Geared Couplings

Rokee® is a Geared Couplings Supplier from China, customized geared couplings according to the drawings which provided by the customer, selling chinese national standard geared couplings, support export, due to excellent quality, complete technical services and superior cost performance, Rokee® industrial coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

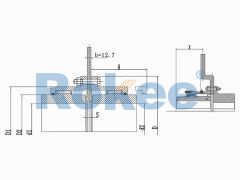

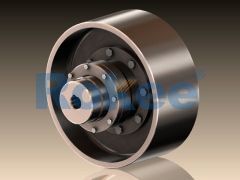

The Drum Gear Coupling is a specially designed advanced Gear Coupling. Its outer teeth are made into a sphere, with the center of the sphere on the axis of the gear. The teeth clearance is slightly larger than the general products and can transfer a greater torque and allow greater angular displacement, enjoying excellent performance and longer life.

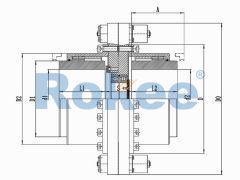

ROD Curved-tooth Gear Coupling is one of the transmission products with core technology independently developed by Rokee and has established and reported corporate technical standards in the country. By combining with the standard coupling technology of advanced countries such as Japan and Germany, we optimized many detailed dimensions, and adopted the toothed design with a large pressure angle and short shaft design for the shaft hole, which reduces the length-diameter ratio, and has a more compact structure and excellent speed performance.

The bolts of similar types are standardized and the parts are universal. Compared with the national standard couplings, our Toothed Couplings can transfer more torque, with greatly reduced mass and small moment of inertia. It meets the European explosion-proof requirements and the comprehensive performance is greatly advanced. We highly recommend you to choose our Crown Gear Couplings for better transmission performance.

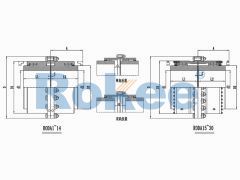

RODA Drum Gear Coupling

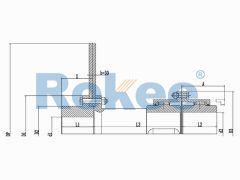

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.RODT Indirect Tube Drum Gear Coupling

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.RODX Intermediate Shaft Drum Gear Coupling

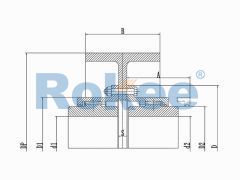

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.RODP Brake Disc Drum Gear Coupling

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.RODF Split Brake Disc Drum Gear Coupling

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.RODW Brake Wheel Drum Gear Coupling

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.RODU Brake Wheel Drum Gear Coupling

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.

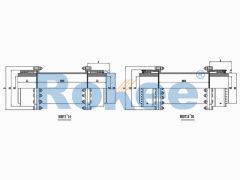

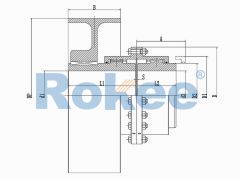

GICL Drum Gear Coupling

GICL drum gear coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.GICLZ Drum Gear Coupling

Half of the GICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.GIICL Drum Gear Coupling

GIICL drum gear coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.GIICLZ Drum Gear Coupling

Half of the GIICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.GCLD Drum Gear Coupling

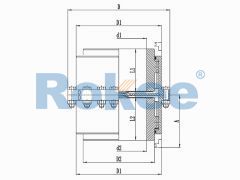

GCLD drum gear coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.NGCL Drum Gear Coupling

NGCL drum gear coupling is designed with a brake wheel, suitable for situations where braking is required.NGCLZ Drum Gear Coupling

NGCLZ drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.WG Drum Gear Coupling

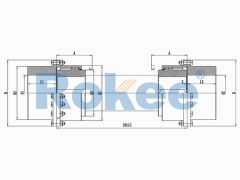

The overall characteristics of WG drum gear coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.WGZ Drum Gear Coupling

WGZ drum gear coupling is designed with a brake wheel, suitable for shoe type braking.WGP Drum Gear Coupling

WGP drum gear coupling is designed with a brake disc, suitable for disc type braking.WGT Drum Gear Coupling

WGT drum gear coupling is designed with indirect tube, suitable for long distance torque transfer.WGC Drum Gear Coupling

WGC drum gear coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.WGJ Drum Gear Coupling

WGJ drum gear coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.

