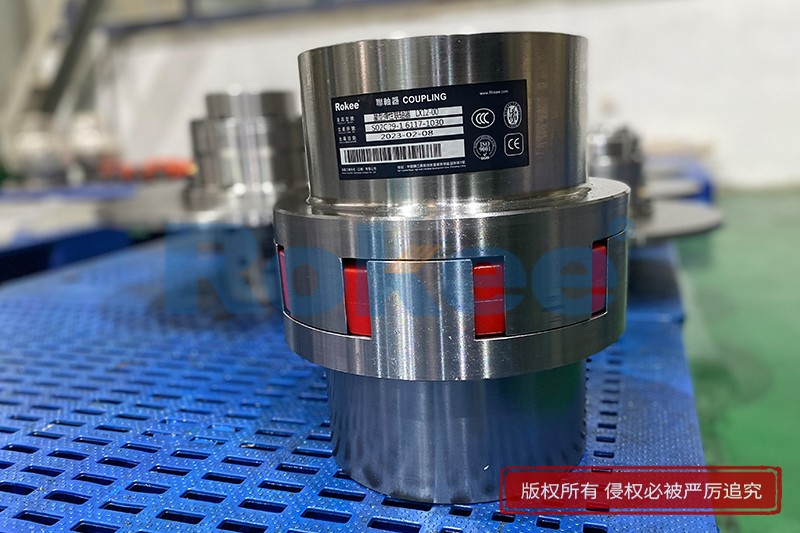

Fire Pump Couplings

Rokee® is Fire Pump Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Fire Pump Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Fire safety systems are critical components of built environments, designed to mitigate the devastating impact of fires on life, property, and infrastructure. Among the numerous elements that constitute a reliable fire protection network, fire pumps stand out as vital devices responsible for delivering adequate water pressure to sprinkler systems, hydrants, and other fire suppression equipment. However, the efficient operation of a fire pump is not solely dependent on the pump itself; it relies on a range of auxiliary components that ensure seamless power transmission and operational stability. One such indispensable component is the fire pump coupling. Serving as the connection point between the pump and its driver—typically an electric motor or a diesel engine—fire pump couplings play a pivotal role in transferring rotational power while accommodating misalignments, absorbing vibrations, and protecting the pump and driver from potential damage.

To fully appreciate the importance of fire pump couplings, it is first essential to understand their fundamental purpose in a fire pump assembly. At its core, a coupling acts as a mechanical bridge between the pump shaft and the driver shaft. When a fire breaks out, the fire pump is activated to draw water from a source—such as a tank, reservoir, or municipal water supply—and distribute it at the required pressure to the fire suppression system. For this process to occur efficiently, the rotational energy generated by the driver must be transmitted to the pump with minimal energy loss. Fire pump couplings facilitate this power transmission by creating a secure yet flexible connection between the two shafts. Unlike rigid connections, which would transfer every vibration and misalignment directly to the pump and driver, couplings are engineered to absorb shocks, dampen vibrations, and compensate for axial, radial, and angular misalignments that may exist between the shafts. These misalignments can arise from a variety of factors, including installation errors, thermal expansion and contraction during operation, or structural shifts in the building over time. By accommodating these misalignments, couplings prevent excessive stress on the pump bearings, seals, and shafts, thereby extending the service life of the entire assembly and reducing the risk of sudden failure during critical fire events.

Another key function of fire pump couplings is to provide a degree of overload protection. In the event of a sudden surge in load—such as a blockage in the water pipeline or a malfunction in the pump impeller—the coupling can act as a sacrificial component, breaking or slipping to prevent the transmission of excessive torque to the driver or pump. This protects the more expensive and critical components of the fire pump system from catastrophic damage, ensuring that the system can be repaired and restored to operational status with minimal downtime. Additionally, couplings facilitate easier maintenance and repair of fire pump systems. By disconnecting the coupling, technicians can separate the pump from the driver without moving the entire assembly, simplifying tasks such as pump inspection, impeller cleaning, and bearing replacement. This not only reduces maintenance time but also minimizes the risk of damage to other components during servicing.

Fire pump couplings are available in several distinct types, each designed to meet specific operational requirements, environmental conditions, and performance criteria. The selection of the appropriate coupling type is a critical decision that directly impacts the efficiency, reliability, and longevity of the fire pump system. The most common types of fire pump couplings include rigid couplings, flexible couplings, and fluid couplings. Each type possesses unique characteristics that make it suitable for particular applications.

Rigid couplings are the simplest type of coupling, consisting of two flanges or sleeves that are bolted directly to the pump and driver shafts. As the name suggests, these couplings provide a rigid connection, meaning they do not allow for any misalignment between the shafts. Instead, they require precise alignment during installation to ensure that the pump and driver shafts are colinear. Rigid couplings are typically used in applications where the pump and driver are mounted on a common base plate, minimizing the risk of misalignment. They are known for their durability, low cost, and simplicity of design, making them a popular choice for small to medium-sized fire pump systems where misalignment is not a significant concern. However, their rigid nature means they do not absorb vibrations or shocks, and any misalignment can lead to excessive stress on the pump and driver components. As a result, rigid couplings are not ideal for applications where thermal expansion or structural shifts are likely to cause misalignment.

