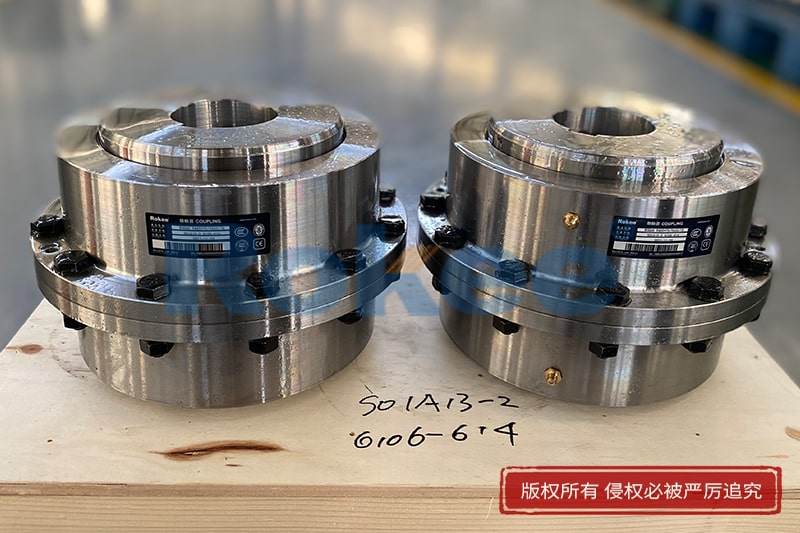

RODA Crowned Teeth Coupling

Rokee® provide RODA Crowned Teeth Coupling, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of mechanical power transmission, couplings serve as critical components that connect rotating shafts, enabling the seamless transfer of torque while accommodating various forms of misalignment. Among the diverse range of coupling types available, the crowned teeth coupling stands out for its exceptional versatility, durability, and ability to handle high torque loads.

The crowned teeth coupling, also known as a crowned gear coupling, is a type of rigid-flexible coupling that utilizes meshing teeth to transmit torque between two shafts. Unlike rigid couplings that require precise alignment and offer no flexibility, or flexible couplings that rely on elastomeric elements for misalignment compensation, crowned teeth couplings combine the rigidity needed for high torque transmission with the flexibility to accommodate angular, parallel, and axial misalignments. This unique combination makes them suitable for a wide array of industrial applications where reliability and performance under demanding conditions are paramount.

Design Characteristics of Crowned Teeth Couplings

The core design of a crowned teeth coupling revolves around two main components: the hub and the sleeve (or flange), each equipped with teeth that mesh together. The defining feature of this coupling type is the crowned profile of the teeth on one of the mating components—typically the hub. The crown is a spherical or cylindrical curvature given to the tooth surface, which differs from the straight teeth found in traditional gear couplings. This curved profile is the key to the coupling’s ability to accommodate misalignment, as it allows for relative movement between the meshing teeth without causing excessive wear or stress.

Most crowned teeth couplings consist of four primary parts: two hubs (each attached to a shaft), an outer sleeve (with internal teeth), and a lubrication system. The hubs are usually forged from high-strength alloy steels, such as nickel-chromium steel or carbon steel, to withstand the high torque and stress encountered during operation. The outer sleeve, which engages with the crowned teeth of the hubs, is also made from durable steel materials, often heat-treated to enhance hardness and wear resistance. The teeth on both the hubs and the sleeve are precision-machined to ensure smooth meshing and efficient torque transmission.

Another important design aspect is the tooth geometry. The number of teeth, module (tooth size), pressure angle, and crown radius are all carefully calculated based on the application requirements, such as torque capacity, shaft diameter, and misalignment range. For example, couplings designed for high torque applications may have fewer, larger teeth to distribute the load over a wider surface area, while those for high-speed applications may have more, smaller teeth to reduce noise and vibration. The crown radius is optimized to allow for the maximum allowable misalignment without compromising the contact area between the teeth.

Lubrication is an integral part of the crowned teeth coupling design. Since the meshing teeth are in direct contact, proper lubrication is essential to reduce friction, minimize wear, and dissipate heat generated during operation. Most couplings are equipped with grease fittings or oil injection ports that allow for regular lubrication. Some high-performance designs may also include sealed housings to prevent lubricant leakage and protect the teeth from contamination by dust, dirt, or moisture.

Operational Principles

The basic operational principle of a crowned teeth coupling is similar to that of a gear train: torque is transmitted through the meshing of teeth on the hubs and the outer sleeve. When one shaft rotates, it drives the attached hub, which in turn rotates the outer sleeve via the meshed teeth. The outer sleeve then drives the second hub, transferring torque to the second shaft. What sets the crowned teeth coupling apart is its ability to accommodate misalignment during this torque transmission process.

