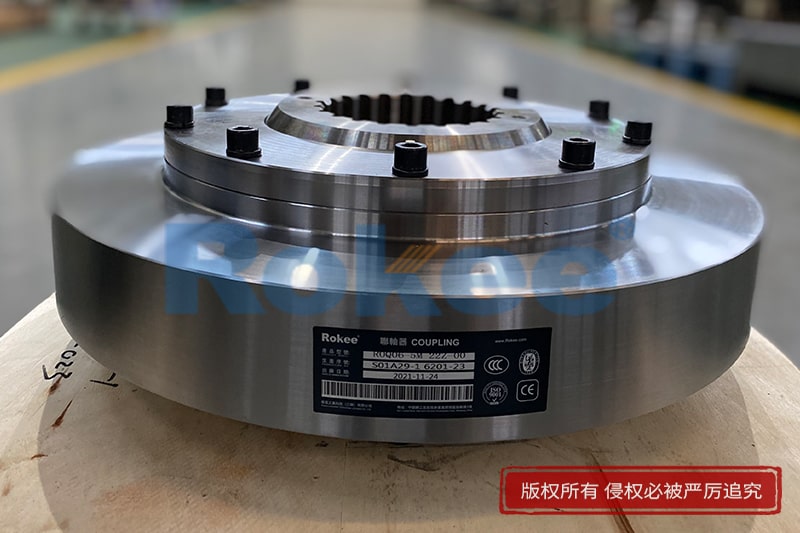

Splined Shaft

Rokee® is Splined Shaft Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Splined Shaft have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of mechanical transmission systems, the splined shaft stands as a critical component that enables efficient power transfer and precise motion control. Unlike traditional shafts with keyways, splined shafts feature a series of longitudinal ridges (splines) on their outer surface that mesh with corresponding grooves in a mating part, such as a hub or gear. This unique design not only enhances the torque-carrying capacity but also ensures alignment between connected components, reducing wear and improving overall system reliability. From automotive transmissions to industrial machinery and aerospace applications, splined shafts play an indispensable role in driving modern mechanical systems.

1. Fundamental Characteristics and Classification of Splined Shafts

Splined shafts are distinguished by their splined profiles, which are designed to transmit torque while maintaining a tight fit between the shaft and its mating component. The key characteristics that define splined shafts include the number of splines, spline profile, pitch diameter, pressure angle, and fit tolerance. These parameters are carefully determined based on the specific application requirements, such as torque load, rotational speed, and environmental conditions.

Based on their spline profiles, splined shafts can be classified into three main types: straight-sided splines, involute splines, and serrated splines.

Straight-sided splines, also known as rectangular splines, feature a simple rectangular cross-section. This type of spline is easy to manufacture and is widely used in applications with moderate torque requirements, such as agricultural machinery and light-duty industrial equipment. The straight sides of the splines allow for easy alignment during assembly, but they may suffer from higher stress concentrations compared to other profiles, limiting their use in high-torque applications.

Involute splines are the most commonly used type in modern mechanical systems, characterized by their involute curve profile. Similar to the teeth of gears, involute splines offer several advantages, including uniform stress distribution, high torque-carrying capacity, and smooth engagement. The involute profile ensures that the load is evenly distributed across the entire length of the spline, reducing localized wear and extending the service life of the component. Additionally, involute splines can be manufactured using standard gear-cutting equipment, making them cost-effective for mass production. They are widely employed in automotive transmissions, heavy-duty industrial machinery, and aerospace systems.

Serrated splines, also referred to as triangular splines, have a triangular cross-section with a small pressure angle (typically 30 degrees). This design provides high radial stiffness and is suitable for applications where axial movement between the shaft and mating part is required, such as in telescopic drives. Serrated splines are often used in automotive steering systems and industrial robots, where precise axial positioning and torque transmission are critical.

Another classification criterion is the fit type between the splined shaft and the mating hub. Common fit types include clearance fit, interference fit, and transition fit. Clearance fit allows for axial movement and easy assembly, making it suitable for applications where thermal expansion or contraction is expected. Interference fit creates a tight bond between the shaft and hub, preventing relative movement even under high torque loads, and is often used in high-performance applications. Transition fit falls between clearance and interference fits, providing a balance between assembly ease and stability.

