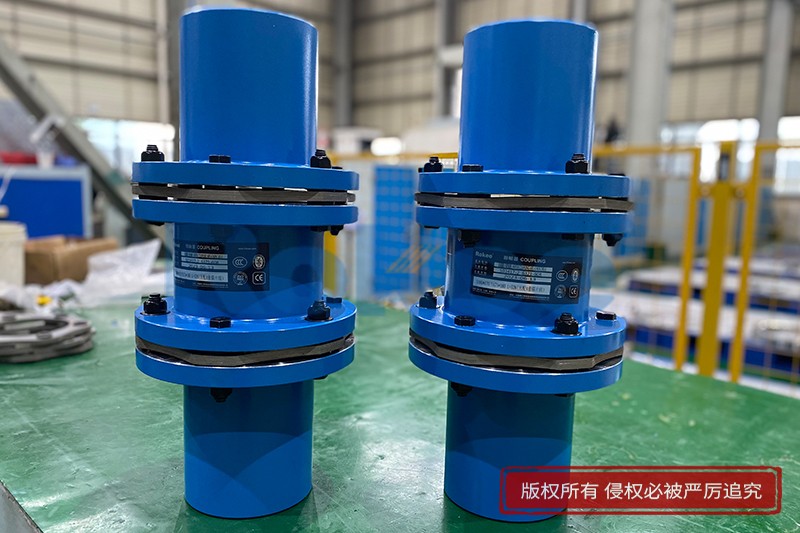

Steel Laminated Flexible Coupling

Rokee® provide Steel Laminated Flexible Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating various forms of misalignment. Among the diverse types of couplings available, steel laminated flexible couplings have emerged as a reliable and versatile solution for a wide range of industrial applications. Characterized by their unique construction using thin steel laminations, these couplings offer a combination of flexibility, strength, and durability that makes them indispensable in scenarios where precision and reliability are paramount.

To understand the functionality of steel laminated flexible couplings, it is essential to first examine their structural composition. Unlike rigid couplings that offer no flexibility, or elastomeric couplings that rely on rubber or plastic elements for compliance, steel laminated flexible couplings feature a central flexible element made up of multiple thin steel sheets (laminations) stacked together. These laminations are typically manufactured from high-quality alloy steel, which undergoes processes such as quenching and tempering to enhance its tensile strength, fatigue resistance, and overall mechanical performance. The laminations are precision-cut into specific shapes—often with holes or slots for bolt connections—that allow them to flex under load while maintaining the integrity of the torque transmission.

The basic structure of a steel laminated flexible coupling consists of three main parts: two hub assemblies and the laminated flexible element. The hubs are designed to attach to the shafts of the driving and driven machines, respectively. They are usually machined from solid steel or cast steel to ensure a secure fit and high torque-carrying capacity. The connection between the hubs and the laminated element is achieved through bolts or studs, which pass through the pre-drilled holes in the laminations and the hubs. In some designs, the laminations are grouped into packs, and spacers may be used between the packs to adjust the flexibility or axial length of the coupling. The number and thickness of the laminations can be tailored to meet specific torque requirements and misalignment capabilities, making the design highly customizable.

The working principle of steel laminated flexible couplings revolves around the ability of the steel laminations to deform elastically when subjected to misalignment or axial movement between the connected shafts. When torque is transmitted from the driving shaft to the hub, the force is transferred through the bolts to the laminated element. The laminations flex to accommodate angular, parallel, or axial misalignment between the two shafts without imposing excessive stresses on the shafts, bearings, or other connected components. Angular misalignment occurs when the shafts are not colinear, while parallel misalignment refers to a lateral offset between the shaft axes. Axial movement, on the other hand, is the linear displacement of one shaft relative to the other along the axial direction. The steel laminations, due to their thin and flexible nature, can absorb these misalignments through elastic deformation, ensuring smooth torque transmission even under less-than-ideal shaft alignment conditions.

One of the most notable advantages of steel laminated flexible couplings is their high torque-carrying capacity relative to their size and weight. The use of high-strength steel laminations allows these couplings to transmit large amounts of torque without compromising on flexibility. This makes them suitable for heavy-duty applications where high power transmission is required, such as in industrial motors, pumps, compressors, and gearboxes. Compared to elastomeric couplings, which may degrade under high torque or temperature, steel laminated couplings maintain their performance even in demanding operating conditions.

Another key benefit is their excellent resistance to harsh environmental conditions. Steel, as a material, is inherently resistant to temperature extremes, chemicals, oils, and moisture—factors that can significantly degrade elastomeric or plastic components. Steel laminated flexible couplings can operate reliably in temperatures ranging from -50°C to 200°C, making them suitable for use in both indoor industrial settings and outdoor applications exposed to the elements. Additionally, they are not susceptible to aging, cracking, or hardening over time, which ensures a long service life and reduces the need for frequent replacements.

Vibration damping is another important advantage of steel laminated flexible couplings. While elastomeric couplings are often preferred for their superior vibration absorption, steel laminated couplings can still effectively dampen moderate levels of vibration and shock loads. The elastic deformation of the laminations helps to absorb and dissipate vibrational energy, reducing the transmission of vibrations from the driving machine to the driven machine. This not only improves the overall stability of the mechanical system but also reduces wear and tear on other components, such as bearings and gears, thereby extending the lifespan of the entire system.

Precision and zero backlash are additional features that make steel laminated flexible couplings highly desirable in precision applications. Backlash, or the clearance between mating components, can lead to inaccuracies in torque transmission and positioning. The laminated design, with its tight bolted connections and rigid steel construction, minimizes or eliminates backlash, ensuring precise and responsive torque transmission. This is particularly important in applications such as robotics, CNC machines, and precision conveyors, where exact positioning and motion control are critical.

