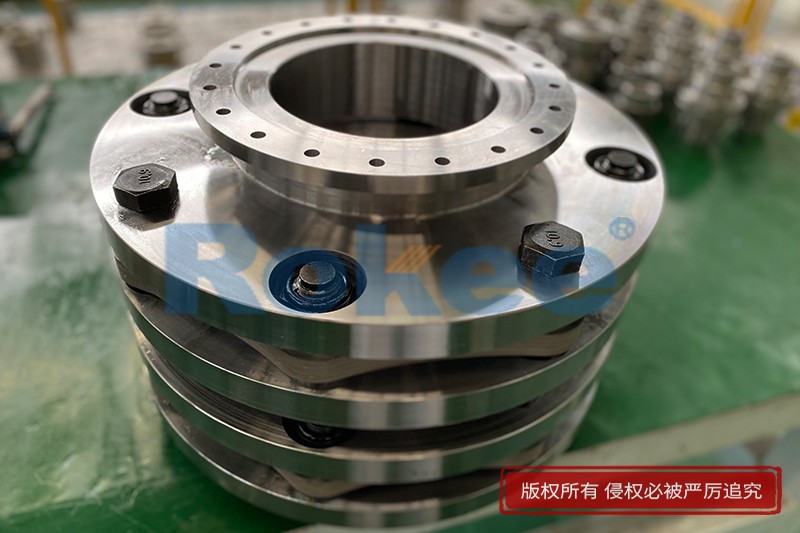

Metal Disc Couplings

Rokee® is Metal Disc Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Metal Disc Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Metal Disc Coupling is a kind of high-performance metal flexible coupling, which compensates axial and angular displacements by the deformation of elastic diaphragm while transferring torque. Metal Disc Coupling features with compact structure, large transmission torque, long service life, maintenance-free, high temperature resistance, acid and alkali resistance, and corrosion resistance, suitable for shafting transmission in high temperature, high speed and corrosive environment.

-

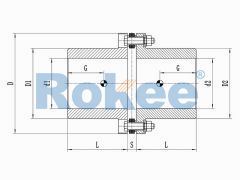

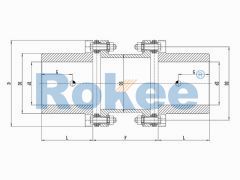

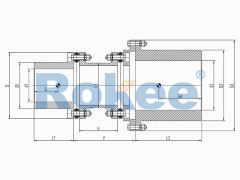

JMI Diaphragm Coupling

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end. -

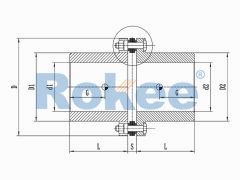

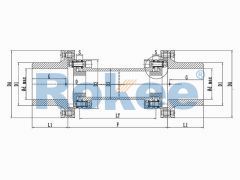

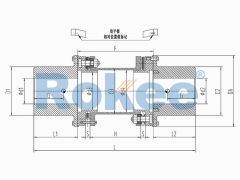

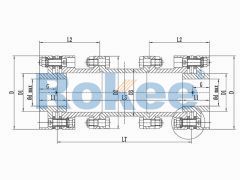

JMIJ Diaphragm Coupling

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end. -

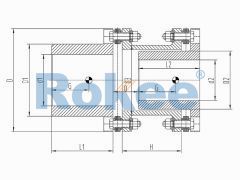

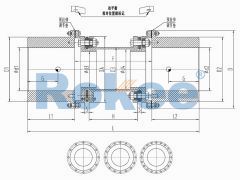

JMII Diaphragm Coupling

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure. -

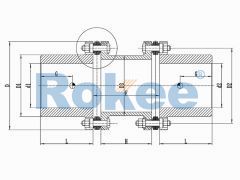

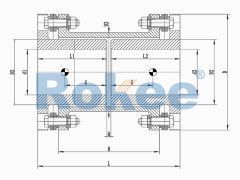

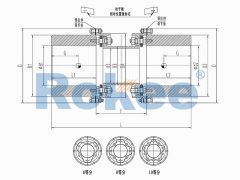

JMIIJ Diaphragm Coupling

JMIIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore. -

RLA Standard Single Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications, but cannot compensate for radial deviation. -

RLM Small Single Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors. -

RLMD Small Double Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm. -

RLAD Standard Double Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications. -

RLAT Super Long Wheelbase Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications. -

RLAR Single Shaft Sleeve Reverse-mounting Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance. -

RLARD Double Shaft Sleeve Reverse-mounting Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller. -

RLAF Large & Small Shaft Mounted Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant. -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications. -

RLQF Flange Type Quick Installation Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm. -

RLQU Improved Flange Quick Installation Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications. -

RLHD High Speed Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.

