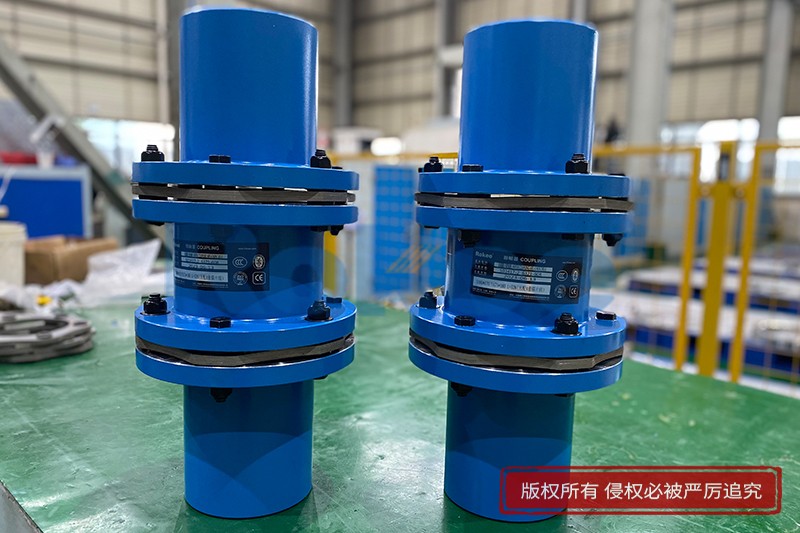

Membrane Couplings

Rokee® is Membrane Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Membrane Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Membrane Coupling is an efficient flexible coupling with no back clearance and free from maintenance. Due to its unique structural design, Membrane Coupling can achieve the perfect delivery of torque. Meanwhile, Membrane Coupling has excellent performances, including large axial and radial compensation ability, low reply feedback force and wide thermal adaptability, etc. With different change design, Membrane Coupling can be applied at most power transmission sites.

-

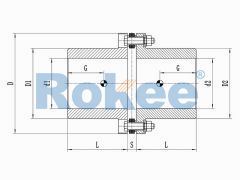

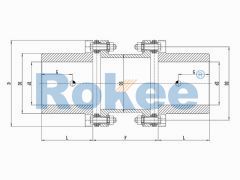

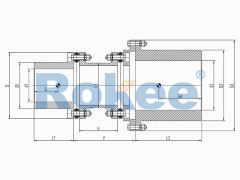

JMI Diaphragm Coupling

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end. -

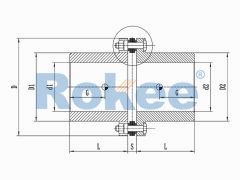

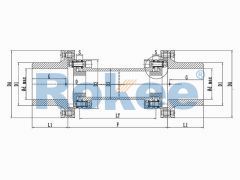

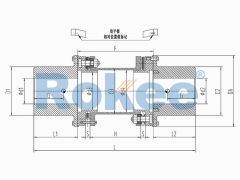

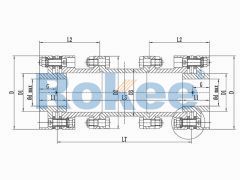

JMIJ Diaphragm Coupling

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end. -

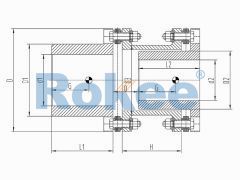

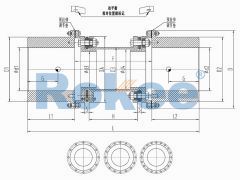

JMII Diaphragm Coupling

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure. -

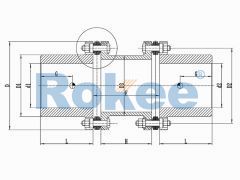

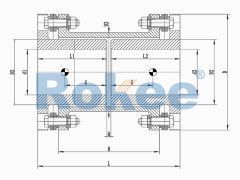

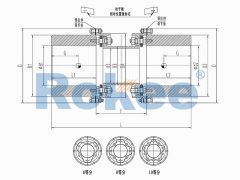

JMIIJ Diaphragm Coupling

JMIIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore. -

RLA Standard Single Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications, but cannot compensate for radial deviation. -

RLM Small Single Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors. -

RLMD Small Double Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm. -

RLAD Standard Double Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications. -

RLAT Super Long Wheelbase Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications. -

RLAR Single Shaft Sleeve Reverse-mounting Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance. -

RLARD Double Shaft Sleeve Reverse-mounting Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller. -

RLAF Large & Small Shaft Mounted Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant. -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications. -

RLQF Flange Type Quick Installation Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm. -

RLQU Improved Flange Quick Installation Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications. -

RLHD High Speed Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.

