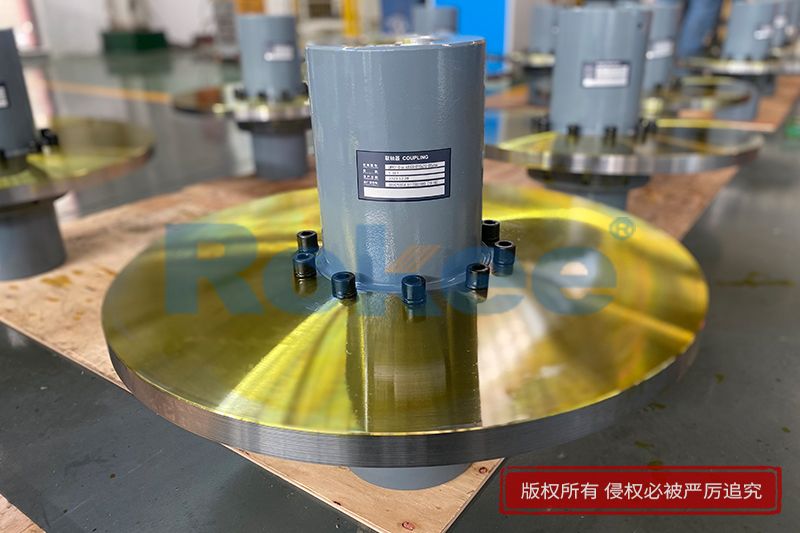

MLPK Flexible Plum Blossom Coupling With Brake Disc

Rokee® provide MLPK Flexible Plum Blossom Coupling With Brake Disc, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the complex ecosystem of industrial power transmission, couplings serve as the critical link between prime movers and driven machinery, ensuring efficient torque transfer while accommodating various misalignments. Among the diverse range of coupling types, the flexible plum blossom coupling has gained widespread recognition for its compact structure, excellent flexibility, and cost-effectiveness. The MLPK series, when integrated with a brake disc, further expands its functional scope, combining power transmission with reliable braking capability.

1. Design Characteristics of MLPK Flexible Plum Blossom Coupling With Brake Disc

The MLPK flexible plum blossom coupling with brake disc is a integrated transmission component that merges the flexible coupling body with a brake disc, designed to meet the dual requirements of torque transmission and emergency braking in industrial systems. Its structural design is characterized by several key components, each playing a vital role in ensuring overall performance.

1.1 Core Components and Their Functions

The primary components of the MLPK coupling include the plum blossom elastic element, two half-couplings, a brake disc, and connecting fasteners. The plum blossom elastic element, typically made of high-quality polyurethane or rubber, is the core flexible component that sits between the two half-couplings. It features a petal-like structure, which gives the coupling its name and enables it to absorb vibration, compensate for misalignment, and dampen shock loads. The half-couplings, usually manufactured from carbon steel or alloy steel through forging or machining processes, are responsible for connecting the coupling to the input (motor) and output (driven equipment) shafts. They are designed with precision to ensure a tight fit with the shafts, minimizing slippage during operation.

The brake disc, a key addition to the MLPK series, is fixedly attached to one of the half-couplings, usually the one connected to the motor shaft or the intermediate shaft. It is a circular metal disc with a smooth friction surface, engineered to work in conjunction with brake calipers or brake shoes to generate braking torque. The material selection for the brake disc is critical to its performance; common materials include gray cast iron, alloy steel, and stainless steel, depending on the application's temperature, speed, and load requirements. The connecting fasteners, such as high-strength bolts and nuts, ensure the secure assembly of all components, preventing disengagement during high-speed operation.

1.2 Structural Design Advantages

One of the prominent structural advantages of the MLPK coupling is its compact and lightweight design. By integrating the brake disc directly into the coupling assembly, it eliminates the need for additional mounting brackets or intermediate components, saving valuable installation space. This compactness is particularly beneficial in applications where space is constrained, such as in small-scale industrial machinery, automation equipment, and automotive powertrains.

