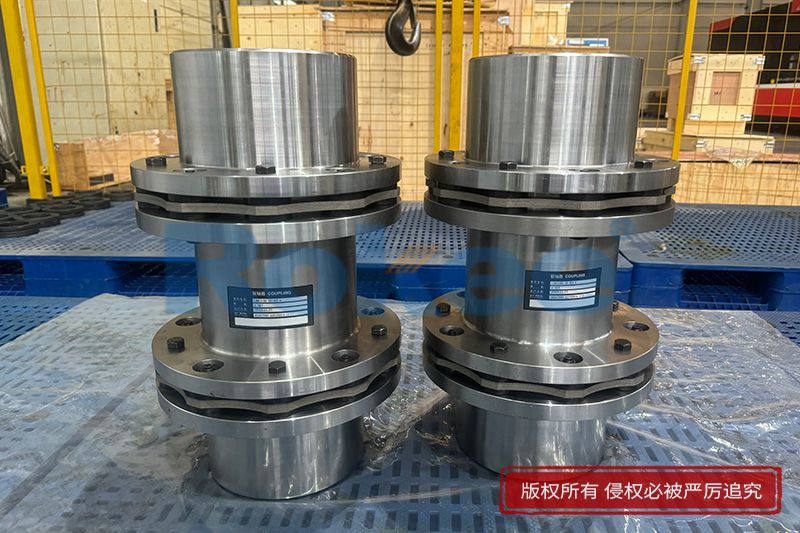

Double Flex Couplings

Rokee® is Double Flex Couplings Supplier from China, Support Customization and Export, due to excellent quality, complete technical services and superior cost performance, Rokee® Double Flex Couplings have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

Double Flex Coupling is a coupling that allows for individual axial displacement of the rotor and allows for a certain deviation in the alignment of two connected rotors. Double Flex Coupling refers to the ability to compensate for the relative deviation of the two axis lines being connected.

In the realm of mechanical power transmission, couplings serve as critical components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating various forms of misalignment. Among the diverse range of couplings available, the double flex coupling stands out for its exceptional ability to handle angular, parallel, and axial misalignments, making it a preferred choice in numerous industrial applications.

To begin with, it is essential to define what a double flex coupling is and how it differs from other coupling types. A double flex coupling is a mechanical device designed to connect two rotating shafts, typically in power transmission systems, with the primary function of transmitting torque while compensating for multiple types of misalignment between the shafts. Unlike single flex couplings, which can only accommodate limited misalignment (usually angular or parallel), double flex couplings feature two flexible elements that work in tandem to provide greater misalignment capacity. This dual-flex design not only enhances the coupling’s ability to absorb shaft deviations but also reduces the transmission of vibration and shock loads between connected components, thereby improving the overall stability and lifespan of the mechanical system.

The design structure of a double flex coupling is relatively straightforward yet engineered for optimal performance. The core components of a typical double flex coupling include two hubs, two flexible elements (often referred to as flex discs or diaphragms), and a central spacer or sleeve. The hubs are designed to attach to the respective shafts, usually via keyways, set screws, or clamping mechanisms, ensuring a secure connection that can withstand the transmitted torque. The flexible elements are mounted between the hubs and the central spacer, and their design is crucial to the coupling’s flexibility and torque-transmitting capability. These flexible elements can be constructed in various configurations, such as disc-shaped, bellows-shaped, or grid-like structures, each offering distinct advantages in terms of flexibility, torque capacity, and resistance to wear.

One of the key design considerations for double flex couplings is the arrangement of the flexible elements. In most cases, the two flexible elements are positioned at a slight angle relative to each other, which allows the coupling to accommodate angular misalignment by flexing in opposite directions. This arrangement also enables the coupling to handle parallel misalignment, as the flexible elements can deform to bridge the offset between the two shafts. Additionally, the central spacer plays a vital role in the coupling’s ability to accommodate axial misalignment, as it provides the necessary space for the shafts to move along their axial direction without causing excessive stress on the flexible elements or the connected components.

