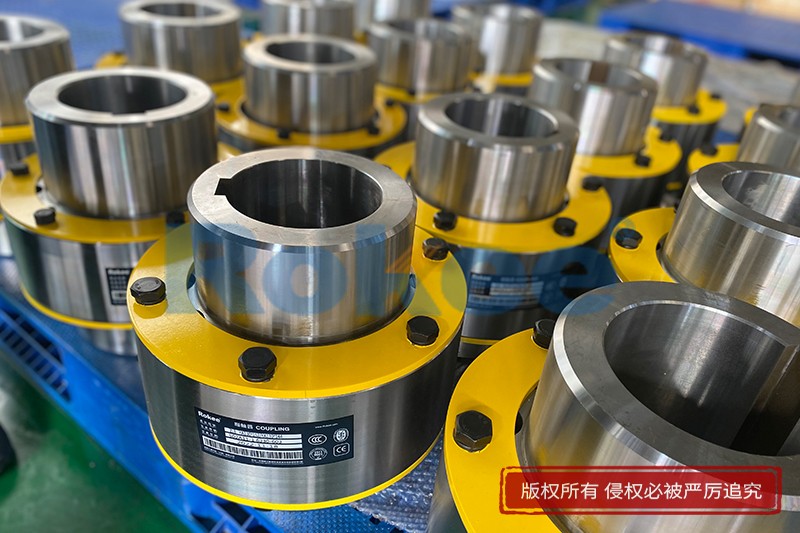

ZL Pin Coupling

Rokee® provide ZL Pin Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the field of mechanical transmission, couplings play a pivotal role as core components that connect two shafts (driving shaft and driven shaft) in different mechanisms to transmit torque and rotational motion. Among the various types of couplings available, the ZL Pin Coupling has gained widespread recognition and application due to its unique structural design, reliable performance, and adaptability to diverse working conditions.

The structural design of the ZL Pin Coupling is characterized by simplicity, rationality, and ease of manufacturing, which lays a solid foundation for its stable operation and wide application. Generally, a standard ZL Pin Coupling consists of four main components: two half-couplings, a set of pins, and rubber bushings. The half-couplings are usually made of high-strength cast iron or steel materials. Cast iron is preferred for general working conditions due to its good castability and cost-effectiveness, while steel is adopted in scenarios requiring higher torque transmission capacity. Each half-coupling is designed with a flange structure, which is equipped with evenly distributed pin holes. The number and size of the pin holes are determined according to the rated torque of the coupling, ensuring that the force is evenly distributed during operation.

The pins are the key force-transmitting elements of the ZL Pin Coupling, and their material selection and structural design directly affect the coupling's torque-bearing capacity and service life. Most pins are made of high-quality carbon steel or alloy steel, which undergo quenching and tempering heat treatment to enhance their hardness, strength, and wear resistance. The rubber bushings, which are sleeved on the pins, are made of elastic materials such as natural rubber or synthetic rubber. These bushings not only play a role in reducing vibration and noise but also compensate for minor deviations in shaft alignment, including axial, radial, and angular misalignments. The structural combination of pins and rubber bushings enables the ZL Pin Coupling to achieve both rigid torque transmission and flexible compensation, making it suitable for a variety of mechanical systems with slight alignment errors.

The working principle of the ZL Pin Coupling is based on the mutual cooperation of its components to realize the transmission of rotational motion and torque. When the driving shaft rotates, it drives the connected half-coupling to rotate synchronously. The pins installed in the pin holes of the driving half-coupling transmit the torque to the rubber bushings. Due to the close fit between the rubber bushings and the pin holes of the driven half-coupling, the torque is further transmitted to the driven half-coupling, thereby driving the driven shaft to rotate. During this process, the rubber bushings undergo elastic deformation under the action of torque, which can effectively absorb the vibration generated by the driving shaft and reduce the impact of vibration on the driven shaft and other components. At the same time, the elastic deformation of the rubber bushings also allows for minor adjustments in the relative position between the two shafts, compensating for the alignment errors caused by installation inaccuracies, thermal expansion and contraction of components during operation, or deformation of the machine base.

