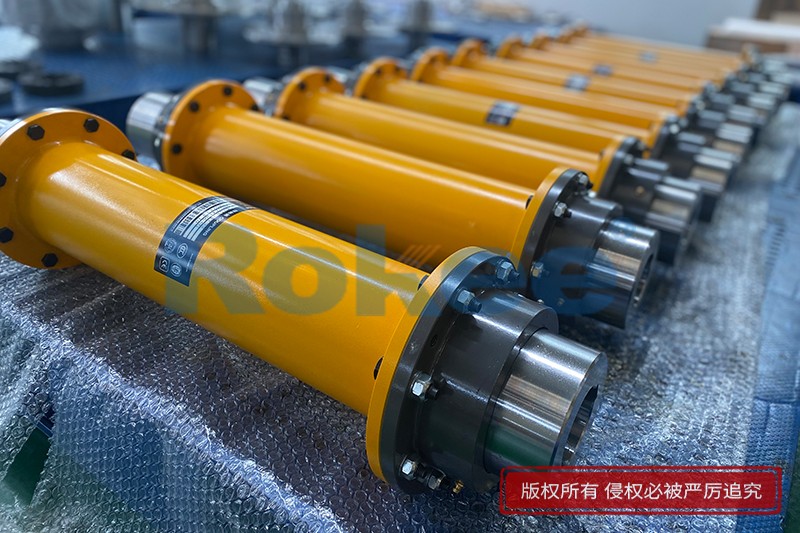

Gear Coupling With Intermediate Shaft

Rokee® provide Gear Coupling With Intermediate Shaft, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, the efficient and reliable transfer of torque between rotating shafts is a fundamental requirement across numerous industrial sectors. Among the various coupling solutions available, gear couplings with intermediate shafts have emerged as a robust and versatile option, particularly suited for applications involving long shaft distances, misalignment compensation, and high torque loads.

Understanding Gear Couplings With Intermediate Shafts: Basic Concepts and Design

A gear coupling is a type of mechanical coupling designed to transmit torque between two shafts while accommodating limited amounts of misalignment, including angular, parallel, and axial misalignment. Unlike rigid couplings, which require precise shaft alignment, gear couplings leverage the meshing of gear teeth to provide flexibility, making them ideal for dynamic operating conditions. When an intermediate shaft is integrated into the design, the coupling assembly is divided into two separate gear coupling units connected by a central intermediate shaft. This configuration extends the overall length of the coupling system, enabling torque transmission between shafts that are spaced far apart, a scenario where direct coupling would be impractical or impossible.

The core components of a gear coupling with intermediate shaft include four main parts: two driving gear hubs, two driven gear hubs, an intermediate shaft, and housing units (optional but common for protection and lubrication). The gear hubs are typically attached to the driving shaft, intermediate shaft, and driven shaft via keyways, splines, or interference fits, ensuring a secure connection that minimizes slippage during torque transmission. The gear teeth on the hubs are precision-machined to mesh with each other, with common designs featuring external teeth on the hubs that engage with internal teeth on a sleeve or flange. In some configurations, the intermediate shaft itself may have gear teeth at both ends, directly meshing with the gear hubs of the driving and driven shafts.

Material selection is a critical aspect of the design process, as the components must withstand high torque, friction, and potential impact loads. Common materials used for gear hubs and intermediate shafts include alloy steels, such as nickel-chromium steel and chromium-molybdenum steel, which offer excellent strength, durability, and wear resistance. The gear teeth are often heat-treated (e.g., carburizing, quenching, and tempering) to enhance their surface hardness, reducing wear and extending the service life of the coupling. For applications in corrosive environments, materials such as stainless steel or specialized coatings may be used to protect against rust and chemical degradation.

Operational Principles: How Gear Couplings With Intermediate Shafts Transmit Torque

The operational principle of a gear coupling with intermediate shaft is rooted in the meshing of gear teeth to transfer rotational motion and torque. When the driving shaft rotates, it imparts motion to the driving gear hub, which in turn meshes with the gear teeth on one end of the intermediate shaft (or with a connecting sleeve that links to the intermediate shaft). The intermediate shaft then rotates, transmitting the torque to the gear hub attached to the driven shaft, ultimately causing the driven shaft to rotate. This sequential transfer of torque through the intermediate shaft allows for power transmission over extended distances, overcoming the limitations of direct shaft-to-shaft coupling.