In the realm of mechanical power transmission, the efficient and reliable transfer of torque between rotating shafts stands as a fundamental requirement across countless industrial operations. Among the diverse array of coupling devices engineered to fulfill this critical function, geared couplings have emerged as a robust and versatile solution, particularly in scenarios demanding high torque capacity, angular misalignment compensation, and durability under harsh operating conditions. Unlike flexible couplings that rely on elastomeric elements or sliding mechanisms, geared couplings leverage the meshing of gear teeth to transmit power, offering unique advantages that make them indispensable in heavy-duty industrial settings.

1. Understanding Geared Couplings: Definition and Core Purpose

A geared coupling is a type of rigid-flexible coupling designed to connect two rotating shafts, enabling the transfer of torque while accommodating limited amounts of angular, parallel, and axial misalignment between them. The defining feature of a geared coupling lies in its use of toothed gears—typically internal and external gears—that mesh together to transmit rotational power. Unlike rigid couplings, which require near-perfect alignment between shafts and cannot absorb misalignment, geared couplings introduce a degree of flexibility through the gear meshing, allowing for minor deviations in shaft positioning without compromising torque transmission efficiency. This combination of rigidity (for high torque transfer) and flexibility (for misalignment compensation) makes geared couplings a preferred choice in applications where shafts may experience thermal expansion, vibration, or minor positional shifts during operation.

The core purpose of a geared coupling extends beyond mere torque transmission; it also serves to protect connected equipment—such as motors, pumps, compressors, and gearboxes—from the damaging effects of misalignment. Misalignment between shafts can lead to excessive vibration, increased wear on bearings and seals, reduced operational efficiency, and premature equipment failure. By accommodating these misalignments, geared couplings mitigate these risks, extending the service life of both the coupling itself and the associated machinery. Additionally, geared couplings provide a means of disconnecting shafts for maintenance or repair, facilitating easier equipment servicing without the need for complete disassembly of the power transmission system.

2. Design Principles and Components of Geared Couplings

The design of a geared coupling is engineered to balance high torque capacity, misalignment tolerance, and structural integrity. While variations exist based on specific applications and operating requirements, all geared couplings share a set of core components and design principles that govern their functionality. Understanding these components is essential to appreciating how geared couplings operate and perform under different conditions.

2.1 Core Components

The primary components of a typical geared coupling include:

- Hub: The hub is a cylindrical component that attaches directly to the end of each shaft. It is typically secured to the shaft using keyways, set screws, or hydraulic fitting methods to ensure a tight, slip-free connection. One of the hubs (or both, in some designs) features external gear teeth that mesh with the internal gear teeth of the sleeve.

- Gear Sleeve (or Coupling Sleeve): The gear sleeve is a hollow cylindrical component with internal gear teeth that mate with the external teeth of the hubs. In some designs, the sleeve may be split into two halves (split sleeve) to facilitate installation and removal without requiring the disassembly of adjacent equipment—a critical advantage in large-scale industrial applications where shaft access is limited. The internal teeth of the sleeve are precision-machined to ensure smooth meshing with the hub teeth.

- Sealing System: Geared couplings require a robust sealing system to prevent the ingress of contaminants (such as dust, dirt, and moisture) and the leakage of lubricant. Common sealing elements include O-rings, lip seals, or labyrinth seals. The sealing system is essential for maintaining the integrity of the lubricant, which is critical for reducing friction and wear between the meshing gear teeth.

- Lubricant: While not a physical component, lubricant plays a vital role in the operation of geared couplings. It reduces friction between the meshing gear teeth, dissipates heat generated during operation, and protects the gear surfaces from corrosion and wear. The type of lubricant used (e.g., mineral oil, synthetic oil, grease) depends on the operating conditions, such as temperature, speed, and load.

2.2 Design Variations

Geared couplings are available in several design variations, each tailored to specific application requirements. The two most common types are:

1. External Gear Couplings: In this design, each hub features external gear teeth that mesh with the internal gear teeth of a single, solid sleeve. External gear couplings are simple in construction and offer high torque capacity, making them suitable for heavy-duty applications. However, their misalignment tolerance is relatively limited compared to other designs.

2. Internal Gear Couplings (Also Known as "Floating Shaft" Couplings): This design incorporates two hubs with external gear teeth, each meshing with a separate internal gear sleeve. A central floating shaft connects the two sleeves, allowing for greater angular and parallel misalignment. Internal gear couplings are often used in applications where shafts are spaced apart or where significant misalignment is expected, such as in conveyor systems or marine propulsion systems.

