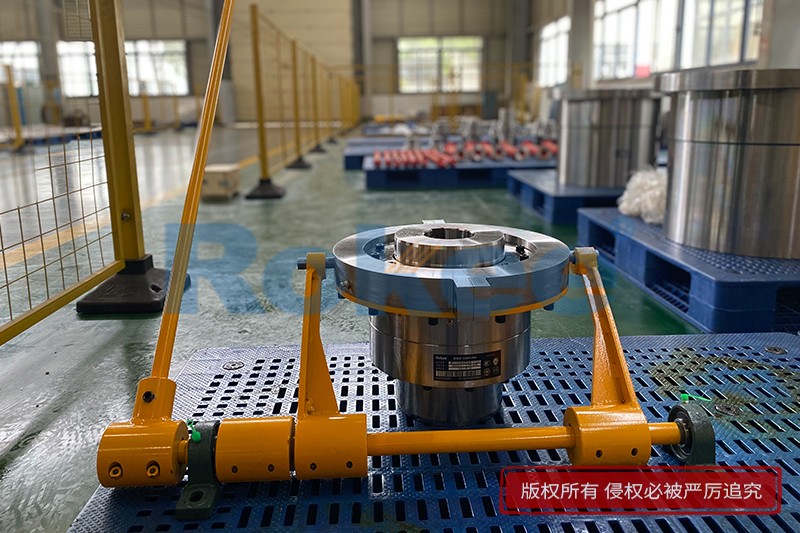

Pulling Fork Gear Coupling

Rokee® provide Pulling Fork Gear Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as critical components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types available, the pulling fork gear coupling stands out for its robust construction, high torque-carrying capacity, and adaptability to harsh operating conditions.

To understand the unique value of pulling fork gear couplings, it is essential to first grasp their core design elements. Unlike flexible couplings that rely on elastomeric components or universal joints, pulling fork gear couplings are classified as rigid-flexible couplings, leveraging gear meshing to achieve both torque transmission and misalignment compensation. The primary components of a typical pulling fork gear coupling include two gear shafts (also known as half-couplings), a pulling fork assembly, and a protective housing. Each gear shaft features external gear teeth that mesh with the internal teeth of the pulling fork, creating a positive drive connection that minimizes power loss during transmission.

The design of the gear teeth is a critical aspect that distinguishes pulling fork gear couplings from other gear coupling variants. Typically, the teeth are cut in a helical pattern, which offers several advantages over straight teeth. Helical teeth ensure gradual meshing between the gear shafts and the pulling fork, reducing impact loads and noise during operation. Additionally, the helical design increases the contact area between the teeth, enhancing the coupling’s ability to withstand high torques and improving overall durability. The pulling fork itself is engineered to accommodate axial movement of the shafts, a feature that is particularly valuable in applications where thermal expansion and contraction of rotating components are common.

Another key design feature of pulling fork gear couplings is the protective housing, which encloses the gear meshing area. This housing serves multiple purposes: it prevents the ingress of dust, dirt, moisture, and other contaminants that could cause premature wear or damage to the gear teeth; it retains the lubricant necessary for reducing friction between moving parts; and it provides a safety barrier to protect personnel from rotating components. The housing is often constructed from high-strength steel or cast iron to withstand the mechanical stresses and environmental conditions encountered in industrial settings.

The operational principle of pulling fork gear couplings revolves around the meshing of gear teeth to transmit torque while compensating for three main types of shaft misalignment: angular misalignment, parallel misalignment, and axial misalignment. Angular misalignment occurs when the axes of the two connected shafts are not collinear but intersect at a point, while parallel misalignment refers to shafts that are parallel but offset from each other. Axial misalignment, on the other hand, involves linear movement of one shaft relative to the other along the axial direction.

When torque is applied to the input shaft, the gear teeth on the input half-coupling engage with the teeth on the pulling fork, transferring rotational force to the fork assembly. The pulling fork then transmits this torque to the output half-coupling via its meshing with the output gear shaft. The helical gear design allows for a certain degree of angular and parallel misalignment by enabling slight relative movement between the meshing teeth. Meanwhile, the sliding fit between the pulling fork and the gear shafts accommodates axial misalignment, ensuring that the coupling remains fully functional even as the shafts move along their axes due to thermal expansion or other factors.

One of the most notable advantages of pulling fork gear couplings is their high torque-carrying capacity. Due to the positive gear meshing connection, these couplings are capable of transmitting significantly higher torques compared to flexible couplings of similar size. This makes them ideal for use in heavy-duty applications where large amounts of power need to be transferred between shafts. Additionally, the robust construction of pulling fork gear couplings—typically using high-strength alloy steels for the gear components—ensures excellent resistance to wear, fatigue, and impact loads, resulting in a long service life even under continuous operation.

Another key benefit of pulling fork gear couplings is their ability to operate effectively in harsh environmental conditions. The enclosed housing protects the internal gear components from exposure to dust, debris, chemicals, and extreme temperatures, making these couplings suitable for use in industries such as mining, steel production, and heavy manufacturing, where operating conditions are often challenging. Furthermore, pulling fork gear couplings have a high tolerance for shock loads and vibration, which are common in these industrial environments. The helical gear design helps to dampen vibration, reducing noise levels and minimizing wear on other components in the mechanical system.