Flexible couplings are the most widely used type of coupling in fire pump systems, thanks to their ability to accommodate misalignments and absorb vibrations. Unlike rigid couplings, flexible couplings incorporate elastic elements—such as rubber, polyurethane, or metal springs—that allow for a limited degree of axial, radial, and angular movement between the shafts. This flexibility makes them ideal for applications where precise alignment is difficult to maintain, such as when the pump and driver are mounted on separate bases or in environments prone to temperature fluctuations. There are several sub-types of flexible couplings, including jaw couplings, sleeve couplings, and disc couplings. Jaw couplings consist of two hubs with protruding jaws that engage with a flexible elastomeric spider. The spider absorbs vibrations and compensates for misalignments, while the jaws provide a secure connection for power transmission. Sleeve couplings, also known as elastomeric couplings, use a flexible sleeve made of rubber or polyurethane that fits over the ends of the two shafts and is secured with set screws. Disc couplings, on the other hand, use thin metal discs to connect the hubs, offering high torsional stiffness while accommodating misalignments. Flexible couplings are valued for their versatility, ability to reduce noise and vibration, and protection of pump and driver components. They are suitable for a wide range of fire pump applications, from small electric-driven pumps to large diesel-driven pumps used in industrial facilities.

Fluid couplings, also known as hydraulic couplings, are a type of flexible coupling that uses a fluid—typically oil—to transmit power between the pump and driver shafts. Unlike mechanical flexible couplings, which rely on elastomeric or metal elements, fluid couplings consist of two rotating impellers: a driving impeller connected to the driver shaft and a driven impeller connected to the pump shaft. The driving impeller accelerates the fluid, which then transfers rotational energy to the driven impeller. This fluid-based power transmission provides several key advantages, including smooth start-up, overload protection, and the ability to absorb shocks and vibrations. Fluid couplings are particularly well-suited for large fire pump systems driven by diesel engines, as they allow for a gradual increase in torque during start-up, reducing the strain on the engine and electrical system. Additionally, in the event of an overload, the fluid coupling will slip, preventing excessive torque from being transmitted to the pump or driver. However, fluid couplings are more complex and expensive than mechanical couplings, and they require regular maintenance to ensure proper fluid levels and prevent leaks. They are also less efficient at high speeds compared to rigid or mechanical flexible couplings, making them less suitable for applications where energy efficiency is a top priority.

When selecting a fire pump coupling, several key design and operational factors must be taken into consideration to ensure optimal performance and reliability. One of the most critical factors is the torque capacity of the coupling. The coupling must be capable of transmitting the maximum torque generated by the driver without failing. The torque requirement is determined by the power output of the driver and the operating speed of the pump. It is essential to select a coupling with a torque rating that exceeds the maximum expected torque to provide a safety margin. Failure to do so can result in coupling failure during critical fire events, leading to a loss of pump operation and potentially catastrophic consequences.

Shaft misalignment is another major consideration in coupling selection. The type and magnitude of misalignment expected in the fire pump system will dictate the type of coupling required. For systems with minimal misalignment, a rigid coupling may be sufficient. However, for systems where misalignment is likely—due to thermal expansion, structural movement, or installation constraints—a flexible coupling with appropriate misalignment capabilities is necessary. It is important to consult the coupling manufacturer’s specifications to ensure that the selected coupling can accommodate the expected axial, radial, and angular misalignments.

Operating speed is also a key factor. The coupling must be designed to operate at the maximum rotational speed of the pump and driver shafts without experiencing excessive wear or failure. High-speed applications require couplings with balanced components to minimize vibration and prevent premature failure. Additionally, the material of the coupling must be able to withstand the centrifugal forces generated at high speeds.

Environmental conditions can also impact coupling selection. Fire pump systems may be installed in a variety of environments, including indoor mechanical rooms, outdoor facilities, and harsh industrial settings. Couplings installed in outdoor or corrosive environments—such as near coastal areas or chemical plants—must be made from corrosion-resistant materials, such as stainless steel or coated carbon steel, to prevent rust and degradation. In high-temperature environments, couplings must be able to withstand elevated temperatures without losing their structural integrity or flexibility. Elastomeric components in flexible couplings, for example, can degrade at high temperatures, so it is essential to select materials that are compatible with the operating temperature range of the system.

The ease of installation and maintenance is another important consideration. Couplings that are simple to install and disassemble can reduce installation time and maintenance costs. For example, jaw couplings with split hubs allow for easy installation without removing the pump or driver shafts, simplifying maintenance tasks. Additionally, couplings that require minimal maintenance—such as those with self-lubricating components—are preferable for fire pump systems, as they reduce the risk of maintenance-related failures.

Proper installation of fire pump couplings is critical to ensuring their performance and the overall reliability of the fire pump system. Poor installation can lead to misalignment, excessive vibration, and premature coupling failure. The following best practices should be followed during coupling installation:

First, ensure that the pump and driver shafts are properly aligned. This is perhaps the most important step in coupling installation. Misalignment can cause excessive stress on the coupling, pump bearings, and driver components. Alignment should be performed using precision tools, such as dial indicators or laser alignment systems. Both angular and parallel alignment should be checked and adjusted to meet the manufacturer’s specifications. It is important to note that alignment should be performed when the system is cold, as thermal expansion during operation can change the alignment of the shafts.