2. Design Principles of Splined Shafts

The design of splined shafts is a critical process that requires careful consideration of various factors to ensure optimal performance and reliability. The primary design objectives are to transmit the required torque without failure, maintain alignment between connected components, minimize wear, and accommodate any axial or radial movements.

One of the key design considerations is torque calculation. The splined shaft must be capable of withstanding the maximum torque generated by the system. The torque capacity of a splined shaft depends on several factors, including the number of splines, the cross-sectional area of the splines, the material strength, and the fit type. Engineers use mathematical models and finite element analysis (FEA) to calculate the maximum allowable torque and ensure that the shaft does not experience plastic deformation or fatigue failure.

Alignment is another critical design principle. Splined shafts must be designed to ensure that the splines mesh perfectly with the mating grooves, preventing misalignment that can lead to uneven wear, noise, and reduced efficiency. This requires precise control of the spline dimensions, including pitch diameter, tooth thickness, and runout. Additionally, the shaft’s overall length and diameter must be designed to fit within the system’s spatial constraints while maintaining sufficient rigidity.

Wear resistance is also an important design consideration, especially in applications with high rotational speeds or frequent load cycles. To enhance wear resistance, designers may incorporate surface treatments, such as carburizing, nitriding, or hard chrome plating, which increase the hardness of the spline surfaces. Additionally, the choice of lubrication is critical; proper lubrication reduces friction between the splined shaft and mating part, minimizing wear and extending the component’s service life.

Axial movement accommodation is another design factor in certain applications. For example, in automotive transmissions, splined shafts must accommodate axial movement caused by gear shifting. This can be achieved by using a clearance fit or by incorporating grooves or shoulders on the shaft to limit axial displacement while allowing for necessary movement.

3. Manufacturing Processes of Splined Shafts

The manufacturing of splined shafts involves several processes, each designed to achieve the required spline profile, dimensions, and surface quality. The choice of manufacturing process depends on factors such as the material, spline type, production volume, and cost constraints. Common manufacturing processes for splined shafts include hobbing, milling, broaching, shaping, and rolling.

Hobbing is a widely used process for manufacturing involute splines, especially in high-volume production. It involves using a hob, which is a cylindrical cutting tool with helical teeth, to cut the splines into the shaft. The hob rotates at a high speed while the shaft rotates and feeds axially, creating the involute profile. Hobbing is efficient and produces high-precision splines with uniform dimensions, making it suitable for mass-produced components such as automotive transmission shafts.

Milling is a versatile process that can be used to manufacture straight-sided, involute, or serrated splines. It involves using a milling cutter to remove material from the shaft’s surface, creating the spline profile. Milling can be performed on both horizontal and vertical milling machines, and it is suitable for low to medium production volumes. However, milling is less efficient than hobbing for high-volume production, as it requires multiple passes to complete the spline profile.

Broaching is a precision machining process used to create internal or external splines with high accuracy. It involves using a broach, which is a long, multi-tooth cutting tool, to remove material in a single pass. Broaching is ideal for producing splines with complex profiles and tight tolerances, and it is often used in aerospace and high-performance industrial applications. However, broaching tools are expensive, making this process more suitable for medium to high production volumes.

Shaping is a process that uses a shaping tool to cut the spline profile by reciprocating motion. The shaft is held in a fixture and rotated incrementally, while the shaping tool moves back and forth to cut each spline tooth. Shaping is suitable for low-volume production or for manufacturing splines with non-standard profiles. It is less efficient than hobbing or broaching but offers greater flexibility in terms of spline design.

Rolling, also known as cold forming, is a chipless manufacturing process that involves using rolling dies to deform the shaft’s surface, creating the spline profile. The shaft is placed between two rolling dies, which rotate and apply pressure to the shaft, displacing material to form the splines. Rolling offers several advantages, including improved material strength (due to work hardening), high production efficiency, and good surface finish. It is widely used for manufacturing straight-sided and involute splines in high-volume production, such as in automotive and agricultural machinery. However, rolling is limited to ductile materials and cannot be used for complex spline profiles.