In the realm of power transmission systems, couplings serve as critical components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating misalignments and absorbing vibrations. Among the diverse range of couplings available, metal disc couplings have emerged as a preferred choice for numerous industrial applications due to their exceptional reliability, high torque capacity, and superior performance under demanding conditions. Unlike flexible couplings that rely on rubber or elastomeric elements, metal disc couplings utilize thin, precision-engineered metal discs to achieve flexibility, offering distinct advantages in terms of temperature resistance, durability, and maintenance requirements.

Fundamental Principles of Metal Disc Couplings

At its core, a metal disc coupling operates on the principle of transmitting torque through a series of thin metal discs that are bolted or clamped between two flanges. The primary function of these discs is to provide flexibility, allowing the coupling to accommodate three types of misalignments commonly encountered in rotating machinery: angular misalignment (where the shafts are inclined relative to each other), parallel misalignment (where the shafts are offset parallel to each other), and axial movement (where the shafts move along their longitudinal axes). The metal discs are designed to flex elastically under the forces generated by these misalignments, ensuring that torque transmission remains efficient while minimizing stress on the connected shafts and bearings.

The design of the metal discs is a critical factor in the performance of the coupling. Typically, the discs are arranged in a stack, with each disc featuring a specific pattern of holes or cutouts that optimize flexibility without compromising torque-carrying capacity. The number of discs in the stack can be adjusted based on the required level of flexibility and torque transmission. When torque is applied, the force is distributed evenly across the discs, ensuring that no single disc bears excessive load. This distributed load-bearing design enhances the overall durability and service life of the coupling.

Another key aspect of the metal disc coupling’s operation is its ability to operate without lubrication. Unlike gear couplings or universal joints, which require regular lubrication to reduce friction and wear, metal disc couplings rely on the inherent properties of the metal discs to withstand rotational forces. This dry-running capability eliminates the risk of lubricant leakage, making them suitable for applications where contamination from lubricants could be detrimental, such as in food processing, pharmaceutical manufacturing, or clean energy systems.

Key Advantages of Metal Disc Couplings

Metal disc couplings offer a multitude of advantages over other types of couplings, making them indispensable in many industrial settings. One of the most significant advantages is their high torque capacity relative to their size. The use of high-strength metal materials allows these couplings to transmit large amounts of torque without excessive bulk, making them ideal for compact machinery where space is at a premium. This high power-to-weight ratio is particularly beneficial in applications such as automotive transmissions, industrial turbines, and heavy-duty pumps.

Temperature resistance is another major benefit of metal disc couplings. Unlike elastomeric couplings, which can degrade at high temperatures (typically above 120°C), metal disc couplings can operate reliably in a wide temperature range, from cryogenic temperatures to over 300°C. This makes them suitable for use in high-temperature applications such as steam turbines, exhaust systems, and industrial furnaces. Additionally, metal discs are not susceptible to ozone degradation, UV damage, or chemical attack from most industrial fluids, further enhancing their durability in harsh environments.

The maintenance-free nature of metal disc couplings is a significant advantage for industrial operators. As mentioned earlier, these couplings do not require lubrication, eliminating the need for regular oil changes, grease applications, and seal replacements. This not only reduces maintenance costs but also minimizes downtime, as the coupling can operate continuously for extended periods without interruption. Furthermore, metal disc couplings have a long service life, with many units lasting for decades under normal operating conditions. When maintenance is required, it typically involves inspecting the discs for signs of wear or fatigue and replacing them if necessary, a process that is relatively simple and straightforward.

Precision torque transmission is another key feature of metal disc couplings. The rigid connection between the shafts, combined with the elastic flexibility of the discs, ensures that torque is transmitted with minimal backlash. Backlash, or the play between connected components, can cause inaccuracies in positioning and speed control, which is particularly problematic in applications such as robotics, CNC machinery, and precision manufacturing. By minimizing backlash, metal disc couplings contribute to improved system accuracy and repeatability.

Finally, metal disc couplings are environmentally friendly compared to couplings that use elastomeric elements. Elastomeric couplings often contain harmful chemicals that can leach into the environment when they degrade or are disposed of. In contrast, metal discs are made from recyclable materials, reducing their environmental impact. Additionally, the absence of lubrication eliminates the risk of oil spills and contamination, making them a sustainable choice for eco-conscious industries.

