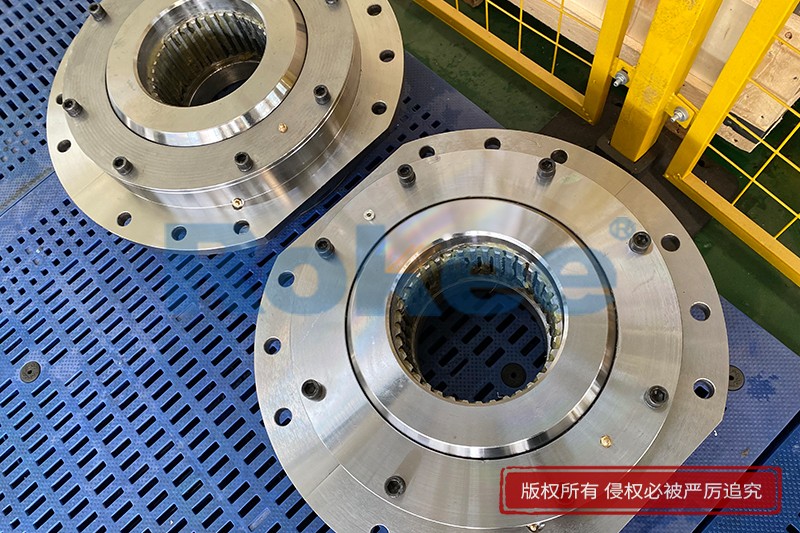

DC Type Drum Coupling For Cranes

Rokee® provide DC Type Drum Coupling For Cranes, non-standard coupling customization, drawing design, batch processing, and export the product to your location.

In the realm of heavy machinery, cranes stand as indispensable assets across construction sites, ports, warehouses, and manufacturing facilities. These powerful equipment pieces are engineered to lift, move, and position heavy loads with precision, reliability, and safety. Behind the seamless operation of a crane lies a complex assembly of components, each playing a vital role in transferring power, ensuring stability, and safeguarding against operational failures. Among these components, the DC type drum coupling holds a position of significant importance. As a key connection element between the crane's motor, gearbox, and drum, the DC type drum coupling is responsible for transmitting torque efficiently, accommodating misalignments, and absorbing shocks and vibrations.

To begin with, it is essential to define what a DC type drum coupling is and how it differs from other coupling types used in industrial machinery. A coupling is a mechanical device designed to connect two rotating shafts, enabling the transmission of power from one shaft to the other while compensating for any misalignment that may exist between them. The DC type drum coupling, specifically tailored for crane drum systems, is a rigid-flexible hybrid coupling that combines the stability of rigid couplings with the flexibility of elastic couplings. Unlike universal joints or flange couplings, which may have limitations in torque capacity or misalignment compensation, the DC type drum coupling is engineered to meet the unique demands of crane operations—high torque transmission, frequent start-stop cycles, varying load conditions, and the need to accommodate axial, radial, and angular misalignments.

The design of DC type drum couplings is characterized by several key features that make them suitable for crane applications. Typically, these couplings consist of two main components: a driving end connected to the gearbox output shaft and a driven end attached to the crane drum. The core of the coupling is a drum-shaped flexible element, which is often made of high-strength rubber, polyurethane, or composite materials. This flexible element is precisely molded to withstand high levels of torque while maintaining elasticity. The drum shape of the flexible element is not arbitrary; it is designed to maximize the contact area between the coupling components, thereby enhancing torque transmission efficiency and distributing stress evenly across the element. Additionally, the coupling incorporates metal hubs or sleeves that are precision machined to ensure a tight fit with the shafts, preventing slippage during operation. Some DC type drum couplings also feature a protective cover that shields the internal components from dust, debris, moisture, and other environmental contaminants, prolonging their service life.

One of the primary functional advantages of DC type drum couplings is their exceptional torque transmission capability. Cranes are required to handle heavy loads, which means the coupling must be able to transmit large amounts of torque from the motor to the drum without failure. The high-strength materials used in the flexible element and the robust design of the metal components enable DC type drum couplings to handle torque ranges that are well-suited for various crane models, from small overhead cranes used in workshops to large gantry cranes employed in ports. Unlike some elastic couplings that may deform or break under excessive torque, DC type drum couplings are engineered to have a high torque capacity, ensuring reliable power transmission even under peak load conditions.