Another key design feature is the modular structure. The individual components (elastic element, half-couplings, brake disc) can be easily disassembled and replaced, simplifying maintenance and reducing downtime. The plum blossom elastic element is designed for quick replacement without the need to move the connected machinery, which significantly improves maintenance efficiency. Additionally, the brake disc is attached using standard fasteners, allowing for easy removal and replacement when worn or damaged.

2. Working Principles

The MLPK flexible plum blossom coupling with brake disc operates based on two core principles: flexible torque transmission through the plum blossom elastic element and mechanical braking through the brake disc and associated braking system. Understanding these principles is essential to grasping the coupling's functionality and performance.

2.1 Torque Transmission Principle

During normal operation, torque generated by the prime mover (e.g., electric motor) is transmitted to the input half-coupling. The plum blossom elastic element, which is inserted into the grooves of both half-couplings, transfers this torque to the output half-coupling and ultimately to the driven machinery. The elastic nature of the plum blossom element allows it to deform slightly under load, which enables the coupling to compensate for three types of misalignment: axial misalignment (axial displacement between shafts), radial misalignment (radial offset between shafts), and angular misalignment (tilt between shafts). This misalignment compensation capability is crucial in industrial applications, as it reduces stress on the shafts, bearings, and other transmission components, extending their service life.

Additionally, the elastic element acts as a vibration damper. It absorbs and dissipates vibrational energy generated by the prime mover or driven machinery, preventing the transmission of vibrations to other parts of the system. This vibration damping effect not only improves the stability and smoothness of operation but also reduces noise levels in the workplace.

2.2 Braking Principle

When braking is required (e.g., during emergency stop, equipment shutdown, or load holding), the braking system (brake calipers or brake shoes) is activated. The brake calipers clamp onto the friction surface of the brake disc, generating frictional force. This frictional force is converted into braking torque, which acts on the input shaft of the coupling, slowing down or stopping the rotation of the prime mover and driven machinery. The key to effective braking is the friction coefficient between the brake disc and the braking elements, as well as the structural integrity of the brake disc to withstand the high temperatures and mechanical stresses generated during braking.

It is important to note that the braking system and the coupling operate independently but in coordination. During normal torque transmission, the brake disc rotates freely with the coupling, and the braking system remains inactive. When braking is initiated, the braking system engages quickly, and the coupling's structure ensures that the braking torque is evenly distributed, preventing localized stress concentrations.

3. Performance Advantages of MLPK Flexible Plum Blossom Coupling With Brake Disc

The MLPK flexible plum blossom coupling with brake disc offers a range of performance advantages that make it suitable for a wide variety of industrial applications. These advantages stem from its unique design and the synergy between the flexible coupling and brake disc components.

3.1 Excellent Flexibility and Misalignment Compensation

Compared to rigid couplings, the MLPK coupling's plum blossom elastic element provides superior flexibility, enabling it to compensate for larger amounts of misalignment. Axial misalignment compensation typically ranges from 2 to 10 mm, radial misalignment from 0.1 to 0.5 mm, and angular misalignment from 0.5° to 3°, depending on the specific model and size of the coupling. This high level of misalignment compensation reduces the risk of premature failure of shafts, bearings, and seals, which are often caused by excessive misalignment in rigid coupling systems.

3.2 Reliable Braking Performance

The integrated brake disc design ensures reliable and responsive braking. The brake disc is engineered to have a high thermal capacity, allowing it to withstand the high temperatures generated during braking without warping or deforming. This thermal stability ensures consistent braking performance even in high-frequency braking applications. Additionally, the smooth friction surface of the brake disc provides a stable friction coefficient, ensuring predictable and controllable braking torque. This reliability is critical in applications where safety is paramount, such as in lifting equipment, conveyor systems, and machine tools.