Material Considerations for Metal Disc Couplings

The performance and durability of a metal disc coupling are heavily dependent on the materials used in its construction. The choice of material for the discs, flanges, and fasteners must be carefully considered based on the application’s requirements, including torque capacity, temperature range, environmental conditions, and corrosion resistance.

The most common material used for the discs is stainless steel, particularly austenitic stainless steels such as 304 and 316. These materials offer excellent corrosion resistance, high tensile strength, and good fatigue resistance, making them suitable for a wide range of industrial applications. 316 stainless steel, in particular, is resistant to saltwater and chemical corrosion, making it ideal for marine and offshore applications. For high-temperature applications, nickel-based alloys such as Inconel or Hastelloy may be used. These alloys can withstand temperatures above 500°C and offer superior creep resistance, making them suitable for use in gas turbines and other high-temperature power generation systems.

The flanges of metal disc couplings are typically made from carbon steel or alloy steel. Carbon steel is a cost-effective option for applications with moderate torque requirements and normal operating temperatures. Alloy steels, such as 4140 or 4340, offer higher strength and hardness, making them suitable for high-torque applications. In corrosive environments, the flanges may be coated with protective materials such as zinc or chrome, or made from stainless steel to prevent rust and degradation.

Fasteners, such as bolts and nuts, are also critical components that must be made from high-strength materials. Grade 8 or 10.9 alloy steel fasteners are commonly used to ensure that the coupling remains securely assembled under high torque and vibration. In corrosive environments, stainless steel or coated fasteners are preferred to prevent seizing and failure.

In addition to the base materials, the manufacturing process also plays a role in the performance of the metal discs. The discs must be precision-cut and finished to ensure uniform thickness and flatness, which is essential for even load distribution. Advanced manufacturing techniques such as laser cutting or water jet cutting are often used to achieve the required precision, ensuring that the discs can flex elastically without cracking or failing prematurely.

Applications of Metal Disc Couplings

Metal disc couplings are used in a wide range of industrial applications, spanning various sectors such as power generation, automotive, aerospace, marine, and manufacturing. Their versatility, reliability, and superior performance make them suitable for both standard and specialized applications.

In the power generation sector, metal disc couplings are widely used in steam turbines, gas turbines, and hydroelectric generators. These applications require couplings that can transmit large amounts of torque, operate at high speeds, and withstand extreme temperatures. Metal disc couplings are ideal for these applications due to their high torque capacity, temperature resistance, and maintenance-free operation. They are also used in wind turbines, where they help to transmit torque from the rotor to the generator while accommodating misalignments caused by wind-induced vibrations.

The automotive industry uses metal disc couplings in high-performance vehicles, racing cars, and electric vehicles. In racing cars, the high torque capacity and low backlash of metal disc couplings are essential for achieving maximum power transfer and precise control. In electric vehicles, the compact size and maintenance-free operation of these couplings make them suitable for use in electric motor drives, where space is limited and reliability is critical.

Aerospace applications also benefit from the use of metal disc couplings. They are used in aircraft engines, auxiliary power units (APUs), and flight control systems. The lightweight design, high strength, and resistance to extreme temperatures make them ideal for aerospace applications, where every pound of weight matters and reliability is non-negotiable. Metal disc couplings are also used in spacecraft propulsion systems, where they must operate in the vacuum and extreme temperature conditions of space.

In the marine industry, metal disc couplings are used in ship propulsion systems, diesel generators, and auxiliary machinery. The corrosion resistance of stainless steel discs makes them suitable for use in saltwater environments, while their high torque capacity ensures efficient power transmission from the engine to the propeller. They are also used in offshore oil and gas platforms, where they must withstand harsh weather conditions and corrosive environments.

In the manufacturing sector, metal disc couplings are used in a wide range of machinery, including pumps, compressors, conveyors, and CNC machines. The precision torque transmission and low backlash of these couplings make them suitable for CNC machines, where accurate positioning and speed control are essential. They are also used in pumps and compressors, where they can accommodate misalignments between the motor and the pump shaft, reducing wear on bearings and extending the service life of the equipment.

