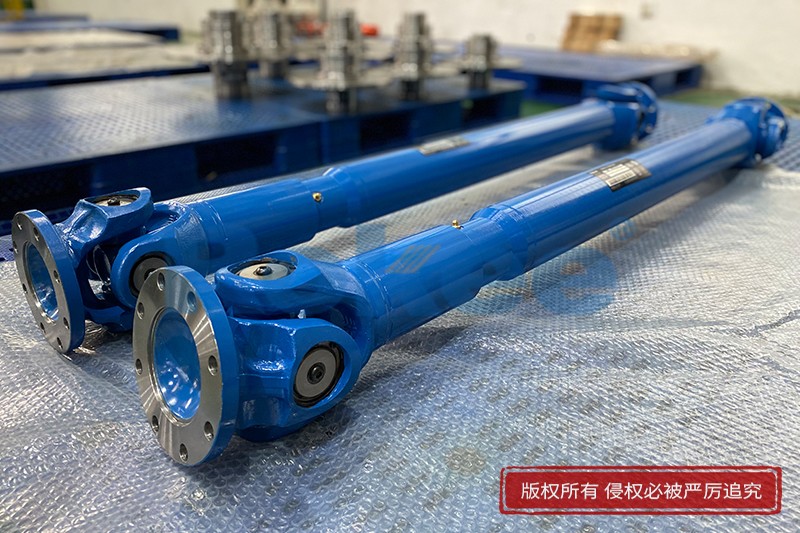

Telescopic Drive Shaft

Rokee® is Telescopic Drive Shaft Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Telescopic Drive Shaft have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of mechanical power transmission, the drive shaft stands as a critical component, facilitating the transfer of rotational energy from a power source—such as an engine or motor—to a driven device, whether it be wheels, propellers, or industrial machinery. Among the diverse types of drive shafts, the telescopic drive shaft (also referred to as a telescoping or sliding drive shaft) distinguishes itself with its unique ability to adjust in length while maintaining efficient power transmission. This adaptability makes it an indispensable solution in applications where relative movement exists between the power source and the driven component, such as in automotive suspensions, agricultural machinery, and aerospace systems.

At its core, a telescopic drive shaft is engineered to address a common challenge in power transmission: accommodating axial displacement between two rotating components without compromising the integrity of the energy transfer. Unlike fixed-length drive shafts, which are limited to applications where the distance between the power source and the driven unit remains constant, telescopic drive shafts feature a two-piece or multi-piece construction that allows for sliding movement along the axial direction. This sliding capability ensures that even when the relative position of the connected components changes—due to factors like suspension compression, thermal expansion, or structural deflection—the drive shaft can maintain a consistent connection, preventing binding, vibration, or premature failure.

The basic working principle of a telescopic drive shaft revolves around the interaction between an outer tube and an inner shaft, which are designed to slide within one another while transmitting torque. To enable torque transfer while allowing axial movement, the mating surfaces of the outer tube and inner shaft are typically machined with splines—longitudinal ridges or grooves that interlock. The splined connection ensures that rotational motion is transferred from one component to the other without slippage, while the sliding fit between the splines permits axial adjustment. In some designs, other torque-transfer mechanisms, such as keyways or polygonal profiles, may be used, but splines are preferred for most high-torque applications due to their ability to distribute stress evenly across a larger contact area, reducing wear and enhancing durability.

The structural design of a telescopic drive shaft is tailored to the specific requirements of its application, with variations in length, diameter, number of splines, and supporting components. A typical assembly includes the outer telescoping tube, inner sliding shaft, splined connection, universal joints (U-joints) or constant velocity (CV) joints at the ends, and sometimes a protective boot or cover. The universal joints or CV joints play a complementary role to the telescopic function, accommodating angular misalignment between the power source and the driven component. While U-joints are suitable for moderate angular displacements, CV joints are preferred in applications requiring higher angles or smoother power transmission, such as in front-wheel-drive vehicles, where the drive shaft must accommodate both axial movement from suspension travel and angular movement from steering.

The protective boot, often made of rubber or thermoplastic materials, is a small but critical component of many telescopic drive shaft assemblies. Its primary function is to seal the splined connection from contaminants such as dirt, dust, moisture, and debris, which can cause corrosion, wear, and premature failure of the splines. Additionally, the boot helps retain lubricant within the splined interface, ensuring smooth sliding movement and reducing friction. In harsh environments—such as off-road vehicles or agricultural machinery—where the drive shaft is exposed to extreme conditions, the boot may be reinforced with abrasion-resistant materials or additional shielding to enhance its longevity.

The selection of materials for telescopic drive shafts is governed by a range of factors, including the required torque capacity, weight constraints, operating environment, and cost. The most commonly used materials for the outer tube and inner shaft are high-strength steels, such as alloy steels or carbon steels, which offer excellent tensile strength, toughness, and wear resistance. These steels are often heat-treated to further enhance their mechanical properties, making them suitable for high-torque applications like heavy-duty trucks, construction equipment, and industrial machinery. In applications where weight reduction is a priority—such as aerospace, racing vehicles, or electric vehicles—lightweight materials like aluminum alloys or carbon fiber composites may be used. Aluminum alloys offer a good balance of strength and weight, while carbon fiber composites provide exceptional strength-to-weight ratios, though they come with higher material and manufacturing costs.

