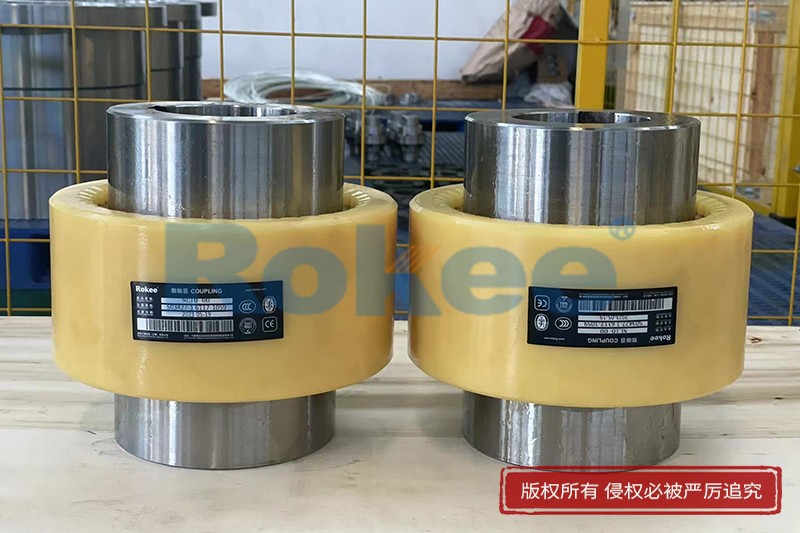

Rubber Gear Coupling

Rokee® is Rubber Gear Coupling Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Rubber Gear Coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of industrial power transmission, couplings serve as critical components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types available, the rubber gear coupling stands out for its unique combination of flexibility, torque-bearing capacity, and durability. This type of coupling integrates the toothed engagement of gear couplings with the elastic properties of rubber elements, making it suitable for a wide array of industrial applications where both power transmission efficiency and shock absorption are essential.

1. Design Principles of Rubber Gear Couplings

The rubber gear coupling is a hybrid design that merges the structural characteristics of gear couplings and elastic couplings. Its core components typically include two toothed hubs, a rubber elastic sleeve (or ring), and sometimes a connecting flange. The design is engineered to leverage the strengths of both rigid and elastic coupling technologies: the toothed hubs ensure efficient torque transmission, while the rubber elements provide flexibility to compensate for misalignment and dampen vibrations.

The toothed hubs are usually made of high-strength metallic materials, with external teeth machined on their outer circumferences. These teeth are designed to mesh with corresponding internal teeth on the rubber elastic sleeve, creating a secure engagement that facilitates torque transfer. The rubber elastic sleeve, which is the key elastic component, is molded to fit precisely between the two toothed hubs. The thickness, shape, and tooth profile of the rubber sleeve are carefully designed to balance torque capacity and flexibility. In some designs, the rubber sleeve may feature reinforcing fibers or layers to enhance its tensile strength and resistance to wear.

Another important design consideration is the accommodation of misalignment. Industrial shafts often experience three types of misalignment: angular misalignment (where the shafts are inclined relative to each other), parallel misalignment (where the shafts are offset axially), and axial misalignment (where the shafts move along their axial direction). The rubber gear coupling is designed to handle moderate levels of all three types of misalignment through the deformation of the rubber elastic sleeve. The flexibility of the rubber allows the toothed engagement to adjust to slight deviations between the shafts without causing excessive stress on the coupling or the connected equipment.

Sealing is also a crucial aspect of the design. To prevent the ingress of dust, moisture, and other contaminants that can damage the rubber elements and the toothed surfaces, rubber gear couplings are often equipped with sealing rings or boots. These seals also help retain any lubricant applied to the toothed surfaces, reducing friction and wear during operation.

2. Working Mechanisms of Rubber Gear Couplings

The fundamental working principle of a rubber gear coupling revolves around the combination of toothed torque transmission and elastic deformation. When torque is applied to one of the shafts, it is transferred to the corresponding toothed hub. The teeth of this hub engage with the internal teeth of the rubber elastic sleeve, causing the sleeve to rotate. The rotational force is then transmitted through the sleeve to the second toothed hub, which in turn drives the connected shaft. This toothed engagement ensures a high level of torque transmission efficiency, as the contact area between the teeth distributes the load evenly.

The rubber elastic sleeve plays a pivotal role in absorbing shocks and vibrations. During industrial operations, equipment such as motors, pumps, and compressors often generate intermittent shocks or continuous vibrations. These vibrations can be detrimental to the connected machinery, leading to increased wear, noise, and even premature failure. The rubber material, with its high elasticity and damping properties, absorbs these vibrations by deforming elastically. When a shock load is applied, the rubber sleeve compresses or stretches momentarily, dissipating the energy of the shock and reducing its impact on the shafts and connected equipment.

