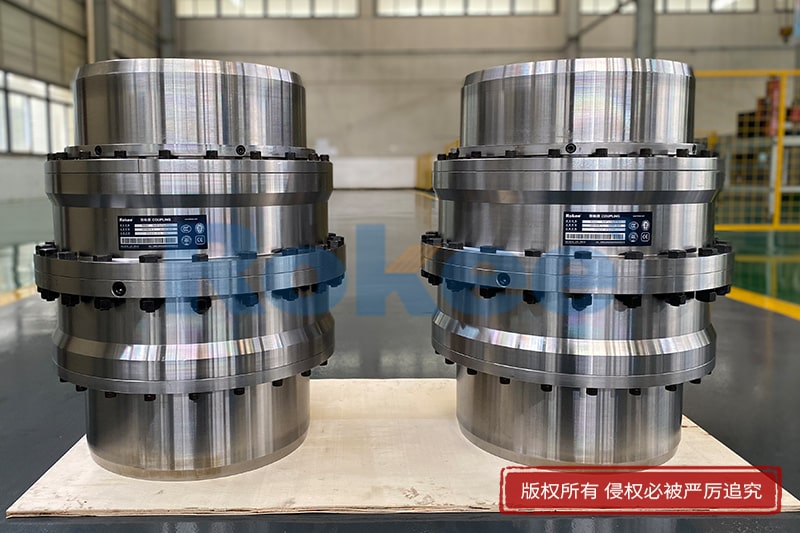

High Performance Couplings

Rokee® is High Performance Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® High Performance Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of mechanical power transmission, couplings serve as the critical interface between rotating components, enabling the seamless transfer of torque while accommodating misalignments, dampening vibrations, and protecting downstream equipment. Among the diverse range of coupling solutions available, high performance couplings stand out for their ability to operate reliably under extreme conditions—including high speeds, heavy loads, and harsh environmental exposures—that would compromise the functionality of standard couplings.

At its core, a high performance coupling is defined by its capacity to transmit high levels of torque with minimal energy loss, maintain precision alignment under dynamic loads, and withstand prolonged exposure to adverse operating conditions such as extreme temperatures, corrosive environments, and high levels of vibration. Unlike standard couplings, which are typically designed for moderate load and speed applications, high performance variants are engineered with advanced materials and sophisticated design features to meet the rigorous demands of modern industrial systems. These couplings play a pivotal role in ensuring the integrity of power transmission systems, as any failure or inefficiency in the coupling can lead to costly downtime, equipment damage, and compromised safety. As such, the design and selection of high performance couplings require a comprehensive understanding of the operational requirements of the system, including torque capacity, speed limits, misalignment tolerance, and environmental constraints.

Fundamental Principles of High Performance Couplings

The primary function of any coupling is to connect two rotating shafts—such as those from a motor and a pump, or a turbine and a generator—and transmit torque between them. High performance couplings build on this basic function by incorporating features that address the challenges of high-demand applications. One of the key principles guiding their design is the balance between torque transmission efficiency and flexibility. While rigid couplings offer high torque transmission efficiency, they lack the ability to accommodate misalignments, which can lead to excessive wear on bearings and shafts. In contrast, flexible high performance couplings are designed to absorb angular, parallel, and axial misalignments, reducing stress on rotating components and extending their service life.

Another fundamental principle is vibration dampening. High-speed rotating systems generate vibrations that can propagate through the power transmission chain, causing noise, reducing equipment precision, and accelerating component fatigue. High performance couplings often integrate elastomeric elements, spring mechanisms, or fluid-filled chambers to dampen these vibrations, minimizing their impact on the system. This vibration dampening capability is particularly critical in applications such as aerospace propulsion systems, high-speed machining centers, and industrial turbines, where even small vibrations can lead to significant performance issues or catastrophic failures.

Thermal management is also a key consideration in the design of high performance couplings. Under high load and speed conditions, couplings generate heat due to friction between moving parts. If not properly managed, this heat can degrade materials, reduce lubricant effectiveness, and compromise the coupling’s structural integrity. High performance couplings are engineered with heat-dissipating features such as optimized surface geometries, cooling fins, or specialized lubricants that can withstand high temperatures. Additionally, the materials used in their construction are selected for their high thermal stability, ensuring that the coupling maintains its performance characteristics even under extreme temperature fluctuations.