In the realm of power transmission systems, the search for efficient, reliable, and durable coupling devices has been a persistent pursuit. Among the various types of couplings available today, membrane coupling has emerged as a critical component in numerous industrial applications, owing to its unique combination of flexibility, high torque capacity, and resistance to harsh operating conditions. Unlike traditional rigid couplings that demand precise alignment between connected shafts, membrane coupling utilizes flexible membrane discs to accommodate misalignments, absorb shocks, and transmit torque smoothly.

1. Working Principles of Membrane Coupling

At its core, the primary function of any coupling is to transmit rotational power from a driving shaft (e.g., from a motor or engine) to a driven shaft (e.g., of a pump, compressor, or gearbox). Membrane coupling achieves this by leveraging the elastic deformation of thin, flat membrane discs (or diaphragms) that connect the two halves of the coupling. The fundamental principle that distinguishes membrane coupling from other flexible couplings (such as jaw couplings or universal joints) is its reliance on the bending and torsional flexibility of the membrane elements, rather than sliding or rolling components.

When torque is applied to the driving shaft, the force is transferred through the coupling hubs to the membrane discs. The membranes, which are typically arranged in a stack or as a single piece, deform elastically to accommodate three types of misalignments: angular misalignment (where the shafts are inclined relative to each other), parallel misalignment (where the shafts are offset horizontally), and axial displacement (where the shafts move along their axial direction). This elastic deformation ensures that the torque transmission remains continuous and smooth, while minimizing the transfer of harmful reaction forces to the connected shafts, bearings, and other components. Importantly, the membrane elements do not experience friction during operation, as there are no moving parts in contact with each other. This absence of friction eliminates wear, reduces maintenance requirements, and extends the service life of the coupling.

Another key aspect of the working principle is the distribution of stress across the membrane discs. The design of the membranes—including their thickness, shape, and number of layers—is optimized to ensure that stress is evenly distributed, preventing localized stress concentrations that could lead to premature failure. In high-torque applications, multiple membrane discs are often stacked together to increase the overall torque capacity, as each disc contributes to the load-bearing capability of the coupling.

2. Structural Configurations of Membrane Coupling

Membrane couplings are available in a variety of structural configurations, each tailored to specific application requirements such as torque capacity, misalignment tolerance, space constraints, and operating environment. The two most common configurations are the single membrane coupling and the double membrane coupling, with variations in hub design, membrane shape, and connection methods.

2.1 Single Membrane Coupling

The single membrane coupling consists of a single set of membrane discs (or a single diaphragm) connected between two hubs. One hub is attached to the driving shaft, and the other to the driven shaft. This configuration is relatively simple in design, lightweight, and cost-effective, making it suitable for applications with moderate torque requirements and small to moderate misalignments. Single membrane couplings are commonly used in light-duty industrial equipment such as small pumps, fans, and electric motors. However, their misalignment tolerance is limited compared to double membrane couplings, and they are not ideal for applications where axial displacement is significant.

2.2 Double Membrane Coupling

The double membrane coupling is the most widely used configuration in heavy-duty and precision applications. It features two sets of membrane discs separated by an intermediate shaft (or spacer). The intermediate shaft provides additional flexibility, allowing the coupling to accommodate larger angular and parallel misalignments, as well as greater axial displacement. The double membrane design also helps to balance the forces acting on the coupling, reducing the bending moment exerted on the connected shafts and bearings. This makes double membrane couplings suitable for high-torque applications such as large compressors, turbines, marine propulsion systems, and industrial gearboxes.