Compared with other types of couplings, the ZL Pin Coupling exhibits several prominent performance advantages that make it stand out in practical applications. Firstly, it has excellent vibration absorption and noise reduction capabilities. The rubber bushings in the coupling act as a buffer between the pins and the half-couplings, which can absorb the impact load generated during the start-up and operation of the machine, reduce the vibration amplitude of the transmission system, and thereby lower the noise level. This advantage is particularly important in mechanical equipment that requires stable and quiet operation, such as precision machine tools and household appliances.

Secondly, the ZL Pin Coupling has good alignment compensation performance. In actual engineering applications, it is difficult to achieve absolute alignment between the driving shaft and the driven shaft due to factors such as installation errors, structural deformation, and temperature changes. The elastic rubber bushings of the ZL Pin Coupling can compensate for axial misalignment within a certain range (usually 0.5-2mm), radial misalignment (0.1-0.5mm), and angular misalignment (0.5°-1°). This not only simplifies the installation process and reduces the requirements for installation accuracy but also avoids excessive stress on the shafts, bearings, and other components caused by misalignment, thereby extending the service life of the entire transmission system.

Thirdly, the ZL Pin Coupling features simple structure, easy manufacturing, and low cost. The number of components is small, and the processing technology of each component is relatively mature, which facilitates mass production and reduces the manufacturing cost. In addition, the installation and disassembly of the coupling are convenient. It only requires fixing the two half-couplings on the driving shaft and the driven shaft respectively, and then inserting the pins with rubber bushings into the pin holes. This simplifies the maintenance work and reduces the downtime of the equipment.

Fourthly, the ZL Pin Coupling has reliable performance and strong adaptability. The high-strength pins and elastic rubber bushings ensure that the coupling can stably transmit torque under different working conditions. It can be used in both high-speed and low-speed transmission systems, and can adapt to various harsh environments such as high temperature, humidity, and dust. However, it should be noted that the rubber bushings are susceptible to aging and damage under long-term high-temperature or oil-soaked conditions, so appropriate material selection should be made according to the specific working environment.

Due to its above-mentioned advantages, the ZL Pin Coupling is widely used in various fields of mechanical engineering. In the industrial production field, it is commonly used in the transmission systems of pumps, fans, compressors, and reducers. For example, in the water supply and drainage system, the ZL Pin Coupling connects the motor and the water pump, transmitting the rotational motion of the motor to the pump impeller to realize the transportation of water. In the ventilation system of factories, the coupling connects the motor and the fan, ensuring the stable operation of the fan and the normal circulation of air. In addition, the ZL Pin Coupling is also used in the transmission systems of conveyors, mixers, and other equipment, playing an important role in improving production efficiency and ensuring the stable operation of the equipment.

In the agricultural machinery field, the ZL Pin Coupling is widely applied in tractors, harvesters, and other agricultural equipment. Agricultural machinery often works in harsh environments with uneven terrain, and the vibration and impact during operation are relatively large. The ZL Pin Coupling's vibration absorption and impact resistance capabilities can effectively protect the transmission system of the agricultural machinery, ensuring its reliable operation. For example, in the transmission system of a tractor, the coupling connects the engine and the gearbox, transmitting the power of the engine to the gearbox to drive the tractor forward and realize various operations such as plowing and sowing.

In the construction machinery field, the ZL Pin Coupling is used in excavators, loaders, cranes, and other equipment. These equipment need to transmit large torque during operation, and the working conditions are complex and harsh. The ZL Pin Coupling's high torque transmission capacity and strong adaptability can meet the requirements of construction machinery. For example, in the transmission system of an excavator, the coupling connects the hydraulic pump and the engine, ensuring the stable output of hydraulic power and the normal operation of the excavator's working mechanism.

In addition to the above fields, the ZL Pin Coupling is also used in the transmission systems of automotive accessories, marine machinery, and other equipment, showing a wide range of application prospects.