Key Design Characteristics of High Performance Couplings

The design of high performance couplings is a complex process that involves balancing multiple performance parameters to meet the specific requirements of the application. Several key design characteristics distinguish these couplings from standard alternatives, including material selection, flexibility mechanisms, torque capacity optimization, and precision manufacturing.

Material selection is perhaps the most critical design decision for high performance couplings. The materials must possess high strength-to-weight ratios, excellent fatigue resistance, and superior resistance to corrosion, wear, and extreme temperatures. Common materials used in high performance couplings include alloy steels, titanium alloys, carbon fiber composites, and advanced polymers. Alloy steels are favored for their high torque capacity and durability, making them ideal for heavy-duty industrial applications. Titanium alloys offer a combination of high strength and low weight, making them suitable for aerospace and automotive applications where weight reduction is a priority. Carbon fiber composites, meanwhile, provide exceptional stiffness, corrosion resistance, and fatigue performance, making them ideal for high-speed applications such as wind turbines and racing engines. Advanced polymers, such as polyurethane and silicone, are often used in flexible elements due to their excellent elasticity, vibration dampening capabilities, and resistance to chemicals and abrasion.

Flexibility mechanisms are another key design feature of high performance couplings. These mechanisms enable the coupling to accommodate misalignments while maintaining efficient torque transmission. Common flexibility mechanisms include elastomeric sleeves, jaw couplings with rubber inserts, diaphragm couplings, and universal joints. Elastomeric couplings use rubber or polymer elements to absorb misalignments and vibrations, making them suitable for applications with moderate misalignment requirements. Diaphragm couplings, on the other hand, use thin, flexible metal diaphragms to transmit torque while accommodating angular and axial misalignments. These couplings are particularly well-suited for high-speed applications due to their high precision and minimal backlash. Universal joints, which consist of two yokes connected by a cross shaft, are used to accommodate large angular misalignments, making them ideal for applications such as automotive drivetrains and agricultural machinery.

Torque capacity optimization is also a critical design consideration. High performance couplings are engineered to transmit the maximum possible torque without exceeding their structural limits. This involves optimizing the cross-sectional geometry of the coupling components, selecting materials with high tensile and shear strength, and ensuring that the coupling is properly balanced to minimize stress concentrations. Additionally, many high performance couplings are designed with overload protection features, such as shear pins or friction clutches, which prevent damage to the coupling and downstream equipment in the event of a torque spike.

Precision manufacturing is essential for ensuring the performance and reliability of high performance couplings. These components require tight tolerances to maintain alignment accuracy, minimize backlash, and ensure smooth operation at high speeds. Advanced manufacturing techniques such as CNC machining, 3D printing, and laser cutting are used to produce coupling components with precise dimensions and surface finishes. CNC machining enables the production of complex geometries with high accuracy, while 3D printing allows for the creation of lightweight, optimized designs that would be difficult or impossible to produce with traditional manufacturing methods. Laser cutting, meanwhile, is used to create precise cuts in thin materials such as diaphragm sheets, ensuring consistent flexibility and torque transmission performance.

Applications of High Performance Couplings Across Industries

High performance couplings find applications in a wide range of industries, where their ability to operate under extreme conditions makes them indispensable. From aerospace and automotive to energy and manufacturing, these couplings play a critical role in ensuring the reliability and efficiency of power transmission systems. Below are some of the key industries where high performance couplings are commonly used, along with specific application examples.

Aerospace Industry

The aerospace industry demands components that are lightweight, high-strength, and capable of withstanding extreme temperatures and vibrations. High performance couplings are used in a variety of aerospace applications, including jet engines, auxiliary power units (APUs), and flight control systems. In jet engines, couplings connect the turbine to the compressor, transmitting high levels of torque at speeds exceeding 10,000 rpm. These couplings must be lightweight to minimize fuel consumption and durable enough to withstand the high temperatures and vibrations generated by the engine. Titanium and carbon fiber composite couplings are commonly used in these applications due to their high strength-to-weight ratios and excellent thermal stability. In flight control systems, precision couplings are used to transmit torque between motors and control surfaces, ensuring accurate and responsive control of the aircraft.

