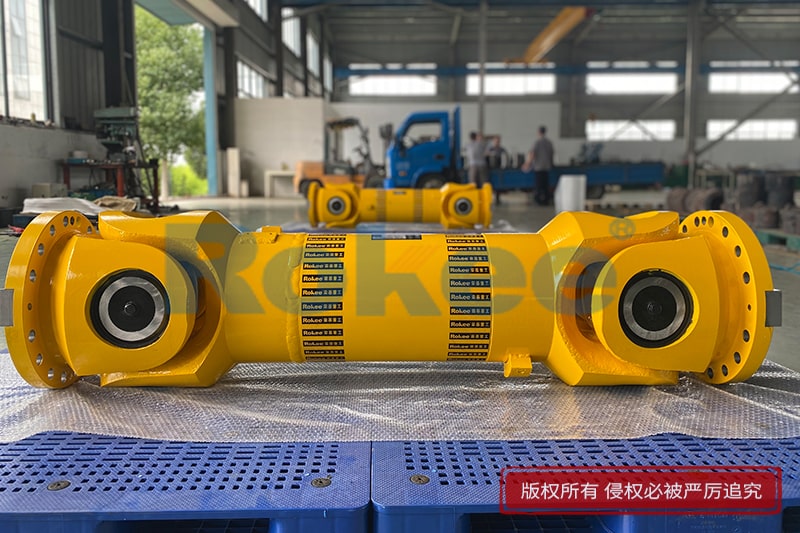

SWC Cardan Coupling

Rokee® provide SWC Cardan Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as critical components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating misalignments and absorbing operational shocks. Among the diverse range of couplings available, the SWC Cardan Coupling stands out for its robust construction, versatility, and ability to handle high torque loads under challenging operating conditions.

1. Fundamental Overview and Design Characteristics of SWC Cardan Coupling

The SWC Cardan Coupling, a type of universal joint coupling, is engineered to transmit rotational power between two shafts that are not perfectly aligned. Unlike simple universal joints, which may suffer from velocity fluctuations when operating at large angles, the SWC Cardan Coupling is designed with a specific configuration that minimizes these fluctuations, ensuring stable power transmission. The term "Cardan" originates from the Italian mathematician and physicist Gerolamo Cardano, who first described the universal joint mechanism, and the "SWC" designation typically refers to the standard series and structural type of this coupling variant.

The core structure of an SWC Cardan Coupling consists of several key components: the input and output shafts, cross shafts (also known as spider assemblies), yokes, and bearing units. The yokes are attached to the respective shafts that need to be connected, and the cross shaft serves as the central connecting element, fitting into the yokes through bearing units. This cross-shaft design allows the coupling to accommodate three types of misalignment: angular misalignment (where the shafts intersect at an angle), parallel misalignment (where the shafts are offset but parallel), and axial misalignment (where the shafts are displaced along their axial direction). The bearing units, which are usually roller bearings or needle bearings, reduce friction between the cross shaft and yokes, ensuring smooth rotation even under high torque loads.

One of the distinguishing design features of SWC Cardan Couplings is their rigid yet flexible construction. The yokes and cross shafts are typically manufactured from high-strength alloy steels, which undergo heat treatment processes to enhance their hardness, toughness, and wear resistance. This material selection ensures that the coupling can withstand the high stresses and loads encountered in heavy-duty applications. Additionally, the coupling is designed with a compact structure, making it suitable for installations where space is limited. The size range of SWC Cardan Couplings varies widely, from small units used in light industrial applications to large-scale couplings employed in heavy machinery, with torque capacity ranging from several hundred Newton-meters to tens of thousands of Newton-meters.

2. Working Principle of SWC Cardan Coupling

The working principle of the SWC Cardan Coupling is based on the ability of the cross shaft to transfer torque between two misaligned shafts while maintaining a relatively constant angular velocity. When the input shaft rotates, it drives the connected yoke, which in turn rotates the cross shaft. The cross shaft then transmits this rotational motion to the output yoke, which drives the output shaft. The bearing units within the yokes allow the cross shaft to pivot freely, accommodating the misalignment between the two shafts.