In addition to the number of membrane sets, variations in membrane shape also contribute to the performance of the coupling. Common membrane shapes include circular, square, hexagonal, and petal-shaped (or "lobed") designs. Circular membranes are the most basic and are used in general-purpose applications, while petal-shaped membranes offer higher flexibility and torque capacity, making them suitable for high-performance applications. The hubs of membrane couplings are typically made of forged steel or aluminum alloy, and they are connected to the shafts using keyways, splines, or shrink-fit connections, depending on the torque requirements and shaft design.

3. Material Selection for Membrane Coupling

The performance and durability of membrane coupling are heavily dependent on the materials used for the membrane discs and hubs. The selection of materials is guided by a range of factors, including torque capacity, operating temperature, corrosion resistance, fatigue strength, and cost. Each component of the coupling—membranes, hubs, and intermediate shafts—requires materials with specific properties to ensure optimal performance.

3.1 Membrane Disc Materials

The membrane discs are the most critical component of the coupling, as they are responsible for accommodating misalignments and transmitting torque. As such, they must possess high elastic modulus, excellent fatigue strength, and good resistance to wear and corrosion. The most commonly used materials for membrane discs are stainless steel, titanium alloy, and carbon fiber-reinforced polymer (CFRP).

Stainless steel (such as 304, 316, and 17-4 PH) is the preferred material for most industrial applications due to its high strength, corrosion resistance, and cost-effectiveness. 17-4 PH stainless steel, in particular, offers excellent fatigue strength and can withstand moderate to high operating temperatures (up to 300°C), making it suitable for a wide range of applications. Titanium alloy is used in high-performance applications where weight reduction is critical, such as aerospace and marine propulsion systems. Titanium alloy has a high strength-to-weight ratio, excellent corrosion resistance, and can operate at higher temperatures (up to 400°C) than stainless steel. However, its high cost limits its use to specialized applications.

Carbon fiber-reinforced polymer (CFRP) is a relatively new material in membrane coupling design. CFRP offers exceptional strength-to-weight ratio, high flexibility, and excellent corrosion resistance. It is particularly suitable for applications where lightweight design and high fatigue resistance are essential, such as in wind turbines and aerospace systems. However, CFRP is more expensive than metal materials, and its performance can be affected by high temperatures (above 200°C), limiting its use in high-temperature environments.

3.2 Hub and Intermediate Shaft Materials

The hubs and intermediate shafts of membrane coupling are typically made of high-strength metals to withstand the torque and axial forces transmitted during operation. Forged carbon steel (such as 45# steel and 40Cr) is commonly used for hubs in general-purpose applications, as it offers high tensile strength and good machinability. For high-torque and high-temperature applications, alloy steels (such as 35CrMo and 42CrMo) are preferred due to their higher fatigue strength and heat resistance. Aluminum alloy is used in lightweight applications where torque requirements are moderate, such as in small electric motors and pumps, as it offers good machinability and corrosion resistance at a lower weight than steel.

4. Applications of Membrane Coupling Across Industries

The unique combination of flexibility, high torque capacity, low maintenance, and durability makes membrane coupling suitable for a wide range of industrial applications. From general manufacturing to specialized sectors such as aerospace and renewable energy, membrane coupling plays a critical role in ensuring reliable power transmission. Below are some of the key industries where membrane coupling is extensively used:

4.1 Energy and Power Generation

In the energy and power generation sector, membrane coupling is used in a variety of equipment, including steam turbines, gas turbines, hydroelectric generators, and wind turbines. In steam and gas turbines, double membrane couplings are used to connect the turbine shaft to the generator shaft, accommodating the misalignments that occur due to thermal expansion during operation. The high torque capacity and fatigue resistance of membrane coupling make it ideal for these high-power applications, where reliability is critical to minimizing downtime. In wind turbines, lightweight membrane couplings (often made of CFRP) are used to connect the rotor to the gearbox, transmitting the torque generated by the rotor while accommodating the misalignments caused by wind loads and rotor imbalance.