A key feature of this design is its ability to accommodate misalignment between the driving and driven shafts. Angular misalignment, which occurs when the shafts are not colinear, is compensated for by the slight angular movement of the gear teeth as they mesh. Parallel misalignment, where the shafts are offset but parallel, is accommodated by the radial clearance between the gear teeth and the ability of the intermediate shaft to bridge the offset distance. Axial misalignment, caused by thermal expansion or contraction of shafts during operation, is handled by the axial movement of the gear hubs along the intermediate shaft or within the coupling sleeves. The flexibility provided by the gear meshing ensures that the coupling can operate smoothly even when the shafts are not perfectly aligned, reducing stress on the shafts, bearings, and other components of the mechanical system.

Lubrication plays a vital role in the operation of gear couplings with intermediate shafts. The meshing gear teeth generate friction during operation, which can lead to wear, heat buildup, and reduced efficiency if not properly lubricated. Lubricants such as mineral oils, synthetic oils, or greases are used to create a protective film between the gear teeth, reducing friction and wear. In addition, lubrication helps to dissipate heat, prevent corrosion, and remove debris that may accumulate during operation. Many gear coupling designs include sealed housings to retain lubricant and prevent contamination from external particles, such as dust, dirt, and moisture.

Key Advantages of Gear Couplings With Intermediate Shafts

Gear couplings with intermediate shafts offer a range of advantages that make them well-suited for a wide variety of industrial applications. One of the primary advantages is their ability to transmit high torque loads. The meshing gear teeth provide a large contact area, allowing the coupling to handle significantly higher torque compared to other types of flexible couplings, such as jaw couplings or elastomeric couplings. This makes them ideal for heavy-duty applications, such as in mining, steel production, and large-scale manufacturing.

Another major advantage is their ability to accommodate long shaft distances. The intermediate shaft acts as an extension, enabling torque transmission between shafts that are separated by several meters, a scenario that would be challenging or impossible with direct coupling. This flexibility in distance makes gear couplings with intermediate shafts particularly useful in large industrial machinery, where components may be spaced far apart to accommodate complex layouts.

The excellent misalignment compensation capability of these couplings is also a significant benefit. As mentioned earlier, they can accommodate angular, parallel, and axial misalignment, reducing the need for precise shaft alignment during installation and operation. This not only simplifies the installation process but also reduces stress on the mechanical system, extending the service life of shafts, bearings, and other components. In dynamic operating conditions, where misalignment may occur due to vibration, thermal expansion, or component wear, this flexibility is crucial for maintaining reliable operation.

Gear couplings with intermediate shafts are also known for their durability and long service life. The use of high-strength materials and precision machining ensures that the couplings can withstand harsh operating conditions, including high temperatures, heavy loads, and exposure to harsh environments. With proper lubrication and maintenance, these couplings can operate for many years without significant wear or failure, reducing downtime and maintenance costs for industrial operations.

Additionally, these couplings offer high efficiency in torque transmission. The meshing gear teeth provide a positive drive, minimizing power loss during transmission. Unlike some flexible couplings that rely on elastomeric elements, which can degrade over time and reduce efficiency, gear couplings maintain consistent performance throughout their service life. This high efficiency is particularly important in energy-intensive applications, where minimizing power loss can lead to significant cost savings.

Diverse Industrial Applications of Gear Couplings With Intermediate Shafts

Due to their robust design, high torque capacity, and flexibility, gear couplings with intermediate shafts find applications in a wide range of industrial sectors. One of the most common applications is in the mining industry, where they are used in equipment such as conveyor systems, crushers, and mills. In conveyor systems, which are used to transport bulk materials over long distances, the intermediate shaft allows for torque transmission between the drive motor and the conveyor drum, even when the motor and drum are spaced far apart. Crushers and mills, which operate under high torque loads, benefit from the high torque capacity of gear couplings, ensuring reliable power transmission during the crushing and grinding processes.

The steel industry is another major user of gear couplings with intermediate shafts. Steel production involves heavy-duty machinery, such as rolling mills, blast furnaces, and continuous casters. Rolling mills, which are used to shape steel into various forms (e.g., sheets, bars, and pipes), require precise and reliable torque transmission between the drive motor and the rolling stands. The intermediate shaft allows for the necessary distance between components, while the misalignment compensation capability ensures smooth operation even under the high loads and vibrations associated with rolling operations.

In the power generation sector, gear couplings with intermediate shafts are used in applications such as wind turbines, hydroelectric generators, and thermal power plants. Wind turbines, for example, require torque transmission between the rotor and the generator, which may be spaced apart due to the turbine's design. The intermediate shaft allows for this distance, while the coupling's ability to accommodate misalignment ensures reliable operation even in windy conditions, where the rotor may experience dynamic loads and vibrations. Hydroelectric generators also use these couplings to transmit torque from the turbine to the generator, handling the high torque loads associated with large-scale power generation.

