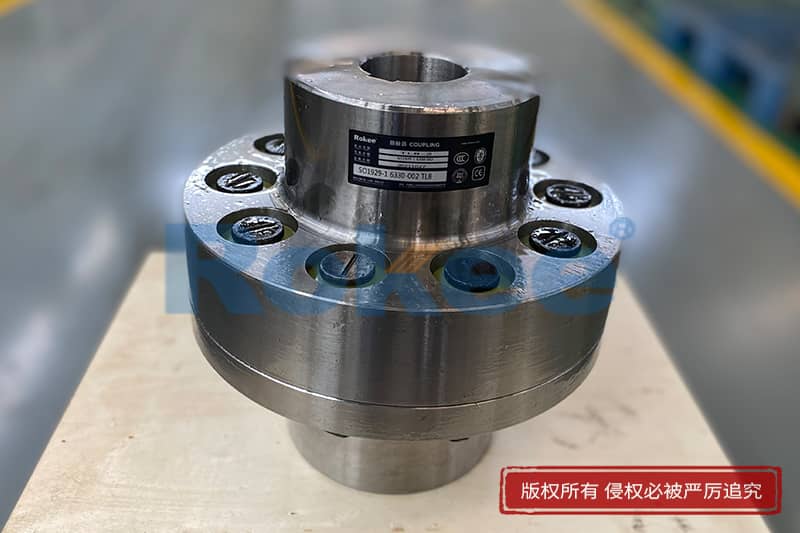

TL Pin and Bush Coupling

Rokee® provide TL Pin and Bush Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as critical components that connect two rotating shafts, enabling the transfer of torque while accommodating various forms of misalignment. Among the diverse range of couplings available, the TL Pin and Bush Coupling stands out for its simplicity, reliability, and versatility in industrial settings. This type of coupling is widely utilized across sectors such as manufacturing, agriculture, mining, and automotive, owing to its ability to handle moderate to high torque loads and adapt to common shaft misalignments.

To understand the functionality of TL Pin and Bush Couplings, it is essential to first examine their structural composition. Unlike complex coupling designs that incorporate intricate gears or flexible elements, the TL Pin and Bush Coupling features a straightforward construction that consists of four primary components: two coupling halves, pins, bushes, and in some cases, a protective cover. Each coupling half is typically fabricated from robust materials such as cast iron, steel, or aluminum alloy, depending on the application requirements for torque capacity and environmental resistance. These coupling halves are mounted on the ends of the two shafts that need to be connected, usually via keyways and set screws or taper-lock bushings to ensure a secure fit and prevent slippage during operation.

The pins are integral to the torque transfer mechanism of the coupling. They are uniformly spaced along the circumference of one of the coupling halves, extending outward from the face of the half. The number and size of the pins vary based on the intended torque rating of the coupling; higher torque applications require more pins or larger diameter pins to distribute the load evenly. The bushes, which are often made from elastic or semi-elastic materials such as rubber, polyurethane, or nylon, are inserted into corresponding holes in the second coupling half. These bushes are designed to fit snugly around the pins, creating a flexible connection between the two coupling halves. The use of elastic bushes is a defining feature of TL Pin and Bush Couplings, as it imparts a degree of flexibility that is crucial for accommodating misalignment and reducing vibration.

The working principle of TL Pin and Bush Couplings revolves around the transfer of torque through the interaction between the pins and bushes. When one shaft rotates, it drives the coupling half attached to it, causing the pins to rotate as well. As the pins turn, they exert a force on the bushes, which in turn transmit the torque to the second coupling half and the connected shaft. The elastic nature of the bushes allows for relative movement between the pins and bushes, which enables the coupling to accommodate three main types of shaft misalignment: axial misalignment (where the shafts are offset along their axial line), radial misalignment (where the shafts are parallel but offset radially), and angular misalignment (where the shafts are not parallel but intersect at an angle). This flexibility is essential in practical applications, as perfect alignment of shafts is nearly impossible to achieve and maintain due to factors such as manufacturing tolerances, thermal expansion, and structural deflection under load.

Another key aspect of the working principle is the damping effect provided by the elastic bushes. During operation, rotating machinery generates vibrations, which can be transmitted through the shafts and cause excessive noise, wear, and fatigue in other components. The elastic bushes in TL Pin and Bush Couplings absorb a significant portion of these vibrations, reducing their transmission to the connected equipment and the surrounding structure. This damping effect not only improves the operational smoothness of the machinery but also extends the service life of both the coupling and the associated components, such as bearings and seals.