Another important design variation is the split-sleeve geared coupling. As mentioned earlier, the split sleeve is divided into two halves, which are bolted together around the hubs. This design eliminates the need to slide the coupling over the end of the shaft during installation or removal, making it ideal for use in tight spaces or with large-diameter shafts that are difficult to move.

2.3 Material Selection

The materials used in the construction of geared couplings are carefully selected to withstand the high loads, stresses, and environmental conditions encountered in industrial operations. The hubs and sleeves are typically made from high-strength alloy steels, such as 4140 or 4340, which offer excellent tensile strength, hardness, and wear resistance. These steels are often heat-treated (e.g., quenched and tempered) to further enhance their mechanical properties. In some cases, stainless steel may be used for applications in corrosive environments, such as chemical processing plants or marine settings. The sealing elements are usually made from elastomeric materials, such as nitrile rubber or氟橡胶, which offer good resistance to lubricants and environmental contaminants.

3. Operational Mechanics: How Geared Couplings Transmit Torque and Compensate for Misalignment

The operational mechanics of a geared coupling revolve around the meshing of gear teeth to transfer torque and the ability of this meshing to accommodate misalignment between shafts. To understand this process, it is helpful to break down the operation into two key functions: torque transmission and misalignment compensation.

3.1 Torque Transmission

When torque is applied to one shaft (e.g., from a motor), the torque is transferred to the hub attached to that shaft. The external gear teeth of the hub mesh with the internal gear teeth of the sleeve, causing the sleeve to rotate in synchronization with the hub. The rotating sleeve then transfers the torque to the second hub (via its meshing gear teeth), which in turn rotates the second shaft (e.g., connected to a pump or compressor). The meshing of the gear teeth ensures a positive, slip-free transfer of torque, making geared couplings highly efficient at transmitting power—typically with efficiency ratings above 99% when properly lubricated and aligned.

The torque capacity of a geared coupling is determined by several factors, including the number of gear teeth, the size and pitch of the teeth, the material strength of the hubs and sleeve, and the quality of the gear meshing. Geared couplings are designed to handle a wide range of torque values, from a few hundred newton-meters to several thousand newton-meters, making them suitable for both light-duty and heavy-duty applications.

3.2 Misalignment Compensation

One of the key advantages of geared couplings is their ability to accommodate three types of misalignment between shafts:

1. Angular Misalignment: This occurs when the axes of the two shafts are not colinear but intersect at a common point (like the blades of a pair of scissors). Geared couplings compensate for angular misalignment by allowing the gear teeth to mesh at a slight angle. The amount of angular misalignment that can be accommodated depends on the design of the coupling, but typical values range from 1° to 5°.

2. Parallel Misalignment: This occurs when the axes of the two shafts are parallel but offset from each other. Geared couplings compensate for parallel misalignment by the relative movement of the gear teeth within the sleeve. The maximum parallel misalignment tolerance is generally smaller than the angular misalignment tolerance, typically ranging from 0.1 mm to 1.0 mm per 100 mm of shaft distance.

3. Axial Misalignment: This occurs when the shafts move toward or away from each other along their axial direction (due to thermal expansion or contraction, for example). Geared couplings accommodate axial misalignment through the sliding of the gear teeth along the axial direction within the sleeve. The axial misalignment tolerance is typically several millimeters, depending on the coupling size.

It is important to note that while geared couplings can accommodate misalignment, excessive misalignment can lead to increased wear on the gear teeth, higher vibration levels, and reduced coupling life. Therefore, proper shaft alignment during installation is still essential to ensure optimal performance and longevity.

4. Key Performance Characteristics of Geared Couplings

Geared couplings possess a set of performance characteristics that distinguish them from other types of couplings and make them well-suited for specific industrial applications. Understanding these characteristics is crucial for selecting the right coupling for a given application.

4.1 High Torque Capacity

As mentioned earlier, geared couplings are designed to handle high torque loads, making them ideal for heavy-duty applications such as mining, steel production, and large-scale manufacturing. The meshing of gear teeth provides a large contact area, allowing for the efficient transfer of high levels of torque without slippage or deformation. This high torque capacity is a key advantage over flexible couplings, which often have lower torque limits due to the limitations of their elastomeric elements.

4.2 Wide Speed Range

Geared couplings can operate effectively over a wide range of rotational speeds, from low-speed applications (e.g., conveyor systems) to high-speed applications (e.g., centrifugal compressors). The precision-machined gear teeth and high-quality lubrication ensure smooth operation even at high speeds, minimizing vibration and noise. However, the maximum operating speed of a geared coupling is limited by factors such as the centrifugal forces acting on the rotating components and the ability of the sealing system to retain lubricant at high speeds.