Automotive Industry

In the automotive industry, high performance couplings are used in high-performance vehicles, racing cars, and electric vehicles (EVs). Racing cars require couplings that can transmit high torque at high speeds while withstanding the rigors of competitive racing, including extreme acceleration, deceleration, and cornering forces. High-performance automotive couplings are often made from lightweight materials such as titanium and carbon fiber, and feature advanced flexibility mechanisms to accommodate misalignments caused by chassis flex. In EVs, couplings are used to connect the electric motor to the drivetrain, transmitting torque efficiently while minimizing energy loss. EV couplings must be compact, lightweight, and capable of operating at high speeds, as electric motors typically generate high torque at low speeds. Additionally, these couplings must be designed to dampen vibrations, ensuring a smooth and quiet ride.

Energy Industry

The energy industry, which includes power generation, oil and gas, and renewable energy, relies heavily on high performance couplings to ensure the reliable operation of critical equipment. In power generation plants, couplings connect turbines to generators, transmitting large amounts of torque at high speeds. These couplings must be capable of withstanding the high temperatures and vibrations generated by the turbine, and must be designed to accommodate misalignments caused by thermal expansion and contraction. High-performance steel and alloy couplings are commonly used in these applications due to their high torque capacity and durability. In the oil and gas industry, couplings are used in drilling rigs, pumps, and compressors, where they must operate in harsh environments characterized by high pressure, corrosive fluids, and extreme temperatures. Corrosion-resistant couplings made from stainless steel or nickel alloys are used in these applications to ensure long-term reliability. In renewable energy systems such as wind turbines, couplings connect the rotor to the gearbox or generator, transmitting torque from the rotating blades to the power generation components. These couplings must be lightweight, durable, and capable of accommodating misalignments caused by wind loads and rotor imbalance. Carbon fiber composite couplings are increasingly being used in wind turbines due to their high strength-to-weight ratio and excellent fatigue resistance.

Manufacturing Industry

The manufacturing industry uses high performance couplings in a variety of equipment, including machining centers, robotics, and conveyor systems. Machining centers require precision couplings to transmit torque from the spindle motor to the cutting tool, ensuring accurate and efficient material removal. High-speed machining centers, in particular, require couplings with minimal backlash and high rotational accuracy to maintain part quality. Diaphragm couplings and bellows couplings are commonly used in these applications due to their high precision and rigidity. In robotics, couplings are used to connect motors to robotic arms and end effectors, enabling precise and responsive movement. These couplings must be lightweight and compact to minimize the inertia of the robotic system, while still providing sufficient torque capacity. Flexible couplings with elastomeric elements are often used in robotics to dampen vibrations and accommodate minor misalignments. In conveyor systems, couplings connect motors to rollers, transmitting torque to move materials along the conveyor. These couplings must be durable and capable of withstanding the constant start-stop cycles and varying loads associated with conveyor operation. Gear couplings and grid couplings are commonly used in conveyor systems due to their high torque capacity and ability to accommodate misalignments.

Technological Advancements in High Performance Couplings

The field of high performance couplings is constantly evolving, driven by advances in materials science, manufacturing technology, and digitalization. These advancements are enabling the development of couplings that are more efficient, reliable, and versatile than ever before. Below are some of the key technological trends shaping the evolution of high performance couplings.

One of the most significant advancements is the development of advanced composite materials. Carbon fiber composites, in particular, have revolutionized the design of high performance couplings, offering a combination of high strength, low weight, and excellent fatigue resistance. These materials are being used to produce couplings that are up to 50% lighter than traditional steel couplings, while maintaining the same or higher torque capacity. Additionally, composite materials are inherently corrosion-resistant, making them ideal for use in harsh environments. Researchers are also exploring the use of nanocomposites—materials reinforced with nanoparticles—to further enhance the mechanical properties of couplings. Nanocomposites offer improved strength, stiffness, and wear resistance compared to traditional composites, opening up new possibilities for high performance coupling design.