4.2 Oil and Gas Industry

The oil and gas industry operates in some of the harshest environments, including high temperatures, high pressures, and corrosive conditions. Membrane coupling is used in equipment such as centrifugal pumps, compressors, and drilling rigs, where it must withstand these harsh conditions while ensuring reliable power transmission. Stainless steel and titanium alloy membranes are preferred in this industry due to their corrosion resistance, and double membrane configurations are used to accommodate the large misalignments that can occur in offshore and onshore drilling equipment.

4.3 Marine and Shipbuilding

In marine applications, membrane coupling is used in propulsion systems, connecting the ship's engine to the propeller shaft. The marine environment is highly corrosive, with saltwater and humidity posing significant challenges to equipment durability. Titanium alloy and stainless steel membrane couplings are used in this industry to resist corrosion, and their flexibility allows them to accommodate the misalignments that occur due to the ship's movement at sea. Membrane coupling is also used in auxiliary equipment such as pumps and generators on board ships, where reliability is critical for safe operation.

4.4 Manufacturing and Automation

In manufacturing and automation, membrane coupling is used in a wide range of equipment, including conveyors, robots, machine tools, and packaging machinery. In robot arms and automated production lines, precision is critical, and membrane coupling is used to transmit torque accurately while accommodating the small misalignments that can occur between the motor and the robot joint. Single membrane couplings are often used in light-duty manufacturing equipment, while double membrane couplings are used in heavy-duty machine tools that require high torque transmission.

4.5 Aerospace Industry

The aerospace industry demands lightweight, high-performance components that can withstand extreme temperatures and pressures. Membrane coupling is used in aircraft engines, connecting the turbine to the gearbox and other components. Titanium alloy and CFRP membranes are preferred in this industry due to their high strength-to-weight ratio, and the coupling's flexibility allows it to accommodate the thermal expansion and misalignments that occur during engine operation. Membrane coupling is also used in spacecraft propulsion systems, where reliability and durability are critical for mission success.

5. Technological Advancements in Membrane Coupling

Over the past decade, significant advancements in materials science, design engineering, and manufacturing technologies have driven the evolution of membrane coupling. These advancements have focused on improving performance, reducing weight, enhancing durability, and expanding the range of applications for membrane coupling. Below are some of the key technological trends shaping the future of membrane coupling:

5.1 Advanced Material Development

The development of new materials has been a major driver of innovation in membrane coupling design. Researchers are exploring the use of advanced composites, such as graphene-reinforced polymers and ceramic matrix composites (CMCs), to improve the performance of membrane discs. Graphene-reinforced polymers offer higher strength, stiffness, and thermal conductivity than traditional CFRP, making them suitable for high-temperature and high-performance applications. CMCs, which consist of ceramic fibers embedded in a ceramic matrix, can withstand temperatures above 1000°C, opening up new applications for membrane coupling in extreme-temperature environments such as gas turbines and rocket engines.

5.2 Finite Element Analysis (FEA) and Computational Design

The use of finite element analysis (FEA) and computational fluid dynamics (CFD) has revolutionized the design of membrane coupling. FEA allows engineers to simulate the behavior of membrane discs under different operating conditions, including torque, misalignment, and temperature, enabling them to optimize the design for maximum strength and minimum weight. By analyzing stress distribution, fatigue life, and elastic deformation using FEA, engineers can develop membrane coupling with improved performance and durability. CFD is also used to analyze the flow of fluids around the coupling in applications where the coupling is exposed to high-velocity fluids (such as in pumps and turbines), helping to reduce drag and improve efficiency.

5.3 Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, has emerged as a game-changing technology in the production of membrane coupling. Traditional manufacturing methods for membrane discs, such as stamping and machining, are limited in their ability to produce complex shapes. 3D printing allows engineers to create membrane discs with intricate geometries, such as optimized petal shapes and internal stress-relief features, which improve flexibility and torque capacity. Additive manufacturing also enables the production of custom-made coupling components for specialized applications, reducing lead times and costs. In addition, 3D printing of composite materials, such as CFRP, is being explored to further enhance the performance of membrane coupling.