The working principle of a double flex coupling revolves around the deformation of its flexible elements to compensate for misalignment while transmitting torque. When torque is applied to the input shaft, it is transferred through the input hub to the first flexible element. The flexible element deforms slightly to accommodate any misalignment between the input shaft and the central spacer, then transmits the torque to the central spacer. From the central spacer, the torque is transferred to the second flexible element, which again deforms to compensate for misalignment between the central spacer and the output shaft, before finally being transmitted to the output hub and the output shaft. Throughout this process, the flexible elements act as a buffer, absorbing vibration and shock loads that may be present in the system, thereby reducing the stress on the shafts, bearings, and other mechanical components.

Material selection is a critical factor that influences the performance, durability, and application range of double flex couplings. The choice of materials for the hubs, flexible elements, and central spacer depends on various factors, including the operating temperature, torque requirements, environmental conditions, and the type of misalignment expected. For the hubs, common materials include carbon steel, alloy steel, and aluminum alloy. Carbon steel is widely used due to its high strength, durability, and cost-effectiveness, making it suitable for most general industrial applications. Alloy steel is preferred for high-torque or high-temperature applications, as it offers enhanced strength and resistance to thermal fatigue. Aluminum alloy, on the other hand, is used in applications where weight reduction is a priority, such as in aerospace or automotive systems.

The flexible elements, being the most critical components in terms of flexibility and torque transmission, are typically made from materials that offer high fatigue resistance and flexibility. Common materials for flexible elements include stainless steel, nickel-based alloys, and composite materials. Stainless steel is a popular choice due to its excellent corrosion resistance, high strength, and ability to withstand moderate temperatures. Nickel-based alloys are used in high-temperature and high-corrosion environments, such as in chemical processing or power generation, as they offer superior thermal stability and resistance to harsh chemicals. Composite materials, such as fiberglass-reinforced polymers, are gaining popularity in certain applications due to their lightweight, high strength-to-weight ratio, and excellent resistance to corrosion and fatigue.

The central spacer, which connects the two flexible elements, is usually made from the same material as the hubs, although in some cases, it may be made from a lighter material such as aluminum alloy to reduce the overall weight of the coupling. The material selection for the central spacer is also influenced by the operating environment, with corrosion-resistant materials being preferred in harsh environments.

Double flex couplings find applications in a wide range of industries and mechanical systems, thanks to their ability to handle multiple types of misalignment and their excellent torque-transmitting capabilities. One of the most common applications is in industrial machinery, such as pumps, compressors, motors, and gearboxes. In these applications, the coupling is used to connect the motor shaft to the pump or compressor shaft, compensating for any misalignment that may occur during installation or operation. This not only ensures efficient power transmission but also reduces the wear and tear on the bearings and other components, extending the lifespan of the machinery.

Another important application area is in the automotive industry, where double flex couplings are used in drivetrain systems, such as in the connection between the engine and the transmission. In automotive applications, the coupling must be able to handle significant misalignment caused by engine vibration and movement, while also transmitting high torque efficiently. The lightweight and high-strength characteristics of some double flex couplings make them ideal for this application, as they help to reduce the overall weight of the vehicle and improve fuel efficiency.

The aerospace industry also utilizes double flex couplings in various systems, such as in aircraft engines and auxiliary power units (APUs). In aerospace applications, the coupling must meet strict requirements for weight, strength, and reliability, as any failure could have catastrophic consequences. Double flex couplings made from high-strength composite materials or nickel-based alloys are often used in these applications, as they offer the necessary strength and durability while keeping the weight to a minimum.

Other applications of double flex couplings include marine propulsion systems, where they are used to connect the engine to the propeller shaft, compensating for misalignment caused by hull flexing and shaft movement; renewable energy systems, such as wind turbines, where they are used to connect the turbine rotor to the generator, handling the misalignment caused by wind-induced vibration; and industrial robotics, where they are used in robotic arms and other moving components, providing precise torque transmission while accommodating small misalignments.