Another crucial advantage of DC type drum couplings is their ability to accommodate multiple types of misalignments. In crane operations, misalignments between the motor, gearbox, and drum shafts are inevitable. These misalignments can occur due to installation errors, thermal expansion and contraction of components during operation, or structural deformations caused by heavy loads. If not properly compensated for, misalignments can lead to increased wear and tear on bearings, shafts, and other components, resulting in premature failure and costly downtime. DC type drum couplings address this issue by allowing for axial movement (movement along the shaft axis), radial movement (side-to-side movement perpendicular to the shaft axis), and angular misalignment (tilting of one shaft relative to the other). The flexible drum element absorbs the forces generated by these misalignments, reducing stress on the connected components and ensuring smooth operation.

Shock absorption and vibration damping are also key performance attributes of DC type drum couplings. Crane operations involve frequent start-stop cycles and sudden load changes, which generate shock loads and vibrations that can be detrimental to the machinery. These shocks and vibrations can cause noise, accelerate component wear, and even lead to structural damage over time. The flexible material of the DC type drum coupling's drum element acts as a buffer, absorbing and dissipating the energy generated by shock loads and vibrations. This not only protects the motor, gearbox, and drum from damage but also improves the overall stability and smoothness of the crane's operation. Operators benefit from reduced noise levels and a more controlled lifting experience, which enhances safety and productivity.

Understanding the operational principle of DC type drum couplings is essential to appreciating their role in crane systems. The basic principle revolves around the transmission of torque through the flexible drum element. When the crane's motor is activated, it generates rotational power that is transmitted to the gearbox, which adjusts the speed and torque to the required levels. The gearbox's output shaft is connected to the driving end of the DC type drum coupling. As the driving end rotates, it imparts torque to the flexible drum element. The drum element, in turn, transfers this torque to the driven end, which is connected to the crane's drum. The drum then rotates, winding or unwinding the hoisting cable to lift or lower the load. Throughout this process, the flexible drum element compensates for any misalignments between the shafts, absorbs shocks from start-stop cycles and load changes, and dampens vibrations, ensuring that the torque is transmitted efficiently and smoothly.

The application scenarios of DC type drum couplings are diverse, covering a wide range of crane types and industries. One of the most common applications is in overhead cranes, which are widely used in workshops, factories, and warehouses for lifting and moving heavy materials within a fixed area. In overhead cranes, the DC type drum coupling connects the gearbox to the hoisting drum, enabling the precise control of load lifting and lowering. Another major application is in gantry cranes, which are used in ports, shipyards, and construction sites for handling large and heavy loads such as containers, steel beams, and ship components. Gantry cranes operate in harsh environments with high torque requirements and frequent misalignments, making DC type drum couplings an ideal choice due to their durability and flexibility.

Jib cranes, which are used for lifting loads in a limited radius, also benefit from the use of DC type drum couplings. These cranes are commonly found in workshops, loading docks, and construction sites where space is limited. The compact design of DC type drum couplings makes them suitable for jib cranes, as they do not require excessive installation space. Additionally, mobile cranes, which are used for on-site lifting in various locations, rely on DC type drum couplings to ensure reliable power transmission even when the crane is in motion, as the flexible element can compensate for the dynamic misalignments that occur during movement.

When selecting a DC type drum coupling for a crane, several key factors must be considered to ensure optimal performance and compatibility. The first factor is the torque capacity of the coupling. It is crucial to select a coupling that can handle the maximum torque generated by the crane's motor and gearbox. Undersized couplings may fail under peak load conditions, while oversized couplings may be unnecessarily expensive and may not fit properly in the crane's assembly. To determine the required torque capacity, it is necessary to calculate the maximum torque that the coupling will be subjected to, taking into account the crane's load capacity, speed, and operating conditions.

Another important factor is the misalignment compensation capability of the coupling. Different crane applications may require different levels of misalignment compensation. For example, cranes operating in harsh environments with significant structural movements may require couplings with a higher misalignment capacity. It is essential to select a DC type drum coupling that can accommodate the expected axial, radial, and angular misalignments of the specific crane system. The manufacturer's specifications should be consulted to ensure that the coupling's misalignment limits match the requirements of the application.

The material of the flexible drum element is also a critical selection criterion. The material must be able to withstand the operating conditions of the crane, including temperature variations, exposure to environmental contaminants, and the mechanical stress of torque transmission and misalignment compensation. Rubber is a common material for flexible elements due to its excellent elasticity and shock absorption properties, but it may not be suitable for high-temperature environments. Polyurethane offers better resistance to abrasion, oil, and chemicals, making it ideal for harsh industrial environments. Composite materials are increasingly being used for their high strength-to-weight ratio and durability, making them suitable for heavy-duty crane applications.

