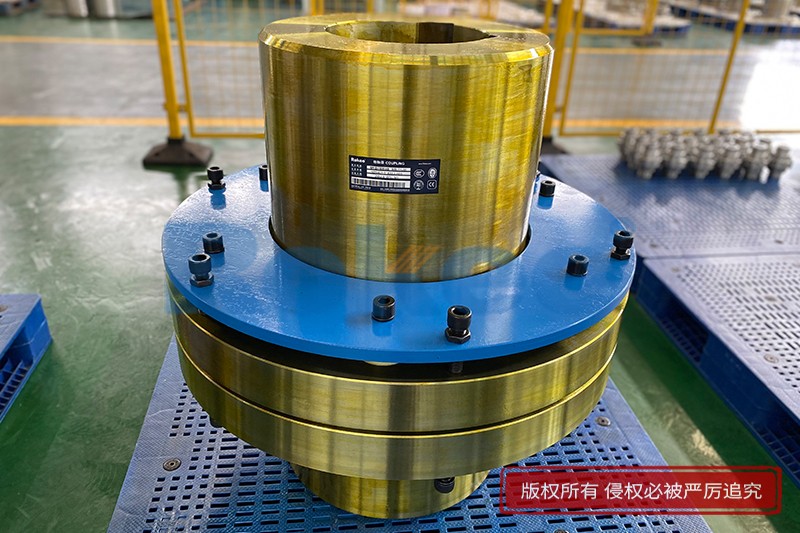

LT15 Flexible Bush Pin Coupling

Rokee® provide LT15 Flexible Bush Pin Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, ensuring the seamless transfer of torque while accommodating various misalignments and reducing operational stress. Among the diverse range of couplings available, the LT Flexible Bush Pin Coupling stands out for its unique combination of flexibility, durability, and cost-effectiveness. This type of coupling has become a staple in numerous industrial settings, from manufacturing plants to power generation facilities, due to its ability to adapt to harsh operating conditions and maintain reliable performance over extended periods.

Design Characteristics of LT Flexible Bush Pin Coupling

The LT Flexible Bush Pin Coupling features a modular and robust design that is engineered to balance flexibility and torque-carrying capacity. At its core, the coupling consists of four main components: two flanges, a set of bushings, pins, and in some cases, a spacer. Each component is meticulously designed to work in harmony, ensuring optimal performance and longevity.

The flanges are typically constructed from high-strength materials such as cast iron, steel, or aluminum alloy, depending on the application requirements. These flanges are mounted on the ends of the shafts that need to be connected, with one flange attached to the driving shaft and the other to the driven shaft. The flanges are designed with a series of evenly spaced holes around their circumference, which are used to accommodate the pins and bushings. The number and size of these holes vary based on the coupling’s torque rating, with larger and more numerous holes used for higher torque applications.

The bushings are the key flexible elements of the coupling and are usually made from elastic materials such as rubber, polyurethane, or nylon. These materials are chosen for their excellent resilience, wear resistance, and ability to absorb shock and vibration. The bushings are inserted into the holes of one of the flanges, creating a flexible interface between the two flanges. The pins, which are made from hardened steel to ensure strength and durability, pass through the bushings and are secured to the other flange. This configuration allows the bushings to act as a buffer, absorbing misalignments and reducing the transmission of shock loads from the driving shaft to the driven shaft.

In some configurations, the LT Flexible Bush Pin Coupling may include a spacer between the two flanges. The spacer is used to increase the distance between the shafts, which is particularly useful in applications where there is a need to accommodate additional components or where the shafts are spaced far apart. The spacer can be made from the same material as the flanges or a lighter material such as aluminum, depending on the weight and space constraints of the application.

Working Principles of LT Flexible Bush Pin Coupling

The primary function of the LT Flexible Bush Pin Coupling is to transmit torque from the driving shaft to the driven shaft while accommodating three types of misalignments: axial, radial, and angular. Axial misalignment occurs when the shafts move along their axial direction, radial misalignment is when the shafts are offset parallel to each other, and angular misalignment is when the shafts are not collinear and form an angle with each other. The coupling’s design allows it to handle these misalignments without compromising the efficiency of torque transmission.

When the driving shaft rotates, it imparts torque to the flange attached to it. This torque is then transferred to the pins, which press against the bushings. The bushings, being flexible, deform slightly to accommodate any misalignments between the two shafts, ensuring that the torque is smoothly transmitted to the second flange and ultimately to the driven shaft. The elastic nature of the bushings also helps to absorb shock and vibration generated during operation, reducing the stress on the shafts, bearings, and other components of the mechanical system.

Another important aspect of the working principle is the damping effect provided by the bushings. As the coupling operates, the bushings undergo cyclic deformation, which dissipates energy and reduces the amplitude of vibrations. This damping effect is crucial in applications where high-speed rotation or uneven load distribution can lead to excessive vibration, which can cause premature wear and failure of components. By reducing vibration, the LT Flexible Bush Pin Coupling helps to improve the overall stability and reliability of the mechanical system.

Key Advantages of LT Flexible Bush Pin Coupling

The LT Flexible Bush Pin Coupling offers a multitude of advantages that make it a preferred choice for many industrial applications. One of the most significant advantages is its excellent flexibility, which allows it to accommodate a wide range of misalignments. Unlike rigid couplings, which require precise alignment of the shafts and can transmit shock and vibration directly, the LT Flexible Bush Pin Coupling’s elastic bushings absorb these stresses, reducing the risk of damage to the shafts, bearings, and other components. This flexibility also simplifies the installation process, as it does not require the same level of precision as rigid couplings.