When selecting a double flex coupling for a specific application, several key factors must be considered to ensure optimal performance and reliability. The first and most important factor is the torque capacity of the coupling. The coupling must be able to transmit the maximum torque generated by the system without failure. It is essential to select a coupling with a torque rating that exceeds the maximum operating torque of the system, to provide a safety margin.

The second factor is the misalignment capacity of the coupling. Different applications require the coupling to handle different types and amounts of misalignment. It is important to select a coupling that can accommodate the maximum expected angular, parallel, and axial misalignment in the system. If the coupling is not capable of handling the required misalignment, it will experience excessive stress, leading to premature failure.

Operating temperature is another critical factor to consider. The materials used in the coupling must be able to withstand the operating temperature range of the system. High-temperature applications require couplings made from materials with high thermal stability, such as nickel-based alloys, while low-temperature applications may require materials that remain flexible and strong at low temperatures.

Environmental conditions, such as the presence of moisture, chemicals, or dust, also influence the selection of a double flex coupling. In corrosive environments, such as in chemical processing plants or marine applications, couplings made from corrosion-resistant materials, such as stainless steel or composite materials, should be selected. In dusty or abrasive environments, couplings with sealed designs may be necessary to prevent the ingress of dust and debris, which can cause wear and damage to the flexible elements.

The size and weight of the coupling are also important considerations, especially in applications where space is limited or weight reduction is a priority, such as in aerospace or automotive applications. It is important to select a coupling that fits within the available space and does not add excessive weight to the system.

Finally, the cost of the coupling should also be considered, although it should not be the sole determining factor. While it may be tempting to select the cheapest coupling available, it is important to balance cost with performance and reliability, as a low-cost coupling that fails prematurely can result in significant downtime and repair costs.

Proper maintenance of double flex couplings is essential to ensure their long-term performance and reliability. Regular inspection is one of the most important maintenance practices. Couplings should be inspected periodically for signs of wear, damage, or misalignment. This includes checking the flexible elements for cracks, tears, or deformation, inspecting the hubs and central spacer for signs of corrosion or wear, and checking the fasteners for tightness.

Lubrication is another important maintenance practice, although it is only required for certain types of double flex couplings, such as those with rolling elements or sliding surfaces. If lubrication is required, it is important to use the correct type and amount of lubricant, as specified by the manufacturer. Over-lubrication or under-lubrication can lead to excessive wear and damage to the coupling.

In addition to regular inspection and lubrication, it is also important to ensure that the coupling is properly installed. Improper installation can lead to excessive misalignment, which can cause premature failure of the coupling and the connected components. During installation, the shafts should be aligned as accurately as possible, and the coupling should be mounted securely to the shafts, using the correct fasteners and torque specifications.

If any signs of wear or damage are detected during inspection, the coupling should be repaired or replaced immediately. Delaying repair or replacement can lead to more serious damage to the system, resulting in costly downtime and repairs.

In conclusion, double flex couplings are essential components in modern mechanical power transmission systems, offering exceptional ability to handle multiple types of misalignment while transmitting torque efficiently. Their unique design, which features two flexible elements working in tandem, makes them suitable for a wide range of applications across various industries, including industrial machinery, automotive, aerospace, marine, and renewable energy. The selection of a double flex coupling requires careful consideration of factors such as torque capacity, misalignment capacity, operating temperature, environmental conditions, size, weight, and cost. Proper maintenance, including regular inspection, lubrication, and proper installation, is crucial to ensure the long-term performance and reliability of the coupling.

As technology continues to advance, the design and material selection of double flex couplings are expected to evolve, with a focus on improving performance, reducing weight, and enhancing durability. The development of new composite materials and advanced manufacturing techniques is likely to result in couplings that offer even higher strength-to-weight ratios, better corrosion resistance, and improved fatigue life. This will further expand the application range of double flex couplings, making them an even more integral part of future mechanical systems.

« Double Flex Couplings » Post Date: 2023/12/23

URL: https://www.rokeecoupling.com/en/tags/double-flex-couplings.html