A key aspect of the SWC Cardan Coupling's operation is its ability to minimize velocity fluctuation, which is a common issue with single universal joints. In a single universal joint, when the input shaft rotates at a constant speed, the output shaft's speed varies cyclically, especially at large angular misalignments. This velocity fluctuation can cause vibration, noise, and increased wear on the coupling and other components. The SWC Cardan Coupling addresses this problem by utilizing a double universal joint configuration (also known as a constant velocity joint arrangement) in many applications. In this configuration, two cross shafts are used, and the angles of misalignment for both joints are equalized. This setup ensures that the velocity fluctuation from the first joint is canceled out by the second joint, resulting in a constant angular velocity at the output shaft.

Another important aspect of the working principle is the transfer of axial force. Depending on the application, SWC Cardan Couplings can be designed to handle axial forces generated during operation. The bearing units are selected and installed to withstand these axial forces, preventing premature failure. Additionally, the coupling's design allows for a certain amount of axial displacement, which is crucial in applications where thermal expansion or contraction of the shafts occurs, such as in high-temperature industrial processes.

3. Key Performance Advantages of SWC Cardan Coupling

SWC Cardan Couplings offer a range of performance advantages that make them a preferred choice in many industrial applications. One of the most significant advantages is their high torque transmission capacity. Due to their robust construction and high-strength materials, these couplings can transmit large amounts of torque without deformation or failure, making them suitable for heavy-duty machinery such as steel rolling mills, mining equipment, and marine propulsion systems.

Another major advantage is their excellent misalignment compensation capability. SWC Cardan Couplings can accommodate large angular misalignments (typically up to 15 degrees or more, depending on the specific model) and significant parallel and axial misalignments. This flexibility is crucial in applications where shaft alignment is difficult to maintain, such as in large-scale industrial machinery where installation tolerances may be wider, or in mobile equipment where the shafts are subject to movement during operation.

Stable and smooth operation is another key benefit of SWC Cardan Couplings. As mentioned earlier, the double universal joint configuration minimizes velocity fluctuation, reducing vibration and noise. This stable operation not only improves the overall performance of the mechanical system but also extends the service life of other components, such as bearings, gears, and shafts, by reducing wear and tear caused by vibration.

SWC Cardan Couplings are also known for their durability and long service life. The use of high-strength alloy steels and precision-manufactured components ensures that the coupling can withstand harsh operating conditions, including high temperatures, high humidity, dust, and corrosive environments. Additionally, the bearing units are designed for long life, with proper lubrication ensuring minimal friction and wear.

Ease of installation and maintenance is another advantage of SWC Cardan Couplings. The compact and modular design allows for easy installation and removal, reducing downtime during maintenance or replacement. Most models are designed with grease fittings that allow for convenient lubrication, which is essential for maintaining optimal performance and extending service life. Furthermore, the components of SWC Cardan Couplings are often standardized, making replacement parts readily available.

4. Wide-Ranging Applications of SWC Cardan Coupling

Due to their robust performance and versatility, SWC Cardan Couplings find applications in a wide variety of industries and mechanical systems. One of the primary applications is in the steel industry, where they are used in steel rolling mills, continuous casting machines, and steel pipe production lines. In these applications, the coupling must transmit high torque between the motor and the rolling mill or casting machine, while accommodating misalignments caused by the heavy loads and thermal expansion of the equipment.

The mining industry is another major user of SWC Cardan Couplings. Mining equipment such as excavators, loaders, conveyors, and crushers require reliable torque transmission in harsh and dusty environments. SWC Cardan Couplings are ideal for these applications due to their durability, high torque capacity, and ability to accommodate misalignments caused by the movement of the equipment and the uneven terrain.

In the marine industry, SWC Cardan Couplings are used in marine propulsion systems, connecting the engine to the propeller shaft. These couplings must withstand the high torque generated by marine engines while accommodating misalignments caused by the movement of the ship and the flexing of the hull. Additionally, they must be resistant to corrosion from saltwater, making the use of corrosion-resistant materials and coatings essential.

The construction industry also relies on SWC Cardan Couplings in equipment such as concrete mixers, cranes, and bulldozers. These machines operate in demanding conditions, with frequent starts and stops, high loads, and significant misalignments. The SWC Cardan Coupling's ability to handle these conditions ensures reliable performance and minimal downtime.