Other industrial applications include large-scale manufacturing equipment, such as extruders, presses, and conveyors in the automotive and aerospace industries. Extruders, which are used to shape plastic, metal, and other materials, require high torque transmission over extended distances, making gear couplings with intermediate shafts an ideal choice. In the marine industry, these couplings are used in ship propulsion systems, where they transmit torque from the engine to the propeller shaft, accommodating the misalignment and distance between the engine and the propeller.

Maintenance Considerations for Gear Couplings With Intermediate Shafts

To ensure the reliable operation and long service life of gear couplings with intermediate shafts, proper maintenance is essential. One of the most critical maintenance tasks is regular lubrication. As mentioned earlier, lubrication reduces friction and wear between the gear teeth, dissipates heat, and prevents corrosion. The type of lubricant used should be appropriate for the operating conditions, including temperature, load, and environment. Lubricant levels should be checked regularly, and the lubricant should be replaced at specified intervals to ensure optimal performance. In addition, sealed housings should be inspected for leaks, as lost lubricant can lead to increased wear and premature failure.

Regular inspection of the gear teeth is also important. The teeth should be checked for signs of wear, such as pitting, scuffing, or chipping, which can occur due to excessive load, misalignment, or inadequate lubrication. If wear is detected, the coupling should be repaired or replaced to prevent further damage to the shafts and other components. The gear hubs, intermediate shaft, and connecting components should also be inspected for cracks, deformation, or loose fasteners, which can compromise the integrity of the coupling.

Shaft alignment should be checked periodically, even though gear couplings can accommodate misalignment. Excessive misalignment can lead to increased wear on the gear teeth and bearings, reducing the service life of the coupling. If misalignment is detected beyond the coupling's rated capacity, adjustments should be made to realign the shafts. This may involve adjusting the position of the motor, gearbox, or other components to ensure that the shafts are as colinear as possible.

In addition, it is important to follow the manufacturer's recommended maintenance schedule, which may include tasks such as cleaning the coupling components, inspecting seals and gaskets, and testing the coupling's performance under load. Training maintenance personnel to properly inspect and maintain the couplings is also crucial, as improper maintenance can lead to premature failure and costly downtime.

Future Trends and Innovations in Gear Coupling Design

As industrial technology continues to advance, gear couplings with intermediate shafts are also evolving to meet the changing needs of modern applications. One of the key trends is the integration of smart technologies for condition monitoring. Sensors embedded in the coupling can monitor parameters such as temperature, vibration, and torque, providing real-time data on the coupling's performance. This allows for predictive maintenance, where potential issues can be detected before they lead to failure, reducing downtime and maintenance costs.

Another trend is the development of lightweight and high-strength materials, such as carbon fiber composites and advanced alloys. These materials offer improved strength-to-weight ratios, reducing the overall weight of the coupling while maintaining or increasing its torque capacity. This is particularly beneficial in applications where weight is a critical factor, such as in aerospace and automotive industries.

Advancements in manufacturing processes, such as additive manufacturing (3D printing), are also impacting gear coupling design. Additive manufacturing allows for the production of complex gear tooth profiles and component geometries that are difficult or impossible to achieve with traditional machining methods. This enables the design of more efficient and durable couplings, tailored to specific applications.

In addition, there is a growing focus on sustainability in industrial design, leading to the development of gear couplings that are more energy-efficient and environmentally friendly. This includes the use of biodegradable lubricants, recyclable materials, and designs that minimize power loss during operation.

Conclusion

Gear couplings with intermediate shafts are a critical component in modern mechanical power transmission systems, offering high torque capacity, flexibility in distance, and excellent misalignment compensation. Their robust design and durability make them well-suited for a wide range of industrial applications, from mining and steel production to power generation and marine propulsion. Proper maintenance, including regular lubrication, inspection, and shaft alignment, is essential to ensure their reliable operation and long service life.

As technology continues to advance, gear couplings with intermediate shafts are expected to become even more efficient, durable, and intelligent, incorporating smart monitoring systems, advanced materials, and innovative manufacturing processes. These advancements will further enhance their role in industrial applications, ensuring the reliable and efficient transmission of torque in an increasingly complex and demanding industrial landscape.

« Gear Coupling With Intermediate Shaft » Post Date: 2023/10/8

URL: https://www.rokeecoupling.com/en/customer-cases/gear-coupling-with-intermediate-shaft.html

- Stiffness of Bush Pin Type Flexible Coupling

- Lamina Coupling Make

- Pin Bush Type Coupling Function

- Customized By The Manufacturer Of The Transmission Seat Diaphragm Coupling

- Flange Gear Coupling Models

- Gear Backlash Of Drum Gear Coupling

- Bush Pin Coupling Drawing

- Small Ball Gear Universal Coupling

- Application of Crown Gear Couplings

- High Precision Diaphragm Coupling