In terms of misalignment compensation, the rubber elastic sleeve’s ability to deform allows the coupling to accommodate slight deviations between the shafts. For example, in the case of angular misalignment, the rubber sleeve on one side of the coupling compresses while the other side stretches, enabling the two toothed hubs to maintain engagement without binding. Similarly, parallel misalignment is compensated for by the lateral deformation of the rubber sleeve. This flexibility not only protects the coupling and shafts from excessive stress but also improves the overall stability and lifespan of the entire power transmission system.

3. Material Considerations for Rubber Gear Couplings

The performance and durability of rubber gear couplings are heavily dependent on the materials used for their components. The selection of materials is based on factors such as the operating environment, torque requirements, temperature range, and resistance to chemicals and wear.

For the toothed hubs, high-strength metals are the preferred choice. Carbon steel and alloy steel are commonly used due to their excellent tensile strength, hardness, and wear resistance. These metals are often heat-treated to further enhance their mechanical properties, ensuring that they can withstand the high torque and stresses encountered during operation. In applications where corrosion resistance is a concern, such as in marine or chemical environments, stainless steel may be used for the hubs.

The rubber elastic sleeve is typically made from synthetic rubbers that offer a balance of elasticity, durability, and resistance to environmental factors. Common rubber materials include nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), and polyurethane. Nitrile rubber is widely used due to its good oil resistance and tensile strength, making it suitable for applications where the coupling may come into contact with lubricants or fuels. EPDM rubber excels in resistance to high temperatures, ozone, and weathering, making it ideal for outdoor or high-temperature operating environments. Polyurethane, on the other hand, offers superior wear resistance and load-bearing capacity, making it suitable for heavy-duty applications.

The selection of the rubber material is critical, as it directly affects the coupling’s flexibility, damping capacity, and lifespan. Factors such as the maximum operating temperature, exposure to chemicals, and the magnitude of shock loads must be carefully considered when choosing the rubber for the elastic sleeve. In some cases, rubber compounds may be customized by adding fillers or additives to enhance specific properties, such as flame resistance or electrical insulation.

4. Application Scenarios of Rubber Gear Couplings

Due to their unique combination of torque transmission efficiency, flexibility, and shock absorption, rubber gear couplings find applications in a wide range of industrial sectors. Their ability to accommodate misalignment and dampen vibrations makes them particularly suitable for use in equipment where shaft alignment is difficult to maintain or where shock loads are common.

One of the primary application areas is in the manufacturing industry, where rubber gear couplings are used in machinery such as conveyors, mixers, and extruders. Conveyors, which are used to transport materials in factories and warehouses, often experience slight misalignments between the motor and the conveyor shaft due to continuous operation and material loading. Rubber gear couplings compensate for these misalignments, ensuring smooth operation and reducing wear on the conveyor components. Mixers and extruders, which operate at high speeds and generate significant vibrations, benefit from the shock absorption properties of rubber gear couplings, which help to stabilize the equipment and reduce noise.

The automotive and transportation industry also utilizes rubber gear couplings in various applications. In commercial vehicles such as trucks and buses, rubber gear couplings are used in the power transmission systems to connect the engine to the transmission or the drive axle. They help to absorb the shocks and vibrations generated by the engine and the road surface, improving the comfort of the vehicle and reducing wear on the transmission components. In addition, rubber gear couplings are used in automotive manufacturing equipment, such as assembly lines and robotic arms, where precise torque transmission and vibration damping are essential.

The energy sector, including power plants and renewable energy facilities, is another important application area. In thermal power plants, rubber gear couplings are used in pumps, fans, and turbines to connect the motors to the rotating equipment. These couplings help to accommodate misalignments caused by thermal expansion and contraction of the shafts, ensuring reliable operation of the power generation equipment. In wind energy facilities, rubber gear couplings are used in wind turbines to connect the rotor to the generator. They absorb the vibrations generated by the rotating rotor and compensate for any misalignments, protecting the generator and other critical components from damage.

Other application areas include the mining industry, where rubber gear couplings are used in crushers, grinders, and conveyor systems to handle the heavy torque and shock loads associated with mining operations; the marine industry, where they are used in ship propulsion systems to connect the engine to the propeller shaft, resisting corrosion and absorbing vibrations from the sea; and the agricultural industry, where they are used in farm machinery such as tractors and harvesters to transmit power efficiently while accommodating misalignments caused by uneven terrain.

5. Installation and Maintenance Practices for Rubber Gear Couplings

Proper installation and regular maintenance are essential to ensure the optimal performance and long lifespan of rubber gear couplings. Improper installation can lead to excessive stress, premature wear, and even failure of the coupling, while neglecting maintenance can result in reduced efficiency and potential equipment downtime.

During installation, the first step is to ensure that the shafts are aligned as accurately as possible. While rubber gear couplings can accommodate moderate misalignment, excessive misalignment will put additional stress on the rubber elastic sleeve and the toothed hubs, reducing their lifespan. Shaft alignment should be checked both radially (parallel misalignment) and axially (angular misalignment) using appropriate tools such as dial indicators. The coupling hubs should be securely fastened to the shafts using keys, set screws, or hydraulic fittings, ensuring a tight and secure connection that prevents slippage during operation.

