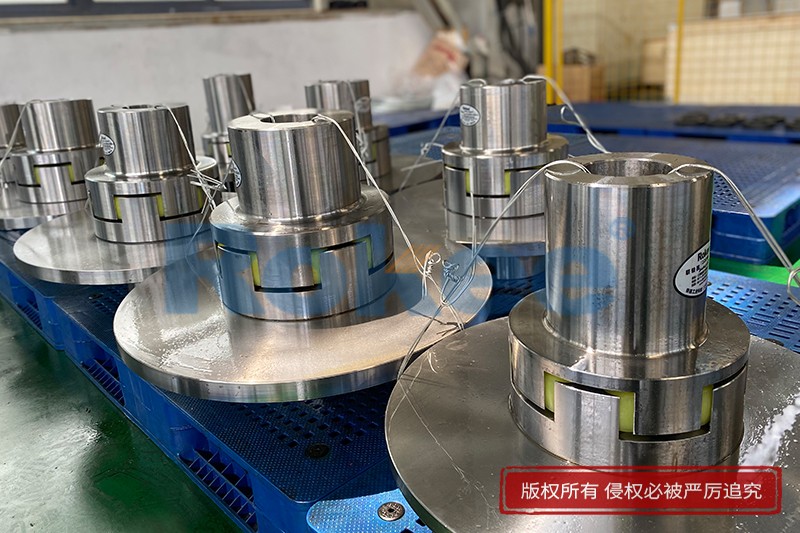

Flexible Jaw Couplings

Rokee® is Flexible Jaw Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Flexible Jaw Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

In the realm of mechanical power transmission, couplings serve as the critical link between rotating shafts, enabling the seamless transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types available, flexible jaw couplings stand out for their simplicity, reliability, and cost-effectiveness, making them a preferred choice in numerous industrial and commercial applications.

-

LM Plum-shaped Flexible Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings. -

LMD Plum-shaped Flexible Coupling

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMS Plum-shaped Flexible Coupling

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer. -

LMZ-I Plum-shaped Flexible Coupling

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required. -

LMZ-II Plum-shaped Flexible Coupling

LMZ-II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required. -

LMPK Plum-shaped Flexible Coupling

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.

1. Definition and Basic Design of Flexible Jaw Couplings

A flexible jaw coupling is a type of mechanical coupling designed to connect two shafts in a power transmission system, facilitating torque transfer while compensating for angular, parallel, and axial misalignments. Unlike rigid couplings, which require near-perfect alignment between shafts, flexible jaw couplings incorporate an elastic element that absorbs misalignments and dampens vibrations, thereby reducing stress on the connected shafts, bearings, and other components.

The basic structure of a flexible jaw coupling consists of three primary components: two jaw-shaped hubs and an elastomeric insert (often referred to as a spider or element). The hubs are typically machined with a series of evenly spaced, curved or straight jaws that interlock with the corresponding features of the elastomeric insert. Each hub is designed to mount onto a shaft via a keyway, set screw, or compression fitting, ensuring a secure connection that minimizes slippage during operation. The elastomeric insert, which sits between the two hubs, acts as the flexible medium that allows for misalignment and vibration absorption.

The number and shape of the jaws can vary depending on the specific application requirements. Common jaw configurations include three, four, or six jaws, with curved jaws being more prevalent due to their ability to distribute torque evenly and reduce stress concentrations. The elastomeric insert is usually designed with a complementary shape to the jaws, ensuring a tight fit that enables efficient torque transfer. Additionally, some designs feature recessed areas or notches in the insert to enhance flexibility and improve vibration damping capabilities.