Another key advantage is its high torque-carrying capacity. Despite its flexibility, the coupling is designed to handle significant amounts of torque, making it suitable for use in heavy-duty applications such as industrial pumps, compressors, and conveyors. The use of high-strength materials for the flanges and pins ensures that the coupling can withstand the rigors of continuous operation without deformation or failure.

The LT Flexible Bush Pin Coupling is also highly durable and requires minimal maintenance. The bushings, which are the only wearable components, are designed to have a long service life, and when they do wear out, they can be easily replaced without the need to disassemble the entire coupling or disconnect the shafts. This ease of maintenance helps to reduce downtime and lower the overall cost of ownership.

Additionally, the coupling is cost-effective compared to other types of flexible couplings such as gear couplings or disc couplings. Its simple design and use of readily available materials make it an affordable option for small and large-scale industrial applications alike. Despite its lower cost, it does not compromise on performance, making it an excellent value for money.

The damping effect provided by the bushings is another major advantage. By absorbing shock and vibration, the coupling helps to reduce noise levels in the workplace, creating a safer and more comfortable environment for workers. It also helps to extend the service life of other components in the mechanical system, such as bearings and seals, by reducing the stress and wear they are subjected to.

Applications of LT Flexible Bush Pin Coupling

Due to its versatility and numerous advantages, the LT Flexible Bush Pin Coupling is used in a wide range of industrial applications. One of the most common applications is in the manufacturing industry, where it is used to connect motors to various types of machinery such as pumps, compressors, fans, and conveyors. In these applications, the coupling’s ability to handle misalignments and absorb shock is crucial, as it ensures the smooth operation of the machinery and reduces the risk of downtime.

The power generation industry also relies heavily on the LT Flexible Bush Pin Coupling. It is used in power plants to connect turbines to generators, where it transmits large amounts of torque while accommodating any misalignments that may occur due to thermal expansion or contraction of the shafts. The coupling’s damping effect is also beneficial in this application, as it helps to reduce vibration and ensure the stable operation of the power generation system.

The automotive industry uses the LT Flexible Bush Pin Coupling in various applications, such as connecting the engine to the transmission or the drive shaft to the differential. In these applications, the coupling’s flexibility and shock absorption capabilities are essential, as they help to smooth out the power delivery and reduce the stress on the transmission components.

Other applications include marine propulsion systems, where the coupling is used to connect the engine to the propeller shaft, and agricultural machinery, such as tractors and harvesters, where it connects the engine to various implements. The coupling is also used in mining equipment, such as crushers and grinders, where it can handle the heavy loads and harsh operating conditions commonly found in mining operations.

Maintenance Considerations for LT Flexible Bush Pin Coupling

To ensure the optimal performance and longevity of the LT Flexible Bush Pin Coupling, proper maintenance is essential. One of the most important maintenance tasks is regular inspection of the coupling components. This includes checking the bushings for signs of wear, such as cracks, deformation, or excessive play. Worn bushings should be replaced immediately, as they can lead to increased vibration, reduced torque transmission efficiency, and damage to the pins and flanges.

It is also important to check the tightness of the pins and other fasteners regularly. Loose fasteners can cause the coupling to vibrate excessively and can lead to premature wear of the components. If any fasteners are found to be loose, they should be tightened to the recommended torque specifications.

Lubrication is another key maintenance consideration. While the bushings are typically self-lubricating, some types may require periodic lubrication to reduce friction and wear. It is important to follow the manufacturer’s recommendations regarding lubrication intervals and the type of lubricant to use. Using the wrong type of lubricant or failing to lubricate the coupling properly can lead to increased wear and reduced performance.

Proper alignment of the shafts is also crucial, even though the LT Flexible Bush Pin Coupling can accommodate misalignments. Excessive misalignment can put additional stress on the bushings and other components, leading to premature failure. Regular alignment checks should be performed, and any misalignments should be corrected as soon as possible.

Finally, it is important to operate the coupling within its specified torque and speed limits. Overloading the coupling or operating it at speeds higher than recommended can cause the components to fail prematurely. It is important to ensure that the coupling is properly sized for the application and that the operating conditions do not exceed its design parameters.

Conclusion

The LT Flexible Bush Pin Coupling is a versatile and reliable component that plays a crucial role in mechanical power transmission. Its unique design, which combines flexibility and durability, makes it suitable for a wide range of industrial applications, from manufacturing and power generation to automotive and marine systems. The coupling’s ability to accommodate misalignments, absorb shock and vibration, and transmit high levels of torque while requiring minimal maintenance has made it a preferred choice for engineers and plant operators worldwide.

By understanding the design characteristics, working principles, key advantages, applications, and maintenance considerations of the LT Flexible Bush Pin Coupling, industrial professionals can make informed decisions about its use in their mechanical systems. Proper selection, installation, and maintenance of the coupling can help to improve the efficiency, reliability, and longevity of the system, reducing downtime and lowering the overall cost of ownership.

As industrial technology continues to advance, the LT Flexible Bush Pin Coupling is likely to remain a vital component in mechanical power transmission systems. Its adaptability to changing operating conditions and its cost-effectiveness make it a timeless solution for the challenges of torque transmission and misalignment accommodation in modern industry.

« LT15 Flexible Bush Pin Coupling » Post Date: 2023/11/6

URL: https://www.rokeecoupling.com/en/customer-cases/lt15-flexible-bush-pin-coupling.html

- Telescopic Cross Universal Joint Coupling

- Center Deviation Of Drum Gear Coupling

- Industrial Universal Coupling

- Universal Cross Joint Coupling Price

- Brake Drum Coupling Sales

- Purpose of Bush Type Couplings

- Diaphragm Flexible Couplings Company

- Gear Coupling Greasing Cycle

- Generator Coupling

- Tire Coupling Drawing