Maintenance Practices for Metal Disc Couplings

While metal disc couplings are relatively maintenance-free, regular inspection and proper care are essential to ensure their optimal performance and longevity. The following maintenance practices are recommended for metal disc couplings:

1. Regular Visual Inspection: Visual inspections should be performed periodically to check for signs of wear, fatigue, or damage to the metal discs, flanges, and fasteners. Signs of wear may include cracks in the discs, corrosion on the flanges, or loose fasteners. Inspections should be conducted with the machinery shut down and locked out to ensure safety.

2. Torque Checking of Fasteners: Fasteners may loosen over time due to vibration. Regular torque checking of bolts and nuts is essential to ensure that they remain tight. The torque should be checked using a torque wrench, and any loose fasteners should be tightened to the manufacturer’s recommended torque specification.

3. Alignment Checking: Misalignment between the connected shafts can cause excessive stress on the metal discs, leading to premature failure. Regular alignment checking is recommended, particularly after any maintenance or repair work on the machinery. Alignment can be checked using laser alignment tools, dial indicators, or other precision measuring equipment. If misalignment is detected, it should be corrected immediately.

4. Replacement of Worn or Damaged Discs: If cracks or other signs of fatigue are detected in the metal discs, they should be replaced immediately. Damaged discs can compromise the performance of the coupling and may lead to sudden failure, which can cause damage to the connected machinery. When replacing discs, it is important to use discs that are compatible with the coupling model and made from the same material as the original discs.

5. Cleaning: Regular cleaning of the coupling is recommended to remove dirt, dust, and other debris that may accumulate on the discs and flanges. Cleaning can be done using a soft brush, compressed air, or a mild cleaning solution. Care should be taken not to scratch or damage the metal discs during cleaning.

6. Storage: If a metal disc coupling is not in use, it should be stored in a clean, dry environment to prevent corrosion. The coupling should be stored in its original packaging or covered with a protective covering to keep out dust and moisture. Shafts should be supported to prevent bending, and the coupling should not be subjected to excessive weight or pressure during storage.

Conclusion

Metal disc couplings are essential components in modern power transmission systems, offering a unique combination of reliability, high torque capacity, temperature resistance, and maintenance-free operation. Their ability to accommodate misalignments, transmit torque with minimal backlash, and operate in harsh environments makes them suitable for a wide range of industrial applications, from power generation and aerospace to automotive and manufacturing. The choice of materials, including stainless steel and nickel-based alloys, ensures that these couplings can withstand the demands of even the most challenging applications.

Proper maintenance practices, including regular inspection, torque checking, alignment checking, and replacement of worn components, are essential to ensure the optimal performance and longevity of metal disc couplings. By following these practices, industrial operators can minimize downtime, reduce maintenance costs, and extend the service life of their machinery.

As industrial technology continues to advance, the demand for high-performance power transmission components is expected to grow. Metal disc couplings, with their superior performance and versatility, are well-positioned to meet this demand, playing a critical role in the efficiency and reliability of modern industrial systems. Whether in a steam turbine, a racing car, or a CNC machine, metal disc couplings are a testament to the importance of precision engineering in power transmission.

« Metal Disc Couplings » Post Date: 2023/11/1

URL: https://www.rokeecoupling.com/en/tags/metal-disc-couplings.html

- 2023-11-01Metal Disc Couplings Wholesale

- 2023-11-01Types of Metal Disc Couplings

- 2023-11-01Metal Disc Couplings Supply

- 2023-11-01Metal Disc Couplings Supplier

- 2023-11-01Metal Disc Coupling Diagram

- 2023-11-01Metal Disc Coupling Specifications

- 2023-11-01Metal Disc Coupling Size Chart

- 2023-11-01Metal Disc Coupling Purpose

- 2023-11-01Metal Disc Coupling Price

- 2023-11-01Metal Disc Coupling Parts

- 2023-11-01Metal Disc Couplings Model

- 2023-11-01Metal Disc Couplings Manufacturer

- 2023-11-01Metal Disc Coupling Make

- 2023-11-01Metal Disc Couplings For Sale

- 2023-11-01Metal Disc Couplings Factory

- 2023-11-01Metal Disc Coupling Effect

- 2023-11-01Metal Disc Coupling Drawing

- 2023-11-01Metal Disc Coupling Disadvantages

- 2023-11-01Metal Disc Coupling Design

- 2023-11-01Custom Metal Disc Coupling

- 2023-11-01Metal Disc Coupling Company

- 2023-11-01Metal Disc Coupling Catalogue

- 2023-11-01Metal Disc Coupling Application

- 2023-11-01Metal Disc Coupling Advantages