2. Operating Principles of Flexible Jaw Couplings

The core operating principle of a flexible jaw coupling revolves around the interaction between the rigid hubs and the flexible elastomeric insert. When torque is applied to one shaft, it is transmitted through the hub to the elastomeric insert via the interlocking jaws. The insert then transfers the torque to the second hub, which in turn drives the connected shaft. The flexibility of the insert allows for relative movement between the two hubs, accommodating the three main types of shaft misalignment:

- Angular Misalignment: This occurs when the axes of the two shafts intersect at an angle. The elastomeric insert bends slightly to accommodate this angle, ensuring that torque transfer remains uninterrupted. Typical angular misalignment capabilities for flexible jaw couplings range from 0.5 to 3 degrees, depending on the design and material of the insert.

- Parallel Misalignment: This refers to the lateral offset between the axes of the two shafts. The flexible insert compresses on one side and stretches on the other to bridge the gap between the misaligned hubs, maintaining torque transmission. Parallel misalignment capacities typically range from 0.1 to 0.5 millimeters per inch of coupling diameter.

- Axial Misalignment: This is the linear movement of one shaft relative to the other along the axial direction. The elastomeric insert can compress or extend to absorb this movement, preventing damage to the shafts and bearings. Axial misalignment capabilities are generally in the range of 1 to 5 millimeters.

In addition to accommodating misalignment, the elastomeric insert also serves as a vibration damper. As the shafts rotate, any vibrations generated by the connected machinery are absorbed by the insert, which converts the vibrational energy into heat. This damping effect helps to reduce noise levels, minimize wear on mechanical components, and improve the overall stability and lifespan of the power transmission system.

3. Material Selection for Flexible Jaw Couplings

The performance and durability of a flexible jaw coupling are heavily influenced by the materials used for its components. The selection of materials is typically based on the application requirements, including torque capacity, operating temperature, environmental conditions, and chemical exposure. Below is a detailed overview of the materials commonly used for the hubs and elastomeric inserts:

3.1 Hub Materials

The hubs of flexible jaw couplings are required to be rigid and strong to withstand the torque and stresses encountered during operation. The most commonly used materials for hubs include:

- Steel: Carbon steel and alloy steel are popular choices for hubs due to their high strength, durability, and resistance to wear. Steel hubs are suitable for high-torque applications, such as those found in industrial motors, pumps, and gearboxes. They can also be heat-treated to enhance their mechanical properties, making them ideal for heavy-duty operations.

- Aluminum: Aluminum hubs are lightweight and offer good corrosion resistance, making them suitable for applications where weight is a critical factor, such as in automotive and aerospace systems. While aluminum has a lower torque capacity than steel, it is sufficient for many light to medium-duty applications. Additionally, aluminum's thermal conductivity helps to dissipate heat generated during operation.

- Cast Iron: Cast iron hubs are known for their high rigidity and wear resistance, making them suitable for applications involving high-speed rotation and heavy loads. They are commonly used in industrial machinery, such as compressors and conveyors. However, cast iron is relatively brittle and may not be suitable for applications with high shock loads.

3.2 Elastomeric Insert Materials

The elastomeric insert is the most critical component in terms of flexibility and vibration damping. The choice of insert material is crucial to ensuring the coupling's performance under specific operating conditions. Common materials for elastomeric inserts include:

- Nitrile Rubber (NBR): NBR is a widely used elastomer due to its excellent oil resistance and good mechanical properties. It is suitable for applications where the coupling is exposed to petroleum-based oils and greases, such as in automotive and industrial gear systems. NBR has a temperature range of -30°C to 100°C, making it suitable for most ambient temperature applications.

- Ethylene Propylene Diene Monomer (EPDM): EPDM offers excellent resistance to weathering, ozone, and chemicals, making it suitable for outdoor applications and environments with exposure to harsh chemicals. It has a wider temperature range than NBR (-40°C to 120°C) and is often used in HVAC systems, water pumps, and outdoor machinery.

- Silicone Rubber: Silicone rubber is known for its exceptional high-temperature resistance, with a temperature range of -55°C to 200°C. It also offers good resistance to weathering and ozone, making it suitable for applications involving high temperatures, such as in engines and industrial furnaces. However, silicone rubber has lower oil resistance than NBR, so it is not recommended for oil-exposed environments.

