LX Star Coupling

Rokee® provide LX Star Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings play an indispensable role as the critical link between rotating shafts. Among the diverse range of coupling types available, the LX Star Coupling has emerged as a reliable and versatile solution, widely adopted across various industrial sectors.

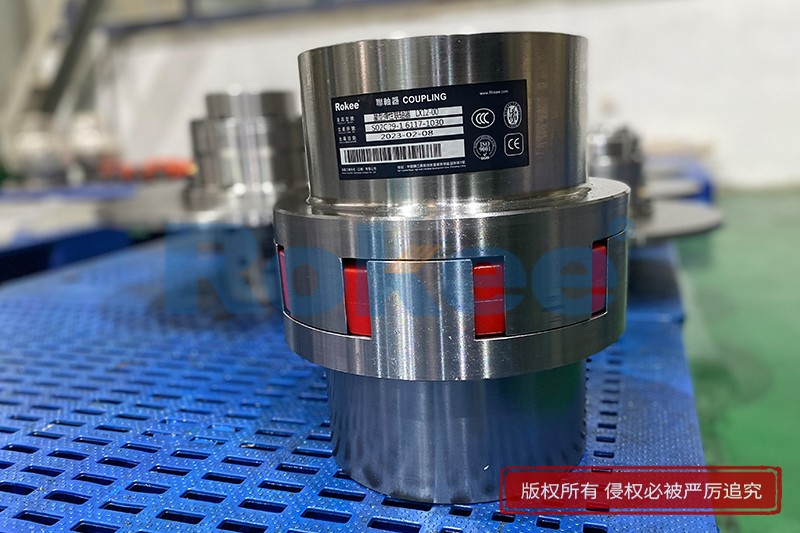

The structural design of the LX Star Coupling is a testament to its practicality and efficiency in power transmission. At its core, this type of coupling consists of three main components: two shaft hubs, a star-shaped elastic element, and several connecting fasteners. The shaft hubs are typically manufactured from high-strength metallic materials such as carbon steel or alloy steel, which possess excellent mechanical properties including high tensile strength, wear resistance, and fatigue resistance. These hubs are designed with a cylindrical structure that features a keyway or spline connection, ensuring a secure and tight fit with the input and output shafts. The keyway design allows for the transmission of torque through the interaction between the key and the hub, preventing relative rotation between the shaft and the hub during operation.

The star-shaped elastic element, which gives the coupling its name, is the most distinctive component of the LX Star Coupling. Unlike rigid couplings that transmit torque directly through hard contact, the elastic element is made from flexible materials such as polyurethane, rubber, or engineering plastics. These materials are selected for their excellent elasticity, shock absorption capacity, and resistance to aging and chemical corrosion. The star-shaped design typically features three or more arms that extend outward from the center, each of which is designed to fit into corresponding grooves on the shaft hubs. This structural arrangement not only enables the transmission of torque but also provides a certain degree of flexibility to compensate for misalignments between the connected shafts.

Connecting fasteners such as bolts and nuts are used to assemble the two shaft hubs and the elastic element into a single integrated unit. The fasteners are carefully selected to match the load-bearing requirements of the coupling, ensuring that the assembly remains tight and stable even under high torque and high-speed operating conditions. In some advanced designs, the fasteners may be equipped with lock washers or thread-locking compounds to prevent loosening due to vibration during operation.

The operational principle of the LX Star Coupling is based on the combination of rigid transmission and elastic compensation. When the input shaft rotates, torque is transmitted from the input hub to the elastic star element through the contact between the hub grooves and the star arms. The elastic element then transfers the torque to the output hub, which in turn drives the output shaft to rotate. During this process, the elastic properties of the star element come into play, allowing the coupling to accommodate three types of shaft misalignments: axial misalignment (relative movement along the shaft axis), radial misalignment (offset perpendicular to the shaft axis), and angular misalignment (tilt between the two shafts). This ability to compensate for misalignments is crucial in practical applications, as perfect alignment between shafts is often difficult to achieve due to manufacturing tolerances, installation errors, or thermal expansion and contraction during operation.

Another key functional characteristic of the LX Star Coupling is its excellent shock absorption and vibration damping capabilities. In mechanical systems, the operation of motors, pumps, compressors, and other equipment often generates vibrations and shocks, which can be transmitted through the transmission shaft to other components, leading to increased wear, reduced service life, and even system failure. The elastic star element of the LX Star Coupling acts as a buffer, absorbing the energy generated by vibrations and shocks, thereby reducing their transmission to the connected shafts and equipment. This not only improves the stability and reliability of the entire transmission system but also reduces noise levels during operation, creating a more favorable working environment.

