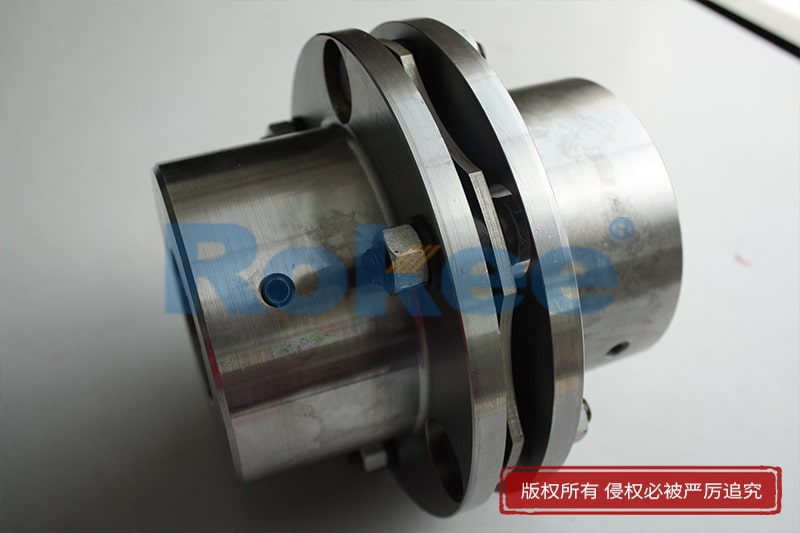

Stainless Steel Single Diaphragm Coupling

Rokee® provide Stainless Steel Single Diaphragm Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating various types of misalignment. Among the diverse range of couplings available, the stainless steel single diaphragm coupling has emerged as a preferred choice in numerous industrial applications due to its unique combination of durability, precision, and resistance to harsh environments.

To begin with, it is essential to clarify the basic structure and working principle of a stainless steel single diaphragm coupling. Unlike rigid couplings that require perfect alignment between shafts, diaphragm couplings utilize a flexible diaphragm to compensate for misalignment. A single diaphragm coupling, as the name suggests, features a single diaphragm disc (or a set of thin diaphragms stacked together) that is bolted to the hubs on both the driving and driven shafts. The diaphragm itself is typically made from high-quality stainless steel, which is selected for its exceptional strength-to-weight ratio and corrosion resistance. When torque is transmitted from the driving shaft to the diaphragm, the diaphragm undergoes elastic deformation to accommodate axial, radial, and angular misalignment between the two shafts without causing excessive stress or wear on the connected components. This elastic deformation capability is the core of the coupling’s functionality, ensuring smooth power transmission even in conditions where perfect shaft alignment is difficult to maintain.

One of the most prominent characteristics of stainless steel single diaphragm couplings is their superior material properties derived from stainless steel. Stainless steel is an alloy composed primarily of iron, chromium, and other elements such as nickel, molybdenum, and titanium. The addition of chromium forms a passive oxide layer on the surface of the steel, which prevents rust and corrosion, making it ideal for use in harsh environments where the coupling may be exposed to moisture, chemicals, or extreme temperatures. Compared to couplings made from carbon steel or other non-stainless alloys, stainless steel single diaphragm couplings exhibit significantly higher resistance to oxidation, acid, alkali, and salt corrosion, extending their service life in challenging operating conditions. Additionally, stainless steel possesses excellent mechanical properties, including high tensile strength, fatigue resistance, and ductility, which enable the diaphragm to withstand repeated elastic deformation without permanent damage, ensuring reliable torque transmission over long periods of operation.

Another key characteristic of stainless steel single diaphragm couplings is their high precision and low maintenance requirements. The manufacturing process of these couplings involves advanced machining techniques, such as CNC milling and turning, to ensure tight tolerances and consistent performance. The diaphragm is designed with precise thickness and geometric dimensions to provide optimal flexibility while maintaining sufficient torque capacity. Unlike couplings that rely on lubrication, such as gear couplings or universal joints, single diaphragm couplings are lubrication-free. This eliminates the need for regular lubrication maintenance, reduces the risk of lubricant leakage (which can contaminate the working environment), and simplifies the overall maintenance process. Furthermore, the absence of sliding or rotating parts in contact with each other minimizes wear and tear, resulting in lower maintenance costs and longer intervals between replacements.