3.3 Vibration Damping and Noise Reduction

The polyurethane or rubber plum blossom elastic element has excellent vibration damping properties. It absorbs vibrational energy from the motor or driven machinery, reducing the amplitude of vibrations transmitted through the transmission system. This not only improves the stability of the entire system but also reduces noise levels. In industrial environments, where noise pollution is a significant concern, this noise reduction feature contributes to a more comfortable and compliant workplace.

3.4 High Torque Transmission Capacity

Despite its compact size and flexible design, the MLPK coupling is capable of transmitting high torque. The half-couplings, made from high-strength steel, are designed to withstand high tensile and shear stresses, ensuring that the coupling can handle the torque requirements of various industrial applications. Torque transmission capacity ranges from a few hundred newton-meters to several thousand newton-meters, depending on the coupling's size and material specifications. This high torque capacity makes the MLPK coupling suitable for use in heavy-duty applications, such as pumps, compressors, and industrial gearboxes.

3.5 Easy Installation and Maintenance

The MLPK coupling's compact and modular design simplifies installation. It does not require complex alignment procedures compared to some other types of couplings, and the integrated brake disc eliminates the need for additional braking system mounting. Maintenance is also straightforward: the plum blossom elastic element can be replaced quickly without disassembling the entire coupling or moving the connected machinery. The brake disc, if worn, can be easily removed and replaced using standard tools. This ease of installation and maintenance reduces downtime and lowers the overall cost of ownership.

4. Typical Applications

The MLPK flexible plum blossom coupling with brake disc is versatile and finds applications in a wide range of industries, thanks to its combination of flexible torque transmission and reliable braking. Below are some of the most typical application areas:

4.1 Industrial Automation and Robotics

In industrial automation systems and robotics, precision and reliability are critical. The MLPK coupling's ability to compensate for misalignment and dampen vibrations makes it ideal for connecting servo motors to ball screws, linear guides, and other precision components. The integrated brake disc provides emergency braking capability, ensuring that the robot or automated equipment stops quickly and safely in the event of a power failure or system fault. Applications include assembly lines, pick-and-place robots, and CNC machine tools.

4.2 Material Handling Equipment

Material handling equipment, such as conveyors, elevators, and hoists, requires both efficient torque transmission and reliable braking. The MLPK coupling is well-suited for these applications, as it can handle the variable loads and misalignments common in material handling systems. The brake disc ensures that the equipment stops precisely when needed, preventing load slippage and ensuring operator safety. For example, in a conveyor system, the coupling transmits torque from the motor to the conveyor belt, while the brake disc stops the conveyor quickly in case of a jam or emergency.

4.3 Pump and Compressor Systems

Pumps and compressors are widely used in industrial, municipal, and agricultural applications. These systems often operate under variable loads and may experience misalignment due to thermal expansion or vibration. The MLPK coupling's flexibility and vibration damping properties help to protect the pump or compressor shafts and bearings, extending their service life. The integrated brake disc provides an additional layer of safety, allowing the system to be quickly shut down in case of a malfunction, such as a pump cavitation or compressor overpressure.

4.4 Automotive and Transportation

In the automotive and transportation industry, the MLPK coupling is used in various applications, such as electric vehicle drivetrains, agricultural machinery, and construction equipment. In electric vehicles, the coupling connects the electric motor to the transmission, compensating for misalignment and damping vibrations. The brake disc works in conjunction with the vehicle's braking system to provide reliable stopping power. In agricultural machinery, such as tractors and harvesters, the coupling handles the high torque requirements and variable loads, while the brake disc ensures safe and controlled stopping during field operations.

4.5 Power Generation Equipment

Small-scale power generation equipment, such as diesel generators and wind turbines, requires efficient torque transmission and reliable braking. The MLPK coupling is used to connect the engine or turbine to the generator, compensating for misalignment caused by thermal expansion or mechanical vibration. The brake disc is used to stop the generator quickly during maintenance or emergency shutdowns, ensuring the safety of maintenance personnel and protecting the equipment from damage.