After the spline cutting or forming process, the shaft may undergo additional finishing operations to improve surface quality and dimensional accuracy. These operations include grinding, polishing, and heat treatment. Grinding is used to achieve precise dimensions and a smooth surface finish, while polishing removes any remaining burrs or imperfections. Heat treatment processes, such as quenching and tempering, are used to enhance the material’s strength and hardness, improving the shaft’s durability and wear resistance.

4. Material Selection for Splined Shafts

The selection of material for a splined shaft is critical to its performance, durability, and cost. The material must possess sufficient strength to transmit the required torque, good wear resistance to withstand repeated contact with the mating part, and appropriate ductility to accommodate any manufacturing processes or operational stresses. Common materials used for splined shafts include carbon steel, alloy steel, stainless steel, and non-ferrous metals such as aluminum and brass.

Carbon steel is the most commonly used material for splined shafts due to its high strength, good machinability, and low cost. Low-carbon steels (such as 1018 steel) are suitable for low-torque applications, while high-carbon steels (such as 1045 steel) offer higher strength and are used in medium-torque applications. Carbon steel shafts are often heat-treated to improve their hardness and wear resistance.

Alloy steel is used in applications requiring high strength, durability, and resistance to fatigue. Alloy steels contain additional elements such as chromium, nickel, and molybdenum, which enhance their mechanical properties. Common alloy steels used for splined shafts include 4140, 4340, and 5140. These steels are widely used in heavy-duty industrial machinery, automotive transmissions, and aerospace applications, where high torque loads and harsh operating conditions are common.

Stainless steel is selected for applications where corrosion resistance is critical, such as in food processing equipment, marine environments, or chemical processing plants. Stainless steel splined shafts offer good strength and wear resistance while maintaining resistance to rust and corrosion. Common types of stainless steel used include 304 and 316, which are austenitic stainless steels with excellent corrosion resistance.

Non-ferrous metals such as aluminum and brass are used in lightweight applications where corrosion resistance or electrical conductivity is required. Aluminum splined shafts are lightweight and have good machinability, making them suitable for aerospace and automotive applications where weight reduction is a priority. Brass splined shafts offer good corrosion resistance and are often used in marine and electrical applications. However, non-ferrous metals have lower strength than steel, limiting their use in high-torque applications.

In addition to the base material, surface treatments can further enhance the performance of splined shafts. As mentioned earlier, carburizing, nitriding, and hard chrome plating are common surface treatments that increase surface hardness and wear resistance. Carburizing involves diffusing carbon into the surface of the shaft, followed by heat treatment to create a hard surface layer. Nitriding diffuses nitrogen into the surface, creating a hard, wear-resistant layer without the need for quenching. Hard chrome plating deposits a layer of chromium on the surface, providing excellent wear and corrosion resistance.

5. Applications of Splined Shafts

Splined shafts are used in a wide range of applications across various industries, thanks to their ability to transmit high torque, maintain alignment, and accommodate axial movement. Below are some of the key application areas of splined shafts:

5.1 Automotive Industry

The automotive industry is one of the largest users of splined shafts. They are used in transmissions, drive shafts, steering systems, and differential assemblies. In manual transmissions, splined shafts connect the gear selector to the gears, allowing for smooth gear shifting by accommodating axial movement. In automatic transmissions, splined shafts transmit torque between the torque converter and the planetary gear set. Drive shafts in rear-wheel-drive and four-wheel-drive vehicles also use splined connections to transmit torque from the transmission to the differential, while accommodating the vertical movement of the suspension.

5.2 Industrial Machinery

Splined shafts are widely used in industrial machinery, such as machine tools, conveyors, pumps, and compressors. In machine tools, such as lathes and milling machines, splined shafts transmit torque from the motor to the spindle, ensuring precise rotation and motion control. Conveyor systems use splined shafts to drive the conveyor belts, providing reliable power transfer even under heavy loads. Pumps and compressors use splined shafts to connect the motor to the impeller or rotor, ensuring efficient fluid or gas transfer.