Lubrication is another important aspect of installation and maintenance. The toothed surfaces of the hubs and the rubber elastic sleeve should be lubricated with a suitable lubricant to reduce friction and wear. The type of lubricant should be selected based on the operating temperature and the materials of the coupling components. It is important to avoid using lubricants that can degrade the rubber material; for example, petroleum-based lubricants may damage certain types of rubber, so synthetic lubricants may be preferred in some cases. The lubricant should be applied evenly to all toothed surfaces before assembly, and the coupling should be checked regularly to ensure that the lubricant is still present and effective.

Regular inspection is a key part of maintenance. During operation, the coupling should be inspected periodically for signs of wear, damage, or deterioration. This includes checking the rubber elastic sleeve for cracks, tears, or hardening, which can indicate that the sleeve is reaching the end of its lifespan. The toothed hubs should be inspected for signs of tooth wear, pitting, or corrosion, which can affect the torque transmission efficiency. The seals should also be checked to ensure that they are intact and preventing the ingress of contaminants. If any damage or wear is detected, the affected components should be replaced promptly to avoid further damage to the coupling or the connected equipment.

In addition to regular inspection, the coupling should be maintained according to the manufacturer’s recommendations. This may include periodic replacement of the rubber elastic sleeve, as rubber materials tend to degrade over time due to fatigue, temperature changes, and exposure to environmental factors. The frequency of replacement will depend on the operating conditions, but it is generally recommended to replace the sleeve every 1 to 5 years, depending on the application.

6. Future Development Trends of Rubber Gear Couplings

As industrial technology continues to advance, rubber gear couplings are evolving to meet the changing demands of modern industrial applications. Several key trends are shaping the future development of these couplings, including the use of advanced materials, improved design optimization, and the integration of smart technologies.

One of the main trends is the development and use of advanced rubber materials. Researchers and manufacturers are exploring new rubber compounds that offer enhanced properties such as higher temperature resistance, improved wear resistance, and longer lifespan. For example, nanocomposite rubbers, which incorporate nanoparticles into the rubber matrix, are being developed to improve the mechanical strength and durability of the elastic sleeve. These advanced materials will enable rubber gear couplings to be used in more extreme operating environments, such as high-temperature industrial processes or applications involving harsh chemicals.

Another trend is the use of computer-aided design (CAD) and finite element analysis (FEA) to optimize the design of rubber gear couplings. These tools allow engineers to simulate the performance of the coupling under various operating conditions, such as different torque loads, misalignment angles, and temperature ranges. This enables the design to be refined to maximize torque capacity, minimize stress, and improve the overall efficiency of the coupling. FEA can also be used to predict the lifespan of the rubber elastic sleeve, allowing for more accurate maintenance scheduling and reducing the risk of unexpected failure.

The integration of smart technologies is also emerging as a trend in the development of rubber gear couplings. Smart couplings equipped with sensors can monitor various parameters such as temperature, vibration, and torque in real-time. This data can be transmitted to a central monitoring system, allowing operators to track the performance of the coupling and detect potential issues before they lead to failure. For example, a sensor that detects an increase in vibration can alert operators to a possible misalignment or wear of the rubber sleeve, enabling them to take corrective action promptly. This predictive maintenance approach can significantly reduce equipment downtime and improve the overall efficiency of the industrial process.

In addition, there is a growing focus on sustainability in industrial manufacturing, and this is influencing the development of rubber gear couplings. Manufacturers are exploring ways to reduce the environmental impact of their products, such as using recycled materials for the metallic components or developing rubber compounds that are more environmentally friendly and easier to recycle. There is also a focus on improving the energy efficiency of rubber gear couplings, which can help to reduce the overall energy consumption of industrial processes.

7. Conclusion

Rubber gear couplings are essential components in industrial power transmission systems, offering a unique combination of torque transmission efficiency, flexibility, and shock absorption. Their hybrid design, which integrates toothed gear engagement with elastic rubber elements, makes them suitable for a wide range of applications across various industrial sectors, from manufacturing and automotive to energy and mining. The performance and lifespan of these couplings are heavily dependent on the selection of appropriate materials, proper installation, and regular maintenance.

As industrial technology continues to advance, rubber gear couplings are evolving to meet the demands of more extreme operating environments and more efficient industrial processes. The development of advanced materials, optimized designs using computer-aided tools, and the integration of smart technologies are driving the future of these couplings, making them more durable, efficient, and reliable.

In conclusion, rubber gear couplings play a critical role in ensuring the smooth and reliable operation of industrial equipment. By understanding their design principles, working mechanisms, and maintenance requirements, industrial operators can select and use these couplings effectively, maximizing the performance and lifespan of their power transmission systems. With ongoing advancements in materials and technology, rubber gear couplings are poised to remain an integral part of industrial power transmission for years to come.

« Rubber Gear Coupling » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/rubber-gear-coupling.html