4.3 Durability and Long Service Life

Constructed from high-strength materials and designed to withstand harsh operating conditions, geared couplings are known for their durability and long service life. The gear teeth are heat-treated to resist wear and fatigue, and the robust sealing system protects the internal components from contaminants and lubricant loss. When properly maintained, geared couplings can last for many years, even in demanding environments such as high-temperature, high-humidity, or dusty industrial settings.

4.4 Resistance to Harsh Environments

Geared couplings are highly resistant to harsh environmental conditions, making them suitable for use in a wide range of industrial settings. The sealed design prevents the ingress of dust, dirt, moisture, and chemicals, which can damage internal components. Additionally, the use of corrosion-resistant materials (such as stainless steel) in some designs allows geared couplings to operate in corrosive environments, such as marine applications or chemical processing plants.

4.5 Low Maintenance Requirements (When Properly Installed)

While geared couplings do require regular lubrication and inspection, their maintenance requirements are relatively low compared to other types of couplings (such as elastomeric couplings, which require periodic replacement of rubber elements). The robust design and durable materials minimize the need for frequent repairs or replacements, reducing downtime and maintenance costs.

5. Applications of Geared Couplings Across Industries

The unique combination of high torque capacity, misalignment tolerance, durability, and resistance to harsh environments makes geared couplings suitable for a wide range of industrial applications. From heavy machinery to precision equipment, geared couplings play a critical role in ensuring the reliable transfer of power. Below are some of the key industries and applications where geared couplings are commonly used:

5.1 Mining and Quarrying

The mining and quarrying industry relies heavily on heavy-duty equipment such as crushers, conveyors, and excavators, which require the transfer of high torque between shafts. Geared couplings are used in these applications to connect motors to crushers and conveyors, accommodating the misalignment that can occur due to the heavy loads and vibrations encountered in mining operations. The durability and resistance to dust and moisture make geared couplings well-suited for the harsh conditions of mines and quarries.

5.2 Steel Production

Steel production involves a range of processes, including smelting, rolling, and casting, which require large amounts of power and high torque transmission. Geared couplings are used in equipment such as rolling mills, blast furnaces, and electric arc furnaces, connecting motors to gearboxes and other rotating components. The high temperature resistance and durability of geared couplings make them ideal for the extreme conditions of steel mills, where temperatures can exceed 1000°C and vibrations are common.

5.3 Manufacturing and Processing

In manufacturing and processing plants, geared couplings are used in a variety of equipment, including pumps, compressors, fans, and mixers. For example, in chemical processing plants, geared couplings connect motors to centrifugal pumps, accommodating the misalignment that can occur due to thermal expansion of the shafts. In food processing plants, stainless steel geared couplings are used to ensure hygiene and resistance to corrosive cleaning agents.

5.4 Marine and Offshore

Marine and offshore applications, such as ship propulsion systems, offshore drilling rigs, and marine pumps, require couplings that can withstand corrosive saltwater environments and accommodate misalignment due to the movement of the vessel. Geared couplings made from stainless steel or other corrosion-resistant materials are used in these applications, providing reliable torque transmission between the ship's engine and propeller, or between motors and offshore drilling equipment.

5.5 Power Generation

Power generation facilities, including thermal power plants, hydroelectric power plants, and wind farms, require reliable power transmission systems. Geared couplings are used in equipment such as turbines, generators, and pumps, connecting the rotating components to ensure efficient torque transfer. In hydroelectric power plants, for example, geared couplings connect the water turbine to the generator, accommodating the misalignment that can occur due to the movement of the turbine shaft under load.

5.6 Construction and Heavy Machinery

Construction equipment such as bulldozers, excavators, and cranes rely on geared couplings to transfer power from the engine to the transmission and other rotating components. The high torque capacity and durability of geared couplings make them suitable for the heavy loads and rough terrain encountered in construction operations. Additionally, the ability to accommodate misalignment ensures reliable operation even when the equipment is operating on uneven surfaces.

6. Maintenance Practices for Geared Couplings: Ensuring Longevity and Reliability

While geared couplings are durable and low-maintenance, proper maintenance is essential to ensure their longevity and reliable performance. Neglecting maintenance can lead to increased wear, reduced torque capacity, vibration, and premature failure, which can result in costly downtime and equipment damage. Below are the key maintenance practices for geared couplings:

6.1 Regular Lubrication

Lubrication is the most critical maintenance task for geared couplings. The meshing gear teeth require a continuous supply of lubricant to reduce friction, dissipate heat, and prevent wear and corrosion. The type of lubricant used should be selected based on the operating conditions (temperature, speed, load) and the manufacturer's recommendations. It is important to maintain the correct lubricant level and to replace the lubricant at regular intervals (typically every 6 to 12 months, depending on usage). Over-lubrication can lead to excessive heat buildup, while under-lubrication can cause metal-to-metal contact between the gear teeth, resulting in rapid wear.