The size and installation requirements of the coupling must also be considered. The coupling must fit within the available space in the crane's assembly, and the mounting dimensions must match the shafts of the motor, gearbox, and drum. It is important to ensure that the coupling can be easily installed and removed for maintenance purposes. Additionally, the coupling's rotational speed must be compatible with the crane's operating speed, as excessive speed can cause the flexible element to degrade prematurely.

Proper maintenance of DC type drum couplings is essential to ensure their long-term performance and reliability. Regular inspection is the cornerstone of effective maintenance. Operators should inspect the coupling for signs of wear, damage, or degradation, such as cracks in the flexible element, loose fasteners, or excessive vibration. Inspections should be conducted before each use of the crane and at regular intervals, depending on the operating conditions and usage frequency. In harsh environments with high levels of dust, moisture, or debris, more frequent inspections may be necessary.

Lubrication is another important maintenance practice for DC type drum couplings. While the flexible element does not require lubrication, the metal hubs and shafts may need to be lubricated to reduce friction and prevent corrosion. It is important to use the correct type of lubricant as recommended by the manufacturer, as using the wrong lubricant can cause damage to the coupling components. Lubrication should be performed at regular intervals, and any excess lubricant should be removed to prevent the accumulation of dust and debris.

If any signs of damage or wear are detected during inspection, the coupling should be repaired or replaced immediately. Delaying repairs can lead to more severe damage to the crane's motor, gearbox, or drum, resulting in costly downtime and potential safety hazards. When replacing the coupling, it is important to select a replacement that is compatible with the crane's specifications, ensuring that the torque capacity, misalignment compensation, and size match the original coupling.

In addition to regular inspection and lubrication, proper storage of DC type drum couplings is also important. If a coupling is not in use, it should be stored in a clean, dry environment away from direct sunlight, moisture, and extreme temperatures. This prevents the flexible element from degrading and the metal components from corroding. Couplings should be stored in their original packaging or covered to protect them from dust and debris.

The importance of DC type drum couplings in crane operations cannot be overstated. These components are critical to ensuring the efficient transmission of power, the protection of other crane components, and the overall safety and reliability of the equipment. A well-selected and properly maintained DC type drum coupling can significantly reduce downtime, lower maintenance costs, and extend the service life of the crane. Conversely, a poorly selected or neglected coupling can lead to frequent failures, increased maintenance costs, and even safety accidents that put operators and equipment at risk.

Looking to the future, the development of DC type drum couplings is likely to be driven by advancements in materials science and manufacturing technology. The use of advanced composite materials is expected to further enhance the torque capacity, durability, and misalignment compensation capabilities of these couplings. Additionally, the integration of smart sensors into DC type drum couplings may become more common, enabling real-time monitoring of the coupling's performance, such as torque levels, temperature, and vibration. This would allow operators to detect potential issues before they lead to failure, further improving the safety and reliability of crane operations.

In conclusion, DC type drum couplings are essential components in crane systems, playing a vital role in power transmission, misalignment compensation, shock absorption, and vibration damping. Their unique design characteristics and functional advantages make them well-suited for the demanding conditions of crane operations across various industries. Selecting the right DC type drum coupling requires careful consideration of torque capacity, misalignment compensation, material selection, and installation requirements. Proper maintenance, including regular inspection, lubrication, and timely repair or replacement, is crucial to ensuring the long-term performance and reliability of the coupling. As the crane industry continues to evolve, DC type drum couplings will remain a key focus for innovation, contributing to the development of more efficient, safe, and reliable crane systems.

« DC Type Drum Coupling For Cranes » Post Date: 2023/10/8

URL: https://www.rokeecoupling.com/en/customer-cases/dc-type-drum-coupling-for-cranes.html

- Plum Blossom Couplings 3D Model

- Is Gear Coupling Used At High Speeds

- Components of Flexible Bush Coupling

- Alignment of Disc Coupling

- Manufacturer Of Drum Gear Coupling

- Standard For Steel Laminae Couplings

- Diaphragm Coupling With Brake Wheel

- Claw Type Elastic Coupling For Pumps

- Universal Joint Coupling Type

- Efficiency of Flexible Diaphragm Couplings