Other applications of SWC Cardan Couplings include power generation (such as in wind turbines and hydroelectric power plants), paper and pulp production, textile machinery, and agricultural equipment. In wind turbines, for example, the coupling connects the gearbox to the generator, transmitting torque while accommodating misalignments caused by the wind load and the movement of the turbine blades. In agricultural equipment such as tractors and harvesters, the coupling is used to transmit power from the engine to various attachments, such as plows and mowers.

5. Essential Maintenance Practices for SWC Cardan Coupling

Proper maintenance is crucial for ensuring the optimal performance and long service life of SWC Cardan Couplings. One of the most important maintenance tasks is regular lubrication. The bearing units and other moving parts of the coupling require adequate lubrication to reduce friction, prevent wear, and protect against corrosion. The type of lubricant used should be appropriate for the operating conditions, such as high temperature, high load, or corrosive environments. Lubrication intervals should be followed strictly, with the coupling inspected for lubricant leakage regularly. If leakage is detected, the seals should be replaced promptly to prevent the loss of lubricant and the entry of contaminants.

Regular inspection of the coupling components is another essential maintenance practice. During inspection, the yokes, cross shaft, and bearing units should be checked for signs of wear, damage, or deformation. Worn or damaged bearings should be replaced immediately, as they can cause increased friction, vibration, and ultimately, coupling failure. The yokes and cross shaft should also be inspected for cracks, which can occur due to fatigue under repeated load cycles. If cracks are detected, the affected components should be replaced to prevent catastrophic failure.

Proper shaft alignment is also important for the performance and longevity of SWC Cardan Couplings. While the coupling can accommodate misalignments, excessive misalignment can increase the load on the bearing units and other components, leading to premature wear. Regular alignment checks should be performed, especially after the installation of the coupling or after any major maintenance work on the machinery. If misalignment is detected beyond the coupling's rated capacity, the shafts should be realigned promptly.

In addition to regular lubrication and inspection, it is important to keep the coupling clean. Contaminants such as dust, dirt, and moisture can enter the bearing units and other components, causing increased wear and corrosion. The coupling should be cleaned regularly to remove these contaminants, with special attention paid to the grease fittings and seals.

Finally, it is important to follow the manufacturer's recommended maintenance guidelines. The manufacturer's guidelines provide specific information on lubrication intervals, lubricant types, inspection procedures, and replacement parts, which are tailored to the specific model of SWC Cardan Coupling. Adhering to these guidelines ensures that the coupling operates at its optimal level and minimizes the risk of unexpected failure.

6. Conclusion

The SWC Cardan Coupling is a vital component in modern mechanical power transmission systems, offering robust performance, versatility, and reliability in a wide range of applications. Its unique design, based on the cross shaft and yoke configuration, enables it to accommodate significant misalignments while transmitting high torque loads with minimal velocity fluctuation. The high-strength materials and precision manufacturing ensure durability and long service life, even in harsh operating conditions.

From the steel and mining industries to marine propulsion and construction equipment, SWC Cardan Couplings play a crucial role in ensuring the efficient and reliable operation of machinery. Proper maintenance, including regular lubrication, inspection, and shaft alignment, is essential for maximizing the performance and longevity of these couplings.

As industrial machinery continues to evolve, with increasing demands for higher torque, greater efficiency, and improved reliability, the SWC Cardan Coupling is likely to remain a key component in power transmission systems. Its ability to adapt to diverse operating conditions and its proven performance make it a preferred choice for engineers and manufacturers across various industries. By understanding the design, working principle, advantages, applications, and maintenance requirements of SWC Cardan Couplings, industry professionals can make informed decisions about their selection and use, ensuring the optimal performance of their mechanical systems.

« SWC Cardan Coupling » Post Date: 2023/9/23

URL: https://www.rokeecoupling.com/en/customer-cases/swc-cardan-coupling.html

- Cross Universal Couplings For Construction Machinery

- Flexible Pin Bush Couplings Factory

- Drawing Of Telescopic Universal Coupling

- Diaphragm Single Section Couplings

- Gap Chart of Brake Drum Gear Couplings

- Water Pump Drum Couplings

- Bush Pin Type Flexible Coupling Drawing

- Double Diaphragm Clamping Type Coupling

- Gear Coupling Diagram

- Nylon Elastic Pin Couplings Wholesale