5.3 Aerospace Industry

In the aerospace industry, splined shafts are used in aircraft engines, landing gear systems, and flight control systems. Aircraft engines require high-precision splined shafts to transmit torque from the turbine to the compressor, ensuring efficient engine operation. Landing gear systems use splined shafts to actuate the landing gear, providing reliable and precise movement. Flight control systems use splined shafts to connect the control surfaces (such as ailerons and elevators) to the actuators, ensuring precise control of the aircraft.

5.4 Agricultural Machinery

Agricultural machinery, such as tractors, harvesters, and tillers, relies on splined shafts for power transmission. Tractors use splined shafts in their transmission systems and power take-off (PTO) shafts, which transmit power to attached implements such as plows and mowers. Harvesters use splined shafts to drive the cutting blades and conveyor systems, ensuring efficient harvesting of crops.

5.5 Robotics and Automation

In robotics and automation systems, splined shafts are used in robotic arms, linear actuators, and servo systems. Robotic arms use splined shafts to transmit torque between the joints, ensuring precise and smooth movement. Linear actuators use splined shafts to convert rotational motion into linear motion, providing accurate positioning. Servo systems use splined shafts to connect the servo motor to the load, ensuring precise torque control and position feedback.

6. Emerging Trends and Future Developments

As technology advances, the design and manufacturing of splined shafts are evolving to meet the growing demands of modern mechanical systems. Several emerging trends are shaping the future of splined shafts:

One of the key trends is the adoption of advanced materials and composites. Lightweight and high-strength materials, such as titanium alloys and carbon fiber composites, are being used to reduce the weight of splined shafts while maintaining or improving their strength. This is particularly important in aerospace and automotive applications, where weight reduction is critical for improving fuel efficiency and performance.

Another trend is the use of additive manufacturing (3D printing) for splined shaft production. Additive manufacturing allows for the creation of complex spline profiles and internal geometries that are difficult or impossible to produce using traditional manufacturing processes. This technology also enables rapid prototyping, reducing the time and cost of developing new splined shaft designs. Additionally, additive manufacturing can be used to produce custom splined shafts for low-volume applications, providing greater flexibility in design.

The integration of smart technologies into splined shafts is another emerging trend. Smart splined shafts are equipped with sensors that monitor parameters such as torque, temperature, and wear, providing real-time data on the component’s performance. This data can be used to predict maintenance needs, prevent unexpected failures, and optimize system performance. Smart splined shafts are particularly useful in critical applications such as aerospace and industrial machinery, where downtime can be costly.

Advancements in manufacturing processes are also driving the evolution of splined shafts. For example, precision rolling technologies are being improved to produce splines with higher accuracy and better surface finish, reducing the need for additional finishing operations. Additionally, hybrid manufacturing processes, which combine traditional machining with additive manufacturing, are being developed to leverage the advantages of both technologies, resulting in more efficient and cost-effective production.

Finally, there is a growing focus on sustainability in the manufacturing of splined shafts. Manufacturers are adopting eco-friendly materials and processes, such as using recycled steel and reducing energy consumption during production. Additionally, the design of splined shafts is being optimized for recyclability, ensuring that the components can be easily recycled at the end of their service life.

7. Conclusion

Splined shafts are essential components in mechanical transmission systems, offering efficient torque transfer, precise alignment, and reliable performance. Their unique design, diverse classifications, and versatile manufacturing processes make them suitable for a wide range of applications across automotive, industrial, aerospace, agricultural, and robotics industries. The selection of materials and surface treatments plays a critical role in enhancing their strength, wear resistance, and corrosion resistance, ensuring optimal performance in various operating conditions.

As technology continues to advance, the future of splined shafts looks promising, with emerging trends such as advanced materials, additive manufacturing, smart technologies, and sustainable manufacturing processes driving innovation. These developments will enable the production of lighter, stronger, more efficient, and more reliable splined shafts, meeting the evolving demands of modern mechanical systems.

In conclusion, the splined shaft remains a cornerstone of mechanical engineering, and its continued development will play a vital role in advancing the performance and efficiency of mechanical systems across industries. By understanding the fundamental characteristics, design principles, manufacturing processes, and applications of splined shafts, engineers can make informed decisions when selecting and designing these critical components, ensuring the reliability and efficiency of the systems they power.

« Splined Shaft » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/splined-shaft.html