Additive manufacturing, or 3D printing, is another technological advancement that is transforming the production of high performance couplings. This manufacturing method enables the creation of complex geometries that would be difficult or impossible to produce with traditional machining techniques. For example, 3D printing can be used to create couplings with internal lattice structures that reduce weight while maintaining strength, or with integrated flexibility mechanisms that eliminate the need for separate components. Additionally, additive manufacturing allows for the production of custom couplings tailored to specific application requirements, reducing lead times and enabling faster prototyping. As additive manufacturing technology continues to advance, it is expected to become more widely used in the production of high performance couplings, particularly for low-volume, high-value applications.

Digitalization and smart technology are also playing an increasingly important role in the evolution of high performance couplings. Smart couplings, equipped with sensors and wireless communication capabilities, are being developed to monitor key performance parameters such as torque, temperature, vibration, and misalignment in real-time. These sensors collect data that can be analyzed to detect potential issues before they lead to failure, enabling predictive maintenance and reducing downtime. For example, a smart coupling in a wind turbine can monitor vibration levels and alert maintenance personnel if the vibration exceeds a threshold, indicating a potential misalignment or bearing failure. Additionally, digital twin technology is being used to create virtual models of couplings, allowing engineers to simulate their performance under different operating conditions and optimize their design. Digital twins can also be used to monitor the performance of physical couplings in real-time, enabling continuous optimization of the power transmission system.

Another key advancement is the development of lubrication-free couplings. Traditional couplings often require regular lubrication to reduce friction and wear, which can be time-consuming and costly. Lubrication-free couplings, which use self-lubricating materials or dry-running components, eliminate the need for regular maintenance, reducing operational costs and improving reliability. These couplings are particularly well-suited for applications where lubrication is difficult or impractical, such as in cleanroom environments, food processing facilities, or space applications.

Challenges and Future Outlook

Despite the significant advancements in high performance coupling technology, there are still several challenges that need to be addressed. One of the main challenges is the high cost of advanced materials and manufacturing techniques. Carbon fiber composites, titanium alloys, and additive manufacturing are all more expensive than traditional materials and methods, making high performance couplings prohibitively expensive for some applications. Researchers and manufacturers are working to reduce these costs by developing new, more cost-effective materials and optimizing manufacturing processes. For example, the development of recycled carbon fiber composites could help reduce the cost of composite couplings, making them more accessible for a wider range of applications.

Another challenge is the need for improved design tools and simulation capabilities. The design of high performance couplings requires a comprehensive understanding of the complex interactions between materials, geometry, and operating conditions. While advances in finite element analysis (FEA) and computational fluid dynamics (CFD) have improved the ability to simulate coupling performance, there is still a need for more accurate and efficient simulation tools. These tools would enable engineers to optimize coupling designs more quickly and accurately, reducing the need for physical testing and accelerating the development process.

Looking to the future, the demand for high performance couplings is expected to grow as industries continue to push the boundaries of performance and efficiency. The increasing adoption of electric vehicles, renewable energy systems, and advanced manufacturing technologies will drive the need for couplings that are lighter, more efficient, and more reliable. Additionally, the growing focus on sustainability will lead to the development of more environmentally friendly couplings, such as those made from recycled materials or designed for easy recycling at the end of their service life.

In conclusion, high performance couplings are critical components in modern power transmission systems, enabling the reliable and efficient operation of equipment across a wide range of industries. Their unique design characteristics, including advanced materials, sophisticated flexibility mechanisms, and precision manufacturing, make them capable of operating under extreme conditions that would compromise standard couplings. As technological advancements continue to drive innovation in materials science, manufacturing, and digitalization, high performance couplings will become even more efficient, reliable, and versatile. By addressing the current challenges of cost and design complexity, manufacturers can make high performance couplings more accessible, enabling their widespread adoption in new applications and contributing to the overall efficiency and sustainability of industrial systems.

« High Performance Couplings » Post Date: 2023/10/20

URL: https://www.rokeecoupling.com/en/tags/high-performance-couplings.html