6.2 Inspection of Seals

The sealing system of a geared coupling is essential for retaining lubricant and preventing the ingress of contaminants. Regular inspection of the seals (O-rings, lip seals, labyrinth seals) is necessary to check for signs of wear, damage, or leakage. If a seal is damaged or leaking, it should be replaced immediately to avoid lubricant loss and contamination of the gear teeth. Additionally, the seal housing should be cleaned regularly to remove any accumulated dust, dirt, or debris.

6.3 Shaft Alignment Checks

While geared couplings can accommodate misalignment, excessive misalignment can lead to increased wear, vibration, and reduced coupling life. Therefore, it is important to check the alignment of the shafts regularly (typically during installation and after any major maintenance or equipment movement). Shaft alignment can be checked using tools such as dial indicators, laser alignment systems, or optical alignment tools. If misalignment is detected beyond the coupling's tolerance, the shafts should be realigned to ensure optimal performance.

6.4 Inspection of Gear Teeth

Regular inspection of the gear teeth is necessary to check for signs of wear, pitting, cracking, or deformation. Wear on the gear teeth can reduce the torque capacity of the coupling and increase vibration. Pitting (small cavities on the gear surface) is often caused by insufficient lubrication or high contact stresses, while cracking can be caused by fatigue or excessive loads. If any damage to the gear teeth is detected, the coupling should be repaired or replaced immediately to prevent catastrophic failure.

6.5 Tightening of Fasteners

The fasteners (bolts, set screws, keyways) that secure the hubs to the shafts and the split sleeve (if applicable) can loosen over time due to vibration. Regular inspection and tightening of these fasteners are necessary to ensure a secure connection. Loose fasteners can cause slippage between the hub and the shaft, leading to wear, heat buildup, and reduced torque transmission. It is important to use the correct torque values when tightening fasteners, as over-tightening can damage the threads or the coupling components.

6.6 Cleaning

Regular cleaning of the geared coupling is necessary to remove accumulated dust, dirt, grease, and debris. A clean coupling is easier to inspect for signs of wear or damage, and it also helps to prevent the buildup of contaminants that can damage the seals and gear teeth. The coupling can be cleaned using a solvent (such as mineral spirits) and a brush, followed by a thorough drying to prevent corrosion.

7. Conclusion

Geared couplings stand as a vital component in modern mechanical power transmission systems, offering a unique combination of high torque capacity, misalignment tolerance, durability, and resistance to harsh environments. Their design, which leverages the meshing of precision-machined gear teeth, enables the reliable transfer of power between rotating shafts while protecting connected equipment from the damaging effects of misalignment. From mining and steel production to marine and power generation, geared couplings play a critical role in ensuring the efficient and reliable operation of countless industrial processes.

Understanding the design principles, operational mechanics, and key performance characteristics of geared couplings is essential for selecting the right coupling for a given application. Additionally, adhering to proper maintenance practices—such as regular lubrication, seal inspection, shaft alignment checks, and gear tooth inspection—is crucial for ensuring the longevity and reliability of geared couplings, minimizing downtime, and reducing maintenance costs.

As industrial operations continue to evolve, demanding higher levels of efficiency, reliability, and performance, the role of geared couplings is likely to remain indispensable. Advances in material science and manufacturing technology will continue to improve the performance and durability of geared couplings, making them even more suitable for the challenging conditions of modern industry. Whether in heavy-duty mining equipment or precision manufacturing processes, geared couplings will continue to be a cornerstone of mechanical power transmission for years to come.

« Geared Couplings » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/blog/geared-couplings.html

Tags: Brake Drum Geared Coupling, pu sandwich panel line

- High Performance Brake Drum Geared Couplings

- Coaxiality of Brake Drum Geared Coupling

- Brake Drum Geared Couplings Company

- Brake Drum Geared Coupling Brands

- Procurement of Brake Drum Geared Coupling

- Supply of Brake Drum Geared Couplings

- High Quality Brake Drum Geared Couplings

- Components of Brake Drum Geared Coupling

- Brake Drum Geared Coupling

- Brake Drum Geared Couplings Factory