The splined connection, being the critical interface for both torque transfer and axial movement, requires materials with high wear resistance and fatigue strength. In many cases, the splines are surface-hardened using processes like carburizing, nitriding, or induction hardening to improve their durability. This surface treatment creates a hard outer layer that resists wear, while the core of the material remains tough, preventing brittle failure under impact or dynamic loads.

Telescopic drive shafts find applications across a wide range of industries, each leveraging their unique adaptability to solve specific power transmission challenges. One of the most prominent applications is in the automotive industry, where they are used in both passenger vehicles and commercial vehicles. In rear-wheel-drive and four-wheel-drive passenger cars, telescopic drive shafts are employed to connect the transmission to the rear differential. As the vehicle travels over uneven terrain, the suspension compresses and extends, causing the distance between the transmission and the differential to change. The telescopic drive shaft adjusts in length to accommodate this movement, ensuring continuous power transmission to the rear wheels. In front-wheel-drive vehicles, the drive shafts (often referred to as half-shafts) are also telescopic, as they must accommodate both the axial movement from suspension travel and the angular movement from steering.

Commercial vehicles, such as heavy-duty trucks, buses, and trailers, also rely heavily on telescopic drive shafts. In these applications, the drive shafts must transmit high torque while accommodating the movement of the suspension and the articulation of the chassis. For example, in articulated buses or trucks with a pivot between the cab and the trailer, telescopic drive shafts are used to transfer power across the pivot point, adjusting in length as the vehicle turns or travels over uneven surfaces. Additionally, in off-road vehicles, such as SUVs and construction equipment, telescopic drive shafts are essential for withstanding the extreme axial and angular displacements encountered in rough terrain.

The agricultural industry is another major user of telescopic drive shafts. Agricultural machinery, such as tractors, harvesters, and tillers, often features multiple moving components that require power transmission across variable distances. For example, a tractor’s power take-off (PTO) shaft, which transfers power from the tractor’s engine to implements like mowers or plows, is typically telescopic. As the implement is raised or lowered, or as the tractor moves over uneven ground, the distance between the PTO and the implement changes, and the telescopic shaft adjusts accordingly. This adaptability ensures that the implement receives a consistent supply of power, improving efficiency and reducing wear on both the tractor and the implement.

In the aerospace industry, telescopic drive shafts are used in a variety of applications, including aircraft landing gear systems, engine accessories, and rotorcraft. In landing gear systems, for example, telescopic drive shafts may be used to transmit power to hydraulic pumps or electric generators, accommodating the movement of the landing gear as it is extended or retracted. In rotorcraft, such as helicopters, telescopic drive shafts help transfer power from the engine to the rotor system, adjusting for the dynamic movement of the rotor hub during flight. The aerospace industry demands extremely high levels of reliability and performance, so telescopic drive shafts used in this sector are typically made from advanced materials like titanium alloys or carbon fiber composites, with stringent quality control and testing procedures.

Industrial machinery, such as conveyor systems, pumps, compressors, and robotic arms, also benefits from the use of telescopic drive shafts. In conveyor systems, for example, telescopic drive shafts can be used to connect the motor to the conveyor rollers, accommodating the thermal expansion of the conveyor frame or the movement of the rollers due to load variations. In robotic arms, where precise movement and power transmission are critical, telescopic drive shafts enable the arm to extend and retract while maintaining rotational power to the end effector, such as a gripper or tool.

The widespread adoption of telescopic drive shafts is attributed to their numerous performance advantages over fixed-length drive shafts. First and foremost is their adaptability to axial displacement, which eliminates the need for complex and expensive alternative solutions, such as flexible couplings or adjustable mounts. This adaptability not only simplifies the design of power transmission systems but also improves their reliability by preventing binding and reducing stress on connected components.

Another key advantage is smooth power transmission. The splined connection and the use of U-joints or CV joints ensure that rotational energy is transferred with minimal vibration and noise, even when the drive shaft is adjusting in length or operating at an angle. This smooth operation is particularly important in applications where precision is critical, such as in automotive powertrains or robotic systems, where vibration can affect performance and comfort.

Telescopic drive shafts also offer enhanced durability when properly designed and maintained. The splined connection distributes torque evenly, reducing stress concentrations and minimizing wear. Additionally, the use of high-strength materials and surface treatments further extends the service life of the drive shaft, making it suitable for high-torque and high-load applications. In comparison to flexible couplings, which may degrade over time due to fatigue or environmental factors, telescopic drive shafts are generally more robust and require less frequent replacement.