5. Maintenance Considerations

Proper maintenance is essential to ensure the long-term performance and reliability of the MLPK flexible plum blossom coupling with brake disc. Below are key maintenance considerations and best practices:

5.1 Regular Inspection

Regular visual and functional inspections should be conducted to identify potential issues early. Inspect the plum blossom elastic element for signs of wear, cracking, or deformation. If the element is worn or damaged, it should be replaced immediately to avoid excessive misalignment and vibration. Inspect the brake disc's friction surface for wear, scoring, or warping. A worn or damaged brake disc can reduce braking performance and should be replaced promptly. Also, check the connecting fasteners for tightness, as loose bolts can cause vibration and lead to component failure.

5.2 Lubrication

While the plum blossom elastic element does not require lubrication, the brake system's moving parts (e.g., brake caliper pins) should be lubricated regularly to ensure smooth operation. Use a high-temperature lubricant suitable for braking systems to prevent seizing and ensure consistent braking performance. Avoid lubricating the brake disc's friction surface, as this will reduce friction and impair braking.

5.3 Alignment Check

Periodically check the alignment of the connected shafts. Even with the coupling's misalignment compensation capability, excessive or prolonged misalignment can increase stress on the coupling components and reduce their service life. Use precision alignment tools, such as laser alignment systems, to ensure that the shafts are aligned within the coupling's specified limits. If misalignment is detected, adjust the position of the motor or driven machinery to correct it.

5.4 Replacement of Worn Components

Replace worn or damaged components promptly to prevent further damage to the coupling and connected equipment. The plum blossom elastic element has a finite service life and should be replaced at regular intervals, even if no visible damage is present. The brake disc's service life depends on the application's braking frequency and load; follow the manufacturer's recommendations for replacement intervals. When replacing components, use genuine replacement parts to ensure compatibility and performance.

5.5 Operating Environment Considerations

The operating environment can have a significant impact on the coupling's performance and service life. Avoid operating the coupling in environments with excessive dust, moisture, or corrosive substances, as these can damage the elastic element and brake disc. If the coupling must be used in such environments, use protective covers or enclosures to shield the components. Also, avoid operating the coupling beyond its specified temperature range, as high temperatures can degrade the elastic element and reduce the brake disc's thermal stability.

6. Conclusion

The MLPK flexible plum blossom coupling with brake disc is a versatile and reliable transmission component that combines the advantages of flexible torque transmission and efficient braking. Its compact design, excellent misalignment compensation, vibration damping, and easy maintenance make it suitable for a wide range of industrial applications, from automation and robotics to material handling and power generation. By understanding its design characteristics, working principles, performance advantages, and maintenance requirements, engineering professionals can select and use the MLPK coupling effectively, ensuring optimal performance and safety in their industrial systems.

As industrial technology continues to advance, the demand for high-performance, multi-functional transmission components will continue to grow. The MLPK flexible plum blossom coupling with brake disc, with its unique combination of flexibility and braking capability, is well-positioned to meet these evolving demands. By incorporating advanced materials and manufacturing processes, future iterations of the MLPK coupling are likely to offer even higher torque capacity, better thermal stability, and longer service life, further expanding its application scope and enhancing its value in industrial power transmission systems.

« MLPK Flexible Plum Blossom Coupling With Brake Disc » Post Date: 2025/12/2

- Tyre Coupling Rubber

- Generator Diaphragm Coupling

- ROQ Internal Spline Coupling

- Elastic Rubber Ring Pin Couplings

- Wholesale Of Small Diaphragm Couplings

- RLAT Laminated Membrane Coupling

- Long Span High-precision Diaphragm Coupling

- End Face Clearance Of Drum Gear Coupling

- Flexible Bush Couplings Company

- Column Pin Flexible Couplings Design