth couplings will continue to play a critical role in the industrial landscape for years to come.

« RODA Curved Tooth Coupling » Post Date: 2023/11/22

URL: https://www.rokeecoupling.com/en/customer-cases/roda-curved-tooth-coupling.html

- Expanded Diaphragm Couplings Characteristics

- Flange Gear Coupling Working Principle

- SWC Cardan Shaft Drawing

- Size Calculation of Bushed Pin Type Coupling

- How To Install The Laminated Flexible Coupling

- Water Pump Pin Coupling Model

- High-end Multi-specification Diaphragm Couplings

- Steel Laminae Coupling Stretch Amount

- Extension Diaphragm Coupling

- Custom Curved Tooth Coupling