Angular misalignment, which occurs when the two shafts are not colinear but intersect at a common point, is compensated for by the crowned tooth profile. The curved surface of the crowned teeth allows the hub to pivot relative to the outer sleeve, ensuring that the teeth remain in contact even when the shafts are at an angle. This pivoting action distributes the load evenly across the tooth surface, preventing concentrated stress points that could lead to premature failure.

Parallel misalignment, where the shafts are parallel but offset from each other, is handled by the sliding of the teeth along the crown radius. As the shafts rotate, the meshing teeth slide slightly relative to each other, accommodating the offset without excessive friction. Axial misalignment, or endplay between the shafts, is typically compensated for by the length of the tooth engagement. The teeth are designed with sufficient axial length to allow for small movements along the shaft axis without disengagement.

It is important to note that while crowned teeth couplings can accommodate moderate levels of misalignment, excessive misalignment can lead to increased wear, noise, and reduced coupling life. Manufacturers typically specify maximum allowable misalignment values for each coupling model, and these limits should be strictly adhered to during installation and operation.

Key Advantages of Crowned Teeth Couplings

Crowned teeth couplings offer a range of advantages that make them a preferred choice in many industrial applications. One of the most significant advantages is their high torque capacity. Due to the rigid meshing of steel teeth, these couplings can transmit much higher torque loads compared to flexible couplings that use elastomeric elements. This makes them ideal for heavy-duty applications such as large motors, pumps, compressors, and industrial gearboxes.

Another major advantage is their ability to accommodate multiple types of misalignment. As discussed earlier, crowned teeth couplings can handle angular, parallel, and axial misalignment, eliminating the need for precise shaft alignment during installation. This not only simplifies the installation process but also reduces the risk of damage to other components in the drive system, such as bearings and seals, which can occur due to misalignment-induced stress.

Durability and long service life are also key benefits of crowned teeth couplings. The use of high-strength steel materials and precision machining ensures that the couplings can withstand harsh operating conditions, including high temperatures, heavy vibrations, and corrosive environments (when properly protected). With regular lubrication and maintenance, these couplings can operate reliably for many years, reducing downtime and replacement costs.

Crowned teeth couplings also exhibit excellent torsional stiffness. Torsional stiffness refers to the coupling’s resistance to twisting under torque, which is important for applications that require precise speed control and position accuracy. Unlike flexible couplings that may have some torsional deflection, crowned teeth couplings maintain a high degree of torsional rigidity, making them suitable for applications such as machine tools, robotics, and precision conveyors.

In addition, these couplings are relatively compact and lightweight compared to other high-torque coupling types. Their compact design allows for easy integration into tight spaces, which is often a requirement in modern industrial machinery. They also operate with minimal noise and vibration, contributing to a quieter and more efficient working environment.

Industrial Applications

The unique combination of high torque capacity, misalignment compensation, and durability makes crowned teeth couplings suitable for a wide range of industrial applications across various sectors. Below are some of the key industries and applications where these couplings are commonly used:

1. Power Generation: In power plants, crowned teeth couplings are used to connect turbines to generators. These applications require the transmission of extremely high torque loads while accommodating slight misalignments that may occur due to thermal expansion and contraction of the shafts during operation. The durability and reliability of crowned teeth couplings make them ideal for this critical application, where downtime can result in significant financial losses.

2. Oil and Gas Industry: The oil and gas sector involves harsh operating conditions, including high pressures, high temperatures, and corrosive environments. Crowned teeth couplings are used in drilling rigs, pumps, compressors, and pipeline systems to transmit torque between motors and driven equipment. Their ability to withstand these harsh conditions and accommodate misalignment makes them a reliable choice for offshore and onshore oil and gas operations.

3. Mining and Mineral Processing: Mining equipment such as crushers, grinders, and conveyors requires high torque transmission to handle heavy loads. Crowned teeth couplings are used to connect motors to these machines, accommodating the misalignments that may occur due to the rough terrain and heavy vibrations common in mining operations. Their durability and resistance to wear ensure reliable operation even in dusty and abrasive environments.

4. Manufacturing and Machinery: In manufacturing facilities, crowned teeth couplings are used in a variety of machinery, including machine tools, robotics, and material handling equipment. Machine tools such as lathes, milling machines, and grinders require precise torque transmission and speed control, which is provided by the high torsional stiffness of crowned teeth couplings. Robotics applications benefit from the coupling’s ability to accommodate slight misalignments while maintaining precise positioning.