The advantages of stainless steel single diaphragm couplings extend beyond their material properties and precision. One of the most significant advantages is their ability to accommodate multiple types of misalignment. Axial misalignment occurs when the two shafts are displaced along the axial direction; radial misalignment is the lateral offset between the shaft axes; and angular misalignment is the tilt between the two shafts. Stainless steel single diaphragm couplings can compensate for all three types of misalignment simultaneously, with typical angular misalignment capacity ranging from 0.5 degrees to 2 degrees, depending on the size and design of the coupling. This versatility makes them suitable for use in a wide range of mechanical systems where shaft alignment may be affected by thermal expansion, vibration, or installation errors.

Additionally, stainless steel single diaphragm couplings offer excellent torsional stiffness. Torsional stiffness refers to the resistance of the coupling to torsional deformation under torque load. High torsional stiffness is crucial in applications that require precise torque transmission, such as machine tools, robotics, and precision instrumentation. Unlike flexible couplings with rubber or elastomeric elements, which may exhibit significant torsional deflection, the stainless steel diaphragm provides high torsional stiffness while maintaining the necessary flexibility to accommodate misalignment. This ensures that the rotational accuracy of the driven shaft is closely synchronized with the driving shaft, minimizing positional errors and improving the overall performance of the mechanical system.

Vibration damping is another notable advantage of stainless steel single diaphragm couplings. While they are not as effective at damping high-frequency vibrations as elastomeric couplings, the elastic deformation of the stainless steel diaphragm can absorb and dissipate a certain amount of vibration energy, reducing the transmission of vibrations from the driving shaft to the driven shaft. This helps to protect sensitive components, such as bearings, gears, and electronic sensors, from premature failure due to vibration-induced fatigue. Moreover, the balanced design of stainless steel single diaphragm couplings minimizes rotational imbalance, which further reduces vibration and noise during operation, creating a quieter and more stable working environment.

The applications of stainless steel single diaphragm couplings are diverse, spanning across various industries where reliability, precision, and corrosion resistance are paramount. One of the primary application areas is the automotive industry, particularly in electric vehicles (EVs) and hybrid vehicles. In EV powertrains, the coupling connects the electric motor to the transmission or differential, requiring precise torque transmission and resistance to the harsh environment under the vehicle (exposure to moisture, road salt, and temperature fluctuations). Stainless steel single diaphragm couplings are well-suited for this application due to their corrosion resistance, high torsional stiffness, and low maintenance requirements.

Another major application area is the aerospace industry. In aircraft engines and auxiliary power units (APUs), couplings must operate under extreme conditions, including high temperatures, high speeds, and exposure to aviation fuels and chemicals. Stainless steel single diaphragm couplings are preferred in these applications because of their lightweight design (high strength-to-weight ratio), high temperature resistance, and ability to accommodate misalignment caused by thermal expansion and vibration. The precision and reliability of these couplings are critical for ensuring the safe and efficient operation of aerospace systems.

The industrial machinery sector also extensively uses stainless steel single diaphragm couplings. In machine tools, such as CNC lathes, milling machines, and grinders, precise torque transmission and rotational accuracy are essential for achieving high-quality machining results. The high torsional stiffness and low backlash of stainless steel single diaphragm couplings make them ideal for these applications, as they minimize positional errors and ensure smooth operation. Additionally, in food processing and pharmaceutical machinery, where hygiene and corrosion resistance are critical, stainless steel single diaphragm couplings are preferred because they can withstand frequent cleaning with water and chemicals without rusting or contaminating the product.