- Polyurethane (PU): Polyurethane inserts offer high tensile strength, good abrasion resistance, and excellent load-bearing capacity. They are suitable for high-torque applications and can withstand higher temperatures than NBR (up to 120°C). PU inserts also have good chemical resistance and are often used in industrial machinery, robotics, and automation systems.

4. Key Advantages of Flexible Jaw Couplings

Flexible jaw couplings offer a multitude of advantages that make them a versatile and cost-effective solution for power transmission applications. These advantages include:

- Simple and Compact Design: The basic structure of flexible jaw couplings consists of only three components, making them easy to manufacture, install, and maintain. Their compact size allows them to be used in applications with limited space, such as in small motors and precision machinery.

- Effective Misalignment Compensation: As discussed earlier, flexible jaw couplings can accommodate angular, parallel, and axial misalignments, reducing the need for precise shaft alignment during installation. This not only simplifies the installation process but also reduces the stress on shafts, bearings, and other components, extending their lifespan.

- Vibration Damping and Noise Reduction: The elastomeric insert absorbs vibrations and shocks, reducing noise levels and minimizing wear on mechanical components. This is particularly beneficial in applications where smooth operation is critical, such as in precision machining equipment and medical devices.

- High Torque Capacity: Despite their simple design, flexible jaw couplings can transmit high levels of torque, making them suitable for a wide range of applications, from light-duty household appliances to heavy-duty industrial machinery.

- Cost-Effectiveness: Compared to other types of flexible couplings, such as disc couplings and gear couplings, flexible jaw couplings are relatively inexpensive to manufacture and maintain. The elastomeric insert is a replaceable component, which means that if it becomes worn or damaged, it can be replaced without having to replace the entire coupling, reducing maintenance costs.

- Versatility: Flexible jaw couplings are available in a wide range of sizes, configurations, and materials, making them suitable for a diverse range of applications. They can be used with electric motors, internal combustion engines, pumps, compressors, conveyors, and many other types of rotating machinery.

5. Typical Applications of Flexible Jaw Couplings

Due to their numerous advantages, flexible jaw couplings are employed in a wide variety of industries and applications. Below are some of the most common applications:

5.1 Industrial Machinery

In industrial settings, flexible jaw couplings are widely used in machinery such as pumps, compressors, fans, and conveyors. For example, in a centrifugal pump system, the coupling connects the electric motor to the pump shaft, transmitting torque while accommodating any misalignment between the two shafts. The vibration damping properties of the coupling help to reduce wear on the pump's bearings and impeller, improving the overall reliability and efficiency of the system.

5.2 Automotive Industry

In the automotive industry, flexible jaw couplings are used in various components, including powertrain systems, steering systems, and air conditioning compressors. For instance, in a car's power steering system, the coupling connects the steering column to the power steering pump, allowing for torque transfer while accommodating the angular misalignment between the two components. The compact size and vibration damping capabilities of the coupling make it ideal for use in the tight spaces of automotive engines.

5.3 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on flexible jaw couplings to connect motors to fans, blowers, and pumps. These couplings help to ensure smooth operation of the HVAC system, reducing noise levels and improving energy efficiency. The EPDM elastomeric inserts are often used in HVAC applications due to their resistance to weathering and ozone, making them suitable for outdoor and indoor environments.

5.4 Precision Machinery

In precision machinery, such as CNC machines, lathes, and milling machines, flexible jaw couplings are used to connect the motor to the lead screws or ball screws. The vibration damping properties of the coupling help to maintain the precision of the machinery, ensuring accurate machining operations. The compact design of the coupling also allows it to be used in the small spaces of precision equipment.

5.5 Renewable Energy Systems

Flexible jaw couplings are also finding increasing use in renewable energy systems, such as wind turbines and solar pumps. In a wind turbine, the coupling connects the generator to the gearbox, transmitting torque while accommodating the misalignment caused by the rotation of the turbine blades. The high torque capacity and durability of the coupling make it suitable for the harsh operating conditions of wind turbines.