One of the primary advantages of TL Pin and Bush Couplings is their simplicity in design and construction. This simplicity translates to several benefits, including ease of manufacturing, lower production costs, and straightforward installation and maintenance. Compared to more complex couplings like gear couplings or disc couplings, TL Pin and Bush Couplings require fewer precision-machined parts, making them more cost-effective for a wide range of applications. The installation process typically involves mounting the coupling halves on the shafts, aligning the shafts as closely as possible, inserting the bushes into the corresponding holes, and securing the pins in place. No specialized tools or complex procedures are required, which reduces installation time and labor costs.

Versatility is another notable advantage of TL Pin and Bush Couplings. They are available in a wide range of sizes and configurations, allowing them to be adapted to different shaft diameters and torque requirements. The choice of materials for the coupling halves and bushes further enhances their versatility. For example, cast iron coupling halves are suitable for general-purpose applications, while steel halves are used for high-torque or heavy-duty applications. Rubber bushes are ideal for applications requiring good vibration damping, while polyurethane bushes offer higher wear resistance and are suitable for harsh operating environments. This flexibility in material selection ensures that TL Pin and Bush Couplings can be tailored to meet the specific needs of various industries and applications.

In terms of performance, TL Pin and Bush Couplings are capable of handling moderate to high torque loads, making them suitable for a wide range of power transmission applications. Their ability to accommodate misalignment and dampen vibrations also contributes to their reliable performance in demanding operating conditions. Unlike rigid couplings, which can cause excessive stress on shafts and bearings when misalignment is present, TL Pin and Bush Couplings distribute the stress evenly through the elastic bushes, reducing the risk of component failure. Additionally, the replaceable nature of the bushes is a significant advantage. Over time, the bushes may wear out due to friction and exposure to environmental factors, but they can be easily replaced without replacing the entire coupling, which reduces maintenance costs and downtime.

The industrial applications of TL Pin and Bush Couplings are diverse, spanning across multiple sectors. In the manufacturing industry, they are commonly used in machinery such as conveyor systems, pumps, compressors, and electric motors. Conveyor systems, which are used to transport materials in factories and warehouses, rely on couplings to connect the motor to the conveyor belt drive shaft. TL Pin and Bush Couplings are well-suited for this application due to their ability to handle the moderate torque loads and accommodate the slight misalignments that may occur due to the long length of the conveyor system. Pumps and compressors also benefit from the vibration damping properties of these couplings, which help to reduce noise and extend the service life of the equipment.

In the agricultural sector, TL Pin and Bush Couplings are used in farm machinery such as tractors, harvesters, and irrigation pumps. Tractors, for example, use couplings to connect the engine to various attachments such as plows, harrows, and mowers. The ability of TL Pin and Bush Couplings to handle high torque loads and accommodate misalignment makes them ideal for these applications, where the machinery is often subjected to rough terrain and variable loads. Irrigation pumps, which are critical for maintaining crop health, rely on couplings to connect the motor to the pump shaft, ensuring efficient transfer of power and reliable operation.

The mining industry, which operates in some of the harshest environments, also utilizes TL Pin and Bush Couplings in equipment such as crushers, conveyors, and mining pumps. Crushers, which are used to break down large rocks into smaller particles, generate high torque loads and significant vibrations. TL Pin and Bush Couplings are able to handle these loads and dampen the vibrations, ensuring smooth and reliable operation. Conveyors in mining operations are often long and subjected to heavy loads, making the misalignment accommodation feature of these couplings essential. Mining pumps, which are used to remove water from mining shafts, also benefit from the reliability and low maintenance requirements of TL Pin and Bush Couplings.

The automotive industry is another sector where TL Pin and Bush Couplings find application, particularly in the transmission systems of commercial vehicles and off-road vehicles. These couplings are used to connect the engine to the transmission or the transmission to the drive axle, enabling the transfer of torque while accommodating the misalignments that occur due to the movement of the vehicle's suspension. The vibration damping properties of the couplings also help to improve the comfort of the vehicle's occupants by reducing the transmission of engine vibrations to the chassis.

While TL Pin and Bush Couplings offer numerous advantages, their successful operation depends on proper installation and alignment. Even though these couplings can accommodate misalignment, excessive misalignment can lead to premature wear of the bushes, increased vibration, and reduced coupling life. Therefore, it is essential to ensure that the shafts are aligned as accurately as possible during installation. The alignment process typically involves checking the radial and angular misalignment using tools such as dial indicators or laser alignment systems. If misalignment is detected, adjustments should be made to the position of the motor or the driven equipment to reduce the misalignment to within the coupling's specified limits.