5. Marine Industry: In ships and other marine vessels, crowned teeth couplings are used to connect the main engine to the propeller shaft. These applications require high torque transmission and the ability to accommodate misalignments caused by the movement of the vessel in the water. The corrosion resistance of properly protected crowned teeth couplings makes them suitable for the marine environment, where saltwater and humidity can cause significant damage to unprotected components.

6. Chemical and Pharmaceutical Industry: Chemical and pharmaceutical processing equipment, such as mixers, reactors, and pumps, often operate in corrosive environments and require reliable torque transmission. Crowned teeth couplings with appropriate material selections and seals are used in these applications to ensure safe and efficient operation.

Selection and Maintenance Considerations

Proper selection and maintenance of crowned teeth couplings are essential to ensure optimal performance and long service life. When selecting a coupling, several key factors should be considered:

1. Torque Requirement: The coupling must be selected to handle the maximum torque generated by the drive system. It is important to consider both the nominal torque and the peak torque, which may occur during startup or transient conditions. Selecting a coupling with a torque capacity that exceeds the application’s requirements can help prevent premature failure.

2. Shaft Diameter and Speed: The coupling must be compatible with the diameter of the shafts being connected. Additionally, the maximum operating speed of the coupling should be greater than the maximum rotational speed of the shafts to avoid resonance and excessive vibration.

3. Misalignment Tolerance: The coupling’s maximum allowable misalignment should match the expected misalignment in the application. Factors such as thermal expansion, shaft deflection, and installation errors should be taken into account when determining the required misalignment tolerance.

4. Operating Environment: The operating environment, including temperature, humidity, corrosive substances, and dust levels, should be considered when selecting the coupling material and seals. For example, in corrosive environments, stainless steel or plated couplings with sealed housings may be required.

5. Installation and Space Constraints: The coupling’s size and design should be compatible with the available installation space. Additionally, the ease of installation and maintenance should be considered, especially in applications where access is limited.

Maintenance of crowned teeth couplings primarily focuses on proper lubrication and regular inspection. Regular lubrication is essential to reduce friction and wear between the meshing teeth. The type of lubricant used should be compatible with the operating temperature and environment. Grease is commonly used for most applications, while oil may be used for high-speed or high-temperature applications. Lubrication intervals should be followed as recommended by the manufacturer, and the lubricant should be replaced periodically to ensure its effectiveness.

Regular inspection is also important to detect signs of wear, damage, or misalignment. During inspection, the coupling should be checked for tooth wear, cracks, corrosion, and lubricant leakage. The shafts should also be checked for alignment to ensure that the misalignment remains within the allowable limits. If any issues are detected, they should be addressed promptly to prevent further damage to the coupling or other components in the drive system.

In addition, proper storage and handling of crowned teeth couplings before installation are important to prevent damage. Couplings should be stored in a clean, dry environment and protected from impact and corrosion. During installation, care should be taken to avoid damaging the teeth or other components, and the coupling should be installed according to the manufacturer’s instructions.

Conclusion

Crowned teeth couplings play a vital role in modern mechanical power transmission systems, offering a unique combination of high torque capacity, misalignment compensation, durability, and torsional stiffness. Their precision design and robust construction make them suitable for a wide range of industrial applications, from power generation and oil and gas to mining and manufacturing. By understanding the design characteristics, operational principles, and selection and maintenance considerations of crowned teeth couplings, engineers and maintenance professionals can ensure that these components operate reliably and efficiently, contributing to the overall performance and longevity of the mechanical systems they serve.

As industrial machinery continues to evolve, with increasing demands for higher torque, higher speed, and greater reliability, crowned teeth couplings are likely to remain a key component in power transmission systems. Ongoing advancements in materials and manufacturing processes, such as the use of advanced alloys and precision machining technologies, will further enhance the performance and capabilities of these couplings, making them even more versatile and suitable for emerging applications.

« RODA Crowned Teeth Coupling » Post Date: 2023/8/31

URL: https://www.rokeecoupling.com/en/customer-cases/roda-crowned-teeth-coupling.html

- Disc Coupling Models

- Single Diaphragm Coupling Input & Output

- Model Of Elastic Sleeve Pin Coupling For Pumps

- Cross Shaft Universal Coupling Bearing

- Rubber Tyre Couplings Parameters

- Membrane Coupling Engineering Drawing

- Membrane Disc Couplings Wholesale

- Types of Bushed Pin Couplings

- Coaxiality of Bush Type Coupling

- Application of Curved Jaw Shaft Coupling