6. Selection and Maintenance Considerations for Flexible Jaw Couplings

To ensure optimal performance and longevity of a flexible jaw coupling, it is essential to select the right coupling for the application and implement proper maintenance practices. Below are key considerations for selection and maintenance:

6.1 Selection Considerations

- Torque Capacity: The first and most important consideration is the torque capacity of the coupling. The coupling must be able to transmit the maximum torque generated by the driving shaft without failure. It is recommended to select a coupling with a torque rating that is 10-20% higher than the maximum operating torque to account for shock loads and other unexpected stresses.

- Shaft Misalignment: The coupling must be able to accommodate the maximum expected misalignment between the two shafts. It is important to measure the angular, parallel, and axial misalignments of the shafts before selecting a coupling to ensure that the coupling's misalignment capacity meets the application requirements.

- Operating Temperature: The operating temperature of the application must be within the temperature range of the elastomeric insert. If the application involves high temperatures, a silicone rubber or polyurethane insert should be selected. For low-temperature applications, NBR or EPDM inserts may be more suitable.

- Environmental Conditions: The environmental conditions, such as exposure to oil, chemicals, weathering, and ozone, must be considered when selecting the material of the elastomeric insert. For example, if the coupling is exposed to oil, an NBR insert should be used. If it is used outdoors, an EPDM or silicone rubber insert is recommended.

- Shaft Size: The coupling must be compatible with the diameter of the shafts being connected. Most manufacturers offer couplings in a range of sizes to fit different shaft diameters. It is important to ensure that the coupling's hub bore size matches the shaft diameter to avoid slippage and ensure a secure connection.

6.2 Maintenance Considerations

- Regular Inspection: It is important to inspect the coupling regularly for signs of wear, damage, or deterioration. The elastomeric insert should be checked for cracks, tears, hardening, or softening, which are indicators of wear. The hubs should also be inspected for signs of corrosion, wear on the jaws, and loose fasteners.

- Lubrication: Some types of flexible jaw couplings require lubrication to reduce wear on the jaws and insert. However, most modern couplings use self-lubricating elastomeric inserts, which do not require additional lubrication. It is important to follow the manufacturer's recommendations regarding lubrication.

- Replace Worn Components: If the elastomeric insert becomes worn or damaged, it should be replaced immediately to avoid damage to the hubs, shafts, and other components. The insert is a relatively inexpensive component, and replacing it is much more cost-effective than replacing the entire coupling or repairing damaged shafts and bearings.

- Shaft Alignment Check: Over time, the alignment of the shafts may change due to thermal expansion, vibration, or wear on the machinery. It is important to check the shaft alignment regularly and make any necessary adjustments to ensure that the coupling is not subjected to excessive misalignment.

7. Conclusion

Flexible jaw couplings are essential components in modern mechanical power transmission systems, offering a simple, reliable, and cost-effective solution for connecting rotating shafts. Their ability to accommodate misalignment, dampen vibrations, and transmit high levels of torque makes them suitable for a wide range of applications, from industrial machinery to automotive systems and renewable energy equipment. The selection of the right coupling, based on factors such as torque capacity, misalignment, operating temperature, and environmental conditions, is crucial to ensuring optimal performance. Additionally, regular inspection and maintenance of the coupling, particularly the elastomeric insert, can significantly extend its lifespan and reduce the risk of equipment failure.

As technology continues to advance, the design and materials of flexible jaw couplings are likely to evolve, further enhancing their performance and expanding their range of applications. However, their fundamental advantages of simplicity, reliability, and cost-effectiveness ensure that they will remain a staple in the field of mechanical power transmission for years to come. Whether in a small household appliance or a large industrial machine, flexible jaw couplings play a vital role in ensuring the smooth and efficient operation of rotating machinery, making them an indispensable part of modern engineering systems.

« Flexible Jaw Couplings » Post Date: 2024/7/11

URL: https://www.rokeecoupling.com/en/tags/flexible-jaw-couplings.html