Additionally, the LX Star Coupling offers the advantage of simple structure, easy installation, and convenient maintenance. Compared to complex coupling types such as gear couplings or universal joints, the LX Star Coupling has fewer components, making its assembly and disassembly straightforward. This simplicity not only reduces the time and labor required for installation but also lowers the maintenance costs. In the event of wear or damage to the elastic element, it can be easily replaced without the need to disassemble the entire shaft system, minimizing downtime and improving the overall operational efficiency of the equipment.

The versatility of the LX Star Coupling is reflected in its wide range of application scenarios across various industrial sectors. One of the most common applications is in the field of general machinery, including pumps, fans, compressors, and conveyors. In these systems, the coupling is used to connect the motor to the working machine, transmitting torque while compensating for any misalignments and absorbing vibrations. For example, in a centrifugal pump system, the LX Star Coupling ensures that the torque from the motor is efficiently transmitted to the pump impeller, while accommodating the slight misalignments that may occur due to the thermal expansion of the pump shaft during operation.

Another important application area is the manufacturing industry, particularly in machine tools such as lathes, milling machines, and grinding machines. Machine tools require precise power transmission to ensure the accuracy of machining operations. The LX Star Coupling, with its ability to transmit torque stably and compensate for minor misalignments, helps to maintain the precision of the machine tool's spindle rotation, thereby improving the quality of the machined parts. Additionally, the shock absorption capability of the coupling reduces the impact of cutting vibrations on the machine tool, extending its service life.

The LX Star Coupling is also widely used in the automotive and transportation industry, particularly in the transmission systems of light-duty vehicles, agricultural machinery, and construction equipment. In these applications, the coupling must withstand harsh operating conditions such as high torque, frequent starts and stops, and significant vibrations. The high-strength construction of the shaft hubs and the durable elastic element make the LX Star Coupling well-suited for these demanding environments. For example, in a small agricultural tractor, the coupling connects the engine to the transmission, ensuring reliable power transmission even when the tractor is operating on uneven terrain.

In addition to these industrial applications, the LX Star Coupling is also used in renewable energy systems such as small wind turbines and solar water pumps. In small wind turbines, the coupling connects the rotor to the generator, transmitting the rotational energy generated by the wind to the generator while compensating for the misalignments caused by the wind load. The elastic element of the coupling also absorbs the vibrations generated by the rotating rotor, protecting the generator from damage.

When selecting an LX Star Coupling for a specific application, several key factors must be taken into consideration to ensure optimal performance and reliability. The first and most important factor is the torque capacity of the coupling. The selected coupling must have a torque rating that is sufficient to handle the maximum torque generated by the system. It is recommended to choose a coupling with a torque capacity that is 1.2 to 1.5 times the maximum operating torque to provide a safety margin. The torque capacity of the LX Star Coupling is determined by the material and size of the shaft hubs, the number and size of the star arms, and the material properties of the elastic element.

Another critical factor is the shaft diameter. The coupling's shaft hubs must be compatible with the diameters of the input and output shafts. Most manufacturers offer LX Star Couplings in a range of standard shaft diameters, and custom sizes can also be produced to meet specific requirements. It is important to ensure that the fit between the hub and the shaft is tight enough to prevent slippage during operation, which can lead to excessive wear and reduced torque transmission efficiency.

The operating speed of the system is also an important consideration. The LX Star Coupling has a maximum allowable rotational speed, which is determined by the material strength of the components and the centrifugal forces generated during rotation. Exceeding the maximum allowable speed can lead to premature failure of the coupling, particularly the elastic element. Therefore, it is essential to select a coupling that can withstand the operating speed of the system.

The type and magnitude of shaft misalignment must also be taken into account. Different applications may have different levels of axial, radial, and angular misalignment. The LX Star Coupling has specific compensation capabilities for each type of misalignment, and it is important to ensure that the selected coupling can accommodate the maximum misalignment expected in the system. If the misalignment exceeds the coupling's compensation range, it can lead to increased stress on the elastic element, reducing its service life and potentially causing failure.

The operating environment is another factor that cannot be ignored. Factors such as temperature, humidity, chemical exposure, and dust levels can affect the performance and service life of the LX Star Coupling. For example, in high-temperature environments, the elastic element may degrade more quickly, so it is necessary to select a coupling with an elastic element made from high-temperature-resistant materials. In corrosive environments, the shaft hubs may need to be coated with anti-corrosion materials or made from corrosion-resistant alloys.