Other notable applications include renewable energy systems (such as wind turbines and solar tracking systems), where couplings must operate in outdoor environments exposed to wind, rain, and temperature extremes; marine systems, where corrosion resistance to seawater is essential; and robotics, where precise motion control and compact design are required. In each of these applications, the unique combination of properties offered by stainless steel single diaphragm couplings makes them a reliable and efficient choice for power transmission.

When selecting a stainless steel single diaphragm coupling for a specific application, several key factors must be considered to ensure optimal performance and reliability. The first and most important factor is the torque capacity. The coupling must be capable of transmitting the maximum torque generated by the driving shaft without exceeding its fatigue limit. It is essential to calculate the operating torque, including peak torques and shock loads, and select a coupling with a torque rating that exceeds these values to provide a safety margin. The size of the coupling (hub diameter, shaft diameter, and length) must also be compatible with the shafts of the driving and driven components.

Misalignment compensation requirements are another critical consideration. The selected coupling must be able to accommodate the maximum expected axial, radial, and angular misalignment in the application. It is important to consult the manufacturer’s specifications to ensure that the coupling’s misalignment capacity matches the requirements of the system. Failure to select a coupling with sufficient misalignment capacity can result in excessive stress on the diaphragm, leading to premature failure.

Operating environment is also a key factor. If the coupling will be exposed to corrosive substances (such as chemicals, seawater, or road salt), high temperatures, or high humidity, it is essential to select a stainless steel grade that is suitable for these conditions. For example, 316 stainless steel offers higher corrosion resistance than 304 stainless steel, making it ideal for harsh chemical or marine environments. Additionally, if the coupling will operate at high speeds, the rotational balance and maximum speed rating of the coupling must be considered to avoid vibration and potential failure.

Mounting and installation requirements should also be taken into account. The coupling must be easy to install and align, and the mounting configuration (flange type, bolt size, and number of bolts) must be compatible with the connected components. Some stainless steel single diaphragm couplings are designed with split hubs, which facilitate easy installation without removing the shafts, making them suitable for applications where shaft disassembly is difficult.

Finally, cost-effectiveness is an important consideration. While stainless steel single diaphragm couplings may have a higher initial cost than some other types of couplings, their long service life, low maintenance requirements, and reliability often result in lower total cost of ownership over time. It is important to balance the initial cost with the expected performance and service life to select the most cost-effective coupling for the application.

In conclusion, stainless steel single diaphragm couplings are versatile and reliable components that play a critical role in modern mechanical power transmission systems. Their unique combination of corrosion resistance, high precision, high torsional stiffness, and ability to accommodate misalignment makes them suitable for a wide range of applications across various industries, including automotive, aerospace, industrial machinery, and renewable energy. When selecting a stainless steel single diaphragm coupling, it is essential to consider factors such as torque capacity, misalignment compensation, operating environment, mounting requirements, and cost-effectiveness to ensure optimal performance and reliability. As industrial technology continues to advance, the demand for high-performance couplings like stainless steel single diaphragm couplings is expected to grow, driven by the increasing need for precision, efficiency, and durability in mechanical systems.

The ongoing development of stainless steel materials and manufacturing technologies is also likely to further enhance the performance of single diaphragm couplings. For example, advancements in stainless steel alloying can improve corrosion resistance and high-temperature performance, while innovations in machining and design can reduce weight and increase torque capacity. These improvements will enable stainless steel single diaphragm couplings to meet the evolving needs of emerging industries and applications, solidifying their position as a key component in the future of mechanical power transmission.

« Stainless Steel Single Diaphragm Coupling » Post Date: 2023/9/23

URL: https://www.rokeecoupling.com/en/customer-cases/stainless-steel-single-diaphragm-coupling.html

- Transmission Method Of Curved-tooth Gear Coupling

- Insulated Diaphragm Coupling

- Elastic Jaw Couplings

- Wear Of Inner Teeth Of Drum Gear Coupling

- Supply of Bushed Pin Flexible Couplings

- Claw Shaped Flexible Couplings

- Tyre Coupling For Fan

- Cross Joint Shaft Models

- Two Half Tyre Couplings

- Flange Flexible Coupling