Proper lubrication is another important consideration for the installation and maintenance of TL Pin and Bush Couplings. While the elastic bushes do not require lubrication, the pins and the coupling halves may need to be lubricated to reduce friction and prevent corrosion. The type of lubricant used depends on the operating conditions, such as temperature, load, and environmental factors. For example, in high-temperature applications, a synthetic lubricant may be required, while in dusty or dirty environments, a grease with good sealing properties may be used. Regular lubrication checks and reapplication are essential to ensure the smooth operation of the coupling.

Maintenance practices for TL Pin and Bush Couplings are relatively simple, thanks to their straightforward design. Regular inspection is the key to preventing unexpected failures. During inspections, the coupling should be checked for signs of wear, such as cracks in the coupling halves, excessive play in the pins and bushes, and damage to the protective cover. The bushes are the most wear-prone component, so they should be inspected regularly and replaced when signs of wear, such as cracks, hardening, or excessive deformation, are detected. Replacing the bushes is a simple process that involves removing the protective cover (if present), extracting the old bushes, and inserting new ones. The pins should also be checked for wear or bending, and replaced if necessary.

In addition to regular inspections and part replacement, it is important to keep the coupling clean and free from debris. Accumulation of dirt, dust, or other contaminants can cause abrasion of the bushes and pins, reducing their service life. The protective cover, if installed, helps to prevent the ingress of contaminants, so it should be checked regularly to ensure it is intact and properly secured. In environments where the coupling is exposed to moisture or corrosive substances, additional protective measures, such as coating the coupling halves with anti-corrosive paint, may be necessary to prevent rust and corrosion.

When selecting a TL Pin and Bush Coupling for a specific application, several factors need to be considered. The first and most important factor is the torque rating of the coupling. The coupling's torque capacity must be sufficient to handle the maximum torque generated by the driving shaft. It is recommended to select a coupling with a torque rating that is slightly higher than the maximum operating torque to provide a safety margin. The shaft diameter is another critical factor, as the coupling halves must be compatible with the diameter of the shafts being connected. The type and amount of misalignment expected in the application should also be considered, as different bush materials have different misalignment capabilities. For example, rubber bushes can accommodate more angular misalignment than polyurethane bushes.

Operating temperature is another important consideration. Elastic bushes can degrade at high temperatures, so it is essential to select a bush material that can withstand the maximum operating temperature of the application. Rubber bushes, for example, have a lower temperature resistance compared to polyurethane or nylon bushes. Environmental factors such as exposure to moisture, chemicals, or abrasive substances should also be taken into account when selecting the coupling materials. For example, in corrosive environments, stainless steel coupling halves may be required, while in abrasive environments, wear-resistant bushes should be chosen.

In conclusion, TL Pin and Bush Couplings are essential components in mechanical power transmission systems, offering a simple, reliable, and cost-effective solution for connecting rotating shafts. Their design, which incorporates elastic bushes, enables them to accommodate misalignment, dampen vibrations, and handle moderate to high torque loads, making them suitable for a wide range of industrial applications. From manufacturing and agriculture to mining and automotive, these couplings play a vital role in ensuring the efficient and reliable operation of machinery. Proper installation, alignment, and maintenance are crucial to maximizing the service life of TL Pin and Bush Couplings, and careful selection based on application requirements ensures optimal performance.

As industrial machinery continues to evolve, the demand for reliable and efficient power transmission components remains high. TL Pin and Bush Couplings, with their inherent advantages of simplicity, versatility, and low maintenance, are likely to remain a popular choice in various sectors. Ongoing advancements in material technology, such as the development of new elastic materials with improved wear resistance and temperature tolerance, may further enhance the performance and application range of these couplings. Whether in small-scale workshops or large-scale industrial facilities, TL Pin and Bush Couplings continue to prove their value as a dependable solution for power transmission needs.

« TL Pin and Bush Coupling » Post Date: 2023/8/17

URL: https://www.rokeecoupling.com/en/customer-cases/tl-pin-and-bush-coupling.html

- Diaphragm Coupling With Liner

- Plum Blossom Coupling Procurement

- Alignment of Flexible Bush Coupling

- Bush Type Coupling Sales

- Principle Of Motor Toothed Coupling

- Stainless Steel High Torque Column Pin Couplings

- High Quality Pin Couplings

- Universal Coupling Assembly

- Structural Form Of Toothed Drum Coupling

- Tire Coupling Tire Body Parameters