Weight reduction is another significant advantage, especially in applications where weight is a critical factor, such as aerospace or electric vehicles. By using lightweight materials like aluminum alloys or carbon fiber composites, telescopic drive shafts can help reduce the overall weight of the system, improving fuel efficiency (in combustion engines) or range (in electric vehicles). Additionally, the compact design of telescopic drive shafts allows for easier integration into tight spaces, making them suitable for applications with limited installation space.

Despite their inherent durability, telescopic drive shafts require regular maintenance to ensure optimal performance and longevity. The most critical maintenance task is the inspection and lubrication of the splined connection. The splines rely on lubricant to reduce friction, prevent corrosion, and minimize wear. Over time, lubricant can degrade or leak out, especially if the protective boot is damaged. Therefore, regular checks of the boot for cracks, tears, or loose clamps are essential. If the boot is damaged, it should be replaced immediately to prevent contaminants from entering the splined interface. Additionally, the splined connection should be re-lubricated at specified intervals, using a lubricant that is compatible with the materials and operating conditions of the drive shaft.

Another important maintenance task is the inspection of the universal joints or CV joints. These joints can wear out over time, leading to increased vibration, noise, or even failure. Signs of joint wear include excessive play, clicking or clunking sounds during operation, or leakage of grease. Regular inspection of the joints, including checking for wear on the bearings and seals, can help identify potential issues before they escalate. If worn components are detected, they should be replaced promptly to prevent damage to the drive shaft or other connected components.

In addition to lubrication and joint inspection, regular visual inspections of the entire drive shaft assembly are recommended. This includes checking for signs of bending, cracking, or corrosion on the outer tube and inner shaft. Bending or cracking can occur due to impact loads, such as those encountered in off-road driving or industrial applications, and can significantly reduce the torque capacity of the drive shaft. Corrosion, especially in harsh environments, can weaken the material and lead to premature failure. Any signs of damage should be addressed immediately, either through repair or replacement of the affected components.

Looking to the future, the development of telescopic drive shafts is poised to be driven by several key trends, including the growing demand for electric vehicles, advancements in materials science, and the integration of smart technologies. The rise of electric vehicles (EVs) presents unique challenges and opportunities for power transmission components. EVs typically have higher torque outputs and require lighter, more efficient drive shafts to maximize range. Telescopic drive shafts made from carbon fiber composites or advanced aluminum alloys are well-suited to these requirements, as they offer high strength-to-weight ratios and low friction. Additionally, the compact design of EV powertrains requires drive shafts that can fit into tight spaces, making the adaptability of telescopic drive shafts even more valuable.

Advancements in materials science are also expected to play a significant role in the future of telescopic drive shafts. The development of new high-strength, lightweight materials—such as magnesium alloys, titanium matrix composites, and advanced polymers—will enable the design of drive shafts that are even lighter and more durable than current models. These materials will also offer improved resistance to corrosion, wear, and extreme temperatures, expanding the range of applications for telescopic drive shafts into more harsh environments, such as deep-sea exploration or high-temperature industrial processes.

The integration of smart technologies is another emerging trend in the field of mechanical components, and telescopic drive shafts are no exception. Future drive shafts may be equipped with sensors to monitor key performance metrics, such as torque, temperature, vibration, and wear. These sensors will provide real-time data to a central control system, enabling predictive maintenance. For example, a sensor detecting increased friction in the splined connection could alert the operator to the need for lubrication or boot replacement before a failure occurs. Additionally, the use of smart materials—such as shape-memory alloys or self-healing polymers—could enable telescopic drive shafts to adapt to changing operating conditions automatically or repair minor damage without human intervention.

Another area of future development is the optimization of splined connection design. Current splined designs are effective but can still experience wear over time, especially in high-torque applications. Researchers and engineers are exploring new spline profiles, such as involute splines with modified pressure angles, or alternative torque-transfer mechanisms, such as magnetic couplings, to reduce wear and improve efficiency. Magnetic couplings, in particular, offer the potential for contactless torque transfer, eliminating the need for lubrication and reducing maintenance requirements. However, magnetic couplings are currently limited by their torque capacity, so further research is needed to make them suitable for high-torque applications.

In conclusion, the telescopic drive shaft is a versatile and essential component in modern power transmission systems, offering unique adaptability to axial displacement that makes it indispensable in a wide range of applications. From automotive and agricultural machinery to aerospace and industrial systems, telescopic drive shafts play a critical role in ensuring efficient, reliable, and smooth power transfer. Their structural design, material selection, and performance advantages are tailored to the specific requirements of each application, while regular maintenance ensures their longevity and optimal performance. Looking ahead, the future of telescopic drive shafts is bright, with advancements in materials, smart technologies, and design optimization poised to enhance their performance, reduce their weight, and expand their range of applications. As industries continue to evolve and demand more efficient, lightweight, and reliable power transmission solutions, the telescopic drive shaft will remain a key component in meeting these challenges.

« Telescopic Drive Shaft » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/telescopic-drive-shaft.html