5.4 Smart Monitoring and Condition-Based Maintenance

The integration of smart sensors and monitoring systems into membrane coupling is another key technological advancement. These sensors can measure parameters such as torque, temperature, vibration, and misalignment in real time, providing valuable data on the performance and condition of the coupling. This data can be analyzed using machine learning algorithms to detect early signs of wear, fatigue, or failure, enabling condition-based maintenance. Condition-based maintenance reduces downtime and maintenance costs by allowing maintenance to be performed only when necessary, rather than on a fixed schedule. Smart monitoring systems are particularly useful in critical applications such as power generation, oil and gas, and aerospace, where unplanned downtime can have severe consequences.

6. Challenges and Future Outlook

Despite the numerous advantages and technological advancements, membrane coupling still faces several challenges. One of the main challenges is the high cost of advanced materials such as titanium alloy and CFRP, which limits their use in cost-sensitive applications. Another challenge is the limited temperature range of some materials, particularly polymers and composites, which restricts their use in high-temperature environments. Additionally, the design and manufacturing of complex membrane geometries require specialized expertise and equipment, which can be a barrier for small and medium-sized manufacturers.

Looking to the future, the demand for membrane coupling is expected to grow, driven by the expansion of industries such as renewable energy, aerospace, and electric vehicles. The development of low-cost, high-performance composite materials will likely reduce the cost of advanced membrane coupling, making them more accessible for a wider range of applications. Further advancements in additive manufacturing will enable the production of even more complex and optimized designs, improving performance and reducing weight. The integration of smart monitoring systems will also become more widespread, making membrane coupling more reliable and efficient.

In conclusion, membrane coupling has established itself as a critical component in power transmission systems, offering a unique combination of flexibility, high torque capacity, and durability. Its diverse range of applications across industries such as energy, oil and gas, marine, and aerospace highlights its versatility and importance. With ongoing advancements in materials science, design engineering, and manufacturing technologies, membrane coupling is poised to become even more efficient, reliable, and cost-effective in the years to come. As industries continue to demand higher performance and greater efficiency from their equipment, membrane coupling will remain at the forefront of power transmission technology.