Versatility is another advantage of pulling fork gear couplings. They can be used with a wide range of shaft diameters and rotational speeds, making them suitable for a diverse array of applications. Whether in low-speed, high-torque applications such as conveyor systems and crushers, or high-speed applications such as pumps and fans, pulling fork gear couplings can be tailored to meet the specific requirements of the system. Additionally, these couplings are compatible with various types of shafts, including solid shafts, hollow shafts, and stepped shafts, further enhancing their versatility.

The industrial applications of pulling fork gear couplings are extensive, spanning numerous sectors where reliable power transmission is critical. In the mining industry, for example, these couplings are commonly used in crushers, grinders, and conveyor systems. Crushers and grinders operate under extremely high torque loads and are exposed to large amounts of dust and debris, making the robust, enclosed design of pulling fork gear couplings an ideal choice. Conveyor systems, which require continuous torque transmission over long distances, benefit from the coupling’s ability to accommodate misalignment and axial movement, ensuring smooth and efficient operation.

In the steel industry, pulling fork gear couplings play a vital role in equipment such as rolling mills, blast furnaces, and steel casting machines. Rolling mills, which are used to shape steel into various forms, require high torque transmission and precise control of shaft rotation. The high torque-carrying capacity and rigidity of pulling fork gear couplings make them well-suited for this application, while their ability to compensate for misalignment helps to prevent damage to the rolling mill components. Blast furnaces, which operate at high temperatures, benefit from the coupling’s enclosed housing and heat-resistant materials, which protect the gear components from extreme heat and contaminants.

The heavy manufacturing sector also relies heavily on pulling fork gear couplings. In applications such as industrial mixers, extruders, and presses, these couplings ensure the reliable transmission of torque while accommodating the misalignment that may occur due to the heavy loads and vibrations associated with these machines. Industrial mixers, for example, require consistent torque transmission to ensure uniform mixing of materials, and the robust design of pulling fork gear couplings ensures that they can withstand the continuous operation and shock loads inherent in this application.

Other notable applications of pulling fork gear couplings include power generation, where they are used in turbines and generators to transmit torque from the turbine to the generator; marine propulsion systems, where they connect the engine to the propeller shaft, accommodating the misalignment that may occur due to the movement of the vessel; and agricultural machinery, such as tractors and harvesters, where they withstand the harsh operating conditions and variable loads associated with agricultural operations.

Proper maintenance is essential to ensure the optimal performance and longevity of pulling fork gear couplings. One of the most critical maintenance tasks is regular lubrication of the gear meshing components. Lubrication reduces friction between the gear teeth, minimizing wear and preventing overheating. The type of lubricant used should be selected based on the operating conditions, including temperature, load, and rotational speed. It is also important to ensure that the lubricant is changed at regular intervals to maintain its effectiveness, as contaminated or degraded lubricant can lead to premature wear and failure of the coupling.

Regular inspection of the coupling components is another important maintenance practice. Inspections should include checking for signs of wear or damage to the gear teeth, such as pitting, scoring, or chipping; examining the pulling fork assembly for cracks or deformation; and inspecting the protective housing for leaks or damage. Any signs of wear or damage should be addressed promptly to prevent further deterioration of the coupling. Additionally, the alignment of the connected shafts should be checked regularly, as excessive misalignment can place additional stress on the coupling components, reducing their service life.

When installing a pulling fork gear coupling, proper alignment of the shafts is crucial. Misalignment beyond the coupling’s rated capacity can lead to increased wear, noise, and vibration, and may ultimately result in coupling failure. The use of precision alignment tools, such as laser alignment systems, is recommended to ensure that the shafts are aligned within the specified tolerances. Additionally, the coupling should be installed according to the manufacturer’s guidelines, including proper torquing of fasteners and correct assembly of the gear components.

In conclusion, pulling fork gear couplings are essential components in modern mechanical power transmission systems, offering a unique combination of high torque-carrying capacity, robust construction, and adaptability to harsh operating conditions. Their design, which leverages helical gear meshing and an enclosed housing, enables them to transmit torque efficiently while compensating for various types of shaft misalignment. With applications spanning mining, steel production, heavy manufacturing, and beyond, these couplings play a critical role in ensuring the reliable and efficient operation of a wide range of industrial equipment.

Proper maintenance, including regular lubrication and inspection, is key to maximizing the service life of pulling fork gear couplings. By understanding their design, functionality, and maintenance requirements, engineers and maintenance personnel can select and use these couplings effectively, ensuring optimal performance and minimizing downtime in industrial operations. As industrial technology continues to advance, the demand for reliable, high-performance power transmission components such as pulling fork gear couplings is likely to remain strong, making them a cornerstone of modern mechanical systems.

« Pulling Fork Gear Coupling » Post Date: 2023/10/11

URL: https://www.rokeecoupling.com/en/customer-cases/pulling-fork-gear-coupling.html

- Small Cardan Shaft

- Structural Diagram Of Laminated Coupling

- Flexible Bush Couplings Drawing

- What Is The Price Of A Single Diaphragm Coupling

- Specifications of Shim Pack Coupling

- What Is The Spacing Between Elastic Diaphragm Couplings

- Crane Drum Couplings Company

- Membrane Couplings Supplier

- Custom High-precision Diaphragm Couplings

- Crown Pin Coupling Assembly Drawing