Second, clean and inspect the shaft ends before installing the coupling. Any dirt, rust, or burrs on the shafts can prevent a secure fit between the coupling hubs and the shafts, leading to slippage or misalignment. The shafts should be cleaned with a wire brush or sandpaper, and any burrs should be removed with a file. Additionally, the coupling hubs should be inspected for cracks, wear, or other damage before installation.

Third, ensure that the coupling hubs are properly seated on the shafts. The hubs should be pressed or heated onto the shafts to ensure a tight fit. Set screws or keyways should be used to secure the hubs to the shafts, preventing slippage during operation. It is important to follow the manufacturer’s recommendations for hub installation, including the use of appropriate fasteners and torque values.

Fourth, install the flexible element—if applicable—correctly. For jaw couplings, the elastomeric spider should be properly seated between the two hubs, ensuring that the jaws engage fully with the spider. For sleeve couplings, the flexible sleeve should be positioned correctly over the shaft ends and secured with set screws. It is important to avoid over-tightening the set screws, as this can damage the shafts or the sleeve.

Finally, check the coupling for proper operation after installation. The system should be test-run, and the coupling should be inspected for excessive vibration, noise, or heat. Any unusual symptoms should be addressed immediately, as they may indicate misalignment or improper installation.

Regular maintenance of fire pump couplings is essential to ensure their long-term performance and reliability. Fire pump systems are required to be operational at all times, so proactive maintenance is critical to preventing unexpected failures. The following maintenance practices should be implemented for fire pump couplings:

Regular inspection is the cornerstone of coupling maintenance. Couplings should be inspected at least annually, or more frequently if the system is operating in harsh conditions. During inspections, technicians should check for signs of wear, damage, or misalignment. This includes inspecting the coupling hubs for cracks, the flexible elements for degradation (such as hardening, cracking, or tearing), and the fasteners for tightness. Additionally, the coupling should be checked for excessive vibration or noise during operation, which can indicate misalignment or component wear.

Lubrication is another important maintenance task for certain types of couplings. Rigid couplings and some flexible couplings may require lubrication to reduce friction and prevent wear. The type and frequency of lubrication should be in accordance with the manufacturer’s recommendations. Over-lubrication or the use of the wrong type of lubricant can lead to component damage, so it is essential to follow the manufacturer’s guidelines.

Replacement of worn or damaged components is critical to maintaining coupling performance. Flexible elements, such as elastomeric spiders or sleeves, have a limited service life and should be replaced periodically, even if they show no obvious signs of wear. Additionally, any cracked or damaged hubs, fasteners, or other components should be replaced immediately to prevent coupling failure. It is important to use genuine replacement parts from the coupling manufacturer to ensure compatibility and performance.

Re-alignment of the shafts should be performed periodically, as misalignment can develop over time due to thermal expansion, structural movement, or component wear. Shaft alignment should be checked during each maintenance inspection and adjusted as needed. Laser alignment systems are recommended for precise alignment, as they provide more accurate results than traditional dial indicators.

The role of fire pump couplings in ensuring the reliability of fire safety systems cannot be overstated. In the event of a fire, every component of the fire protection network must function flawlessly to ensure the safety of occupants and the protection of property. A failed coupling can disrupt power transmission to the fire pump, rendering the entire suppression system ineffective. This can lead to the rapid spread of fire, resulting in significant loss of life and property damage. By contrast, a well-selected, properly installed, and well-maintained coupling ensures that the fire pump operates efficiently and reliably when it is needed most.

Furthermore, fire pump couplings contribute to the overall cost-effectiveness of fire safety systems. By protecting the pump and driver from damage caused by misalignment, vibrations, and overloads, couplings extend the service life of these expensive components, reducing the need for frequent repairs and replacements. Additionally, the ease of maintenance facilitated by couplings reduces maintenance costs and downtime, ensuring that the fire pump system remains operational with minimal disruption.

In conclusion, fire pump couplings are essential components of fire safety systems, playing a critical role in power transmission, misalignment compensation, vibration absorption, and overload protection. The selection of the appropriate coupling type—whether rigid, flexible, or fluid-based—depends on a range of factors, including torque requirements, shaft misalignment, operating speed, environmental conditions, and maintenance needs. Proper installation and regular maintenance are key to ensuring the performance and reliability of fire pump couplings, as well as the overall effectiveness of the fire pump system. As fire safety continues to be a top priority in built environments, the importance of high-quality, well-maintained fire pump couplings will remain paramount. By understanding the functions, types, and considerations associated with these components, facility managers, engineers, and technicians can ensure that their fire pump systems are equipped to handle the demands of fire suppression, protecting life and property for years to come.

« Fire Pump Couplings » Post Date: 2024/7/11

URL: https://www.rokeecoupling.com/en/tags/fire-pump-couplings.html