« Membrane Couplings » Post Date: 2023/11/15

URL: https://www.rokeecoupling.com/en/tags/membrane-couplings.html

- 2025-02-25Efficiency of Flexible Membrane Coupling

- 2025-02-25Procurement of Flexible Membrane Coupling

- 2024-10-07Size Calculation of Flexible Membrane Coupling

- 2024-10-07Schematic Diagram of Flexible Membrane Couplings

- 2024-09-27Flexible Membrane Couplings For Sale

- 2024-09-27Flexible Membrane Coupling Models

- 2024-09-27Components of Flexible Membrane Coupling

- 2024-09-20Flexible Membrane Coupling Standard Sizes

- 2024-09-20Parts of Flexible Membrane Coupling

- 2024-09-06Misalignment Tolerance of Flexible Membrane Coupling

- 2024-09-06Function of Flexible Membrane Couplings

- 2024-09-06Gap Chart of Flexible Membrane Coupling

- 2024-08-30Material of Flexible Membrane Coupling

- 2024-08-30Flexible Membrane Coupling Price

- 2024-08-30Coaxiality of Flexible Membrane Coupling

- 2024-08-23Types of Flexible Membrane Coupling

- 2024-08-23Uses of Flexible Membrane Coupling

- 2024-08-23Working Principle of Flexible Membrane Coupling

- 2024-08-17High Performance Flexible Membrane Couplings

- 2024-08-17High Quality Flexible Membrane Couplings

- 2024-08-17Installation of Flexible Membrane Coupling

- 2024-08-17Lubrication of Flexible Membrane Coupling

- 2024-08-17Machine Drawing of Flexible Membrane Couplings

- 2024-08-07Classification of Flexible Membrane Couplings

- 2024-08-07Application of Flexible Membrane Coupling

- 2024-08-07Angle of Flexible Membrane Coupling

- 2024-08-07Alignment of Flexible Membrane Coupling

- 2024-08-073D Model of Flexible Membrane Coupling

- 2024-07-25Maintenance of Flexible Membrane Coupling

- 2024-07-25Flexible Membrane Couplings Manufacturer

- 2024-07-25Flexible Membrane Coupling Calculation

- 2024-07-25Catalogue of Flexible Membrane Couplings

- 2024-07-18Supply of Flexible Membrane Couplings

- 2024-07-18Purpose of Flexible Membrane Couplings

- 2024-07-18Grease of Flexible Membrane Coupling

- 2024-07-18Flexible Membrane Coupling Sales

- 2024-07-18Disadvantages of Flexible Membrane Coupling

- 2024-04-15Expansion Sleeve Type Membrane Couplings

- 2024-04-15Extra Long Wheelbase Membrane Couplings

- 2024-04-15Flange Type Membrane Couplings

- 2024-04-15Flexibility Membrane Couplings

- 2024-04-15Heavy Load Membrane Couplings

- 2024-04-15Heavy Membrane Couplings

- 2024-04-15High Speed Membrane Couplings

- 2024-04-15Hydraulic Pressure Membrane Couplings

- 2024-04-15Industry Membrane Couplings

- 2024-04-15Integrated Membrane Couplings

- 2024-04-15Large And Small Axis Installation Membrane Coupling

- 2024-04-15Locking Disc Membrane Couplings

- 2024-04-15One-way Membrane Couplings

- 2024-04-15Quick Fit Type Membrane Couplings

- 2024-04-15Reverse Installation Of Shaft Sleeve Membrane Coupling

- 2024-04-15Servo Membrane Couplings

- 2024-04-15Single Section Membrane Couplings

- 2024-04-15Single Shaft Sleeve Membrane Couplings

- 2024-04-15Small-scale Membrane Couplings

- 2024-04-15Stainless Steel Membrane Couplings

- 2024-04-15Standard Membrane Couplings

- 2024-04-15Steel Rolling Membrane Couplings

- 2024-04-15Stepped Style Membrane Couplings

- 2024-04-15Two-way Membrane Couplings

- 2023-12-26Metal Membrane Couplings

- 2023-12-26Membrane Coupling With Intermediate Shaft

- 2023-12-26Membrane Coupling With Intermediate Section

- 2023-12-26Membrane Coupling With Counterbore

- 2023-12-26Membrane Coupling For Water Pump

- 2023-12-26Membrane Coupling For Vacuum Pump

- 2023-12-26Membrane Coupling For Support Seat

- 2023-12-26Membrane Coupling For Steam Turbine

- 2023-12-26Membrane Coupling For Pumps

- 2023-12-26Membrane Coupling For Paper Making Machinery

- 2023-12-26Membrane Coupling For Paper Making Equipment

- 2023-12-26Membrane Coupling For Induced Draft Fan

- 2023-12-26Membrane Coupling For Gearbox

- 2023-12-26Membrane Coupling For Front Pump

- 2023-12-26Membrane Coupling For Electrical Machinery

- 2023-12-26Membrane Coupling For Compressor

- 2023-12-26Membrane Coupling For Circulating Pump

- 2023-12-26Membrane Coupling For Booster Fan

- 2023-12-26Membrane Coupling For Ball Mill

- 2023-12-26Expansion Sleeve Membrane Couplings

- 2023-12-26Double Section Membrane Couplings