Steel laminated flexible couplings find applications across a wide range of industries, thanks to their versatility and robust performance. In the manufacturing industry, they are commonly used in CNC machining centers, lathes, milling machines, and industrial robots, where precision and reliability are essential. The zero backlash and high torque capacity of these couplings make them ideal for these applications, as they ensure accurate motion control and consistent performance.

In the energy sector, steel laminated flexible couplings are used in power generation systems, such as gas turbines, steam turbines, and hydroelectric generators. These applications require couplings that can transmit large amounts of torque while accommodating minor misalignments caused by thermal expansion or shaft deflection. The high-temperature resistance and durability of steel laminated couplings make them well-suited for these harsh operating environments.

The automotive and transportation industry also relies on steel laminated flexible couplings for various applications. They are used in the drive trains of heavy-duty vehicles, such as trucks, buses, and construction equipment, where they transmit torque from the engine to the transmission or differential. Additionally, they are used in railway locomotives and rolling stock, where they must withstand high loads and vibrations while ensuring reliable power transmission.

In the marine industry, steel laminated flexible couplings are employed in ship propulsion systems, connecting the main engine to the propeller shaft. The marine environment is particularly harsh, with high humidity, saltwater corrosion, and temperature fluctuations. Steel laminated couplings, when properly coated or treated for corrosion resistance, can withstand these conditions, ensuring reliable performance and long service life.

Other applications include pumps and compressors in the oil and gas industry, conveyor systems in material handling, and fans and blowers in HVAC systems. In each of these applications, the steel laminated flexible coupling provides a reliable solution for torque transmission, misalignment accommodation, and vibration damping.

Proper maintenance is essential to ensure the optimal performance and longevity of steel laminated flexible couplings. While these couplings are relatively low-maintenance compared to elastomeric couplings, regular inspections and maintenance procedures can help prevent premature failure and ensure safe operation.

One of the most important maintenance tasks is regular inspection of the laminations for signs of wear, fatigue, or damage. Over time, the laminations may develop cracks, bends, or signs of corrosion, which can compromise their strength and flexibility. Inspections should be conducted periodically, with the frequency depending on the operating conditions and the criticality of the application. Visual inspections can be performed to check for obvious signs of damage, while more detailed inspections may involve the use of non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, to detect internal defects.

Another key maintenance procedure is checking and tightening the bolts that connect the laminations to the hubs. Loose bolts can lead to excessive vibration, uneven torque distribution, and premature wear of the laminations. Bolts should be checked regularly using a torque wrench to ensure they are tightened to the manufacturer's recommended torque specifications. If any bolts are found to be loose, they should be tightened immediately. In some cases, it may be necessary to replace worn or damaged bolts to maintain the integrity of the connection.

Lubrication is also an important aspect of maintenance, although steel laminated flexible couplings typically require less lubrication than other types of couplings, such as gear couplings. The bolts and nuts should be lubricated periodically to prevent corrosion and ensure easy removal during maintenance or replacement. However, it is important to avoid over-lubrication, as excess lubricant can attract dirt and debris, which can cause wear on the laminations and other components.

Proper shaft alignment is critical for the performance and longevity of steel laminated flexible couplings. While these couplings can accommodate minor misalignments, excessive misalignment can lead to increased stress on the laminations, premature fatigue, and reduced service life. Regular shaft alignment checks should be performed using precision alignment tools, such as laser alignment systems, to ensure that the shafts are aligned within the manufacturer's recommended limits. If misalignment is detected, corrective action should be taken immediately to adjust the position of the machines.

In addition to regular inspections and maintenance, it is important to replace the laminated element when it shows signs of excessive wear or damage. The lifespan of the laminated element depends on the operating conditions, such as torque load, misalignment, temperature, and vibration. Manufacturers typically provide guidelines for the replacement interval based on these factors. Replacing the laminated element in a timely manner can prevent catastrophic failure of the coupling and minimize downtime of the mechanical system.

In conclusion, steel laminated flexible couplings are essential components in modern mechanical power transmission systems, offering a unique combination of high torque capacity, flexibility, durability, and precision. Their design, which leverages the elastic properties of thin steel laminations, allows them to accommodate various forms of misalignment while transmitting torque smoothly and efficiently. These couplings are widely used across a range of industries, from manufacturing and energy to automotive and marine, due to their ability to perform reliably in harsh operating conditions.

Proper selection and maintenance of steel laminated flexible couplings are critical to ensuring their optimal performance and longevity. By understanding the design principles, advantages, and applications of these couplings, engineers and maintenance professionals can make informed decisions about their use in specific mechanical systems. With their versatility and robust performance, steel laminated flexible couplings are likely to remain a key component in mechanical power transmission for years to come, adapting to the evolving needs of industrial and commercial applications.

« Steel Laminated Flexible Coupling » Post Date: 2023/11/22

URL: https://www.rokeecoupling.com/en/customer-cases/steel-laminated-flexible-coupling.html

- Application of Crown Pin Couplings

- Flange Type Membrane Couplings

- Bush Pin Type Flange Couplings

- Allowable Error Of Elastic Diaphragm Coupling

- Disadvantages of Pin Bush Couplings

- Benefits Of Single Diaphragm Couplings

- Single Hinged Gear Coupling

- Brake Elastic Column Pin Couplings

- Parts of Brake Drum Geared Coupling

- Water Pump Diaphragm Coupling Price