The correct installation and reasonable maintenance of the ZL Pin Coupling are crucial to ensuring its stable operation and extending its service life. In terms of installation, the following points should be noted: Firstly, before installation, the surface of the shafts and the inner holes of the half-couplings should be cleaned to remove oil stains, rust, and other impurities to ensure a tight fit between the half-couplings and the shafts. Secondly, the coaxiality of the driving shaft and the driven shaft should be adjusted as much as possible. Although the ZL Pin Coupling has a certain alignment compensation capacity, excessive misalignment will increase the stress on the pins and rubber bushings, accelerating their wear and reducing the service life of the coupling. Thirdly, when installing the pins and rubber bushings, care should be taken not to damage the rubber bushings. The pins should be inserted into the pin holes smoothly, and the tightness between the rubber bushings and the pin holes should be appropriate. Too tight will cause difficulty in installation and increase the resistance during operation, while too loose will cause vibration and noise.

In terms of maintenance, regular inspection of the ZL Pin Coupling is essential. Firstly, the wear status of the pins and rubber bushings should be checked regularly. If the rubber bushings are found to be aging, cracking, or falling off, they should be replaced in time. If the pins are found to be worn, deformed, or broken, they should also be replaced immediately to avoid failure of the coupling. Secondly, the tightness of the bolts connecting the half-couplings and the shafts should be checked regularly. If the bolts are loose, they should be tightened in time to prevent the half-couplings from slipping on the shafts, which will affect the torque transmission. Thirdly, in the case of long-term operation of the equipment, the coupling should be disassembled and cleaned regularly, and lubricating oil should be applied to the pins and other moving parts to reduce wear. In addition, for couplings working in harsh environments such as high temperature, humidity, and dust, protective measures should be taken to prevent the components from being corroded and damaged.

With the continuous development of mechanical engineering technology, the requirements for couplings are becoming higher and higher. In the future, the ZL Pin Coupling will also develop in the direction of high performance, long service life, and intelligence. In terms of material improvement, researchers will develop new rubber materials with better high-temperature resistance, oil resistance, and aging resistance to improve the adaptability of the rubber bushings to harsh environments. At the same time, the pins and half-couplings may adopt new high-strength and lightweight materials, such as composite materials, to reduce the weight of the coupling while improving its torque transmission capacity.

In terms of structural optimization, the structural design of the ZL Pin Coupling will be further improved. For example, the shape and size of the pin holes and pins may be optimized through finite element analysis to make the force distribution more uniform and improve the bearing capacity of the coupling. In addition, the connection method between the half-couplings and the shafts may be improved to enhance the connection reliability and simplify the installation and disassembly process.

In terms of intelligence, with the development of the Internet of Things and sensor technology, intelligent monitoring functions may be added to the ZL Pin Coupling. For example, sensors are installed on the coupling to real-time monitor parameters such as vibration amplitude, temperature, and torque during operation. The monitoring data is transmitted to the control system, and the working status of the coupling is judged through data analysis. When an abnormality is found, an alarm is issued in time to remind the staff to carry out maintenance. This can realize the predictive maintenance of the coupling, reduce the downtime of the equipment, and improve the operational efficiency of the entire mechanical system.

In conclusion, the ZL Pin Coupling is a kind of mechanical transmission component with simple structure, reliable performance, and wide application. Its unique combination of rigid pins and elastic rubber bushings gives it excellent vibration absorption, alignment compensation, and torque transmission capabilities, making it play an important role in industrial production, agricultural machinery, construction machinery, and other fields. Correct installation and regular maintenance are essential to ensure the stable operation and long service life of the ZL Pin Coupling. With the continuous progress of technology, the ZL Pin Coupling will continue to be optimized and improved, showing broader application prospects in the future mechanical transmission field. For engineering and technical personnel, a deep understanding of the performance characteristics and application requirements of the ZL Pin Coupling is of great significance for rational selection, correct use, and effective maintenance of the coupling, and for improving the reliability and efficiency of the mechanical system.

« ZL Pin Coupling » Post Date: 2023/8/17

URL: https://www.rokeecoupling.com/en/customer-cases/zl-pin-coupling.html

- Octapetal Claw Couplings

- Characteristics Of Universal Joint Shaft

- Flange Gear Coupling Installation

- Misalignment Tolerance of Bush Pin Coupling

- Efficiency of Shim Pack Coupling

- Elastic Pin Couplings With Brake Disc

- Self Locking Diaphragm Coupling

- Column Pin Flexible Coupling Drawing

- Special Gear Coupling For Lifting

- Flexible Laminated Membrane Coupling Design