- 2023-12-26Double Axis Sleeve Membrane Couplings

- 2023-12-26Dilated Joint Membrane Couplings

- 2023-12-26Currency Membrane Couplings

- 2023-12-26Connecting Rod Type Membrane Couplings

- 2023-12-26Conical Sleeve Type Membrane Couplings

- 2023-12-26Automation Membrane Couplings

- 2023-11-28Flexible Laminated Membrane Coupling Working Principle

- 2023-11-28Flexible Laminated Membrane Coupling Tagging

- 2023-11-28Flexible Laminated Membrane Couplings Supply

- 2023-11-28Flexible Laminated Membrane Coupling Specifications

- 2023-11-28Flexible Laminated Membrane Coupling Procurement

- 2023-11-28Price of Flexible Laminated Membrane Couplings

- 2023-11-28Parts of Flexible Laminated Membrane Couplings

- 2023-11-28Flexible Laminated Membrane Couplings Manufacturing Enterprise

- 2023-11-22Flexible Laminated Membrane Couplings Manufacturer

- 2023-11-22Flexible Laminated Membrane Coupling Function

- 2023-11-20Membrane Coupling Working Principle

- 2023-11-20Membrane Couplings Wholesale

- 2023-11-20Uses of Membrane Couplings

- 2023-11-20Membrane Coupling Torque

- 2023-11-20Membrane Coupling Tagging

- 2023-11-20Membrane Couplings Supply

- 2023-11-20Membrane Coupling Structural Diagram

- 2023-11-20Membrane Coupling Stiffness

- 2023-11-20Membrane Coupling Specifications

- 2023-11-20Membrane Coupling Size Chart

- 2023-11-20Membrane Coupling Size Calculation

- 2023-11-20Purpose of Membrane Couplings

- 2023-11-20Membrane Coupling Price

- 2023-11-20Membrane Coupling Parts

- 2023-11-20Models of Membrane Couplings

- 2023-11-20Membrane Coupling Misalignment Tolerance

- 2023-11-20Material of Membrane Couplings

- 2023-11-20Membrane Couplings Manufacturer

- 2023-11-20Membrane Coupling Maintenance

- 2023-11-20Membrane Coupling Lubrication

- 2023-11-20Membrane Coupling Grease

- 2023-11-20Membrane Coupling Gap Chart

- 2023-11-20Membrane Coupling Function

- 2023-11-16Flexible Laminated Membrane Coupling Design

- 2023-11-16Flexible Laminated Membrane Couplings Company

- 2023-11-16Flexible Laminated Membrane Couplings Factory

- 2023-11-16Flexible Laminated Membrane Couplings Supplier

- 2023-11-16Membrane Couplings Supplier

- 2023-11-16Membrane Coupling Sales

- 2023-11-16Membrane Coupling Procurement

- 2023-11-16Membrane Coupling Manufacturing Enterprise

- 2023-11-16Membrane Coupling Machine Drawing

- 2023-11-16Membrane Coupling Installation

- 2023-11-15Membrane Couplings For Sale

- 2023-11-15Membrane Couplings Factory

- 2023-11-15Membrane Coupling Exploded View

- 2023-11-15Membrane Coupling Engineering Drawing

- 2023-11-15Efficiency of Membrane Couplings

- 2023-11-15Disadvantages of Membrane Couplings

- 2023-11-15Membrane Coupling Design

- 2023-11-15Customized Membrane Coupling

- 2023-11-15Components of Membrane Coupling

- 2023-11-15Membrane Coupling Company

- 2023-11-15Classification of Membrane Couplings

- 2023-11-15Membrane Coupling Catalogue

- 2023-11-15Membrane Coupling Calculation

- 2023-11-15Membrane Coupling Brands

- 2023-11-15Membrane Coupling Assembly Drawing

- 2023-11-15Membrane Coupling Applications

- 2023-11-15Membrane Coupling Alignment

- 2023-11-15Membrane Coupling Advantages

- 2023-11-15Membrane Coupling 3D Model

- 2023-11-11Flexible Laminated Membrane Coupling Applications

- 2023-11-11Disadvantages of Flexible Laminated Membrane Couplings

- 2023-11-11Flexible Laminated Membrane Coupling Size Calculation

- 2023-11-10Flexible Laminated Membrane Coupling Size Chart

- 2023-11-10Flexible Laminated Membrane Coupling Catalogue

- 2023-11-10Flexible Laminated Membrane Coupling Drawing

- 2023-11-10Flexible Laminated Membrane Coupling Purpose

- 2023-11-09Models of Flexible Laminated Membrane Couplings

- 2023-11-09Flexible Laminated Membrane Couplings Wholesale

- 2023-11-09Types of Flexible Laminated Membrane Couplings

- 2023-11-09Flexible Laminated Membrane Coupling Diagram

- 2023-11-09Flexible Laminated Membrane Couplings Seller

- 2023-11-09Customized Flexible Laminated Membrane Coupling

- 2023-11-09Flexible Laminated Membrane Coupling Advantages

- 2023-10-20Membrane Coupling Types

- 2023-10-20Membrane Coupling Drawing

- 2023-10-20Flexible Membrane Couplings

- 2023-10-20Disc Membrane Couplings