Proper installation and maintenance are essential to ensure the long-term performance and reliability of the LX Star Coupling. During installation, the first step is to ensure that the input and output shafts are aligned as accurately as possible. Although the coupling can compensate for minor misalignments, excessive misalignment will increase the load on the elastic element and reduce its service life. Alignment can be checked using tools such as a dial indicator or a laser alignment tool. The next step is to install the shaft hubs onto the shafts, ensuring that the key is properly seated in the keyway and that the hub is tightened securely using the appropriate fasteners.

After installing the hubs, the elastic star element is placed between the two hubs, ensuring that each arm of the star fits into the corresponding groove on the hubs. The connecting fasteners are then installed and tightened to the specified torque. It is important not to over-tighten the fasteners, as this can compress the elastic element excessively, reducing its elasticity and shock absorption capacity. Finally, the entire assembly should be checked to ensure that there is no interference between the coupling and other components, and that the coupling rotates freely without any binding.

Regular maintenance is crucial to detect potential issues early and prevent unexpected failures. Maintenance tasks include regular inspections of the coupling components for signs of wear, damage, or deformation. The elastic element should be checked for cracks, hardening, or excessive wear, as these are indicators that it may need to be replaced. The connecting fasteners should also be inspected regularly to ensure that they are tight and that there is no signs of loosening. In addition, the alignment of the shafts should be checked periodically, as misalignments can increase over time due to wear of the bearings or other components.

Lubrication is another important aspect of maintenance, although the LX Star Coupling generally requires minimal lubrication compared to rigid couplings with moving parts. However, if the coupling is used in a dusty or high-temperature environment, it may be necessary to apply a small amount of lubricant to the keyway and the contact surfaces between the hub and the shaft to prevent corrosion and reduce wear. It is important to use the appropriate type of lubricant that is compatible with the materials of the coupling components.

Looking ahead, the future development of the LX Star Coupling is likely to be driven by advancements in materials science and manufacturing technology. One of the key trends is the development of high-performance elastic materials that offer improved durability, higher temperature resistance, and better chemical resistance. For example, the use of composite materials or modified polyurethanes may enhance the elastic element's ability to withstand harsh operating conditions, extending the service life of the coupling.

Another trend is the adoption of advanced manufacturing processes such as 3D printing and precision machining. 3D printing technology allows for the production of complex-shaped star elements with optimized designs that improve torque transmission efficiency and misalignment compensation capabilities. Precision machining, on the other hand, ensures that the shaft hubs and other components have tighter tolerances, improving the overall performance and reliability of the coupling.

In addition, the integration of smart technologies into the LX Star Coupling is an emerging trend. The incorporation of sensors to monitor parameters such as torque, temperature, vibration, and misalignment can provide real-time data on the coupling's operating condition. This data can be transmitted to a central monitoring system, allowing for predictive maintenance and early detection of potential issues. Predictive maintenance can significantly reduce downtime, lower maintenance costs, and improve the overall efficiency of the transmission system.

Furthermore, there is a growing focus on sustainability and energy efficiency in the industrial sector, which is likely to influence the design of the LX Star Coupling. Manufacturers may develop lighter-weight couplings using high-strength, lightweight materials, which can reduce the energy consumption of the transmission system. Additionally, the use of recyclable materials in the production of coupling components can help to reduce the environmental impact of the product.

In conclusion, the LX Star Coupling is a versatile and reliable component in mechanical power transmission systems, offering a unique combination of structural simplicity, efficient torque transmission, misalignment compensation, and shock absorption. Its wide range of applications across various industrial sectors, from general machinery to renewable energy systems, is a testament to its practical value. By carefully considering factors such as torque capacity, shaft diameter, operating speed, misalignment, and operating environment during selection, and adhering to proper installation and maintenance practices, engineers and technicians can ensure that the LX Star Coupling delivers optimal performance and a long service life.

As materials science, manufacturing technology, and smart technologies continue to advance, the LX Star Coupling is poised to become even more efficient, durable, and intelligent. These advancements will further expand its application scope and enhance its role in supporting the reliable and efficient operation of modern industrial systems. Whether in traditional manufacturing or emerging renewable energy sectors, the LX Star Coupling will remain an essential component in the field of mechanical power transmission for years to come.

« LX Star Coupling » Post Date: 2023/10/8

URL: https://www.rokeecoupling.com/en/customer-cases/lx-star-coupling.html

- Flexible Plum Couplings Takeover

- Pump Couplings

- Which Is The Best Manufacturer For Industrial Universal Shafts

- Cross Bearing Universal Joint Coupling

- Gap Chart of Brake Drum Couplings

- Hydraulic Sleeve Type Diaphragm Coupling

- Custom Column Pin Sleeve Coupling

- Disc Coupling Models

- Cross Shaft Universal Coupling For Sale

- Elevator Gear Coupling